FINAL PROJECT

DESIGNING A CHLOROFORM PLANT

USING ACETONE AND CHLORINE

WITH CAPACITY 19,000 TONNES PER ANNUM

By :

MUHAMMAD FAHMI HAKIM

D 500 112 007

Supervisor :

1. Muhammad Mujiburrohman, S.,T. M.,Eng. Phd

2. Emi Erawati, S.,T. M.,Eng

CHEMICAL ENGINEERING DEPARMENT ENGINEERING FACULTY

ABSTRACT

The growth of the world population continues to rise and leads to increases in the need for particular goods. This affects development and establishment of new industries in the world, including in Indonesia.Chloroform is one of industries have been good prospect. For need chloroform, indonesia still importing from the other countries, so manufacturing chloroform in Indonesia is good solusion to minimmize need of importing from other countries.

Chloroform used as an anesthetic and a non-polar solvent in laboratories or by industries. From many factors as availbillity raw materials, transportation, need of chloroform in indonesia and overseas, can determine capacity otimmum to produce chlorofprm is 40,000 tonnes/annum. With reacted between chlorine and aceton in ratio 27,522 kg of acetone and 2,752 kg of chlorine in batch reactor ( T=50oC and P=1 atm) during 2 hours, will be produce chloroform and byproducts like as calcium acetate Ca(CH3COO)2, calcium hydroxide (Ca(OH)2),

calcium chloride (CaCl2).

Plant will be build at 2017 in the Cilegon,banten with area is 48.732 m2 . From the calculate, get the value of BEP is 40.9 % (at range 40% - 60%) and for POT is 0.5 years (maksimmum 2 years). So if this plant will be build so many advantages and very profitably.

CHAPTER I OVERVIEW 1.1BACKGROUND

The growth of the world population continues to rise and leads to increases in the need for particular goods. This affects development and establishment of new industries in the world, including in Indonesia. Indonesia, which so far largely relies on imports to meet the need of the population, is actually able to satisfy it without imports from other countries, i.e. by establishing the manufacturers in Indonesia.

Chloroform is one of the chemicals whose demand is continuously increasing in Indonesia and therefore establishment of chloroform manufacturers will have a pretty good prospect so as to meet the need of chloroform both at home and overseas. The establishment of chloroform manufacturers in Indonesia will reduce imports and diversify products with high economic values which add to state revenues and provide employment.

1.2 PURPOSE

Manufacture of chloroform plant have ad purpose, as :

1.1 To meet the need of chloroform both at home and overseas

CHAPTER II LITERATURE REVIEW

2.1 The Designed Production Capacity

The maximum amount of production done within a particular unit of time is called production capacity. There is many factors that inffluences to determine production capacity are :

a Availability of Raw Materials

Acetone & chlorine is the main raw materials of chloroform manufacture. acetone as the main raw material which is obtained from PT. Smartlab Indonesia costs IDR 145,000 while production of chlorine through the interaction between chlorine gas and calcium hydroxide which is obtained from PT Asahimas Chemical costs IDR 15,000. All of raw materials near with plant design (Cilegon,Banten).

b Minimmum Design Capacity

In indonesia, there is no chloroform plant.This is design capacity of chloroform plant in overseas :

Chloroform Plant Capacity (ton/years) 1.Dow Chemical Company, Freeport, Texas

2.Dow Chemical Company, Plaquemine, Louisiana 3.Hanlin Group Inc., Moundsville, West Virginia 4.Vulcan Materials Company, Geismar, Louisiana 5.Vulcan Materials Company, Wichita, Kansas

60.750 90.000 18.000 40.500 72.000

From this factors, can be detrmine the capacity optimmum to get high profit is 40,000 tonnes/annum and for location manufacture this plant will be build in the Cilegon,Banten. With the assumptions that it will:

1. Be able to export chloroform as the world demand for chloroform keeps on increasing

2.2 Types of The Process

There is many types to prododuce chloroform, like : a Methane Chlorination

In methane chlorination reactions can produce yield ranges from 90 to 95%, but use of fixed bed reactors requires that the cantilever construction made is strong enough to support the catalyst.

b Photochemical Chlorination

Yield will be produce are 90% and this reactions can reduce impurities in the resulting chloromethane, but The capacity per reactor is low so very slow reactions.

c Reaction between Acetone and Chlorine

2 CH3COCH3(l)+ 6 CaOCl2.H2O(s) 2 CHCl3(l) + Ca(CH3COO)2(s) +

2 Ca(OH)2 (s) +3 CaCl2(s)+ 6 H2O(l)

This reaction will be produce crude chloroform in the batch reactors and will be purification with destillation process. Yield from this reaction is 86 - 91 %. But the process include conventional process.

CHAPTER III

RESEARCH METHODOLOGY

3.1 Thermodynamics Review

Review of thermodynamics aims at finding out the properties of a reaction, including exothermic or endothermic as well as the direction of its reaction including reversible or irreversible. The determination of exothermic or endothermic reaction is considered from the calculation of standard reaction heat (Hr).

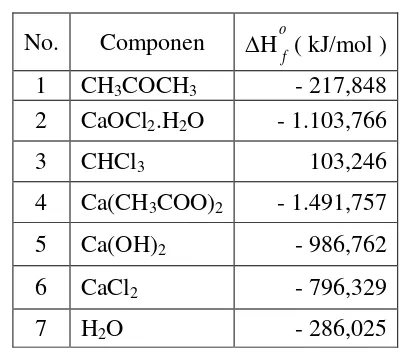

Tabel 3.1 data of ∆Ho

f every component at 298K

No. Componen Hof( kJ/mol )

Because the value of Hr is negative, the reaction of chloroform forming is

exothermic. To find out the direction of a reaction in thermodynamics aspect, it needs the principles of chemistry equilibrium. Use this formula :

3.3 Main Equipment Process a Reactor Batch

Code : R-110

Function : Reaction between chlorine and acetone, will produce chloroform for 2 hours. Type : Batch reactors are equipped stirrer and

heating coil Volume : 70.979 m3 Total : 4 buah (parallel)

Dimension : Height = 8.312 m Diameter = 5.791 m Thick head = 0.00635 m Thick shell = 0.00793 m Agitator : Turbin

Diameter : 1.524 m Height : 0.305 m Width agitator : 0.381 m Width baffle : 0.457 m rpm : 45 rpm motor power : 22 HP Material Construction : Stainless stell SA 167 type 304

b Mixer 01

Code : M-110

Function : Mix between chlorine and water

Type : Vertical cylinder with head and bottom shaped torispherical

Amount : one

Agitator : Type marine propeller with 3 blades and 4 baffle Diameter : 1.370 m

Rpm : 53.705 rpm Tenaga motor : 6 HP

Materials : Carbon steel grade CSA-285

c Coloumn Destillation

Code :D-110

Function :Make a pure chloroform. Type : plate coloumn with sieve tray Temperature : Feed = 62.2oC

Top = 60.4oC Bottom= 94.0oC Shell Diameter :Top = 0.941 m

Bottom= 0.941 m Thick :Top = 0,0048 m Bottom= 0,0048 m

Material :Stainless stell SA 167 type 304 Height Shell : 20.56 m

Column Height : 17.515 m Top section : 12.419 m Bottom section : 5.096 m Support : 3,048 m

Head Type : Torispherical dishedhead Thick head : Top =0,0048 m

Bottom = 0,0048 m Height head : Top = 0,2068 m Bottom = 0,8683 m Plate Type : Sieve tray

Plate spacing : 0,60 m

d Decanter

Code : H-110

Function : Separating the main product of byproducts use density.

Total : 12 Diameter tank : 2.190 m Length tank (L) : 6.571 m

Material Construction : Stainless stell SA 167 type 30

3.4 Operational Value

Chloroform production process by making a reaction between acetone and chlorine in principle consists of some stages, i.e :

raw materials preparation stage

reaction stage

product purification stage

CHAPTER IV RESULT OF RESEARCH

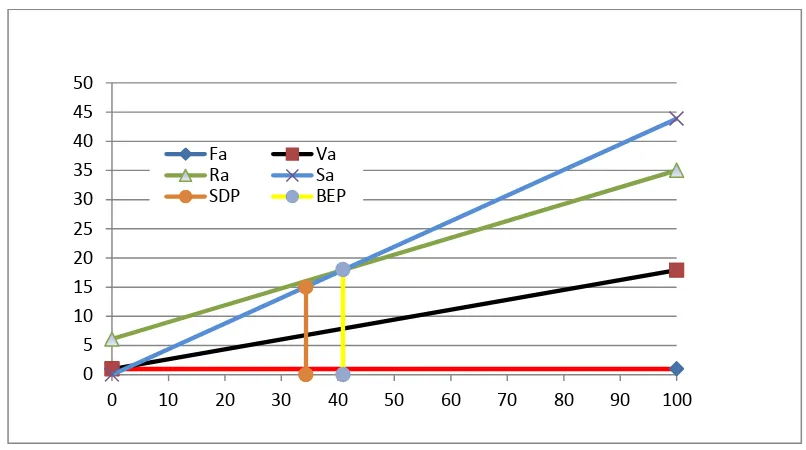

BEP in the manufacture of chlororfom with capacity 40,000 tonnes/annum is 40.90 % with POT befor tax is 0.36 years and after tax is 0.5 years. ROI before tax can get value is 270.72 % and after tax is 189.509%. This number can shown chloroform plant feseable to building in Cilegon,Indonesia. If the BEP value more decrease and value of ROI will be increase, so profit will be get the plant also increase.

Discount cash flow minimmum is 25% from the bank, and chloroform plant can get 55.51%, this is also can shown that chloroform plant feseable to build in indonesia.

Figure 6.2 Graph of Feasibility Analysis

0 5 10 15 20 25 30 35 40 45 50

0 10 20 30 40 50 60 70 80 90 100

Fa Va

Ra Sa

CHAPTER V CONCLUSION A. Conclusion

We can get the conclusion from Plant Design of Chloroform from acetone

and chlorine in capacity 40,000 tonnes/years :

1. Precent Return On Invesment (ROI) before tax is 270.727 %

2. Precent Return On Invesment (ROI) after tax is 189.509 %

3. Pay Out Time (POT) before tax is 0.36 years

4. Pay Out Time (POT) after tax is 0.5 years

5. Break-even Point (BEP) is 40.90 %

6. Shoutdown Point (SDP) is 34.35 %

7. Discounted Cash Flow (DCF) is 55.51%.

BIBLIOGRAPHY

Amonette JE, PM Jeffers, O Qafoku, CK, Wietsma, and Truex. 2009. Carbon Tetrachloride and Chloroform Attenuation Parameter Studies:

Heterogeneous Hydrolytic Reactions. PNNL-18735, Pacific Northwest National Laboratory, Richland, Washington.

Aries, R.S., and Newton, R.D. 1955. Chemical Engineering Cost Estimation , Mc Graw-Hill Book Co. Inc, New York.

Badan Pusat Statistik. 2014. Statistik Perdagangan Luar Negeri Indonesia.Jakarta.

Donald, E.G. 1989. Chemical Engineering Economics. Van Nostrond. New York.

Hani Handoko, T. 1990. Manajemen Personalia dan Sumber Daya Manusia. Penerbit Liberty, Jogjakarta.

Ketta, Mc. J.J. and Cunningham, W.A. 1992. Encyclopedia of Chemical Processing and Design. Vol. 40, Marcel Decker, Inc., New York

Keyes, F., and Clark, R.S., 1959, Industrial Chemistry : 4 th edition. John Wiley and Sons, Inc, New York.

Kirk, R.E., and Othmer, V.R. 1998. Encyclopedia of Chemical Technology : 4th ed. John Wiley & Sons Inc., New York

Levenspiel, O.. 1972. Chemical Reaction Engineering : 2nd ed. John Wiley & Sons, Inc., New York.

Perry, R.H. and Green, D.W. 1999. Perry’s Chemical Engineer’s Handbook, 7th ed. McGraw-Hill Book Company, New York

Chemical Engineers, 3rd edition, Mc Graw-Hill Book Company, Tokyo.

Pudjaatmaka, A.H., Setiono, L. 1984. Buku Teks Analisis Anorganik Makro dan Semimikro. PT Kalman Media Pustaka, Jakarta.

Severn, W.H., Degler, H.E., and Miles, J.C. 1954. Steam, Air and Gas Power : 5th ed. John Wiley and Sons inc., New York.

Smith, J.M. and Van Ness, H.C. 1996. Introduction to Chemical Engineering Thermodynamics, Prentice Hall, Englewood Cliffs., New Jersey.