Recent Decisions in

Technologies for

Sustainable Development

Recent Decisions in

Technologies for Sustainable

Development

Selected, peer reviewed papers from the

3

rdInternational Conference on

Sustainable Technology Development

(ICSTD 2014),

October 30-31, 2014, Bali, Indonesia

Edited by

A. Ghurri, N.P.G. Suardana, N. N. Pujianiki,

I. N. Arya Thanaya, A.A. Diah Parami Dewi,

I. N. Budiarsa, I. W. Widhiada,

Copyright2015 Trans Tech Publications Ltd, Switzerland

All rights reserved. No part of the contents of this publication may be reproduced or transmitted in any form or by any means without the written permission of the

publisher.

Trans Tech Publications Ltd Churerstrasse 20

CH-8808 Pfaffikon Switzerland

http://www.ttp.net

Volume 776 of

Applied Mechanics and Materials ISSN print 1660-9336

ISSN cd 1660-9336 ISSN web 1662-7482

Full text available online athttp://www.scientific.net

Distributedworldwide by and in the Americas by

Trans Tech Publications Ltd Trans Tech Publications Inc.

Churerstrasse 20 PO Box 699, May Street

CH-8808 Pfaffikon Enfield, NH 03748

Switzerland USA

Phone: +1 (603) 632-7377

Fax: +41 (44) 922 10 33 Fax: +1 (603) 632-5611

Preface

This volume was selected from papers presented at the 3rd International Conference on

Sustainable Technology Development (ICSTD Bali 2014), which have been held in Udayana

University Bali during October 30-31, 2014. The conference was organized by Faculty of Engineering,

University of Udayana Bali Indonesia. This conference covered wide range of engineering issues

toward the achievement of sustainablility.

In order to meet high standard of Applied Mechanics and Materials, the organization committee

has made their efforts to do the following things. Firstly, all submitted papers have been reviewed by 2

anonymous expert reviewers, poor quality papers have been rejected after reviewing. Secondly,

periodically review meetings have been held around the reviewers about three times for exchanging

reviewing suggestions. Finally, the conference organization had several preliminary sessions before the

conference. Through efforts of the scientific committee and Editors team, the volume will be the best

collected papers.

We would like to thank the Faculty of Engineering, University of Udayana, the member of

organizing and scientific committees, and also to TTP publisher.

Editors

Ainul Ghurri

N.P.G. Suardana

Ni Nyoman Pujianiki

I Nyoman Arya Thanaya

A.A. Diah Parami Dewi

I Nyoman Budiarsa

I Wayan Widhiada

I Putu Agung Bayupati

Table of Contents

Preface

Chapter 1: Technologies of Sustainable Development in Civil

Engineering, Transportation and Urban Planning

Sustainable Development of Concrete Using GGBS: Effect of Curing Temperatures on the Strength Development of Concrete

G. Turu'allo 3

Properties of Sand Sheet Asphalt Mixture Incorporating Waste Plastic

I.N.A. Thanaya, I.G.R. Purbanto and I.G. Wikarga 9

Asphalt Pavement Temperature Profile for Tropical Climate in Indonesia

I.M.A. Ariawan, B.S. Subagio and B.H. Setiadji 17

The Development of Slurry Seal Design with Ordinary Portland Cement Replacement by Low Calcium Fly Ash

A. Setyawan, D. Sarwono and M.S. Adnan 24

The Structural Properties Assessment of Thin Hot Mixture Asphalt for Pavement Preservation

A. Setyawan, A.H. Mustafa Elshawesh and S. As'ad 30

Mechanical Strength of Hydraulic Binder Made by Blending Type I Portland Cement and Pozzolan

I.M.A.K. Salain 36

Laboratory Tests on Failure of Retaining Walls Caused by Sinusoidal Load

A.M. Hidayati, R.W. Sri Prabandiyani and I.W. Redana 41

Deformation Behavior of Concrete due to the Influence of the Steel Ring Width Variations as the External Confinement

E. Safitri, I. Imran, Nuroji and S. Asa'ad 47

Evaluation of High Grade Recycled Coarse Aggregate Concrete Quality Using Non-Destructive Testing Technique

N.N. Kencanawati, J. Fajrin, B. Anshari, Akmaluddin and M. Shigeishi 53

Experimental and Theoretical Investigation of Bolted Bamboo Joints without Void Filled Material

G.M. Oka, A. Triwiyono, A. Awaludin and S. Siswosukarto 59

The Significant Importance to Measure Road Safety

S.A. Caroline 66

Accessibility to Location of Activities in Denpasar City, Bali-Indonesia

P.A. Suthanaya 74

Travel Time Estimation Based on Spot Speed with Instantaneous and Time Slice Model

A.M.H. Mahmudah, A. Budiarto and S.J. Legowo 80

Port Location Selection Model: Case Study of Tourism Sector in Bali

R.M.N. Budiartha, T. Achmadi and D. Manfaat 87

Determining Passenger Car Equivalent for Motorcycle at Mid-Block of Sesetan Road

I.G.R. Purbanto 95

Readiness Criteria: Indonesias New Initiative to Ensure Sustainable Development Program

A. Merthayasa 101

Conceptual Framework of Bidding Strategy in Order to Improve Construction Project Performance

I.N.Y. Astana, H.A. Rusdi and M.A. Wibowo 108

The Conceptual Framework of Design Change Effects in Some Project Delivery Systems

A.A.G.A. Yana, H.A. Rusdi and M.A. Wibowo 114

An Identification of Construction Project Overheads for Sustainable Cost Management and Controlling Practices (CMCPs)

N.M. Jaya and A. Frederika 121

Risk Analyses for Riau Regional Water Supply Projects (SPAM), Indonesia

b Recent Decisions in Technologies for Sustainable Development

S. Purnawan, I.W. Sukania and L. Widodo

Chapter 2: Materials and Technologies for a Sustainable Development

169

The Property and Applicability to Auto Industry of Natural Fiber Reinforced Composites

R.H. Hu, Z.G. Ma, S. Zheng, C.L. Zheng and A.J. Jiang 179

Fracture Parameters of Short Carbon Fiber Reinforced Polycarbonate Composite Fabricated by Injection Molding Process

M.G. Hwang, G.H. Kim, H.J. Park, Y.G. Lee, C.M. Yang, J.K. Lim and H.Y. Kang 186

Effect of Polar Extract of Cocoa Peels Inhibitor on Mechanical Properties and Microstructure of Mild Steel Exposed in Hydrocloric Acid

Gunawarman, Y. Yetri, Emriadi, N. Jamarun, Ken-Cho, M. Nakai and M. Niinomi 193

Hardness Distribution and Effective Case Depth of Low Carbon Steel after Pack Carburizing Process under Different Carburizer

D.N.K.P. Negara, I.D.M.K. Muku, I.K.G. Sugita, I.M. Astika, I.W. Mustika and D.G.R. Prasetya 201

The Effect of Solidification on Acoustical of Tin Bronze 20Sn Alloy

I.K.G. Sugita and I.G.N. Priambadi 208

Morphological Analyses and Crystalline Structures of Anodic TiO2Thin Film on Ti6Al4V

Alloy Using Phosphate and Calcium Containing Electrolyte under Different Voltage and Calcium Molarity

I.N.G. Antara, K.I.M. Gatot, I.M. Budiana and D.K. Choi 215

Determination of Optimal Clinker Factor in Cement Production by Chemical Grinding Aids Addition

T. Eryanto and E. Amrina 223

Wear of Carbon Steel (0.65%C) in Rolling-Sliding Contact with Creep Ratio

M. Widiyarta, T.G.T. Nindhia and H. Mudiastrawan 229

Hardness Prediction Based on P-h Curves and Inverse Material Parameters Estimation

I.N. Budiarsa 233

The Influence of Austenisation Temperature and Holding Time on Mechanical Properties, Scale Thickness, and Microstructure in Alloy Steel

A. Aziz, M. Hidayat and I. Hardiyanti 239

Hardness, Density and Porosity of Al/(SiCw+Al2O3p) Composite by Powder Metallurgy

Process without and with Sintering

K. Suarsana and R. Soenoko 246

Development of Fiberglass Woven Roving Composite as an Alternative Material for the Hull of Fishing Boat

Winarto, W. Eddy, R. Liza and H. Syamsul 253

Tensile Strength of Banana Fiber Reinforced Epoxy Composites Materials

A.P. Irawan and I.W. Sukania 260

Green Composites Based on Recycled Plastic Reinforced Local Sisal Fibers

N.P.G. Suardana, N.M. Suaniti and I.P. Lokantara 264

Cement Bonded Sol-Gel TiO2Powder Photocatalysis for Phenol Removal

N. Hafizah and I. Sopyan 271

Modeling Discharge of the Bangga Watershed under Climate Change

I.W. Sutapa, M. Bisri, Rispiningtati and L. Montarcih 133

Water Resources Management of Subak Irrigation System in Bali

I.N. Norken, I.K. Suputra and I.G.N.K. Arsana 139

Study of the Evolution of Sanur Beach Nourishment Project for Beach Enhancement

I.G.B.S. Dharma and S.S. Efendi 145

Numerical Simulation of Breaking Waves in a Wave Group by SPH

N.N. Pujianiki 151

The Study on Bore Piles Foundation of the Reinforced Concrete Arch Bridge Beams of Tukad Pekerisan and Tukad Penet

I.N. Sutarja and I.W. Wayan Redana 157

The Importance of the Physical Boundary Line onBali Coastal Tourist Resorts

A. Rajendra, N. Temple and R. Nicholls 163

I.N.S. Winaya, R.S. Hartati, I.P. Lokantara, I.G. Subawa and I.M.A. Putrawan

Chapter 3: Advanced Decisions in Mechanical Engineering

300

Magnetic Camera and its Applications in Aging Aircraft, Express Train and Pipelines for Green Technology

J.Y. Lee and J.M. Kim 309

Buckling Analysis on Pechiko Field of Fixed Offshore Platform in Makassar Strait

M.Z.M. Alie, Y.R. Palentek and D.G. Sesa 313

Simulation of a Differential-Drive Wheeled Mobile Lego Robot Mindstorms NXT

I.W. Widhiada, C.G.I. Partha and Y.A.P. Wayan Reza 319

Design and Simulation of Five Fingers Gripper for Dexterous Pick-Up Various of Components

I.W. Widhiada, E. Pitowarno, C.G.I. Partha and Y.A.P. Wayan Reza 325

Tar Balls Collector for Mechanical Recovery in Combating Oil Spill on the Marine Environment

C.P. Mahandari, M. Yamin and D.S.A. Asandi 331

Three Wheel Bike as Physical Therapy Equipment for Post-Stroke Patient

I.M.L. Batan, Rodika and M. Riva'i 337

Geometric Progression Application in Design Transmission Gear Ratio

A.A.I.A.S. Komaladewi, I.G.A.K. Suriadi and I.K.A. Atmika 343

Role of Risk Management in Effective Maintenance

H.A. Yuniarto and P.F. Paristiawati 349

Redesign Combustion Air Shelter of the Furnace to Improve the Performance in Melting Bronze for Manufacturing Gamelan

I.G.N. Priambadi, I.K.G. Sugita, A.A.I.A.S. Komaladewi, K. Astawa and I.W.B. Adnyana 355

Model of Carbon Dioxide (CO2) Emission from Motorcycle to the Manufactures, Engine

Displacement, Service Life and Travel Speed

A.M. Mulyadi and S. Gunarta 361

Experimental Study of Heat Transfer Characteristics of Condensed Flow on the Vertical Wave Plates

W.H. Piarah and Z. Djafar 371

Forces Analysis on a Spherical Shaped Delivery Valve of Hydram Pump

M. Suarda 377

The Influence of Distance Variation between Rings with Sloping Position on the Cylinder Surface to Drag Coefficient

S.P.G.G. Tista, A. Ghurri and H. Wijaksana 384

Auto PID Tuning of Speed Control of DC Motor Using Particle Swarm Optimization Based on FPGA

H. Tayara, D.J. Lee and K.T. Chong 390

Mobile Robot Motion Planning to Avoid Obstacle Using Modified Ant Colony Optimization

N. Habib, A. Soeprijanto, D. Purwanto and M.H. Purnomo 396

Mobile Robot Motion Control Using Laguerre-Based Model Predictive Control

M. Chipofya, D.J. Lee and K.T. Chong 403

Chapter 4: Application of Alternative Energy and Information

Technologies

Applied Mechanics and Materials Vol. 776 c

Review on Zn-Based Alloys as Potential Biodegradable Medical Devices Materials

M.S. Dambatta, D. Kurniawan, S. Izman, B. Yahaya and H. Hermawan 277

Bone Implant Materials from Eggshell Waste

I. Sopyan 282

Boiling Phenomenon of Tabulate Biomaterial Wick Heat Pipe

W.N. Septiadi and N. Putra 289

Fluidization Characteristic of Sewage Sludge Particles

I.N.S. Winaya, R.S. Hartati and I.N.G. Sujana 294

d Recent Decisions in Technologies for Sustainable Development

Experimental Investigation of Micro-Hydro Waterwheel Models to Determine Optimal Efficiency

L. Jasa, A. Priyadi and M.H. Purnomo 413

Understanding Peak Average Power Ratio in VFFT-OFDM Systems

N.M.A.E.D. Wirastuti 419

Fusing Multiple Inexpensive GPS Heading Data via Fuzzified Ad-Hoc Weighing

F.P. Vista IV, D.J. Lee and K.T. Chong 425

Tree Data Structure Implementation in Android Base System of E-Ulambebantenan

A.A.K.O. Sudana and A.A.G. Brampramana Putra 431

Design and Implementation of Web-Based Geographic Information Systems on Mapping Hindu s Temple

N. Piarsa and K. Adi Purnawan 437

Improving Biogas Quality through Circulated Water Scrubbing Method

H.S. Tira, Y.A. Padang, Mirmanto and Hendriono 443

Study on Solar Generating Apparatus for Solving Problem of Shadow

J.W. Chang, S.S. Kim, J.K. Lim and J.J. Lee 449

An Experimental Study on the Thickness of Stainless Steel as an Electrode in Alkaline Fuel Cell

M. Sucipta, I.M. Suardamana, I.K.G. Sugita, M. Suarda and K. Astawa 455

Transient Thermal Efficiency of Natural Hybrid Dryer System on Chimney Height Variation of Exhaust Moist Air

CHAPTER 1:

CHAPTER 2:

Applied Mechanics and Materials Vol 776 (2015) pp 208-214 Submitted: 2015-02-19 © (2015) Trans Tech Publications, Switzerland Accepted: 2015-04-10 doi:10.4028/www.scientific.net/AMM.776.208

The Effect of Solidification on Acoustical of Tin Bronze 20Sn Alloy

I Ketut Gede Sugita

1,a, I G. N.Priambadi

2,b1.2

Department of Mechanical Engineering Faculty of Engineering Udayana University a

[email protected] ,[email protected]

Keywords:tin bronze, dendrite, acoustical, SDAS, solidfication rate

Abstract. This study was designed to determine the effect of the solidification rate on the acoustic properties of the bronze alloy of 20% wt. Sn. Copper and commercially pure tin is melted in a furnace to a temperature 1000, 1100 and 1200⁰C.The melted metal is poured into molds variation temperature of 200, 300 and 400⁰C. Materials castings were cut and machined for specimen damping capacity test.

The results showed that the reduction in mold temperature leads to an increase solidification rate, which causes the shortness of the solidification time. The variation of the solidification rate affects on the morphology of the microstructure and acoustical properties of the material. By increasing the solidification rate influence on the secondary dendrite arm spacing (SDAS) decreases.It causes the material hardness increases and the damping capacity of material decreases. There is a significant correlation between the material hardness and the damping capacity of materials.

Introduction

Tin bronze with a composition of 87.5-80% Cu-20-22.5% Sn are generally used for musical traditional materials such as bell, gamelan. It is because these alloys have good mechanical properties, are stable in room temperature conditions, and have good acoustical characteristics that can produce long sound (low damping vibration ) [1,2]. Commonly, the products are made of bronze musical instruments such as gongs, bells, made by casting process.

One of the important parameters in the casting process is the process of solidification. It is a process of change in the liquid phase to the solid phase. The solidification rate is influenced by the temperature gradient of the liquid metal with the mold temperature. Preheating the metal mold aims to avoid sudden temperature changes (temperature shock). Initial temperature of the mold that has been studied is the temperature of 450-500 ⁰C [3], 300-400 ⁰C temperature [4]. Mold preheating (300-400⁰C) on the gravity casting and high pressure can increase the fluidity. Campbell [4], states that when the use of mold temperature approaching the the molten metal temperature, the fluidity of alloy will be unlimited. The increased temperature lowers the nucleation rate and the cooling rate. It increases the grain size and DAS [5]. Solididification rate also affects the form of the solidification of dendrite tip radius. The higher the cooling rate, the more refined microstructure is formed, and the pointy end of the dendrite is formed [6].

Related to this, there were several studies which have been conducted, such as: solidification binary alloy system [7], solidification bronze alloy Cu-8% Sn [8], Cu-Sn peritectic alloy [9] and the evolution of structure in the Cu-Sn alloy [10]. The solidification rate affects the micro structures such as grain size and dendrite arm spacing (DAS). Changes on microstructure form directly affect on the mechanical and acoustical properties of material castings.

Applied Mechanics and Materials Vol. 776 209

Experimental Procedure

Alloy used in this study is tin bronze 20 Sn. The chemical composition of the alloy is shown in Table 1. The pure commercial alloys are melted in a crucible furnace until the temperature of 1000, 1100 and 1200⁰C variations. Metal that has been melted is poured in the mold with a size of 250x55x15 mm. Mold is preheated at temperatures of 200, 300 and 400⁰C. Billet castings were cut and machined. This is done for testing hardness and damping capacity specimens. Set-up of damping capacity measurement refers to ASTME1876-01 standards [11], it shown in Figure 1. The calculations of damping capacity use the method of logarithmic decrement.The damping capacity was determined under simply supported free vibration bending model. The logarithmic decrement

, derived from the amplitude decay of specimen under free vibration, is given by [8].

1 A

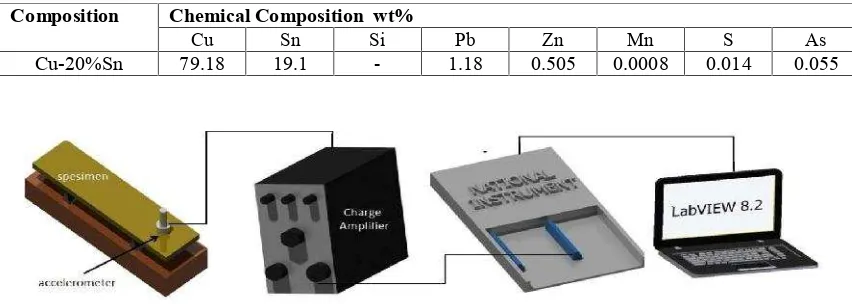

Table 1 Chemical composition of alloy

Composition Chemical Composition wt%

Cu Sn Si Pb Zn Mn S As

Cu-20%Sn 79.18 19.1 - 1.18 0.505 0.0008 0.014 0.055

Figure 1. Set-up of damping capacity test

Results

Solidification Characteristics

210 Recent Decisions in Technologies for Sustainable Development

Figure 2. The effect of molds temperature on solidification of bronze 20Sn

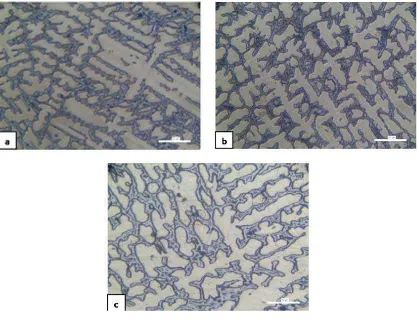

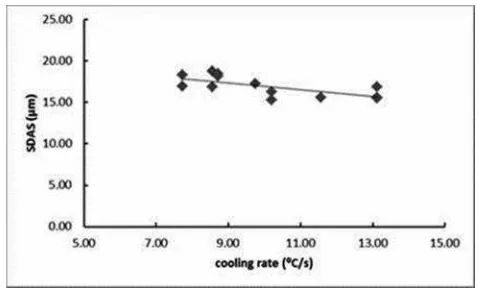

The resullt of metallographic studies show that variation solidification rate have affected microstructure form forming. Figure 3 a-c shows the microstructure of bronze alloy of 20% wt. Sn due to solidification rate. The relatively tip dendrite shape is occurred at the solidification rate of 13.112⁰C/s (Figure 4a), and then it is getting spherical and bigger in accordance with the decrease of solidification rate (Figure 3b-c). There is no change phase that occurs due to the differences in the cooling rate. The relationship of the secondary dendrite arm spacing size (SDAS) and the solidification rate is shown in Figure 4. The Size SDAS is getting decreases in accordance with the increase of solidification rate.

Figure 3. Microstructure of alloy on ssolidification rate variations a) 13.112⁰C/s, b) 10.206⁰C/s and c) 7.722⁰C/s.

Applied Mechanics and Materials Vol. 776 211

Figure 4. SDAS as a function of cooling rate

Relationship of cooling rate on VHN.

Figure 3 shows that the hardness of material (VHN) characteristic increases as with solidification rate increases, eventhough has the opposite relationship with SDAS. The faster the cooling rate in the solidfication process affects on finer the grain structure and the structure is more dense. Material hardness is correlated with the density of a material.

Figure 5. VHN as a function of cooling rate

Relationship of cooling rate on damping capacity

Damping capacity is a measure of a material's ability to release energy during their vibration. Low damping capacity means the ability of the alloy to release mechanical energy/low vibration is characterized by the length of vibration. The materials having lower damping capacity vibrates longer than those of having higher damping capacity. Figure 6 shows the relationship of cooling rate with the damping capacity of tin bronze. The damping capacity of materials decreased along with the increase of the cooling rate casting process.

212 Recent Decisions in Technologies for Sustainable Development

Relationship of VHN on damping capacity

Figure 7. Damping capacity as a function of VHN

Figure 7 shows the relationship of material hardness (VHN) with the damping capacity of tin bronze. The hardness of materials has a direct impact on the acoustic properties of the material, especially the damping capacity of the material. The harder the materials, the lower the damping capacity will be.

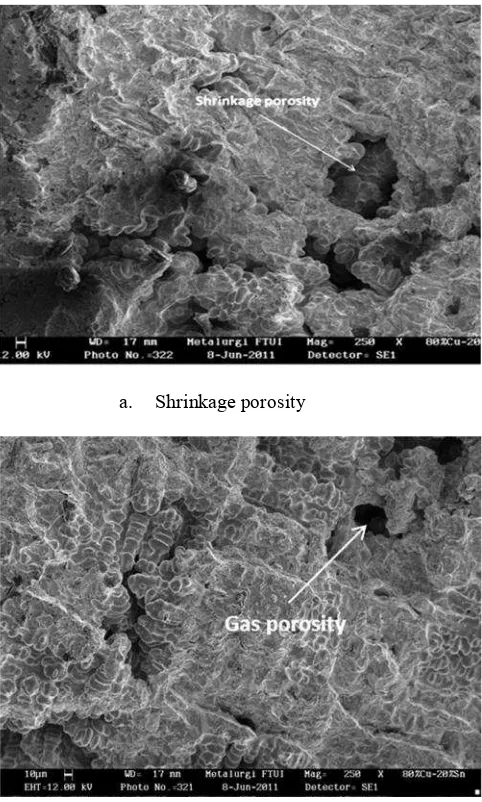

Casting defects

a. Shrinkage porosity

b. Gas porosity

Applied Mechanics and Materials Vol. 776 213

Casting process produces multiple defects in the form of casting defects such as gas porosity and shrinkage porosity. Porosity is caused by two sources: shrinkage during solidification and trapped gas. Alloys generally have higher densities in the solid state compared to the liquid state, forming dendrite defects in the solidification interface called the shrinkage porosity (Figure 8a). Feeding casting process resulting turbulent flow can trap gases in liquids to form gas porosity. The casting process on tin bronze alloy is also having defective castings such as gas porosity and shrinkage porosity, as shown in Figure 8 b.

Discussion

The difference molds temperature rate were affected by variation of gradient temperature between molten metal and mold temperature. The higher temperature difference between the liquid metal with the mold temperature, the more speed of the solidification rate. The solidification rate is influenced by the variations in the temperature gradient between the molten metal to the mold temperature. The difference in the solidification rate affects on the shape of the resulting microstructure. The size of SDAS tends to decrease in accordance with the increase of the solidification rate. It is caused by the less time available diffusion of nucliation [11,4]. During the solidification process the mold temperature increases due to heat transfer from the molten metal into the mold. Mold absorbs the heat released by the molten metal, then heat is released into the surrounding environment. Heat mold increasing temperature gradient will decrease the liquid metal with the interface, so that the solidification rate is inhibited. This causes the longer time needed for a complete solidification. The larger dendrite shape is occurred on the lower speed of solidification rate. Research on the solidification rate of the material of no bronze is also observed that the variation in the form of dendrite structure is influenced by variations in the speed of the solidification of the wall into the mold until the mold. [3,13]. Solidification rate also affects the form of dendrite tip radius. The higher the cooling rate, the more subtle microstructure formed, the smaller SDAS, and the more pointed dendrite tip radius will be (6,13,14 and 15]. The smaller SDAS are formed and the harder the properties of the material hardness. The high solidification rate produces hardness of materials better than that of low rate of solidification. Finer structures are formed at a high solidification rate. These will form many grain boundaries which can inhibit the movement of dislocations. Therefore, the alloy strength increases [16].

Damping capacity is the ability of the materials to release elastic energy when the alloy is getting impulse vibration. According to De Silvia [16] internal damping of material is influenced by microstructural defects such as grain boundaries and impurities. Porosity is caused by two sources, namely: shrinkage defect and gas trapped during solidification. Alloys generally have higher densities in the solid state compared to the liquid state so that the shrinkage porosity formed on solidification. Turbulent flow of molten metal during casting processes impact to trapping gases and form porosity defect. Shape defects also occur due to shrinkage between the dendrite tips will cause holes (voids) in the material. Void defects influence on the increase in the damping capacity of material [17]. The increase in material damping capacity is caused by the vibrations that propagate in the the material is absorbed by some porosity of material.

Conclusions

214 Recent Decisions in Technologies for Sustainable Development

References

[1] Lisovskii, V. A., Lisovskaya.O.B, Kochetkova,L.P., Favstov, Y.K., Sparingly Alloyed Bell Bronze with Elevated Parameters of Mechanical Properties, Journal Metal Science and Heat Treatment 49 (2007) 232-235.

[2] Hosford, F.W., Mechanical Behaviour of Materials, Cambridge University Press, 2005. [3] Kaplan, M. and Yieldiz, A.K., The Effects of Production Methods on Microstructures and

Mechanical Properties of an Aluminum Bronze, Materials Letters, (2003), 4402-4411.

[4] Campbell, J., The New Metallurgy of Cast Metals, Second Edition, Butterworth Heinemann. 2003.

[5] Stefanescu, D.M., Science and Engineering of Casting Solidification, Kluwer Academic/Plenum Publisher, New York, Boston, Dordrecht, London, Moscow, 2002.

[6] Stefanescu, D.M. and Ruxanda, R., Fundamentals of Solidification, Metallography and Microstructures, ASM Handbook 9, (2004), 71 92.

[7] Lee, S.L. and Tzong, R., Y., Latent Heat Method for Solidification Process of a Binary Alloy System, Journal of Heat and Mass Transfer, 38 (1995) 1237-1247.

[8] Martorano, M.,A. and Capocchi, J., D.,T., Heat Transfer Coefficient at the Metal-Mould Interface in the Unidirectional Solidification of Cu-8%Sn Alloys, Journal of Heat and Mass Transfer 43 (2000) 2541-2552.

[9] Kohler, F., Germond L, Wagniere J-D., Rappaz M., Peritectic Solidification of Cu Sn Alloys: Microstructural Competition at Low Speed, Acta Materialia 57 (2008) 56 68.

[10] Zhao, Y., Bian, X., Qin, J, Qin, X., Hou, X., Structural Evolution in the Solidification Process of Cu Sn Alloys Journal of Non-Crystalline Solids, 353 (2007), 4845 4848.

[11] ASTM, E 1876-01, Standard Test Method for Dynamic Young, Shear Modulus, and Poisson s Ratio by Impulse Excitation of vibration, ASTM International, 2002.

[12] Halvaee, A. and Talebi, A., Effect of Process Variables on Microstructure and Segregation in Centrifugal Casting of C92200 Alloy, Journal of Materials Processing Technology 118 (2001) 123 127.

[13] Hemanth, J., Effect of Cooling Rate on Dendrite Arm Spacing (DAS), Eutectic Cell Count (ECC) and Ultimate Tensile Strength (UTS) of Austempered Chilled Ductile iron, Materials and Design 21 (2000) 1-8.

[14] Shen, J., Liu, Y. C. and Hoxie, A., Rapid Directional Solidification in Sn-Cu Lead-Free solder Journal of University of Science and Technology Beijing Volume Z3. 2006.

[15] Zhang, L,Y, Jiang, Y,H, Ma, Z, Shan, S.F, Jia,Y.Z, Fan, C.Z, Wang, W.K, Effect of Cooling Cate on Solidified Microstructure and Mechanical Properties of Aluminium-A356 Alloy, Journal of Materials Processing Technology 207 (2008) 107 111.

[16] Askeland, D.R., The Science and Engineering of Materials, University of Misouri-Rolla, California, USA, 1984.