FST4826

LABORATORY FOR PROCESSING OF

PLANT AND ANIMAL PRODUCTS

EXPERIMENT 6

FRUITS AND VEGETABLES

Title : Processing of Fruit Jam

GROUP MEMBERS

:

CHUA CHIAO LEE

170512

LEW KAH WAI

167685

MOHAMMAD NAQIYUDDIN

169925 BIN MOHAMED

EHWAL

GROUP

: 1

OBJECTIVE

To evaluate the effect of jam composition/formulation on physiochemical properties and organoleptic attributes of fruit jam.

INTRODUCTION

Fruits and vegetables do not have a long shelf life in their un-processed forms. Un-processed fruits and vegetables are food commodities that are perishable. Thus, most kinds of fruits and vegetables are usually processed into jam, juices, jellies or pickles in order to extend their shelf life. According to Paul, the making of jellies and other preserves is an old and popular process to keep fruits far beyond their normal storage life. (Singh, 2014).

Jams are thick, sweet spreads made by cooking crushed or ground fruits with sugar. Jams tend to hold their shape, but it is generally less firm than jellies. [ CITATION Bar08 \l 2052 ]. Normally, jam is made of mixture of not less than 45 parts by weight of fruits or fruits ingredient and 55 parts by weight of saccharine ingredient. Jams are usually sugar-acid-pectin gels or low methoxyl pectin calcium gel and the main ingredients of jams are including fruits, sugar, pectin and acid.

Different fruits will give each product its characteristic flavor and colour. Normally, flavourful, just ripen fruits are used for producing better taste of jam. Acid is added into jams for both gel formation and flavoring purpose. The amount of acids added varies among fruints used for jam production. Usually, under-ripen fruits will need higher amount of acids. Besides acids, sugar is also another important ingredient for jam production. This is because sugars can help in preserving fruits, forming gel and also contributing in the flavor of jam. [ CITATION Bar08 \l 2052 ].

commercially available pectin will include citric acid as an ingredient to help ensure it is working with the products successfully. Pectin can be in both powder and liquid forms. (Anonymous, 2012).

MATERIALS AND APPARATUS

MATERIALS

1. Fruits (Pineapples) 2. Sugars

3. Pectin A and B 4. Water

5. Citric Acid APPARATUS

1. oBrix Meter

2. pH meter

3. Air Tight Containers 4. Thermometer

5. Cooking Utensils

PROCEDURE

The two whole pineapples are weighted.

The fruits are cut and the peel and core are removed.

The weight of the cut fruits is determined

The pH, oBrix and moisture content of fruits are noted.

Jam mixture is calculated as below: For every 100g

45 parts fruits by weight 55 parts sugar (by weight)

The mashed fruit is bought to slow boil and the temperature is noted.

The fruits are heated until 30 minutes with constant stirring.

Pectin with sugar is mixed thoroughly (1 part pectin to 15 part sugar) to the fruit for 30 seconds.

The remaining sugar is added and the mixture is bought to slow boil.

The mixture is measured from time to time until oBrix is within 65-68.

The weight of jam is recorded and the yield is calculated.

Citric acid is added until the mixture has a pH 3.2 (except group 4 and 5)

The containers are exhausted in hot water bath.

Hot filled jam (85oC) is poured into sterile containers.

The lid is tighten.

RESULT AND DISCUSSION

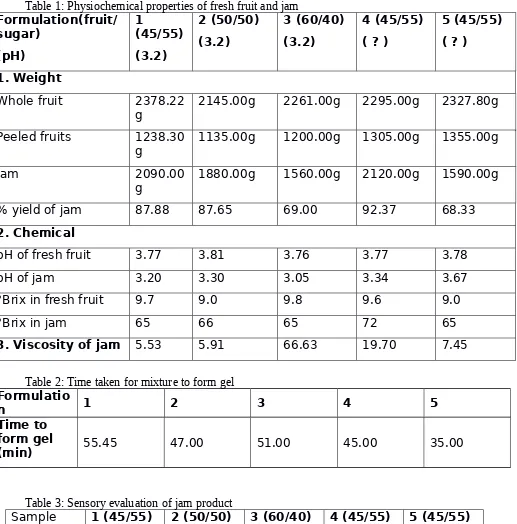

Table 1: Physiochemical properties of fresh fruit and jam

Formulation(fruit/ % yield of jam 87.88 87.65 69.00 92.37 68.33

2. Chemical

pH of fresh fruit 3.77 3.81 3.76 3.77 3.78 pH of jam 3.20 3.30 3.05 3.34 3.67 °Brix in fresh fruit 9.7 9.0 9.8 9.6 9.0

°Brix in jam 65 66 65 72 65

3. Viscosity of jam 5.53 5.91 66.63 19.70 7.45

Table 2: Time taken for mixture to form gel

Formulatio

n 1 2 3 4 5

Time to form gel

(min) 55.45 47.00 51.00 45.00 35.00

Table 3: Sensory evaluation of jam product

Sample 1 (45/55) 2 (50/50) 3 (60/40) 4 (45/55) 5 (45/55)

Color 1.69 ±

0.58 2.06 ± 0.59 2.17 ± 0.71 1.91 ± 0.66 1.37 ± 0.55 Aroma 2.11 ±

Taste 1.86 ±

0.43 1.66 ± 0.68 1.54 ± 0.51 2.26 ± 0.61 2.40 ± 0.69 Acceptabili

ty 1.86 ± 0.36 1.80 ± 0.58 1.71 ± 0.46 2.14 ± 0.49 2.37 ± 0.60

In this experiment we try to evaluate the effect of jam formulation on physiochemical properties and organoleptic attribute of fruit jam. We were using five different formulation which differ in the ratio of fruit and sugar, type of pectin and pH value. The yield of jam from group formulation 4 is the highest (92.37%). The fresh fruit used for every formulation is different from each other. The yield might be varies due of the way we cut off the pineapple skin, some group may cut the pineapple deep into the flesh cause the yield of jam will be decrease. The formulation or specifically the volume of sugar added into the mixture also one of the factor. In this experiment we used two different pectin, the slow setter pectin and the fast setter pectin. Only formulation 5 were used fast setter pectin while the rest four formulation used the slow setter pectin. Addition of pectin had no significant effect on the pH of the finished jam. Sufficient pectin levels however improved the texture, gel formation and enhanced spread ability of the jam ( Emmanuel 2006).

All pH value of the pineapple dropped when in processed into jam. The pH of the jam for sample 1, 2 and 3 were fixed to be around 3.2 using acid. Fast setting pectin believes to have higher pH value (3.67) compared to the other sample where it used slow setting pectin (3.20, 3.30, 3.05, 3.34). Optimum firmness is achieved within definite pH ranges for the particular pectin used. Slow-set pectin often are used in commercial jelly manufacture and attain a maximum firmness at pH 3.0 to pH 3.15. Rapid-set pectin are used for jams and preserves because they set at a higher temperature before fruit components float to the top of the jar and attain maximum firmness at pH 3.30 to 3.05. The upper limits for successful gel set are pH 3.4 and pH 3.6 for slow set and rapid set pectin respectively (Smith 2006).

liquid phase of the jam product is 67.89%. However, higher total sugar quantities (up to 70 to 72%) found in products is explained by increased reducing sugar solubility, resulting from sucrose inversion.

The viscosity of the jam happen to be highest (66.63) in the formulation 3 with 60/40 fruit to sugar ratio. There are many factor that influence this figure and one of it is the pH of the jam. This agree with the findings by Egan et al. (1985) which reported that pH that near to or below 3.0 might result in hard gels.

After sensory evaluation were conducted jam from formulation 5 happen to score highest in each attribute besides color. But in term of color jam from formulation 3 become the most desirable. In term of overall acceptability the jam from formulation 3 score lowest compared to the others. This may due to sugar used in the formulation which is lower than the others.

CONCLUSION

In conclusion, the ratio of fruit to sugar could affect the desirable attribute in jam product and also the physiochemical properties of the jam. The pectin used in the formulation, pH and the °Brix of the jam effect the gel strength of the jam. Also the specific pectin have their own pH that will result in jam desirable attribute. Texture of jam is a composite property related to a number of physical properties such as, pH, sugar concentration, viscosity and elasticity, and their relationship is complex.

QUESTIONS

1. What is the function of pH in jam making?

high, the jelly will weep or lose liquid. At low pH the concentration of the hydrogen ion is higher which tend to repress the ionization of the galacturonate carboxyl group. The tendency of the negatively charged carboxyl groups to repel each other is eliminated.

2. What is the effect of °Brix on the gel strength of the jam?

°Brix refer to the sugar concentration inside the solution, higher °Brix means higher sugar concentration and resulted decrease in water that available to keep pectin from interacting. The result was increase in gelling and possibly some crystal formulation due to lowered water concentration.

3. How does the selection of pectin type affect the quantity, processing time and quality of the product?

Pectin are increasingly identified by their degree of methylation (DM). Slow-set refers to a pectin within the 60 to 65 DM range, while rapid-set refers to pectin within the 68 to 75 DM range. The rapid- set pectin cause the jam yield will be lower than the slow-set pectin. Rapid-set pectin will be causing the mixture to turn into jam faster compared to slow-Rapid-set pectin. In term of the quality of product the rapid-set pectin will give better quality compared to slow-set, but other variable have to be taken into consideration such as the pH, temperature and the sugar concentration of the jam.

4. How did the consistency of jam change when the ration of pectin to sugar was altered? Explain what caused the behavior observed?

REFERENCES

1. Emmanuel Ohene Afoakwa, Dorinda Nartey, Joseph Ashong, and George Annor. "Effect of Sugar, Pectin and Acid Balance on the Quality Characteristics of Pineapple (Ananas Comosus) Jam. " Proceeding of the 13th World Food Congress. . Nantes, France, pp 1405-1406, September 17-21, 2006.. Sep. 2006. Available at: http://works.bepress.com/georgeamponsahannor/7

2. Smith, D. (2006) Food Jellies: Food Processing for Entrepreneur Series. Retrieved from : http://www.ianrpubs.unl.edu/pages/publicationD.jsp?publicationId=418

3. Egan H, Kirk RS, Sawyer R (1985). Person’s chemical analysis of foods. Churchill Livingston, Edinburgh London, pp. 9-10

4. Biswal RN, Bozorgmehr K (1991). Equilibrium data for osmotic concentration of potato in NaCl-water solution. J. Food Process. Eng., 14: 237-245.

5. Anonymous. (2012, August 10). What is Pectin? Retrieved November 10, 2014, from Baking Bites: http://bakingbites.com/2012/08/what-is-pectin/

6. Ingham, B. H. (2008). Making Jams, Jellies and Food Preserves. Retrieved 11 7, 2014, from Winconsin Safe Food Preservation Series:

http://learningstore.uwex.edu/assets/pdfs/B2909.pdf

7. Singh, R. P. (2014). Fruit preserves, jams, and jellies. Retrieved November 7, 2014, from Encyclopedia Britannica: