Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

Temperature & Density for Castings

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

FIGURE 5.1 (a) Temperature as a function of time for the solidification of pure metals. Note that freezing takes place at a constant temperature. (b) Density as a function of time.

T

emperature

Time Cooling of liquid

Cooling of solid

B A

Liquid

Liquid + solid

Solid Freezing begins

Freezing ends Freezing

temperature

Specific density

Time Shrinkage of liquid Shrinkage of solid

Solidification shrinkage

Two-Phased Alloys

FIGURE 5.2 (a) Schematic illustration of grains, grain boundaries, and particles dispersed throughout the structure of a two-phase system, such as lead-copper alloy. The grains represent lead in solid solution of copper, and the particles are lead as a second phase. (b) Schematic illustration of a two-phase system, consisting of two sets of grains: dark and light. Dark and light grains have their own compositions and properties.

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

Phase Diagram for Nickel-Copper

FIGURE 5.3 Phase diagram for nickel-copper alloy system obtained by a low rate of solidification. Note that pure nickel and pure copper each have one freezing or melting temperature. The top circle on the right depicts the nucleation of crystals; the second circle shows the formation of dendrites; and the bottom circle shows the solidified alloy with grain boundaries.

Solid

(42% Cu-58% Ni) Liquid

(50% Cu-50% Ni) First solid

(36% Cu-64% Ni)

Liquid

(58% Cu-42% Ni)

0 36 42 50 58 67 100

Solid solution

Alloy composition

Liquid solution

Fraction liquid

0 1

Solidus Liquidus

L + S

Solid solution (50% Cu-50% Ni)

1981

CS CO CL 1082 1980

2280 2350 2395 2651 1455

1249 1288 1313

T

emperature (°F)

°C

Composition (% by weight)

Copper (Cu)

Irn-Iron Carbide Phase Diagram

FIGURE 5.4 (a) The iron-iron carbide phase diagram. (b) Detailed view of the microstructures above and below the eutectoid temperature of 727°C (1341°F). Because of the importance of steel as an engineering material, this diagram is one of the most important phase diagrams.

400 500 600 700 800 900 1000 1100

0 0.5 1.0 1.5 2.0 2.5

1000 1500 2000 727°C °F T emperature (°C)

Carbon (% by weight)

! + Fe3C

"

" + Fe3C

Fe3C

Ferrite

! ! ! !

!

"+ !

T

emperature (°C)

Carbon (% by weight) 1000 1200 1400 800 600 400 1600

0 1 2 3 4 5 6 6.67

1000 1500 2500

2000

Cementite (Fe3C)

Liquid 727°C 1495°C 1538°C 1394°C 912°C °F 0.77% 0.022% 4.30% 2.11% 1148°C

" (ferrite)

" + cementite

! + cementite

! + liquid

# (Ferrite)

Detail view

(a) (b)

! (austenite)

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

Texture in Castings

FIGURE 5.5 Schematic illustration of three cast structures of metals solidified in a square mold: (a) pure metals, with preferred texture at the cool mold wall. Note in the middle of the figure that only favorable oriented grains grow away from the mold surface; (b) solid-solution alloys; and (c) structure obtained by heterogeneous nucleation of grains.

(a) Chill zone

Equiaxed structure Equiaxed zone

(b) (c)

Alloy Solidification & Temperature

FIGURE 5.6 Schematic illustration of alloy solidification and temperature distribution in the solidifying metal. Note the formation of dendrites in the semi-solid (mushy) zone.

L + S

TS TL

Liquid

Solid

Solid Solid

Mushy zone

Dendrites Mold

wall

Liquid

Liquid

T

emperature

Alloying element (%)

S

L Liquidu

s S

olidu s

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

Solidification Patterns for Gray Cast Iron

FIGURE 5.7 Schematic illustration of three basic types of cast structures: (a) columnar dendritic; (b) equiaxed dendritic; and (c) equiaxed nondendritic. Source: After D. Apelian.

(a)

(b) 0.05–0.10% C

Steel

0.25–0.30% C Steel

Minutes after pouring Minutes after pouring

0.55–0.60% C Steel

8 11 40 60 90 102

5 2 15 2 16 2

Sand mold

Chill mold

Sand mold

Chill mold

Sand mold

Cast Structures

FIGURE 5.9 Schematic illustration of cast structures in (a) plane front, single phase, and (b) plane front, two phase. Source: After D. Apelian.

(a) (b) (c)

Solid Solid

Solid Liquid Liquid Liquid

Mold wall

(a)

Solid Liquid Mold

wall Liquid

(b)

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

Mold Features

FIGURE 5.10 Schematic illustration of a typical sand mold showing various features. Open riser

Vent

Pouring basin (cup)

Drag Cope

Sand Sprue

Sand Flask

Parting line Mold

cavity Well

Gate

Core (sand)

Blind riser

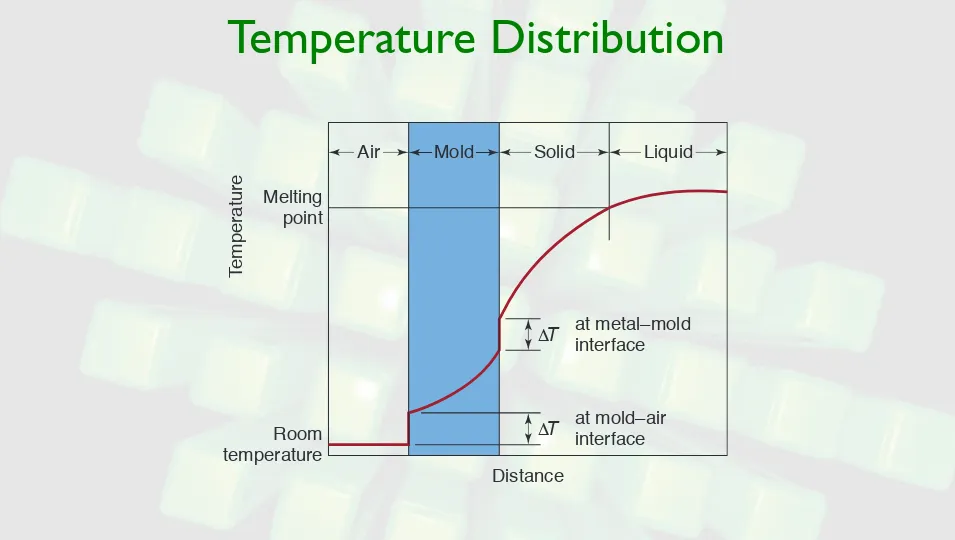

Temperature Distribution

FIGURE 5.11 Temperature distribution at the mold wall and liquid-metal interface during solidification of metals in casting. Room

temperature

Distance

at mold–air interface

at metal–mold interface

Melting point

T

emperature

Air Solid Liquid

!T

!T

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

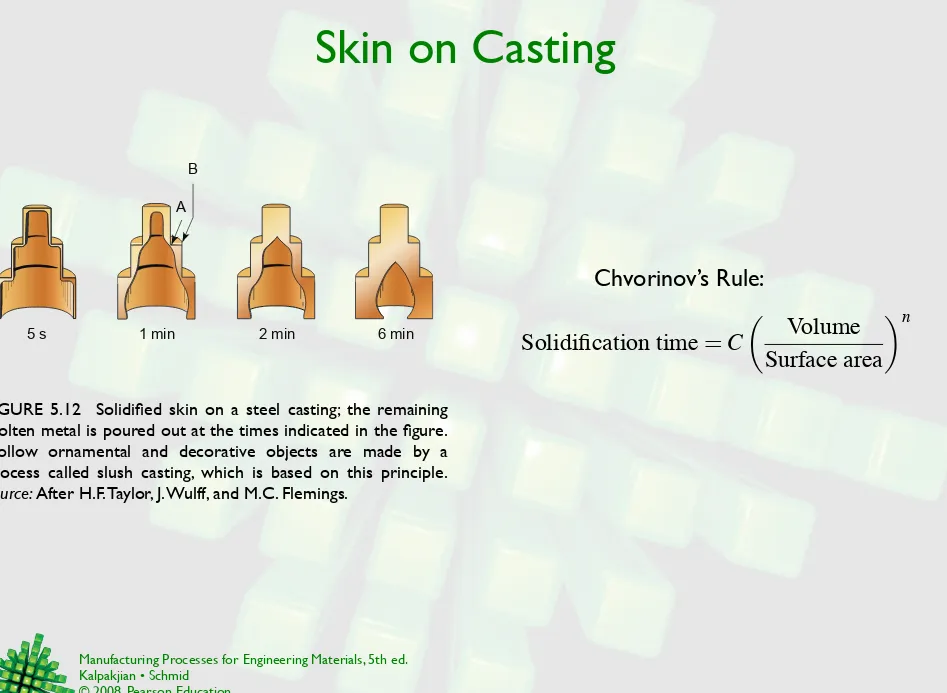

Skin on Casting

FIGURE 5.12 Solidified skin on a steel casting; the remaining molten metal is poured out at the times indicated in the figure. Hollow ornamental and decorative objects are made by a process called slush casting, which is based on this principle. Source: After H.F. Taylor, J. Wulff, and M.C. Flemings.

5 s 1 min 2 min 6 min

A B

Chvorinov’s Rule:

Solidification time

=

C

!

Volume

Surface area

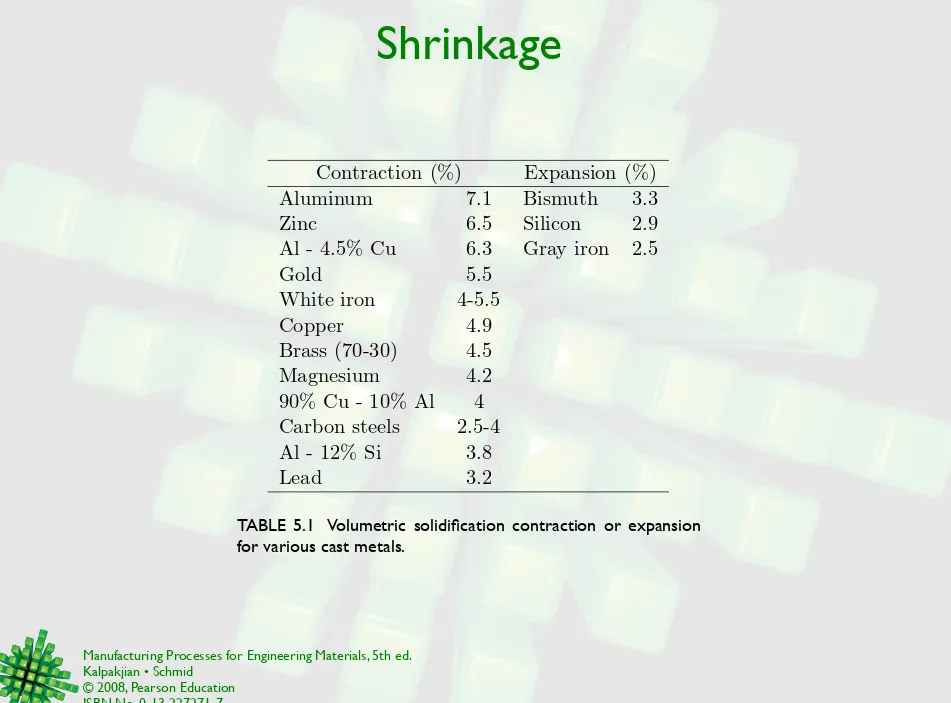

Shrinkage

Contraction (%)

Expansion (%)

Aluminum

7.1

Bismuth

3.3

Zinc

6.5

Silicon

2.9

Al - 4.5% Cu

6.3

Gray iron

2.5

Gold

5.5

White iron

4-5.5

Copper

4.9

Brass (70-30)

4.5

Magnesium

4.2

90% Cu - 10% Al

4

Carbon steels

2.5-4

Al - 12% Si

3.8

Lead

3.2

Man

ufacturing Pr

ocesses f

or Engineering Materials,

5th ed. Kalpakjian • Schmid © 2008, P earson Education ISBN No . 0-13-227271-7

Cast Material

Pr

oper

ties

FIGURE 5.13 Mechanical pr oper ties for various gr oups of cast allo ys. Compar e with various tables of pr oper ties in Cha pter 3. Source: Courtesy of Steel F

ounders' Society of

America. Steel Nodular iron Gray iron Malleable iron Aluminum based Copper based Magnesium based Nickel based Zinc based

Ultimate tensile strength (psi x 103)

300 280 260 240 220 200 180 160 140 120 100 80 60 40 20 0 2000 1800 2000 1800 1600 1400 1200 1000 800 600 400 200 MPa (a) 300 280 260 240 220 200 180 160 140 120 100 80 60 40 20 0 1600 1400 1200 1000 800 600 400 200 Steel Nodular iron Gray iron Malleable iron Aluminum based Copper based Magnesium based Nickel based Zinc based

Yield strength (psi x 103)

MPa (b) Nodular iron Gray iron Malleable iron Aluminum based Copper based Magnesium based Nickel based Zinc based Titanium metal Titanium alloys Cast steel

0 5 10 15 20 25 30

0 50 100 150 200

GPa

Modulus of elasticity (psi x 106)

0 2 4 6 8 10 12

W rought Cast Steel Nodular iron Gray iron Malleable iron Aluminum based Magnesium based Titanium metal Titanium alloy Tensile strength/density ratio (in x 105)

(d) (c) Nodular iron Gray iron Aluminum based Copper based Magnesium based Nickel based Zinc based Steel Malleable iron 800 700 600 500 400 300 200 100 0

Brinell harbness (HB)

(e) Malleable iron 70 60 50 40 30 20 10 0 90 80 70 60 50 40 30 20 10 0 Steel Nodular iron Gray iron J

Impact energy (ft-lb, Charpy V-notch)

(f ) 70 60 50 40 30 20 10 0 Nodular iron Malleable iron Copper based Nickel based Steel Gray iron Copper based Nickel based Reduction of area (%)

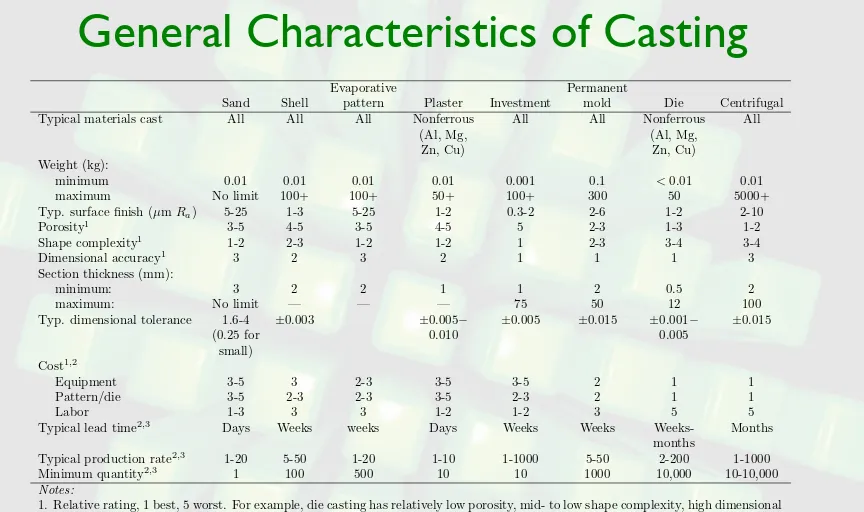

General Characteristics of Casting

TABLE 5.2 General characteristics of casting processes.

Evaporative Permanent

Sand Shell pattern Plaster Investment mold Die Centrifugal

Typical materials cast All All All Nonferrous All All Nonferrous All

(Al, Mg, (Al, Mg,

Zn, Cu) Zn, Cu)

Weight (kg):

minimum 0.01 0.01 0.01 0.01 0.001 0.1 <0.01 0.01

maximum No limit 100+ 100+ 50+ 100+ 300 50 5000+

Typ. surface finish (µm Ra) 5-25 1-3 5-25 1-2 0.3-2 2-6 1-2 2-10

Porosity1

3-5 4-5 3-5 4-5 5 2-3 1-3 1-2

Shape complexity1

1-2 2-3 1-2 1-2 1 2-3 3-4 3-4

Dimensional accuracy1

3 2 3 2 1 1 1 3

Section thickness (mm):

minimum: 3 2 2 1 1 2 0.5 2

maximum: No limit — — — 75 50 12 100

Typ. dimensional tolerance 1.6-4 ±0.003 ±0.005− ±0.005 ±0.015 ±0.001− ±0.015

(0.25 for 0.010 0.005

small)

Cost1,2

Equipment 3-5 3 2-3 3-5 3-5 2 1 1

Pattern/die 3-5 2-3 2-3 3-5 2-3 2 1 1

Labor 1-3 3 3 1-2 1-2 3 5 5

Typical lead time2,3

Days Weeks weeks Days Weeks Weeks Weeks- Months

months

Typical production rate2,3

1-20 5-50 1-20 1-10 1-1000 5-50 2-200 1-1000

Minimum quantity2,3

1 100 500 10 10 1000 10,000 10-10,000

Notes:

1. Relative rating, 1 best, 5 worst. For example, die casting has relatively low porosity, mid- to low shape complexity, high dimensional accuracy, high equipment and die costs and low labor costs. These ratings are only general; significant variations can occur depending on the manufacturing methods used.

2. Data taken from Schey, J.A., Introduction to Manufacturing Processes, 3rd ed, 2000.

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

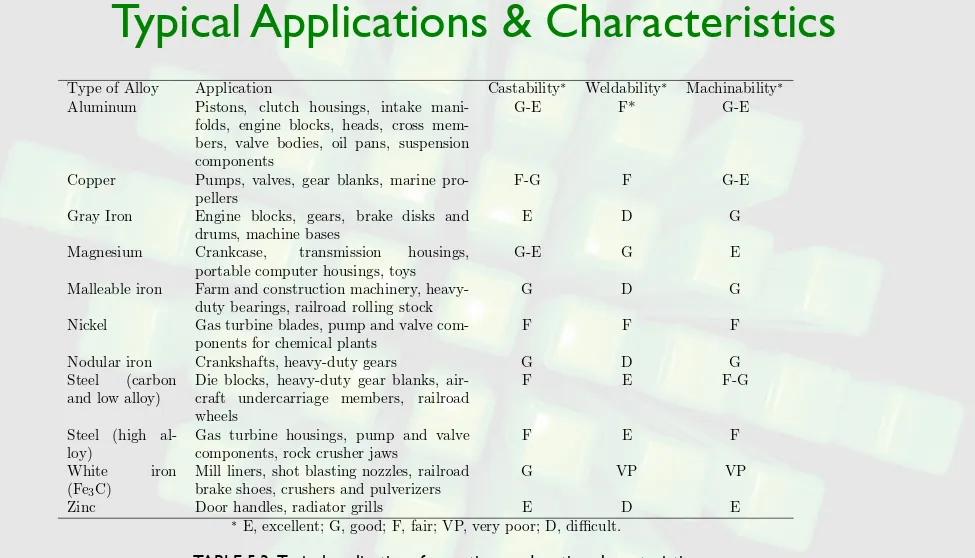

Typical Applications & Characteristics

TABLE 5.3 Typical applications for castings and casting characteristics.

Type of Alloy Application Castability∗ Weldability∗ Machinability∗

Aluminum Pistons, clutch housings, intake

mani-folds, engine blocks, heads, cross mem-bers, valve bodies, oil pans, suspension components

G-E F* G-E

Copper Pumps, valves, gear blanks, marine

pro-pellers

F-G F G-E

Gray Iron Engine blocks, gears, brake disks and

drums, machine bases

E D G

Magnesium Crankcase, transmission housings,

portable computer housings, toys

G-E G E

Malleable iron Farm and construction machinery,

heavy-duty bearings, railroad rolling stock

G D G

Nickel Gas turbine blades, pump and valve

com-ponents for chemical plants

F F F

Nodular iron Crankshafts, heavy-duty gears G D G

Steel (carbon

and low alloy)

Die blocks, heavy-duty gear blanks, air-craft undercarriage members, railroad wheels

F E F-G

Steel (high al-loy)

Gas turbine housings, pump and valve components, rock crusher jaws

F E F

White iron

(Fe3C)

Mill liners, shot blasting nozzles, railroad brake shoes, crushers and pulverizers

G VP VP

Zinc Door handles, radiator grills E D E

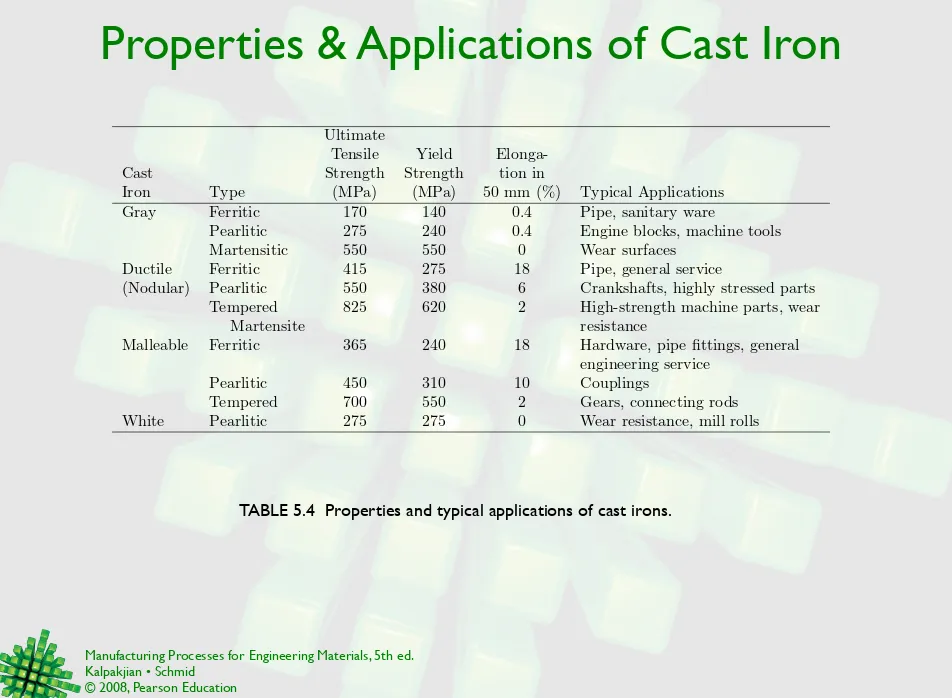

Properties & Applications of Cast Iron

TABLE 5.4 Properties and typical applications of cast irons.

Ultimate

Tensile Yield

Elonga-Cast Strength Strength tion in

Iron Type (MPa) (MPa) 50 mm (%) Typical Applications

Gray Ferritic 170 140 0.4 Pipe, sanitary ware

Pearlitic 275 240 0.4 Engine blocks, machine tools

Martensitic 550 550 0 Wear surfaces

Ductile Ferritic 415 275 18 Pipe, general service

(Nodular) Pearlitic 550 380 6 Crankshafts, highly stressed parts

Tempered 825 620 2 High-strength machine parts, wear

Martensite resistance

Malleable Ferritic 365 240 18 Hardware, pipe fittings, general

engineering service

Pearlitic 450 310 10 Couplings

Tempered 700 550 2 Gears, connecting rods

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

Nonferrous Alloys

TABLE 5.5 Typical properties of nonferrous casting alloys.

Casting UTS Yield Strength Elongation Hardness Alloy Condition Method∗ (MPa) (MPa) in 50 mm (%) (HB) Aluminum

357 T6 S 345 296 2.0 90

380 F D 331 165 3.0 80

390 F D 279 241 1.0 120

Magnesium

AZ63A T4 S, P 275 95 12 —

AZ91A F D 230 150 3 —

QE22A T6 S 275 205 4 —

Copper

Brass C83600 — S 255 177 30 60

Bronze C86500 — S 490 193 30 98

Bronze C93700 — P 240 124 20 60

Zinc

No. 3 — D 283 — 10 82

No. 5 — D 331 — 7 91

ZA27 — P 425 365 1 115

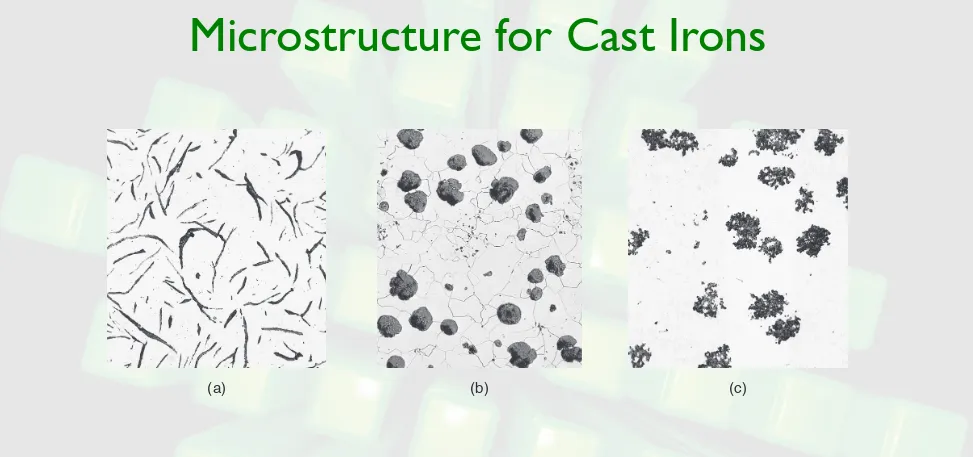

Microstructure for Cast Irons

FIGURE 5.14 Microstructure for cast irons. (a) ferritic gray iron with graphite flakes; (b) ferritic nodular iron, (ductile iron) with graphite in nodular form; and (c) ferritic malleable iron. This cast iron solidified as white cast iron, with the carbon present as cementite (Fe3C), and was heat treated to graphitize the carbon.

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

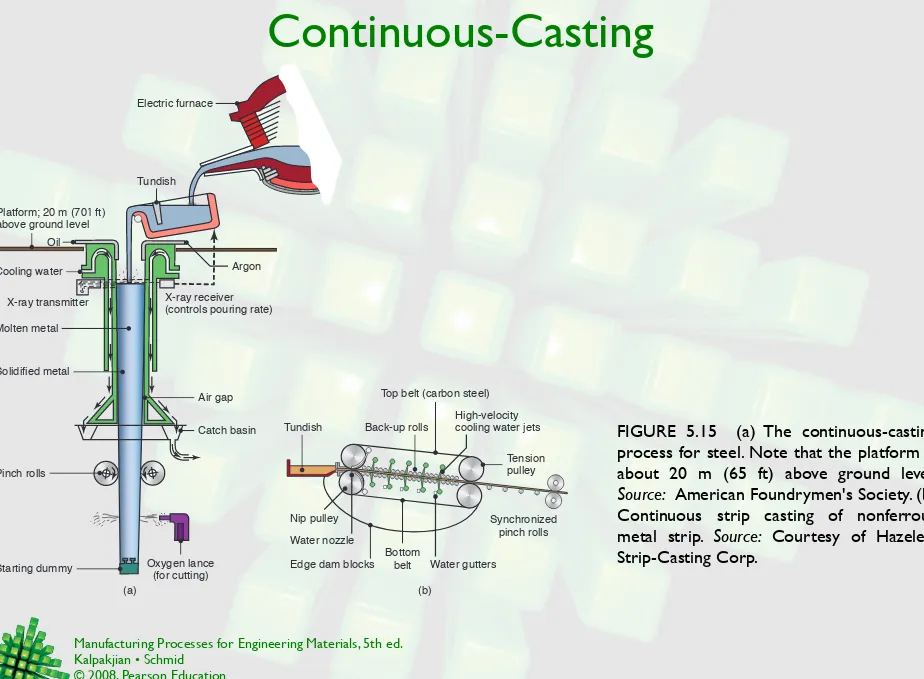

Continuous-Casting

FIGURE 5.15 (a) The continuous-casting process for steel. Note that the platform is about 20 m (65 ft) above ground level. Source: American Foundrymen's Society. (b) Continuous strip casting of nonferrous metal strip. Source: Courtesy of Hazelett Strip-Casting Corp.

Electric furnace

Tundish

Argon

X-ray receiver

(controls pouring rate) X-ray transmitter

Molten metal

Solidified metal Oil Cooling water

Platform; 20 m (701 ft) above ground level

Air gap

Catch basin

Pinch rolls

Oxygen lance (for cutting) Starting dummy

Tundish

Top belt (carbon steel) High-velocity cooling water jets Back-up rolls

Bottom

belt Water gutters

Nip pulley Synchronized pinch rolls

Tension pulley

Edge dam blocks Water nozzle

Sand

Casting

FIGURE 5.16 Schematic illustration of the sequence of operations in sand casting. (a) A mechanical drawing of the part, used to create patterns. (b-c) Patterns mounted on plates equipped with pins for alignment. Note the presence of core prints designed to hold the core in place. (d-e) Core boxes produce core halves, which are pasted together. The cores will be used to produce the hollow area of the part shown in (a). (f) The cope half of the mold is assembled by securing the cope pattern plate to the flask with aligning pins, and attaching inserts to form the sprue and risers. (g) The flask is rammed with sand and the plate and inserts are removed. (h) The drag half is produced in a similar manner. (j) The core is set in place within the drag cavity. (k) The mold is closed by placing the cope on top of the drag and securing the assembly with pins. (l) After the metal solidifies, the casting is removed from the mold. (m) The sprue and risers are cut off and recycled, and the casting is cleaned, inspected, and heat treated (when necessary). Source: Courtesy of Steel Founders' Society of America.

Cope ready for sand

Cope after ramming with sand and removing pattern,

sprue, and risers

Drag ready for sand

Drag after removing pattern Core halves

pasted together

(e) (f) (g) (h) (i)

Sprue Risers Flask

Drag with core set in place

(j)

Cope and drag assembled and ready for pouring

(k) Cope

Drag Closing pins

Casting as removed from mold; heat treated

(l)

Casting ready for shipment

(m) (a)

Mechanical drawing of part Cope pattern plate Drag pattern plate Core boxes (d)

(b) (c)

Core prints Gate

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

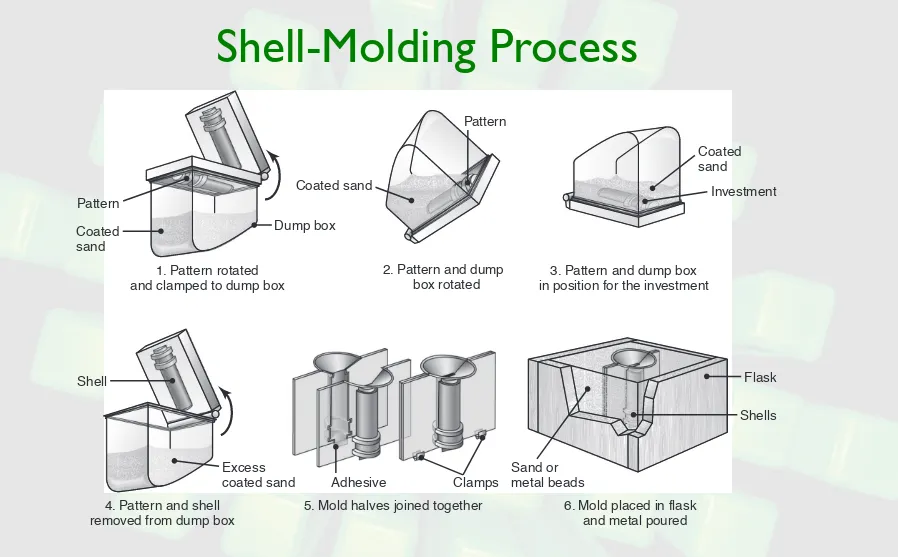

Shell-Molding Process

FIGURE 5.17 Schematic illustration of the shell-molding process, also called the dump-box technique.

Pattern

Coated sand

Dump box

1. Pattern rotated and clamped to dump box

Shell

Excess coated sand

4. Pattern and shell removed from dump box

Coated sand

3. Pattern and dump box in position for the investment

Investment Pattern

Coated sand

2. Pattern and dump box rotated

Adhesive Clamps

5. Mold halves joined together

Flask

Sand or metal beads

Shells

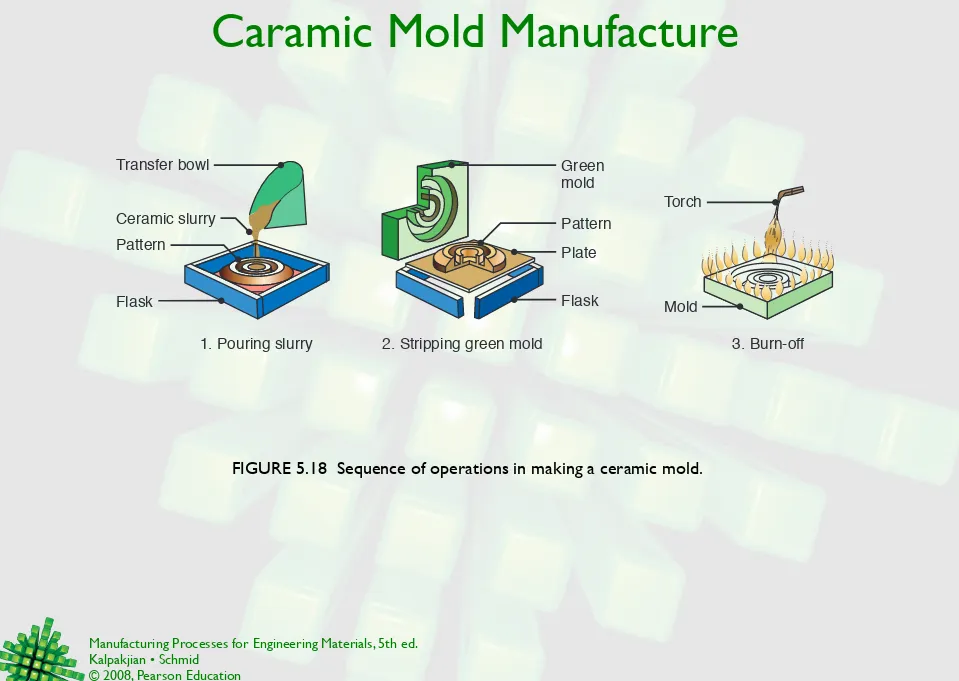

Caramic Mold Manufacture

FIGURE 5.18 Sequence of operations in making a ceramic mold.

3. Burn-off 2. Stripping green mold

1. Pouring slurry

Flask Green mold

Pattern

Plate Ceramic slurry

Pattern

Transfer bowl

Flask

Torch

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

Vacuum-Casting Process

FIGURE 5.19 Schematic illustration of the vacuum-casting process. Note that the mold has a bottom gate. (a) before and (b) after immersion of the mold into the molten metal. Source: After R. Blackburn.

Mold

(a) (b)

Induction furnace

Vacuum

Casting

Evaporative Pattern Casting

FIGURE 5.20 Schematic illustration of the expendable-pattern casting process, also known as lost-foam or evaporative-pattern casting.

1. Pattern molding

4. Compacted in sand 5. Casting

6. Shakeout 2. Cluster assembly

3. Coating

Cluster

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

Investment Casting

FIGURE 5.21 Schematic illustration of investment casting (lost wax process). Castings by this method can be made with very fine detail and from a variety of metals. Source: Steel Founders' Society of America.

9. Shakeout 8. Pouring

7. Pattern meltout 6. Completed mold

Casting

10. Pattern Molten

metal Autoclaved

Molten wax or plastic

Heat Heat

1. Injection wax or plastic pattern

4. Slurry coating 2. Ejecting

pattern

5. Stucco coating 3. Pattern

assembly (tree) Wax

Rotor Microstructure

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

Pressure & Hot-Chamber Die Casting

FIGURE 5.23 The pressure casting process, utilizing graphite molds for the production of steel railroad wheels. Source: Griffin Wheel Division of Amsted Industries Incorporated.

Airtight chamber

Ladle Refractory tube

Molten metal Air pressure Railroad wheel Graphite mold

FIGURE 5.24 Schematic illustration of the hot-chamber die-casting process.

Gooseneck Nozzle

Die cavity

Hydraulic shot cylinder

Plunger rod

Plunger

Molten metal

Pot Ejector die

Cover die

Cold-Chamber Die Casting

FIGURE 5.25 Schematic illustration of the cold-chamber die-casting process. These machines are large compared to the size of the casting, because high forces are required to keep the two halves of the die closed under pressure.

Shot cylinder Metal

sleeve Cover

disc Closing

cylinder

Ejector box

Ejector platen (Moves)

Ejector die half

Hydraulic cylinder

Shot sleeve Ejector box

Ladle

Stationary die half

Plunger rod Stationary platen Cavity

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

Properties of Die-Casting Alloys

Ultimate

Elonga-Tensile Yield tion Strength Strength in 50 mm

Alloy (MPa) (MPa) (%) Applications

Aluminum 380 320 160 2.5 Appliances, automotive

(3.5 Cu-8.5 Si) components, electrical motor

frames and housings, engine blocks.

Aluminum 13 300 150 2.5 Complex shapes with thin

(12 Si) walls, parts requiring strength at

elevated temperatures

Brass 858 (60 Cu) 380 200 15 Plumbing fixtures, lock hard-ware, bushings, ornamental cast-ings

Magnesium 230 160 3 Power tools, automotive

AZ91B (9 Al - 0.7 Zn) parts, sporting goods

Zinc No. 3 (4 Al) 280 — 10 Automotive parts, office equip-ment, household utensils, build-ing hardware, toys

Zinc No. 5 (4 Al - 1 Cu) 320 — 7 Appliances, automotive parts, building hardware, business equipment

Source: The North American Die Casting Association

Centrifugal Casting

FIGURE 5.26 Schematic illustration of the centrifugal casting process. Pipes, cylinder liners, and similarly shaped hollow parts can be cast by this process.

Free roller Drive roller

Mold

(a) (b)

Drive shaft

Spout

Rollers

Ladle Molten metal

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

Semicentrifugal Casting

FIGURE 5.27 (a) Schematic illustration of the semicentrifugal casting process. Wheels with spokes can be cast by this process. (b) Schematic illustration of casting by centrifuging. The molds are placed at the periphery of the machine, and the molten metal is forced into the molds by centrifugal forces.

(a) (b)

Mold

Molten metal

Casting Flasks

Holding fixture

Drag

Revolving table

Casting Pouring basin

and gate

Squeeze-Casting

FIGURE 5.28 Sequence of operations in the squeeze-casting process. This process combines the advantages of casting and forging.

1. Melt metal 2. Pour molten metal into die

3. Close die and apply pressure

4. Eject squeeze casting, charge melt stock,

repeat cycle Die

Ejector pin

Finished casting

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

Turbine Blade Casting

FIGURE 5.29 Methods of casting turbine blades: (a) directional solidification; (b) method to produce a single-crystal blade; and (c) a single-crystal blade with the constriction portion still attached. Source: (a) and (b) After B.H. Kear, (c) Courtesy of ASM International.

(c)

(a) (b)

Radiant heat

Columnar

crystals Constriction

Chill plate Columnar

crystals Heat baffles

Radiant heat

Crystal Growing

FIGURE 5.30 Two methods of crystal growing: (a) crystal pulling (Czochralski process) and (b) floating-zone method. Crystal growing is especially important in the semiconductor industry. (c) A single-crystal silicon ingot produced by the Czochralski process. Source: Courtesy of Intel Corp.

(c)

(a) (b)

~1 rev/s

10

µ

m/s

Liquid Seed

20

µ

m/s

Induction coil

Single crystal

Polycrystalline

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

Melt-Spinning Process

FIGURE 5.31 (a) Schematic illustration of the melt-spinning process to produce thin strips of amorphous metal. (b) Photograph of nickel-alloy production through melt-spinning. Source: Courtesy of Siemens AG.

(b) (a)

Crucible Induction coil

Melt

Strip Gas

Austenite-Pearlite Transformation

FIGURE 5.32 (a) Austenite to pearlite transformation of iron-carbon alloys as a function of time and temperature. (b) Isothermal transformation diagram obtained from (a) for a transformation temperature of 675°C (1247°F). (c) Microstructures obtained for a eutectoid iron-carbon alloy as a function of cooling rate. Source: Courtest of ASM International.

(a) 25 75 50 0 100 75 25 50 100 0 Austenite (%) Pearlite (%) Time (s)

600°C 650° 675°

1 10 102 103

50

0 100

Percent of austenite

transformed to pearlite

T emperature ( ° C) Austenite (%) ° F 50 100 0 600 500 700 800 1000 1200 1400

50% Completion curve Pearlite Completion curve (~100% pearlite) Eutectoid temperature Austenite (unstable) Begin curve (~0% pearlite) Transformation temperature 675°C

Transformation begins

1 10 103 104 105

Transformation ends Austenite (stable) 102 Time (s) T emperature ( °C) 200

100 200

400 600 800 1000 1200 1400 300 400 500 35°C/s 140 °C/s 600 700 800 Eutectoid temperature

M (start) Critical cooling rate °F Martensite Martensite

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

Phase Diagram for Aluminum-Copper

FIGURE 5.33 (a) Phase diagram for the aluminum-copper alloy system. (b) Various microstructures obtained during the age-hardening process.

X

T

emperature

X—solid solution

XA—quenched, solid solution retained

AB—age-hardened, precipitation starts

(submicroscopic)

AC—over-aging, precipitate

agglomerates

100 95 90 Aluminum (Al)

0 5 10 Copper (Cu)

70 400 900 1100 Liquid

+ liquid

20 200 500 600 700

(b) (a)

1300

Composition (% by weight)

T

emperature (°C)

°F

A B C

Time

Outline of Heat Treating

TABLE 5.7 Outline of heat treatment processes for surface hardening.

Element

Metals added to General Typical

Process hardened surface Procedure characteristics applications Carburizing Low-carbon

steel (0.2% C), alloy steels (0.08-0.2% C)

C Heat steel at 870-950◦

(1600-1750◦F) in an

at-mosphere of carboaceous gases (gas carburizing) or carbon-containing solids (pack carburizing). Then quench.

A hard, high-carbon surface is produced. Hardness 55-65 HRC. Case depth <

0.5-1.5 mm (<0.020 to 0.060 in.).

Some distortion of part dur-ing heat treatment.

Gears, cams, shafts, bearings, piston pins, sprockets, clutch plates Carbonitriding Low-carbon steel

C and N Heat steel at 700-800◦C

(1300-1600◦F) in an

atmo-sphere of carbonaceous gas and ammonia. Then quench in oil.

Surface hardness 55-62 HRC. Case depth 0.07-0.5 mm (0.003-0.020 in.). Less distor-tion than in carburizing.

Bolts, nuts, gears.

Cyaniding Low-carbon steel (0.2% C), alloy steels (0.08-0.2% C)

C and N Heat steel at 760-845◦C

(1400-1550◦F) in a molten

bath of solutions of cyanide (e.g., 30% sodium cyanide) and other salts.

Surface hardness up to 65 HRC. Case depth 0.025-0.25 mm (0.001-0.010 in.). Some distortion.

Bolts, nuts, screws, small gears.

Nitriding Steels (1% Al, 1.5% Cr, 0.3% Mo), alloy steels (Cr, Mo), stain-less steels, high-speed steels

N Heat steel at 500-600◦C

(925-1100◦F) in an atmosphere of

ammonia gas or mixtures of molten cyanide salts. No fur-ther treatment.

Surface hardness up to 1100 HV. Case depth 0.1-0.6 mm (0.005-0.030 in.) and 0.02-0.07 mm (0.001-0.003 in.) for high speed steel.

Geards, shafts, sprockets, valves, cutters, boring bars

Boronizing Steels B Part is heated using boron-containing gas or solid in con-tact with part.

Extremely hard and wear-resistance surface. Case depth 0.025-0.075 mm (0.001-0.003 in.).

Tool and die steels.

Flame hardening

Medium-carbon steels, cast irons

None Surface is heated with an oxyacetylene torch, then quenched with water spray or other quenching methods.

Surface hardness 50-60 HRC. Case depth 0.7-6 mm (0.030-0.25 in.). Little distortion.

Axles, crankshafts, piston rods, lathe beds, and centers.

Induction hardening

Same as above None Metal part is placed in cop-per induction coils and is heated by high frequency cur-rent, then quenched

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

Heat Treatment Temperature Ranges

FIGURE 5.34 Temperature ranges for heat treating plain-carbon steels, as indicated on the iron-iron carbide phase diagram.

0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

T

emperature (

°C

)

600 700 800 900 1000

1200 1400 1600 1800

Normalizing

Full

annealing

Acm

Spheroidizing 738°C

A3

A1

Composition (% C)

Casting Processes Comparison

TABLE 5.8 Casting Processes, and their Advantages and Limitations.

Process Advantages Limitations

Sand Almost any metal is cast; no limit to size, shape or weight; low tooling cost.

Some finishing required; somewhat coarse finish; wide tolerances.

Shell mold Good dimensional accuracy and sur-face finish; high production rate.

Part size limited; expensive patterns and equipment required.

Expendable pattern Most metals cast with no limit to size; complex shapes

Patterns have low strength and can be costly for low quantities.

Plaster mold Intricate shapes; good dimensional accuracy and finish; low porosity.

Limited to nonferrous metals; limited size and volume of production; mold making time relatively long.

Ceramic mold Intricate shapes; close tolerance parts; good surface finish.

Limited size.

Investment Intricate shapes; excellent surface fin-ish and accuracy; almost any metal cast.

Part size limited; expensive patterns, molds, and labor.

Permanent mold Good surface finish and dimensional accuracy; low porosity; high produc-tion rate.

High mold cost; limited shape and in-tricacy; not suitable for high-melting-point metals.

Die Excellent dimensional accuracy and surface finish; high production rate.

Die cost is high; part size limited; usu-ally limited to nonferrous metals; long lead time.

Centrifugal Large cylindrical parts with good quality; high production rate.

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

Chills

FIGURE 5.35 Various types of (a) internal and (b) external chills (dark areas at corners), used in castings to eliminate porosity caused by shrinkage. Chills are placed in regions where there is a larger volume of metal, as shown in (c).

(a)

(b)

(c)

Porosity Chill

Casting

Boss Chill Sand

Casting Chill

Hydrogen Solubility in Aluminum

FIGURE 5.36 Solubility of hydrogen in aluminum. Note the sharp decrease in solubility as the molten metal begins to solidify.

Hydrogen solubility

Fusion

Solid

Liquid

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

Elimination of Porosity in Castings

FIGURE 5.37 (a) Suggested design modifications to avoid defects in castings. Note that sharp corners are avoided to reduce stress concentrations; (b, c, d) examples of designs showing the importance of maintaining uniform cross-sections in castings to avoid hot spots and shrinkage cavities.

(a) Poor

Good

(b) (c) (d)

Shrinkage cavity

Poor Poor

Design Modifications

FIGURE 5.38 Suggested design modifications to avoid defects in castings. Source: Courtesy of The North American Die Casting Association.

Use radii or fillets to avoid corners and provide uniform cross-section.

Wall sections should be uniform.

Sloping bosses can be designed for straight die parting to simplify die design.

Ribs and/or fillets improve bosses.

Side cores can be eliminated with this hole design. Deep cavities should be on one side of the casting where possible. Poor Good

Poor Good

Poor Good

Poor Good Poor Good Poor Good

Core in cover half

Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid

© 2008, Pearson Education ISBN No. 0-13-227271-7

Economics of Casting

FIGURE 5.39 Economic comparison of making a part by two different casting processes. Note that because of the high cost of equipment, die casting is economical mainly for large production runs. Source: The North American Die Casting Association.

Cost per piece (relative)

8

7

6

5

4

3

2

1

0

100 101 102 103 104 105 106

Number of pieces

Die cast

Sand cast

Lost-Foam Casting of Engine Blocks

FIGURE 5.40 (a) An engine block for a 60-hp 3-cylinder marine engine, produced by the lost-foam casting process; (b) a robot pouring molten aluminum into a flask containing a polystyrene pattern. In the pressurized lost-foam process, the flask is then pressurized to 150 psi (1000 kPa). Source: Courtesy of Mercury Marine