I Made Miasa

!" # $ % & &

I Ketut Gede Sugita

'

This research was carried out to investigate the acoustics feasibility of using silicon bronze (( # )*) alloy to replace tin bronze (( # +)* ) alloy for Balinese traditional musical instruments. This research is the next step of the previous research that has sucessfully showed better mechanical properties of ( #* alloy compared to ( #* alloy. The acoustical properties of interest in this study are: speed of sound ( ), sound radiation coefficient (,) and frequency resistance (& & frequency’s shift). The casted alloys were cut and machined for the test specimens. The acoustical properties of both alloys were measured and compared. The investigations were carried out according to ASTM Standard E 1876 01. For frequency shift investigation, the original fundamental frequency of each alloy is measured and then each alloy is subjected to impact load by hitting them as they are played in daily use. The total number of cycles (hits) experienced by each alloy is 72,000. Finally the resulting fundamental frequency is measured and compared to the previous (before hitting) conditions. The frequencies were measured after a certain interval numbers of hit until total of 72,000 hits. The results showed that ( #* alloy has speed of sound ( ) and sound radiation coefficient (,) that are almost the same as those of ( #* alloy. For frequency’s shift, both alloy showed that they do not experience any frequency change after 72,000 hits. This is a good sign showing the potential of silicon bronze alloy as an alternative material for Balinese musical instruments replacing tin bronze alloy currently used.

20th International Congress on Sound and Vibration (ICSV20), Bangkok, Thailand, 7 11 July 2013

The high tin bronze alloy with composition of 18 22 wt. % * has good acoustical properties which is capable of producing long lasting sound due to its low vibration damping 1,2. It is commonly used for music instrument materials such as bell, Javanese and Balinese gamelan. This is a double phase alloy containing brittle particles of ( -"* ! intermetallic (δ phase), which is harder

and more brittle than other alloys. However, the main disadvantages of high tin bronze properties are: it has a low crack resistance (it cracks easily), it is brittle and expensive. Moreover, tin bronze cannot resist low temperature because it has a low frost resistance. At temperature below minus (20

to 25)oC this alloy becomes brittle and cracks may appear resulted in poor sound quality3. Meanwhile silicon bronze is an alloy that has good cast ability and higher mechanical properties than tin bronzes. In addition, the silicon bronze has high elastic properties, possesses a higher cor rosion resistance than a tin bronze, does not lose its properties at low temperatures and it is cheaper than tin bronze4,5. Therefore, based on the abovementioned facts, this study was carried out to in vestigate the feasibility of silicon bronze alloy as a subtitute of tin bronze alloy used for music in strument materials.

!"# $#

%& "

#

#

% # %&' % " #''

This study was started with the preparation of raw materials that will be casted such as copper (( ), tin (* ) and silicon (*). The composition of copper and tin for tin bronze alloys and the com position of copper and silicon for silicon bronze alloys were designed in accordance with the results of the authors’ previous studies 6,7. The alloys under investigation were made of ( # )* and ( # +)* . The composition of the alloy studied in this research is listed in Table 1. The acoustics properties comparisons were made with respect to ( # +)* as the reference alloy because it is commonly used for making bells or gamelans. The commercial pure copper and commercial pure silicon were melted in crucible furnace at temperature of 1000oC. The resulting casted billets were cut and finished for acoustical test specimens. In this investigation three pieces of elements were prepared for each alloy, so that in total there are 6 specimens.

Composition of the alloys. Standard E 1876 018, and the lay out of the measurement is depicted in Fig.1.

20th International Congress on Sound and Vibration (ICSV20), Bangkok, Thailand, 7 11 July 2013

For frequency shift investigation, the original fundamental frequency of each alloy is meas ured and then each alloy is subjected to impact load by hitting them such as when they are played in daily use. The total number of cycles (hits) experienced by each alloy is 72,000. Finally the result ing fundamental frequency is measured and compared to the previous (before hitting) conditions. The frequencies were measured after a certain interval numbers of hit until total of 72,000 hits. Fig ure 2 shows the experimental set up for frequency resistance tests.

. Set–up for frequency resistance measurement.

From the measurements of fundamental frequency based on ASTM Standard E 1876 01, the Young’s modulus ( ) can be calculated from

(Pa) (1)

where:

= Young’s modulus [Pa] = mass of the bar [gr] 0= width of the bar [mm] 3= length of the bar [mm]

= thickness of the bar [mm]

= fundamental resonant frequency of the bar in flexure [Hz] 4" = correction factor, in this case it has a value of

!". (2)

As one of the acoustics properties of interest in this study, the speed of sound traveling through material ( ) is then calculated using the following formula

# $ % (m/s) (3) where% is the measured density of the specimen.

The sound radiation coefficient , describes how much the vibration of the body is damped due to sound radiation9. It can also be regarded as an index of the amplitude of vibration that a ma terial will sustain for a given excitation force (a dynamic property) combined with a measure of its stiffness for a given mass (a static property)10. Particularly, a large sound radiation coefficient is preferred if a loud sound is desired. The sound radiation coefficient can be calculated from9

20th International Congress on Sound and Vibration (ICSV20), Bangkok, Thailand, 7 11 July 2013

(

#' & ' %

'

''

'

( %$# %& % ') * * #+ # #'

Figure 3a and 3b show the fundamental frequencies of the specimens for both ( # +)* and ( # )* alloys respectively. As can be seen, for both alloys, the first three modes appeared. The fundamental one is used to calculate the Young’s Modulus ( ) using Eq. (1) and then the remaining

and , are calculated from Eq. (3) and Eq. (4).

.Fundamental resonant frequency of the bar in flexure

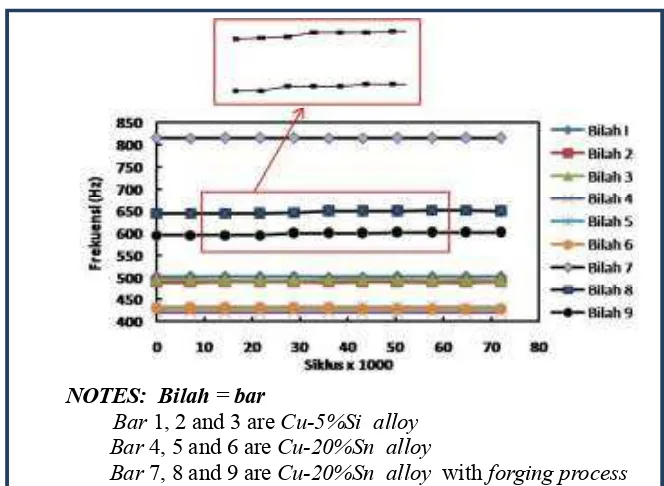

The frequency resistance which describes the resistance of the material with respect to the shift of frequency after being hit for certain numbers of cycles is depicted in Fig. 4 below. In addi tion to the “untreated” ( # +)* and ( # )* alloys, the results from ( # +)* alloy with prior forging treatment (bar #7 9) were also presented in Fig. 4.

' 1, 2 and 3 are ( # )* ' 4, 5 and 6 are ( # +)*

' 7, 8 and 9 are( # +)* with

. Frequency resistance test results

( ' %& " "# #'

20th International Congress on Sound and Vibration (ICSV20), Bangkok, Thailand, 7 11 July 2013

It can be seen from Fig. 4 that most of the frequencies of the bars (Bilah # 1 6) measured af ter a certain number of cycles remain unchanged (constant). No frequency shift indicates that the bar will not detune (lost its tune) easily so that a good sound quality can be maintained. An interest ing phenomenon was observed for ( #* alloys that experienced forging process after casting and cutting. These alloys easily change their frequencies, and in this study frequency shifts up to 6 Hz were observed. It seems that the forging process that is currently applied for these alloys tends to deteriorate their acoustics properties as indicated by the frequency shift. Furthermore, Table 2 showed that that ( #* alloy has a speed of sound ( ) and a sound radiation coefficient (,) that are almost the same as those of ( #* alloy.

,

& '

Based on the results of this study, it can be concluded that ( #* alloy with a proper composi tion can become a potential material to substitute the currently used ( #* alloy while maintaining its sound quality.

1

Scott, D.A., 1991, 2 8 , The

Getty Conservation Institute.

2

Hosford, F.W., 2005, ' , Cambridge University Press.

3

Favstov, Y. K., Zhravel, L.V. andKochetkova, L.P., Structure and Damping Capacity of

Br022 Bell Bronze, 9 * 8 4 , , pp. 449 451, (2003.)

4

Lisovskii, V. A., Lisovskaya. O. B, Kochetkova, L. P. andFavstov, Y. K., Sparingly Alloyed Bell Bronze with Elevated Parameters of Mechanical Properties, 9 *

8 4 , , pp. 232 235, (2007).

5

Smith, F.W., 1993, * , Second Edition, McGraw

Hill Inc.

6 I KetutGede Sugita, R. Soekrisno, I Made Miasa and Suyitno, Mechanical and damping prop

erties of silicon bronze alloys for music applications, 9 :

4 9 4# 9 ;* , No. 6, (2011).

7

I KetutGede Sugita, R. Soekrisno, I Made Miasa and Suyitno, The effect of annealing temper

ature on damping capacity of the bronze 20%Sn alloy 9 :