Developments in recirculation systems for

Mediterranean fish species

Jean Paul Blancheton *

Ifremer,Chemin de Maguelone,34250 Pala6as-les-Flots, France

Abstract

Nowadays, most European commercial hatcheries use recirculating water systems for all the different stages of Mediterranean fish rearing, from breeders to fingerlings several grams in weight. Despite a higher initial investment relative to flow-through systems, this technol-ogy reduces production costs mainly because much less energy is required for heating and the survival rate of the fingerlings is much higher. The introduction of recirculation systems has sped up the development of reliable and cost effective hatcheries. Commercial pre-growing units with recirculating systems are now used to produce fish weighing several tenths of a gram at the end of the cold season. This increases the productivity of cage structures, offers the possibility of introducing the fish into less sheltered areas, or may simply be an attempt to meet market demand in some countries. Fish farms are characterized by large rearing units, high stocking densities (more than 100 kg m−3), a large increase in biomass and

long-term rearing. Several experimental size units (2 – 5 tons of annual production) have proved to be effective. Applying this technology to actual commercial farms (several hundred to several thousand tons) would require that the problem of drastically scaling-up all of the components of the rearing system be overcome. To achieve this, several companies are now involved with the French research institute Ifremer in the operation and evaluation of pilot commercial size production units (50 – 70 tons of annual production) financed by private investors, French public funds, and the European Economic Union. Two of these units, one situated in the south of France, the other in Iceland have now been built and the production of sea bass (Dicentrarchus labrax) has just begun. A third is under construction in the west of France (Brittany) and will be used for turbot (Scophthalmus maximus) production. The overall aim of these experiments is to provide data that will enable a model to be constructed that will describe, as far as possible, how each component of the recycling system works. p Based on this model, a more complete model will be constructed with which the optimal farm size can be determined, taking into account geographical, biological and economical

www.elsevier.nl/locate/aqua-online

* Tel.:+33-97289481302; fax: +33-467682885.

E-mail address:[email protected] (J.P. Blancheton)

0144-8609/00/$-see front matter© 2000Else6ier Science B.V.All rights reser6ed.

parameters. In parallel, Ifremer is developing a research program in four main areas : (1) the influence of the rearing environment on fish; (2) the influence of fish on the rearing environment; (3) reducing the environmental impact of the farms, and (4) the optimization of the primary water treatment system, and its integrated management. The most promising foreseeable improvement in recirculating systems used for growing Mediterranean fish are: (1) an increase in mechanical filtration efficiency; (2) a better understanding of the standard optimal rearing medium parameters; (3) more information on the bacterial populations and how to control them, and (4) the incorporation and recycling of waste. © 2000 Elsevier Science B.V. All rights reserved.

Keywords:Recirculating systems; Mediterranean fish

1. Introduction

It is now widely acknowledged that fish supplies from the world fisheries are unlikely to increase substantially and that the expansion of the aquaculture sector will probably provide the solution to the problem of the projected shortfalls (Chamberlain and Rosenthal, 1995). The potential of aquaculture has been clearly demonstrated by the rapid expansion of this sector: it is the fastest growing food-producing sector in the world, with an annual growth rate of almost 10% between 1984 and 1995, compared with 3% for livestock meat and 1.6% for capture fisheries production (FAO, 1997). Although Mediterranean fish make up only a small percentage of the worldwide aquaculture production, the growth in this sector is following a similar pattern of expansion. Most sea bass fingerlings reared in farms are produced in recirculating systems, which minimizes land requirements and the impact on the environment, thanks to the high level of control over the environment in which the fish are grown. Studies are in progress to define economically efficient recirculating systems for the on-growing phase (from several grams to the market size) of the production of Mediterranean fish.

In the first part of this paper, commercial scale recirculating systems that are now being used to produce various species of Mediterranean fish (from breeders to fingerlings) will be presented, and the method used to define efficient commercial scale production units will also be described. In the second part, we will look at various aspects of fish rearing in recirculating systems, concerning particularly the fish and their behavior, the bacteria present within the rearing systems, and technical problems.

2. Recirculating systems in commercial scale

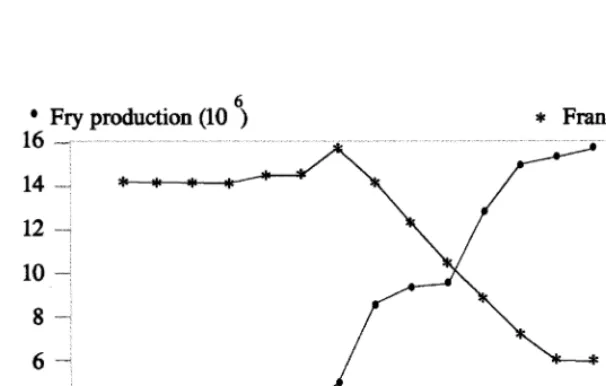

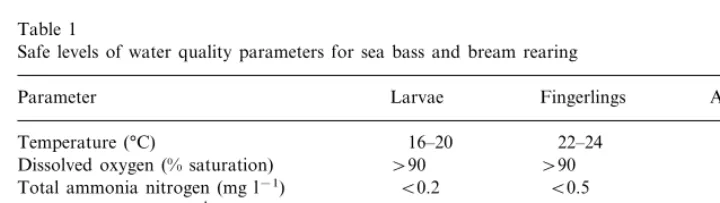

now averages 1.5 French fr. per fish (De la Pomelie, pers. commun.). The two main explanations for the fact that production has increased by 15 times in the past 1o years are: (1) a steady improvement in feed composition and feeding procedures, and (2) the use of water recirculation technology. Flow through hatcheries on marine water supplies are subject to large fluctuations in water quality that are difficult to control. However, recirculation systems provide a rearing medium that is constant and adjustable, showing only slight and slow variations. Moreover, there is minimal heat loss in recirculated water systems, which normally operate above ambient water temperature. In a recirculating system, the saving in heating energy required for the production of 1 g fingerlings corresponds to approximately 50% of the production cost of fingerlings from a heated flow through hatchery (Fig. 2). The type of recirculating system that seems most promising for sea bass and bream, the specific treatment processes and their impact on water quality were extensively described (Blancheton and Coves, 1993; Blancheton et al., 1996, 1997). The water quality parameters levels that are being targeted as safe levels in fry, fingerlings and adult fish production systems are summarised in Table 1.

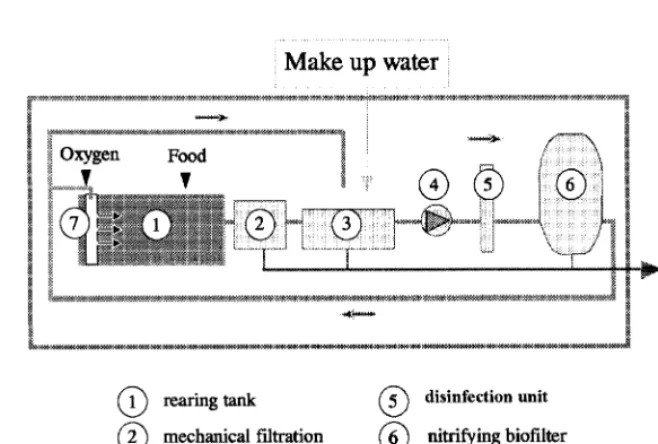

A diagram of a recirculating rearing system for the production of larvae and fingerlings is presented in Fig. 3, and the main characteristics of fish rearing and of the system are summarized in Table 2.

During the 1990s, an increasing number of French fish farms that used sea cages needed to increase their production to meet an expanding market demand. Given the inherent difficulties in physically enlarging their rearing systems, they decided to

Fig. 2. Direct production cost of 100 000 1-g sea bass fingerlings in flow through and recirculation systems.

Table 1

Safe levels of water quality parameters for sea bass and bream rearing

Adults

Dissolved oxygen (% saturation) \90 \90

B2

increase the productivity of their existing facilities. On the French Mediterranean coast, the annual mean weight of fish stocked in cages increases with the average weight at stocking (Fig. 4). Therefore, the cage productivity per unit volume increases and one solution was to stock the cages with fish that had been pre-grown in a recirculating system.

biomass; (3) the packed column is adapted to efficiently remove the dissolved carbon dioxide produced by fish respiration; and (4) the pH is maintained at around 7 by injection of sodium hydroxide (NaOH).

Fig. 3. Recirculating system used for larval rearing of Mediterranean species.

Table 2

Recycling system for larval rearing and fingerling production

System characteristics Rearing characteristics

Fingerlings

Larvae Larvae Fingerlings

Mesh filter

Final average Sand filter

body weight

40 mg 1–5 g

UV disinfec-Initial stocking

tion density

0.4 kg m−3

0.4 kg m−3 Biological filter

Final stocking Packed column

density

30 kg m−3 Heating cool-4 kg m−3

ing Duration

Oxygenation Aeration

90 days 40 days

Cleaning every

Fig. 4. Annual mean weight increase for sea bass at different weights stocked in sea cages.

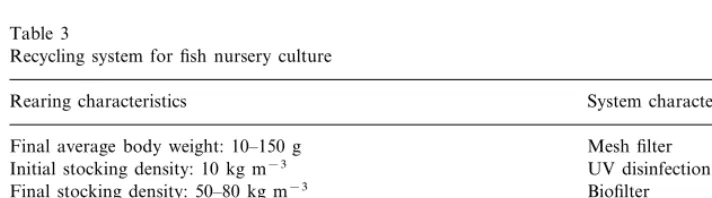

Table 3

Recycling system for fish nursery culture

System characteristics Rearing characteristics

Mesh filter Final average body weight: 10–150 g

Initial stocking density: 10 kg m−3 UV disinfection Biofilter Final stocking density: 50–80 kg m−3

Packed column (CO2) Duration: 1–6 months

Make up water\100% of rearing volume per day Heating and cooling

Oxygenation Cleaning every cycle

pH control

3. Developing recirculating on-growing systems

is presented on Fig. 5. Although efficient seawater denitrification processes function at a pilot scale, no commercial farm uses it at the present time for Mediterranean fish production, and nitrate limitation is operated through water renewal. Until now, fish farms using recirculating systems for Mediterranean fish production have always been economic failures. This might be explained either by faults in the technical design of the production system or by incorrect operation over the long-term (not stocked and managed at optimal production level).

The promising results obtained recently with laboratory size units encouraged the European Union to contribute to the development of industrial farms by financing pilot units on an commercial scale through the DG 13 and Eureka programs. Iceland, Sweden and France are all involved in the DG 13 project, referred to as

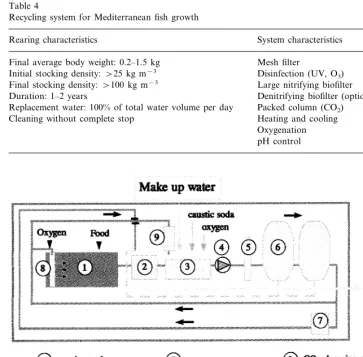

Table 4

Recycling system for Mediterranean fish growth

Rearing characteristics System characteristics

Final average body weight: 0.2–1.5 kg Mesh filter

Disinfection (UV, O3) Initial stocking density:\25 kg m−3

Final stocking density:\100 kg m−3 Large nitrifying biofilter

Duration: 1–2 years Denitrifying biofilter (optional) Packed column (CO2) Replacement water: 100% of total water volume per day

Cleaning without complete stop Heating and cooling Oxygenation pH control

Mari-Tech. The project focuses on the recirculating loop of two pilot commercial size units, which are designed to produce 50 – 70 tons of sea bass per year. The completion date for the project is at the beginning of 2000 and the final result will provide a pool of practical and theoretical knowledge on the design, management and cost of the pilot commercial farms.

The Eureka project involves Iceland and France and concerns aspects of fish rearing at high density in large production units such as the scaling-up of demand feeding systems, the swimming activity of fish living in high density populations and the improvement of feed for fish waste reduction. Additionally the project will investigate combining UV radiation and ozone for disinfection, optimization of the fish environment for fish growth, optimization of the replacement water/ recircu-lated water ratio, the acid/base equilibrium of fish in recirculating water, and the supervision of the production units. These two projects should provide much of the information necessary for the design of efficient commercial production units.

4. Some particular questions related to fish rearing in recirculating systems

4.1.Water quality and fish density

One of the most significant advantages of recirculating systems is that they allow the key water quality characteristics to be properly regulated. The technical means for efficient regulation exist, but we still know very little about the right level at which regulation should be carried out (Russo and Thurston, 1991; Handy and Poxton, 1993; Tomasso, 1994). Recent experiments have been carried out in single parameter conditions in order to determine the optimal level of such basic parame-ters as temperature, TAN or pH (Lemarie´ et al., 1996), but almost nothing is known concerning the effect of carbon dioxide or nitrate, or the possible synergistic effect of some of these substances on Mediterranean fish growth. Moreover, to be profitable, such systems have to be run with high fish densities. Some very important aspects of fish behavior in high rearing densities such as swimming and feeding are still poorly understood. Both are closely related to the feeding strategy that should be used in rearing facilities and also to fish welfare, which must always be taken into account, in as much as it is possible to define it precisely.

4.2.Feed effect

Fig. 6. Average cumulative feed intake during the first hours of the photoperiod in relation to the daily exposure to light.

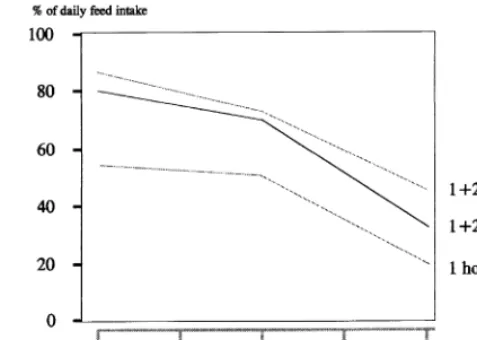

4.3.Effect of photoperiod

The photoperiod also has a determining impact on fish feeding behavior, consequently on the entire rearing system (Cove`s, pers. commun.), and the maxi-mum level of feed intake and fish growth are obtained with long photoperiod times. The average cumulative feed intake of fish subjected to varying photoperiod times increases drastically from less than 40% during the first 2 h for fish exposed to 20 h of light per day to more than 80% for fish exposed to only 4 h of light per day (Fig. 6). This concentration of the feeding activity in a short period of time results in a rapid surge in oxygen demand, followed by the excretion of a large quantity of matter into the rearing medium. This has important consequences for the size of the treatment loop, since a system that is able to cope with such strong variations in water quality would have be very large and probably economically not viable. Therefore, to limit the daily water quality variations resulting from the concentra-tion of the feeding activity, the farm manager should increase rather than decrease the light exposure time.

4.4.Mechanical filtration

particles smaller than 20 mm (Chen et al., 1993; Heinen et al., 1996). Suspended solids that are not removed from the recirculating flow are partly dissolved and broken apart, mainly in the pump and their decay in the biological filter increases the ammonia production and the oxygen demand of the rearing system (Golz et al., 1996). One reason for such a modest efficiency of mechanical filters is that the standard drum or disc filters are made with woven materials, which drastically limits the possibility of using the small pore sizes that provide low porosity. Actually, the void surface percentage of a filter cloth with a 60-mm mesh is around 60%, whereas the void surface percentage of a 5-mm mesh is less than 1%. The porosity of the microscreen is a key parameter to determine the hydraulic capacity of the filter, the filter wash frequency and the waste water quantity (Cripps, 1995; Kelly et al., 1997). Other kinds of filter cloths are now being developed that could provide both high porosity and small pore size.

4.5.Bacterial acti6ity

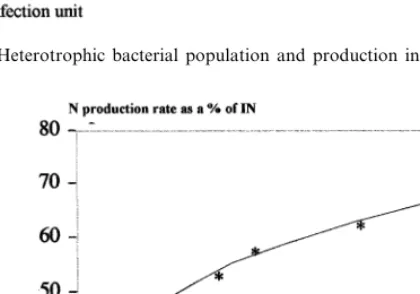

The influence of bacterial activity in a recirculating system is of the utmost importance. For instance, in high fish density recirculating systems, bacteria and fish consume similar quantities of oxygen per kg of fish produced. However very little is known about the kind of bacteria that are present within these systems, apart from the nitrifying bacteria. Autotrophic nitrifying bacteria are far less numerous than heterotrophic bacteria, even when a biological filter, which is usually considered to be a nitrogen transformer, is used. Important questions remain unanswered, concerning the stability in quantity and composition of the heterotrophic bacteria population within the different components of a recirculating rearing system. Similarly, the main factors that influence these bacteria are not well understood. According to recent studies (Leonard et al., 2000), it appears that the concentration of free bacteria is stable when the rearing characteristics are stable and that the highest concentration is observed at the outlet of the rearing tanks. Yet if one examines bacterial production expressed as colony forming units (CFU) in the main components of the system, the biological filter (FB) appears to be the main source of bacteria and is a determining element in the growth of bacteria, when the UV disinfecting unit (UV) efficiency is 97% on average (Fig. 7). Com-pared to this, the rearing tanks (RT) and pipes (P) have little effect on the bacterial population . Models are being developed, to evaluate the evolution of the hetero-trophic population under various operating conditions of the recirculation system.

4.6.Treatment and recycling of waste

operated. If we consider nitrogenous waste, it is clear from Fig. 8 that the more closed the system is (expressed as a number of the total water volume exchanged per day), the less dissolved nitrogen (expressed as a percentage of the ingested nitrogen) will be released into the effluent (Pagand et al., 1999, 2000). Some trials have been carried out with effluents from Mediterranean fish to produce mollusks and algae (Shpigel et al., 1993). Another solution is to treat in parallel the recirculating system effluent (first treatment loop) in a second treatment loop (Fig. 9). Aquaculture waste from the first loop of recirculating systems more closely resembles urban waste than that produced by flow through systems, and is thus easier to treat using standard techniques. Some recent experiments have shown that high rate algal ponds fed with seawater effluents produce macroalgae year round

Fig. 7. Heterotrophic bacterial population and production in a recirculating system.

Fig. 9. Treatment and reuse of the waste water from a recirculation system.

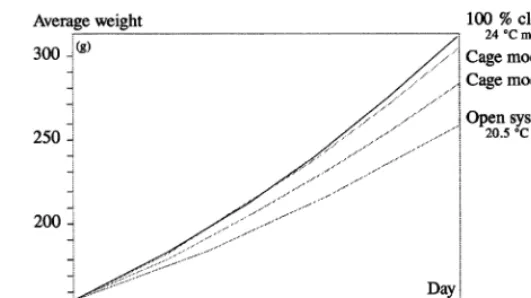

Fig. 11. Sea bass growth in a 100% closed system with high rate algal pond as secondary treatment.

(Pagand et al., 1999, 2000). The average yearly nitrogen (DIN) and phosphorus (RP) removal efficiency were respectively 60 and 50% with a minimum of below 40%, which falls to 20% during the cold period (Fig. 10). Moreover, if re-injected into the first loop, water treated in the high rate algal pond seems to have no detrimental effect on fish growth, at least over a short period of time. The growth of sea bass reared in a completely closed system, with waste water re-injection in the first recirculation loop after treatment in a high rate algal pond (secondary loop), was compared to a control in flow through system over a period of 2 months. In the completely closed system, the fish growth was comparable to cage culture growth model result, while in the flow through system, it was lower (Fig. 11). New experiments are planned to calibrate and validate a model of the two loops, which will greatly contribute to define the best operating conditions for sea bass produc-tion in the Mediterranean area.

5. Conclusion

that fast growing fish, either genetically modified or other species, and an optimal use of natural resources, could greatly improve the cost efficiency of the system. Together with the energy budget of such facilities, which was not dealt with in this article, the most promising foreseeable improvements in recirculating systems for Mediterranean fish rearing are: (1) an increase in mechanical filtration effi-ciency; (2) a better knowledge of the optimal level of key parameters in the rearing medium; (3) a better knowledge of the bacterial populations that will lead to improved methods to control them, and (4) the incorporation and recycling of waste products.

References

Blancheton, J.P., Coves D., 1993. Closed system in intensive marine finfish hatcheries — State of the art and future prospects. In: Barnabe´, G., Kestemont, P. (Eds.), Production, Environment and Quality, Bordeaux Aquaculture’92, European Aquaculture Society, Special Publication No. 18, Ghent, Belgium, 1993, pp. 87 – 93.

Blancheton, J.P., De la Pome´lie C., Vincent, M., 1996. Potential gains through new rearing technologies: culture in recirculation systems. Seabass and seabream culture: problems and prospects. In: Chatain, B., Saroglia, M., Sweetman, J., Lavens, P. (Eds.), International Workshop on Seabass and Seabream Culture, Verona, Italy, October 16 – 18, 1996. European Aquaculture Society, Oostende, pp. 189 – 205.

Blancheton, J.P., Coves, D., Lemarie, G., 1997. Intensive land-based marine fish aquaculture in closed system, hatchery and ongrowing units: state of the art and prospects. J. Jpn. Aquacult. Soc. Suisanzoshoku H9, 143 – 149.

Boujard, T., Me´dale, F., 1994. Regulation of voluntary feed intake in juvenile rainbow trout fed by hand or by self-feeders with diets containing two different protein/energy ratios. Aquat. Living Resour. 7, 211 – 215.

Chamberlain, G., Rosenthal, H., 1995. Aquaculture in the next century, opportunities for growth, challenges of sustainability. World Aquacult. 26, 21 – 25.

Chen, S., Coffin, D.E., Malone, R.F., 1993. Production characteristics and modelling of aquaculture sludge from a recirculating aquaculture system using a granular media biofilter. In: Wang, J.K. (Ed.), Techniques for Modern Aquaculture. American Society of Agricultural Engineers, St. Joseph, MI, pp. 16 – 25.

Cripps, S.J., 1995. Serial particle size fraction and characterization of an aquaculture effluent. Aquacul-ture 133, 323 – 339.

FAO, 1997. Review of the state of world aquaculture. FAO Fisheries Department, FAO Fisheries Circular, 886, Rev. 1, FAO, Rome, 163 pp.

Golz, W., Rusch, K.A., Malone, R.F., 1996. Developing backwash protocols for floating bead filters: A model of solids loading and biofilm retention effect on nitrification. In: Libey, G., Timmons, M. (Eds.), Successes and Failures in Commercial Recirculating Aquaculture (Conference Proceedings). Northeast Regional Agricultural Engineering Service, Ithaca, NY, pp. 196 – 205.

Handy, R.D., Poxton, M.G., 1993. Nitrogen pollution in mariculture: toxicity and excretion of nitrogenous compounds by marine fish. Rev. Fish Biol. Fish. 3, 205 – 241.

Heinen, J.M., Hankins, J.A., Adler, P.R., 1996. Water quality and waste production in a recirculating trout culture system with feeding of a higher energy or a lower energy diet. Aquacult. Res. 27, 699 – 710.

Kelly, L.A., Bergheim, A., Stellwagen, J., 1997. Particle size distribution of wastes from freshwater fish farms. Aquacult. Int. 5, 65 – 87.

Lemarie´, G., Coves, D., Dutto, G., Gasset, E., Person-Le Ruyet, J., 1996. Chronic toxicity of ammonia for European seabass (Dicentrarchus labrax) juveniles. In: Swanson, C., Young, P., MacKinlay, D. (Eds.), Applied Environmental Physiology of Fishes Symposium Proceedings. International Congress on the Biology of Fishes, San Francisco State University, July 14 – 18, 1996. American Fisheries Society, Bethesda, MD, pp. 65 – 76.

Leonard, N., Blancheton, J.-P., Guiraud, J.P., 2000. Population of heterotrophic bacteria in an experimental recirculating aquaculture system. Aquacult. Eng. 22, 109 – 120.

Pagand, P., Blancheton, J.-P., Lemoalle, J., Casellas, C. High rate algal pond for the treatment of marine effluent from a recirculating fish rearing system. Aquacult. Res., in press.

Pagand, P., Blancheton, J.-P., Casellas, C., 2000. A model for predicting the quantities of dissolved inorganic nitrogen released in effluents from sea bass (Dicentrarchus labrax) recirculating water system. Aquacult. Eng. 22, 137 – 153.

Russo, R.C., Thurston, R.V., 1991. Toxicity of ammonia, nitrite and nitrate to fishes. Aquaculture and water quality. In: Brune, E., Tomasso, J.R. (Eds.), Advances in World Aquaculture. WAS Publ., 3, pp. 58 – 59.

Shpigel, M., Neori, A., Popeer, D.M., Gordin, H., 1993. A proposed model for ‘environmentally clean’ land-based culture of fish, bivalves and seaweed. Aquaculture 117, 115 – 128.

Tomasso, J.R., 1994. Toxicity of nitrogenous wastes to aquaculture animals. Rev. Fish. Sci. 2, 291 – 314.

.