The Influence of Sintering Time and Temperature of SiCw+Alzolp Reinforrement on Aluminum Matrix Composite Characteristics.

Teks penuh

Gambar

Dokumen terkait

Charpy impact test result showed that there was slightly increasing value of toughness for one hour, two hour and three hour sample but then decrease for four hour

As the holding time range might not be able to accomplish the maximum crystallization for the annealing temperature range between 65°C and 85°C, further research

Symbol Control Factor H0 condition A Variation of Sn Rejected B Temperature Rejected C Holding Time Accepted Density Variation Parameter Sn The findings of the hypothesis

Penelitian ini bertujuan untuk identifikasi hidroksiapatit dari tulang ikan bandeng dan untuk mengetahui bagaimana pengaruh variasi suhu sintering terhadap karakteristik pada tulang

The effect of liquid phase concentration on the setting time and compressive strength of hydroxyapatite/bioglass composite cement ABSTRACT Composite scaffolds of hydroxyapatite HAp

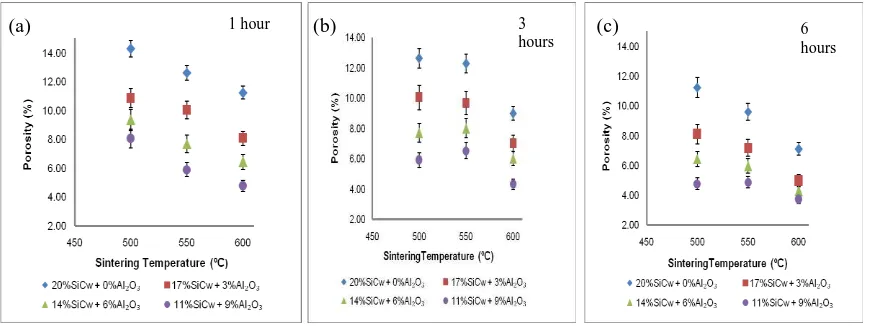

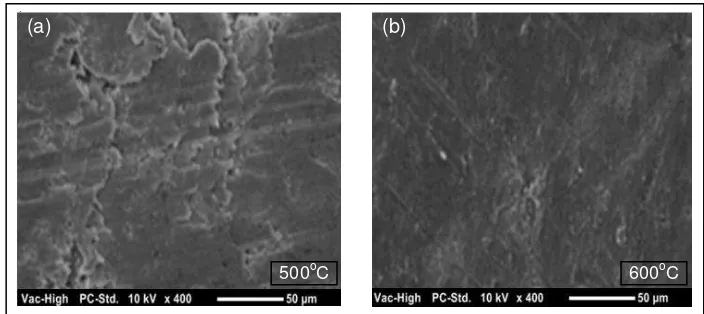

Furthermore, obtained results show that the increase in the sintering temperature induces the increase in the grain size.However, study of the dielectric properties, show an interesting

Conclusions Three stress relieving parameters such as heating temperature, holding time and stabilization temperature have an influential effect on the physical and mechanical