International Journal of Universal Pharmacy and Bio Sciences 3(5): September-October 2014

PROCESSING OF FRUITS WITH SPECIAL REFERENCE TO

S. APETALA

FRUIT JELLY PREPARATION

Prosenjit Pramanick1*, Sufia Zaman2, Abhijit Mitra2

1

Department of Oceanography, Techno India University, Salt Lake Campus, Kolkata 700 091, India

2

Department of Marine Science, University of Calcutta, 35, B. C. Road, Kolkata 700 019, India; also attached to Techno India University, Salt Lake Campus, Kolkata 700 091, India.

KEYWORDS:

The scientific method of preparing jam, jelly, fruit bar and other fruit

products has opened a livelihood option in the modern era. These

fruit products are not only nutritionally rich, but they are also

economically viable to initiate a small scale industry. Preservation

and processing of fruit products are also important to maintain the

quality of the end products. The present paper is an approach to

develop various fruit products along with their preservation and

processing technology with special reference to jelly prepared from

Sonneratia apetala fruit, commonly available in Indian Sundarbans.

This jelly is rich in vitamin C and the source material (S. apetala

pulp) is abundantly found during the monsoon period. Proper storage

and marketing linkage may help to sustain small scale mangrove

INTRODUCTION:

Fruits are generally high in fibre, water, sugars, mineral, enzymes1 and their regular consumption in

sufficient amount could help in reduction of risk of cancer, cardiovascular diseases, stroke, Alzheimer

diseases, cataracts etc. They are also important sources of vitamin C, which is necessary in human diet

for activating the antibodies and combat diseases in the body2. A large amount of the carbohydrates

present in the fruits as fibre, usually made up of cellulose, hemicellulose, and pectic substances, is not

digested and passes through the digestive system. A small quantity of starch may also be present in

fruit, but it typically converted to sugars during the ripening process. Negligible quantities of protein

and fat are found in fruits. Fats are most typically associated with the waxy cuticle surface of the fruit

skin. Exceptions to this rule are avocados and olives, the flesh of which may contain as much as 20

percent oil.

Different food products like jam, jelly, fruit bar and marmalade are prepared from raw edible fruits.

Fruit jams, jellies and marmalades are made by cooking fruits (pieces, pulps and/or juice) with sugars,

gelling agents (usually pectin) and edible (usually organic) acids, and concentrating the mixture until a

characteristic and suitable consistency is obtained3. This is one of the oldest processes used by mankind

to preserve fruit for consumption in the off-season4. The minimum amount of fruits in the final product

may vary from about 35–45 wt % 3. Insoluble solids in the products may range from 0.9 to 10 wt % 5.

Modern manufacturing requirements for uniform gel strength and appearance preclude reliance on fruit

native pectin, which may vary in content and quality, depending on fruit maturity and variety.

Consequently, commercial pectin of known quality and gelling capacity is added to jam and jelly

formulations to achieve the desired gel strength 4. Considering the nutritional value of fruit products,

this paper attempts to highlight the preparation of Sonneratia apetala fruit jelly in livelihood domain of

Sundarbans. The Work has great relevance as the region is poverty stricken and is prone to sea level

rise, erosion, frequent natural calamities etc.

FRUIT PRODUCTS AND THEIR PREPARATION

Preparation and processing of fruit products is extremely important for maintaining the quality of

finished product. Some common methods of preparing juice, jam and jelly from fruits are discussed

here.

Fruit Juice

One of the most common fruit products is fruit juice (Fig. 1). Fruit juice is the liquid part of the fruit

that extracted by squeezing or crushed the fruit. The juice may be turbid or clear. It may have been

concentrated and later reconstituted with water suitable for the purpose of maintaining the essential

composition and quality factors of the juice. The addition of sugars or acids can be permitted but must

FIGURE 1:Fruit Juice extract

Fruit juice can be extracted as following procedure.

Collection of fruit samples

Washing

Either cut in half or select whole fruit

Extract the juice by squeezing

Packing

Fruit Jam

Jam is a type of fruit spread product (Fig. 2) made from whole, cut or crushed fruit boiled with sugar.

Almost any fresh fruit can be made into jam by mashing or slicing it fine, adding an approximately

equal amount of sugar, and simmering until it reaches the proper concentration or gel at 218° to 222°F;

(103°–105°C). It appears very rustic: a squishy, somewhat homogenous spread. It is frequently possible

to identify the original fruit just by looking at a jam. Jam tastes much like the original fresh fruit.

Jam is prepared as per the standard protocol7 and modified as follow:

Collection of fruit samples

Washing

Extract fruit pulp

Boil and add sugar

Addition of pectin and citric acid

Judging the end point (70°B)

Packing in a sterilized jar

Cool and stored in refrigerator

Fruit Jelly

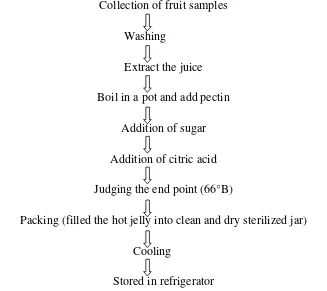

Jelly is defined as the semisolid fruit product made from fruit juice8 (Fig. 3). It should be clear and free

from any residual parts of fruit and firm to hold its shape.

The standard procedure8 follows the jelly production at the industrial level and it is modified as follow: Collection of fruit samples

Washing

Extract the juice

Boil in a pot and add pectin

Addition of sugar

Addition of citric acid

Judging the end point (66°B)

Packing (filled the hot jelly into clean and dry sterilized jar)

Cooling

Stored in refrigerator

We prepared jelly from Sonneratia apetala fruit (Fig. 4), which is a mangrove tree found in Sundarbans

at lower Gangetic delta. The fruit is rich in Vitamin C9.

FIGURE 4:Sonneratia apetala fruit FIGURE 5:Sonneratia apetala jelly The jelly (Fig. 5) prepared from S. apetala fruit was found to be nutritionally high compared to orange

jelly and mango jelly9-11 (Table 1). This fruit available during monsoon season in lower Gangetic delta.

This region experiences extreme tidal surges, cyclonic depression and continuous erosion. The people

mostly are below poverty line and earned their livelihood depending on the forest products (like timber,

honey, wax, fishes etc.). These forest resources are obtained in illegal ways. It is expected that sizable

percentage of the population of this area may be attracted towards this jelly manufacturing technology

and upgrade their economic profile. However, proper institutional mechanism and capacity building are

Table 1:Comparison of nutrition values of fruit jellies with S. apetala fruit jelly

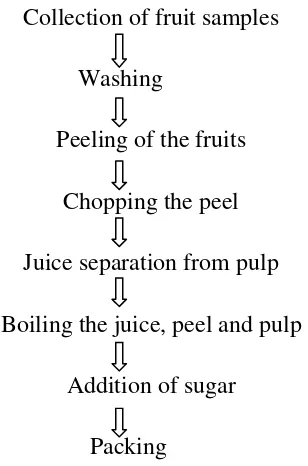

Marmalade is a fruit finished product made from the juice and peel of citrus fruits boiled with sugar and

water (Fig. 6). It can be produced from kumquats, lemons, limes, grapefruits, mandarins, sweet

oranges, bergamots and other citrus fruits, or any combination thereof. It looks like a jelly.

FIGURE 6:Fruit Marmalade

and minerals). Because of its complex nature, studies on jam’s structure are scarce and mostly

empirical.

Sugarless jam and jelly are made from fruit sweetened with an artificial sweetener along with a gelling

agent such as gelatin or pectin. These jams and jellies are made in small quantities, stored in the

refrigerator and must be used within 4 to 6 weeks.

Fruit Bar

Fruit bar is a type of cookies containing chopped fruits, either mix in the dough or spread between

layers of dough then baked and cut in bars. It has a chewy texture (Fig. 7).

FIGURE 7:Fruit Bar

Fruit bar can be prepared by maintaining the standard protocol12 and modifies as follow:

Collection of fruit samples

Washing

Weigh the pulp

Boiled and addition of sugar

Continued boiling with stirring

Addition of milk powder

Addition of hydrogenated fat

Addition of citric acid

Judging the end point (TSS 72 %)

Poured in tray and cooled at room temperature

Cut into equal pieces

INGREDIENTS OF JAM, JELLY PRODUCTS AND ITS SIGNIFICANCE

Pectin

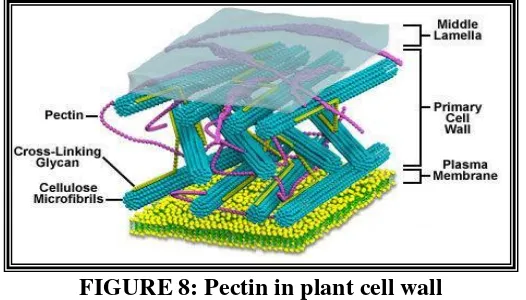

Pectin is a white, amorphous, colloidal hetero-polysaccharide (carbohydrate) that is used as thickening

or gelling agent in the production of jam, jelly and other similar products. It naturally found in primary

cell wall of terrestrial plants and helps in the binding of cells together (Fig. 8). Pectin molecules are so

tightly liked to cell wall that they cannot be extracted by water and this water insoluble form is called

protopectin. Protopectin becomes soluble by acid hydrolysis and then extracted in hot water.

FIGURE 8:Pectin in plant cell wall

The amount of pectin in the fruit varies with the kind of fruit and degree of ripeness. The pectin content

of fruit is species specific in nature. S. apetala has rich pectin content. Under ripe fruit has higher

pectin content. As fruit ripens, the pectin is changed to a non gel-forming substance through broken

down it by the enzymes namely pectinase and pectinesterase and therefore the fruit becomes softer as

the middle lamellae break down and cells become separated from each other.

The molecular structure of pectin is composed of D-galacturonic acid molecules, which are linked to each other by α 1-4-glycosidic bond to formation of polygalacturonic acid (Fig. 9). Pectin molecules become heteropolysaccharide by neutral sugars like arabinose, galactose and xylose, which are linked

as side chains to the pectin macromolecules13-17. Around 80 % of the carboxyl groups of galacturonic

acid are esterifies with methanol and on this basis pectin is divides into two types. One is high

methoxyl pectin and another is low methoxyl pectin (Fig. 10).

FIGURE 10:High methoxyl pectin (left) and Low methoxyl pectin (right)

The gelling power of the pectin is based on its molecular weight i.e. the number of chains link a pectin

molecule boast. Pectin molecules contain negative charge that makes them to move away from each

other due to repulsion force. This negatively charged pectin molecule is changes to neutral molecule by

the addition of acid, allowing them to more close together and moving around freely for unbound

water. Addition of sugar helps in the binding of water molecules and form hydrogen bridges between

non-esterified carboxyl groups and this hydrophobic interaction binds the pectin molecules together

(Fig. 11). Methylester groups are the hydrophobic part of the pectin molecule. Hydrophobic forces push

them into aggregate formations, and form a gel matrix within pectin network. High methoxyl

pectin will only form gel if the amount of soluble solids is higher than 65% and the pH is 2.0 - 3.8.

FIGURE 11:Hydrophobic bridge of high methoxy pectin

Low-ester pectins need calcium to form a gel, but can do so at lower soluble solids and higher

pH-values than high-ester pectins. Normally low-ester pectins form gels with a range of pH from 2.6 to 7.0

and with soluble solids content between 10 and 70%.

Consumption of pectin has been shown to reduce blood cholesterol levels. The mechanism appears to

be an increase of viscosity in the intestinal tract, leading to a reduced absorption of cholesterol from

bile or food18. In the large intestine and colon, microorganisms degrade pectin and liberate short-chain

fatty acids that have positive influence on health.

Sugar

Sucrose is usually used in homemade jellied fruit products. From a practical point of view, it may be

advantageous to substitute other sugars for sucrose, either because of cost, or to reduce the likelihood of

crystallization, or for flavor modification19. Partial replacement of sucrose with other sugars such as

maltose, glucose, syrups, or high fructose corn syrup altered the setting times and certain rheological

properties of model gels20. Sweeteners such as brown sugar, sorghum, and molasses are not

recommended because their flavors overpower the fruit and their sweetness varies. Artificial sweeteners

than sugar and more healthful. However, when it is heated, it loses complexity of its fragrance, flavor

and perhaps also some of its health promoting properties. Besides, honey contains more water and so

may necessitate longer boiling. It also produces lot of foam during cooking and gelled preserves made

with honey tend to be soft. Therefore, honey cannot be used in making the fruit finished products.

The exact amount of sugar for the production is depends on the acidity level, the natural sugar content,

and the type of product desired. If sugar content is too low, the resulting jelly will be tough; excessive sugar, on the other hand, will create a “soft set” that can be broken easily.

Sugar plays some important roles in jam, jelly preparation by way be gelling, preserving, color

retardation etc. Each of these roles is discussed separately.

Gelling

Sugar is essential in the gelling process of jams and jellies to obtain the desired consistency and

firmness. Pectin, a natural component of fruits, has the ability to form gel only in the presence of sugar

and acid. Sugar attracts and holds water during the gelling process.

Preserving

Sugar prevents the spoilage of jams and jellies. Properly prepared and packaged products are free from

bacteria and yeast cells until the lid is opened and exposed to air. Once the jar is opened, sugar

incapacitates any microorganisms by its ability to attract water through osmosis (the process whereby

water will flow from a weaker solution to a more concentrated solution through semi-permeable

membrane). In that case, water is withdrawn from these microorganisms toward the concentrated sugar

syrup. The microorganisms become dehydrated and incapacitated, and are unable to multiply and bring

about food spoilage. In jellies and jams, a concentrated sugar solution of at least 65% is necessary to

perform this function. Since the sugar content naturally present in fruits in less than 65%, it is essential

to add sugar to raise it to this concentration for products preparation. Color Retention

Sugar helps to retain the color of the fruit products through its capacity to attract and hold water. Sugar

absorbs water more readily than other components in jam and jellies. Thus, sugar prevents the fruit

products from absorbing water which would cause its color to fade through dilution.

Acid

Citric acid is normally used in jam, jelly preparation. Acid acts as a flavouring agent in the jam, jelly

production. It also helps in the gel formation by lowering the pH. The pH must be adjusted of

approximately 3.1. Too much acid (pH < 2.5) will cause the gel to lose liquid and too little acid cannot

PRESERVATION OF FRUITS AND THEIR PRODUCTS

moisture in the fruit is driven off, leaving a stable food that has a moisture content below that at which

microorganisms can grow. There are three basic systems for dehydration: sun drying, such as that used

for raisins; hot-air dehydration; and freeze-drying.

Dehydration has a number of advantages. Dehydrated fruit has a virtually unlimited shelf life when

held under proper storage conditions. Drying does not significantly reduce the calories or minerals, and

vitamin losses are similar to other preservation methods. Dehydrated fruits are typically reduced in

weight by 75 to 90 percent.

Although dehydration offers a convenient product form, it usually requires a careful inactivation of

enzymes. This is usually accomplished by blanching of the fruit or by chemical inactivation. Typically,

sulfur dioxide is added for its antioxidant and preservative effects. In order to control browning, the

fruit is often treated prior to dehydration with sodium sulfite and sodium bisulfite.

Thermal processes

In thermal processing, heat is used to destroy spoilage organisms and to inactivate troublesome

enzymes. Enzymes are typically responsible for browning, softening, and the development of

off-flavours. Canning is the thermal process for high-acid fruit products, in which fruit or fruit products are

hot-filled or heated in a hermetically sealed container. The process temperature is generally 88° C (190°

F).

Chemical preservation

Chemicals also can be used as a preservative, either through artificial addition or through the action of

microorganisms. An example of the latter method is yeast fermentation, which can cause an increase in

ethyl alcohol sufficient to preserve the fruit product. Pickling is another example of chemical

preservation. In the case of pickling, the product may be preserved by the addition of salt, sugar, acetic

acid (vinegar), and alcohol. High sugar content also acts as a fruit preservative by tying up all available

moisture so that microorganisms cannot grow.

Irradiation

Although irradiation is an expensive method, it has been shown to be an effective means of extending

the shelf life of fresh fruits. Irradiated fruit products have not been well received by the public, even in

ROLE OF ENZYMES IN FRUITS PRODUCTS

Pectinase

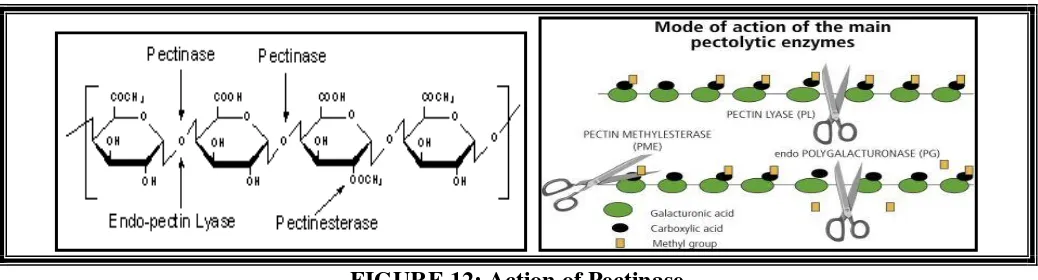

The most important enzyme in fruits is Pectinase that breaks down the pectin into sugars and

galacturonic acid. It can be derived from other organisms such as fungi (e.g. Aspergillus niger).

Pectinase become activated at 45 to 55 °C and work well at a pH of 4.5 to 5.5.

It catalyzes the random hydrolysis of 1,4-α-D-galactosiduronic linkages in pectate and other

galacturonans, and degrades the structure of plant cell wall (Fig. 12). So it speeds up the release of juice

and helps the industries to save money and time.

FIGURE 12:Action of Pectinase

Pectinase improves the color and the aroma of the juice. When the pectinase breaks down the pectin, it

removes the cloudiness in the fruit juice. This reduces the density of the juice, which increases the

volume of juice and makes it easier to pour. Pectinase also breaks down starches in the fruit juice which

eliminates any plant materials left in the juice.

Invertase

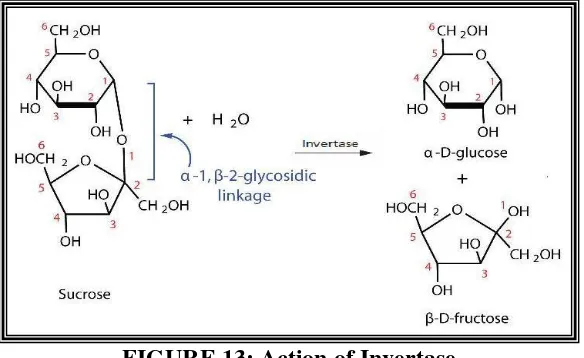

Invertase is another important enzyme in the fruit products. It derived from beneficial strain of

Saccharomyces cerevisiae. Invertase is a carbohydrate digesting enzyme that hydrolyses the sucrose

into its component parts, glucose and fructose by cleaving of α-1, β-2-glycosidic linkage (Fig. 13). In

the preparation of fruit products, added sugar contact with water and invertase enzyme become

activated and split the sucrose. This chemical change in mixure produces some benefits in jam and jelly

quality including brightness, fruit favor enhancement and the avoidance of crystallization in case the

FIGURE 13:Action of Invertase

Small scale fruit based industry; where the rope is tied?

Today, preparation of several fruit products like jam, jelly, and fruit bar, fruit marmalade can be easily

prepared as home based industry. However, proper preservation and marketing are two important

factors that determine the fate of the industry. The marketing chain is very week particularly in the

islands of Indian Sundarbans and hence promotion of S. apetala based fruit jelly in the city market has

great uncertainty. Such innovative small scale mangrove based industry can only breathe if research

units, academic institutes, island dwellers and business houses may be roped in a loop.

REFERENCES:

1. Akintunde BO., Tunde Akintunde TY., Adejumo AO. (2004) Development of a Manual fruit

juice Extracto, NIFOL, 22, 178-182.

2. Iwe MO., Obaje PO., Akpapunam MA. (2003) Organoleptic Assessment of Selected Fruit

Juices Produced with citrus populace gum powder (Okoho) extracted with the aid of edible

Starches. NIFOI, 21, 79-84.

3. Fügel R., Carle R., Schieber A. (2005) Quality and authenticity control of fruit purées, fruit

preparations and jams – a review. Trends Food Sci. Tech., 16, 433–441.

4. Baker RA., Berry N., Hui YH. (1996) Fruit Preserves and Jams. In: Biology, Principles, and

Applications Technomic Publishing Co. Inc, Lancaser, PA.

5. Egbekun MK., Nda-Suleiman EO., Akinyeye O. (1998) Utilization of fluted pumpkin fruit

(Telfairia occidentalis) in marmalade manufacturing. Plant Foods Hum Nutr., 52, 171–176.

6. FAO. 1992. Codex Alimentarius, Fruit Juices and Related Products. 6.

7. Sindumathi G., Amutha S. (2014) Processing and quality evaluation of coconut based jam.

IOSR J. Environ. Sci. Toxicol. Food Technol., 8 (1), 10-14.

8. Madhav A., Pushpalatha PB. (2002) Quality upgradation of jellies prepared using pectin

Full Text Available On www.ijupbs.com

9. Pramanick P., Zaman S., Bera D., Raha AK., Mitra A. (2014) Mangrove fruit Products: A

search for alternative livelihood for Island dwellers of Gangetic delta. Int. J. Pharm. Res.

Scholars, 3 (1), 131-137.

10.http://slism.com/calorie/200339/

11.http://www.nutrition-and-you.com/food-nutrition.html

12.Vidhya R., Narain A. (2011) Formulation and Evaluation of Preserved Products Utilizing under

Exploited Fruit, Wood Apple (Limonia acidissima). Am-Eurasian J. Agric. Environ. Sci., 10 (1),

112-118.

13.Kapoor M., Beg QK., Bhushan B., Dadhich KS., Hoondal GS. (2000) Production and partial

purification and characterization of a thermoalkalistable polygalacturonase from Bacillus sp.

MG-cp-2.‖. Process Biochem., 36, 467–473.

14.Kashyap DR., Vohra PK., Chopra S., Tewari R. (2001) Applications of pectinases in the

commercial sector: A review. Bioresource Technol., 77, 215-227.

15.Singh SA., Plattner H., Diekmann H. (1999) Exopolygalacturonate lyase from a Thermophilic

Bacillus sp. Enzyme Microb. Tech., 25, 420–425.

16.Naidu GSN., Panda T. (1998) Production of pectolytic enzymes – a review. Bioprocess Eng.,

19, 355-361.

17.Hoondal GS., Tiwari RP., Tewari R., Dahiya N., Beg QK. (2002) Microbial alkaline pectinases

and their industrial applications: a review. Appl. Microbiol. Biotecnol., 59, 409-418.

18.Sriamornsak P. (2003) Chemistry of Pectin and its Pharmaceutical Uses: A Review. Silpakorn

University International Journal, 3, 206.

19.Ahmed GE. (1981) High methoxyl pectins and their uses in jam manufacture - a literature

survey. The British Manufacturing Industries Research Association. Scientific and Technical

Surveys No. 127, 16.

20.May CD., Stainsby G. (1986) Factors Affecting Pectin Gelation in Wedlock. Williams, P.A.

(eds.) Elseveir Applied Science Publishers. New York. 515–523.