Plant oil emulsion modifies internal atmosphere, delays fruit

ripening, and inhibits internal browning in Chinese pears

Zhiqiang Ju

a,*, Yousheng Duan

b, Zhiguo Ju

baLaiyang Agricultural College,Shandong,PR China

bFruit Research Lab,R&D Department,Eureka Biotechnology Company,Shandong,PR China

Received 3 December 1999; accepted 8 May 2000

Abstract

’Laiyang Chili’ and ‘Ya Li’ (Pyrus bertschneideri Reld) pears were treated with 3, 6, and 9% emulsions of commercial or refined (reduced a-tocopherol levels) plant (soybean, corn, peanut, linseed, and cottonseed) oils at

harvest an stored at 0°C for 6 months. Effects of oil treatments on ethylene production, respiration, fruit firmness, fruit color, soluble solid content (SSC), titratable acids (TA), internal browning (IB), and internal CO2, O2, and

ethanol were studied. At the same concentration, oil treatments induced similar responses regardless of their sources or theira-tocopherol concentrations. In both cultivars, ethylene production and respiration in fruit treated with 9%

oils were lower in early storage and higher in late storage than that in the controls. Oils at 6% reduced IB, at 9% inhibited IB completely, and at 3% was not effective after 6 months at 0°C and 7 days at 20°C. Plant oil treatment maintained fruit color, firmness, SSC, and TA in a concentration-dependent manner during storage. In the first 4 months storage, 9% corn oil-treated fruit contained similar partial pressure of CO2and O2as the controls. After 5

months storage, oil-treated fruit contained higher partial pressure of CO2and lower levels of O2than the controls.

When held at 20°C for 7 days, changes of internal CO2and O2were slower but partial pressure of CO2were higher,

and O2were lower, in 9% corn oil-treated fruit than in the controls. Internal ethanol was not affected by oil treatment

compared with control, either during storage or 7 days at 20°C. No off-flavor was detected in either oil-treated and control fruit by sensory evaluation. © 2000 Elsevier Science B.V. All rights reserved.

Keywords:Plant oil; Internal browning; Ethylene; Flesh firmness; Skin color; CO2; O2; Ethanol;Pyrus bertschneideriReld

www.elsevier.com/locate/postharvbio

1. Introduction

One of the major disorders that develops during storage in Chinese pears is internal browning (IB) * Corresponding author. Present address: TFRL, ARS,

USDA, Tree Fruit Research Lab, USDA-ARS, 1104 N. West-ern Ave., Wenatchee, WA 98801, USA. Tel.: + 1-509-6642280; fax: +1-509-6642287.

E-mail address:[email protected] (Z. Ju).

of the flesh and core regions (Ju, 1988; Ju and Zhu, 1988; Sornsrivichai et al., 1990b; Crisosto et al., 1994). Two types of IB exist in Chinese pears. The first is senescent IB, which develops within one month storage (Crisosto et al., 1994). Mature fruit are more susceptible to senescent IB than immature fruit. Storage temperatures from 0 to 10°C do not affect senescent IB, but delaying cooling increases senescent IB incidence (Crisosto et al., 1994). The second is temperature related IB (chilling IB), which develops only af-ter 2 or 3 months storage at 0°C. A gradual decrease of temperature at the beginning of stor-age reduces chilling IB development (Tian et al., 1987) and immature fruit are more susceptible to chilling IB than mature fruit (Tian et al., 1987; Ju et al., 1994).

When applied at harvest, plant oils delay cli-macteric rise in ethylene and ripening and main-tained fruit quality attributes in ‘Golden Delicious’ apples and ‘Bartlett’ pears (Ju et al., 2000b) and inhibit scald development and de-greening in ‘Delicious’ apples (Ju et al., 2000a) during and after prolonged cold storage. Simi-larly, coating fruit with wax or polymers also reduces fruit softening and chlorophyll degrada-tion (Meheriuk and Porritt, 1972; Sornsrivichai et al., 1990a; Saftner, 1999). The other reason for coating fruit with wax or polymers is to reduce chilling injury in fruit (Hagenmaier and Shaw, 1992). The effects of coating fruit with plant oils on fruit quality attributes and storage disorder in Chinese pears have not been re-ported.

The mechanism by which fruit coatings delay fruit senescence is explained primarily as a re-sponse to the modification of internal atmo-sphere, including CO2, O2, and ethylene (Banks

et al., 1993; Saftner, 1999). The effects of plant oil coatings on internal atmospheres of fruit have not been studied. Therefore, our objective was to investigate the effects of different plant oil emulsions on ethylene production, respira-tion, IB, fruit color, firmness, soluble solid con-tent (SSC), titratable acids (TA), internal atmosphere (CO2 and O2), and ethanol using

two cultivars of Chinese pears, ‘Ya Li, and ‘Laiyang Chili’.

2. Materials and methods

2.1. Plant materials

In 1997, ‘Ya Li and ‘Laiyang Chili’ (Pyrus bertscheneideri Reld) were harvested on Septem-ber 12 and 21, respectively, from commercial or-chards. At harvest, 12 fruit from each of three replications were used for maturity evaluation and ethylene measurement. Plant oils (soybean, corn, peanut, linseed, and cottonseed oil) with high a-tocopherol levels (500 – 800 mg kg−1, commercial plant oil) or low a-tocopherol levels (B5 mg kg−1

, refined plant oil) were used. Emulsions containing 60% (v/v) of each plant oil were made by mixing four parts of plant oil, one part of monoacylglycerol, one part of Tween 60, and four parts of hot water (previously heated to 90°C) at 90°C with active stirring. The freshly prepared emulsions were cooled to room temper-ature, diluted to 3, 6, and 9% with tap water, and used for fruit treatment at 20°C. Fruit with-out treatment served as control. Each treatment included three replications and each replicate contained 250 fruit, which were dipped in 40 l emulsions for 3 min, left at room temperature for 4 h, put in cardboard boxes, and stored at 0°C for 6 months. Thirty fruit from each replica-tion were removed from storage each month for analysis. Ethylene production was measured in ten fruit immediately after storage. Internal browning was evaluated in 20 fruit after 7 days at 20°C following cold storage. The rest of the fruit in each replicate were used for fruit quality (including fruit color, firmness, SSC, TA, IB, and off-flavor) measurements after six months at 0°C and 7 days at 20°C. Off-flavor was evalu-ated as yes or no by four trained personnel.

The same experiment was repeated in 1998 except an additional 150 fruit from each of the three replications were put into storage and used for respiration and internal CO2, O2, and ethanol

respiration and internal CO2, O2, and ethanol

measurements in 1998.

2.2. Ethylene, respiration, and internal C02, 02 and ethanol measurement

In 1997, six fruit from each of the three replica-tions were submerged in saturated ammonium sulfate solutions according to Beyer and Morgan (1970) and 1 ml, air samples was drawn from the head space and used for internal ethylene mea-surement. Ethylene production rate was measured using 30 peel discs taken from ten fruit using a No. 9 brass cork borer (1.2 cm diameter). The discs were put into a 20-ml, test tube and sealed. After 30 min, 0.5 ml, of air was drawn from the headspace and used for ethylene analysis.

Measurements of respiration, ethylene, CO2, O2

and ethanol in 1998 were conducted by the fol-lowing methods. Thirty fruit from each of the three replications were removed from storage ev-ery month and held at 20°C. Air samples for internal ethylene, CO2, and O2measurement were

taken at day 0, 1, 3, 5, and 7 as described above. For ethylene production and respiration measument, five fruit from each replication were re-moved from storage, held at 20°C for 3 h, and placed in 4-l glass jars at 20°C. The jars were connected to a flow-through system with a flow rate of 100 ml, min−1. After 2 h equilibrium, a

0.5 ml, air sample was drawn from the headspace for ethylene analysis and a 1 ml, sample for respiration measurement. To prepare samples for ethanol measurement, 50 g mesocarp tissue (10 g from each of the five fruit) was homogenized in 50 ml, water and centrifuged at 3000×g for 10 min. Then, 5 ml, supernatant was moved to a 20 ml test tube. The test tube was sealed and incubated at 60°C for 1 h and 0.5 ml air in headspace was withdrawn and used for ethanol measurement.

A gas chromatograph (Hewlett-Packard Model 5890A) fitted with a glass column (610×3.2 mm Ld) packed with Porapak Q (90-100 mesh) was used for gas measurements. Oven, injector, and FID temperatures were 50, 50, and 200°C, respec-tively, for ethylene and 115, 115, and 200°C for ethanol. Gas flows for N2, H2, and air were 30,

30, and 300 ml min−1, respectively. For CO 2 and

O2 measurements, a 30 m×0.53 mm i.d.

polystyrene (GSQ) column (J & W Scientific, Fol-som, Calif.) and a thermal conductivity detector were used. Column and detector temperature were 40 and 120°C, respectively, and the He flow rate was 4.8 ml min−1.

2.3. IB e6aluation

IB (including flesh and heart browning) was assessed in fruit that was cut into four equal parts longitudinally and rated as percent incidence and intensity using the scale of 1=1 – 10%, 2=11 – 33%, 3=34 – 66%, and 4=67 – 100% of the cut surface affected.

2.4. Measurement ofotherfruit quality

Fruit color, firmness, SSC, and TA were as-sessed both at harvest and after cold storage following 7 days at 20°C. Fruit color was mea-sured by the ‘L, a, b’ parameter with aMinolta Chromo Meter (DP-301, Minolta, Osaka, Japan). Firmness was measured with an Electronic Pres-sure Tester (EPT-1, Lake City Technical Products Inc., Kelowna, BC, Canada) equipped with a 8-mm tip. Readings were made on two pared sides of each fruit. SSC was assessed with a Digital Refractometer (PR-1, Atago Co. Ltd., Japan) on a combined sample of juice extracted from ten fruit in each replicate. TA was measured by titrat-ing 5 ml, of juice extracted from ten fruit in each replicate using a Standard pH Meter and Titrator (PHM 82, Radiometer America, Cleveland, Ohio) and expressed as percentage of malic acid equivalents.

2.5. Statistical analysis

3. Results

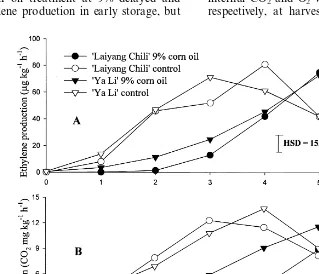

3.1. Effects of oil treatments on ethylene production

Similar trends in internal ethylene concentra-tion and ethylene producconcentra-tion rate (either mea-sured with whole fruit or fruit peel) were found in 1997 and 1998 seasons. Only ethylene production rate from whole fruit in 1998 is presented in Fig. 1A. In control fruit from ‘Ya Li’ and ‘Laiyang Chili’, ethylene was undetectable at harvest, rose after one month of storage, reached the maximum at three or four months storage, and decreased thereafter. No difference in effects among soy-bean, corn, peanut, linseed, and cottonseed oil or between commercial plant oil and refined plant oil on ethylene production was found (data not shown). Corn oil treatment at 9% delayed and reduced ethylene production in early storage, but

increased ethylene production in late storage com-pared with controls in both cultivars (Fig. 1A).

3.2. Effects of oil treatments on fruit respiration

Trends in changes of respiration were similar in fruit from ‘Ya Li’ and ‘Laiyang Chili’ (Fig. 1B). Respiration in control fruit was low at harvest, increased during storage, and decreased after reaching the maximum around 4 months. Com-pared with that in controls, respiration rates in 9% oil-treated fluit were lower in the first three months and higher after 5 months storage.

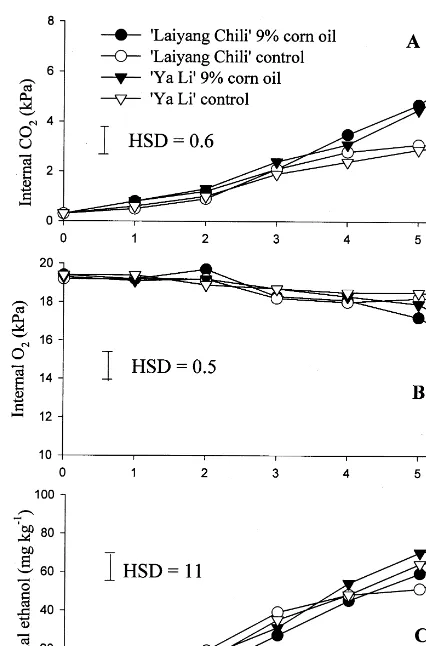

3.3. Effects of oil treatments on internal CO2, O2, and ethanol

In control fruit of ‘Ya Li’ and ‘Laiyang Chili’, internal CO2 and O2 were about 0.3 and 19 kPa,

respectively, at harvest (Fig. 2A and B). When

Fig. 2. Effects of corn oil treatments on internal CO2, O2, and

ethanol concentrations in ‘Ya Li’ and ‘Laiyang Chili’ during 6 months storage at 0°C in 1998. ‘Ya Li’ and ‘Laiyang Chili’ were harvested on September 16 and 23, 1998, respectively, dipped in 9% corn oil emulsion for 3 min, and stored at 0°C in air for 6 months. Untreated fruit served as control.

of O2 in oil-treated fruit were slower than in

control fruit (Fig. 3). After 7 days at 20°C, oil-treated fruit contained higher levels of CO2 (9.6

kPa) but similar levels of O2 compared with

con-trols (Fig. 3A, B). Ethanol was not affected by oil treatment both during cold storage (Fig. 2C) and during ripening at 20°C (Fig. 3). Both oil-treated and control fruit contained about 135 mg kg−1

ethanol at day 7 (data not shown). Sensory evalu-ation did not perceive off-flavor in either control or oil-treated fruit (data not shown).

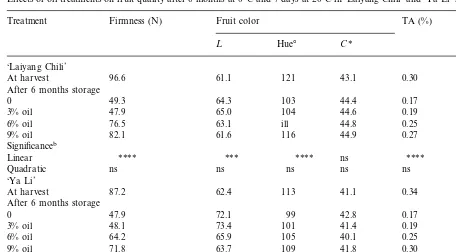

3.4. Effects of oil treatments on other fruit quality

Since all oils at the same concentration showed similar effects on fruit and trends in results were similar between 1997 and 1998, pooled data of the different oils from the 2 years were presented in Table 1. Oil treatments retained fruit color, firm-ness, SSC, and TA. The effects of oil treatments on these measurements were concentration dependent.

Fig. 3. Effects of corn oil treatments on internal CO2and O2

concentration in ‘Laiyang Chili’ and ‘Ya Li’ at 20°C following 6 months storage at 0°C in 1998. ‘Ya Li’ and ‘Laiyang Chili’ were harvested on September 16 and 23, 1998, respectively, dipped in 9% corn oil emulsion for 3 min, stored at 0°C in air for 6 months, and removed to 20°C for CO2and O2

measure-ment. Untreated fruit served as control. measured at removal from storage, CO2increased

and O2 decreased to 3 and 18 kPa, respectively,

after 6 months. Ethanol level was low (B5 mg kg−1

) at harvest and increased to about 70 mg kg−1 by 6 months (Fig. 2C). When control fruit

were ripened at 20°C for 7 days after 6 months storage, internal CO2 increased and O2 decreased

to 8 and 12 kPa, respectively, (Fig. 3A, B). Oil-treated fruit contained similar levels of CO2 after

4 months and similar levels of O2after 5 months,

but higher levels of CO2 and lower levels of O2

Table 1

Effects of oil treatments on fruit quality after 6 months at 0°C and 7 days at 20°C in ‘Laiyang Chili’ and ‘Ya Li’ in 1997 and 1998a

Firmness (N)

Treatment Fruit color TA (%) SSC (%)

L Hue° C*

‘Laiyang Chili’

61.1 121

At harvest 96.6 43.1 0.30 15.8

After 6 months storage

Quadratic ns ns ns ns ns

‘Ya Li’

62.4 113

At harvest 87.2 41.1 0.34 12.1

After 6 months storage

aNo differences were found among oils from different sources, between commercial and refined oils, or between 1997 and 1998.

Data are means from 1997 and 1998 using pooled data from different oil treatments.

b****,***,** or ns represent, respectively, significant atP50.0001, 0.001, 0.01 or not significant.

Table 2

Effects of oil treatments on IB development after 6 months at 0°C and 7 days at 20°C in ‘Laiyang Chili’ and ‘Ya Li’ in 1997 and 1998a

Oil treatment (%) ‘Ya Li’ ‘Laiyang Chili’

IB (%)

aNo differences were found in trends among oils from different sources, between commercial and refined plant oils, or between

1997 and 1998 treatments. Data represent the means of the same concentration from difrerent oil treatments in 1997 and 1998.

b****, * or ns represent, respectively, significance atP50.000 1, 0.0 1 or not significant.

3.5. Effects of oil treatments on IB

Data from 1997 and 1998 were similar and therefore means from the 2 years were combined

controlling IB among different plant oils or be-tween commercial plant oil and refined plant oil. Using the pooled data, the inhibition of IB by oil treatments was concentration dependent. Oil at 9% inhibited IB development completely.

4. Discussion

Plant oil emulsions, regardless of the sources of oil, at 9% concentration delayed ethylene produc-tion and respiraproduc-tion, maintained fruit quality at-tributes, such as firmness, color, SSC, and TA, and controlled IB completely after 6 months stor-age. In comparison to European pears where a soft fruit at consumption is desired, high quality Chinese pears have high firmness and green skin color. Although other coating materials such as wax or synthesized polymers also improve those quality attributes (Meheriuk and Porritt, 1972; Sornsrivichai et al., 1990a; Saftner, 1999), they often cause off-flavor development after pro-longed storage (Hagenmaier and Shaw, 1992; Grant and Burns, 1994) and therefore, are pri-marily restricted to applications seeking cosmetic effects such as increase of gloss after storage (Grant and Burns, 1994). In our experiment, etha-nol levels in oil-treated and control fruit were similar and no off-flavor was perceived even after 6 months storage plus 7 days ripening at 20°C. In ‘Golden Delicious’ apples (Saftner, 1999), internal CO2 and O2 were 16 and 6 kPa in shellac-coated

fruit, and 14 and 8 kPa in wax-coated fruit, respectively, after 6 months storage at 0°C. While wax coating did not cause ethanol accumulation, shellac coating caused ethanol accumulation but only when fruit were removed from storage to 20°C. Since internal concentrations of CO2 were

lower and O2 were higher in oil-treated pears

compared with wax-coated apples (Saftner, 1999; Saftner et al., 1999), oil may be a safer treatment to avoid off-flavor. Thus, plant oil treatment at harvest provides an effective and convenient tool in maintaining fruit quality of Chinese pears.

Ethylene plays a critical role in inducing fruit ripening and senescence (Saltveit, 1999). Our re-sults indicate that the positive effects of plant oils on fruit quality attributes may relate to delayed

ethylene production, although the mechanism by which plant oils inhibit ethylene production is not clear. In wax coated fruit, the inhibition of ethyl-ene production is proposed as aresult of modified internal atmosphere including elevated CO2 and

reduced O2 (Hagenmaier and Shaw, 1992; Banks

et al., 1993; Saftner et al., 1999). In plant oil-treated fruit, however, we did not detect differ-ences in CO2 and O2 concentrations compared

with control fruit during early storage (Fig. 2A, B) when ethylene production was inhibited by oil treatment. But this does not rule out the involve-ment of modified atmosphere in affecting ethylene production. For example, fruit peels produce more ethylene than flesh on both fresh and dry weight bases in apples and pears (Ju et al., unpub-lished data). In plant oil-treated fruit, internal CO2 and O2 might be different in the oil-treated

fruit peel from the flesh, especially in the early storage period. The total internal atmosphere as-sessments used in this experiment may not be able to reflect this difference. Therefore, the mecha-nism of ethylene inhibition by oil treatment in early storage warrants further investigation.

References

Banks, N.H., Dadzie, B.K., Cleland, D.J., 1993. Reducing gas exchange of fruits with surface coating. Postharvest Biol. Technol. 3, 269 – 284.

Beyer, E.M., Morgan, P.W., 1970. A method for determining the concentration of ethylene in the gas phase of vegetable plant tissues. Plant Physiol. 46, 252 – 254.

Crisosto, C.H., Gamer, D., Crisosto, G.M., 1994. Late harvest and delayed cooling induce internal browning of ‘Ya Li’ and ‘Seuri’ Chinese pears. Hort. Sci. 29, 667 – 670. Grant, L.A., Burns, J., 1994. Application of coatings. In:

Krochta, J.M., Baldwin, E.A., Nisperos-Carriedo (Eds.), Edible coatings and films to improve food quality, Tech-nomic Publ. Co., Lancaster, PA, p. 189 – 200.

Hagenmaier, R.D., Shaw, P.E., 1992. Gas permeability of fruit coating waxes. J. Amer. Soc. Hort. Sci. 117, 105 – 109. Ju, Z., 1988. Advances in research of phenolic metabolism and

fruit quality of pears. J. Laiyang Agri. Coll. 3, 59 – 64 (Chinese with English abstract).

Ju, Z., Duan, Y., Ju, Z., 2000a. Mono-, di-, and tri-acylglyc-erols and phospholipids from plant oils inhibit scald devel-opment in ‘Delicious’ apples. Postharvest Biol. Technol. 19, 1 – 7.

‘Bartlett’ pears after prolonged cold storage. J. Hort. Sci. Biotechnol. (in press).

Ju, Z., Yuan, Y., Liu, C., 1994. Effects of low temperature on H2O2level and heart browning of ‘Chili’ and ‘Ya Li’. Sci.

Agri. Sinica 27, 77 – 81 (Chinese with English abstract). Ju, Z., Zhu, G., 1988. Advances in research of fruit tissue

browning. Plant Physiol. Comm. 6, 75 – 77 (Chinese). Meheriuk, M., Porritt, S.M., 1972. Effects of waxing on

respiration, ethylene production, and other physical and chemical changes in selected apple cultivars. Can. J. Plant Sci. 52, 245 – 259.

Saftner, R.A., 1999. The potential of fi-uit coating and film treatments for improving the storage and shelf-life qualities of ‘Gala’ and ‘Golden Delicious’ apples. J. Am. Soc. Hort. Sci. 124, 682 – 689.

Saftner, R.A., Conway, W.S., Sams, C.E., 1999. Postharvest calcium infiltration alone and combined with surface coating

treatments influence volatile levels, respiration, ethylene production, and internal atmospheres of ‘Golden Delicious’ apples. J. Am. Soc. Hort. Sci. 124, 553 – 558.

Saltveit, M.R., 1999. Effect of ethylene on quality of fresh fruits and vegetables. Postharvest Biol. Technol. 15, 279 – 292. Sornsrivichai, L., Boontham, K., Pipattanwongs, N., 1990a.

Effects of wax coating on storage life and fruit quality of five Asian pear (Pyrus pyrifolia) cultivars. Acta Hort. 279, 511 – 528.

Sornsrivichai, L., Boontham, K., Pipattanwongs, N., 1990b. Storage behavior of five Asian pear (Pyrus pyrifolia) culti-vars, produced in northern Thailand. Acta Hort. 279, 533 – 539.

Tian, M., Sheng, Q, Li, Y., 1987. Effects of low temperature storage on ethylene production, membrane permeability, and polyphenol oxidase activity in ‘Ya Li’. Acta Plant Sinica 29, 614 – 619 (Chinese with English abstract).