52

Thermal and Adhesive with The Addition of Local

Montmorillonite Nanoparticles to The Manufacture of

Nanocomposites Polyurethane

Zaimahwati

*1,,Yuniati

1, Ramzi Jalal

1, Syahman Zhafiri

21Department of chemical engineering Politeknik Negeri Lhokseumawe (State Polytechnic of Lhokseumawe), Jl. Medan-Banda Aceh,

Buketrata, Lhokseumawe, Indonesia

2 Department of Chemistry, Faculty of Mathematics and natural Sciences, University Sumatera Utara, Jl. Bioteknologi No. 1 Medan 20155,

Indonesia

Abstract- This study investigates effect of local montmorillonite quantity on polyurethane nanocomposite production as coating material. Normally, Nanocomposite polyurethane causes reaction between propylene glycol and methylene diisocyanate by addition of local montmorillonite that is applied as coating material. In the selected methodology, characterization of polyurethane nanocomposite group is conducted by spectroscopy FT-IR., Thermal characteristic is examined by thermogravimetric analysis. Effectivity of polyurethane nanocomposite is measured by ISO2409 adhesive characteristic. As a result, polyurethane nanocomposite thermogram analysis with addition of montmorillonite achieved higher temperature in comparison to polyurethane without addition of montmorillonite. Furthermore, effectivity of polyurethane nanocomposite as coating material is also increased since 2nd classification becomes 1st classification.

Keywords— polyurethane, thermal, adhesive, montmorillonite.

I. INTRODUCTION

The polyaddition reaction. Polyurethanes are Technology development can be done by material engineering, one of which is composite manufacture. Preparation of a composite polymer is carried out by combining two or more different so as to enhance the mechanical properties of the composite. Polyurethanes are polymeric materials containing a polyurethane (- NHCOO -) group in the main chain, the urethane group is formed from the reaction between the isocyanate group and the hydroxyl group. Polyurethanes are used extensively in high-resilient flexible foams, rigid foam insulation panels, durable rubber tires, high performance glue, spadex fiber, carpet tools and hard plastic parts. Polyurethanes are generally formed from the reaction between two or more hydroxyl functional groups with two or more isocyanate groups and the reaction type is also called very easily formed polymeric materials for a wide range of applications, among which are produced as foams, polyurethane elastomers, coatings and adhesives (Mihail, 2005). Polyurethanes have low heat capability when compared with other polymers (Rehab, 2005). Some of the literature reported as a filler on polyurethane ie chalk, silica, kaolin and natural zeolite (Gultom

,

2016) can increase the heat of the polyurethane foam.Polyol is an organic compound having more than one or more hydroxyl groups, in the material industry is

53

material is insoluble in water or solvent. Thinner solvent, transparent liquid used for dissolving resin and for mixing and obtaining suitable viscosity for the painting process. Additives serve as a complementary material used to enhance the paint properties in terms of strength, durability and application when painting.Bentonite is a cheap mineral and in the polymer industry its use as a very economical filler (Rihayat and Suryani 2013). The main content of bentonite is montmorillonite (Fisli, 2008). Montmorillonite as the current application because of its current utilization as a nano-sized filler known as nanofiller, can be applied to polymeric materials producing nanocomposites with only a small quantity can improve the physics properties of the nanocomposite (Diego, 2012). In this research, the development of polyurethane nanocomposite material reacts polypropylene glycol with methylene diisocyanate with addition of montmorillonite particles. The purpose of addition of montmorillonite to enhance the coating of heat resistant material and adhesive strength

II. EXPERIMENT 2.1 Material

Natural bentonite taken from North Aceh, diisocyanate (Merck), polyetilen glikol (Merck), dibutyltin dilaurate (Merck), cetyl trimetyl bromidda`(Merck), botanadiol (Merck).

2.2 The processing of bentonite montmorillonite

Natural bentonite was taken from Blangdalam village,sub-distric of Nisam, North Aceh. It was being crushed, seived and dried at temperature of 105 oC and stored in desiccators. Then sample fractionation was much 25 gram and it was put into 1L of aquades. Ultrasonic waves were given for 15 minutes with 750 Watt power at room temperature. Then, the sediment was taken by pouring floated suspension into other container and its filtrate was being resettled. These fraction were being dried in oven at 105 oC for 3 hours and were crushed until reached a size of 250 mesh. These fraction were storedin desiccator and were later identified by X-ray.

2.3 The modification of montmorillonite-CTAB

Cetyl trimetyl ammonium bromide 0,05 mol was weighedand dissolved with 250 ml of aquadest in 500 ml beaker glass. Then, it was heated at 80 oC for 1 hour. In a seperate place, 20 gram of MMT was dissolved with 250 ml of aquades in 1 L beaker glass. Then MMT solution dispersion was put into CTAB solution stirred for 1 hour and was filltered. Montmorillonite was washed with aquadest

until it was free from chloride and bromide. Montmorillonite was stored in oven at 60 oC for 24 hours and was analyed using X-ray.

2.4 Manufacture of Polyurethane Nanocomposite Film

The preparation of polyurethane film follows the modification of polyurethane manufacturing procedure. A number of commercial polyols (polypropylene glycol) were mixed with MMT organisms (1%, 2%, 3%, 4% and 5%) and catalysts in the mixing container at room temperature for 10 min to obtain homogeneous mixture, plus isocyanate (MDI) again for 5 minutes until the mixture is homogeneous (look for polyol comparative conditions: MDI). Then applied to a prepared metal specimen, the result of the test panel is silenced at room temperature to evaporate the solvent. The polyurethane film layer on the metal panel is tested for adhesion (ISO 2409), FTIR and TGA.

2.5 Characterization Of Research Results

1. FT-IR Analysis Infrared spectroscopy of nanocomposites obtained with KBr pellets using Shimadzu FTIR spectrophotometer. Spectra obtained in the mid-infrared region (4000-400 cm-1) at room temperature.

2. Thogogravimetric analysis The TGA analysis was performed using Shimadzu DTG-60 instrument. The sample was weighed with mg mass and heated at room temperature up to 800 oC with a heating rate of 20 oC / min. The analysis is done by increasing the sample temperature gradually and determining the weight loss to the temperature change. All specimens tested under the nitrogen gas stream.

3. Adhesive Testing Iso 2409

The apparatus used for the adhesive test is a sharp cutter (cutter) cutter and crosscut tape of 3 M. The polyurethane film layer in the prepared test application is scratched with a blade of 11 lines with a distance of 2 mm at a uniform distance. The same scratch is also made perpendicular to the first gesture so as to form a small square pattern of 100 pieces. The crusscut tape is attached evenly over the scratches made, then the end of the crosscut is pulled rapidly in the 60o direction towards the panel surface. The level of film damage indicates the quality of its adhesive power.

54

3.1. Polyurethanes Characterization as Material CoatingMaterial

Preparation of polyurethane composite coating material is reacting commercial polyol (polypropylene glycol) with methylene diisocyanate (MDI) plus montmorillonite resulting from bentonite insulation, and applied to iron specimens. In Figure 1 the material specimens were coated with polyurethane / MMT in the ratio of Polyol: MDI: MMT is 70: 30: 5% the result is better, on flat and smooth surface. Figure 1 material specimen with commercial polyurethane coating, polyurethane coating with addition of montmorillonite.

Figure. 1 Application of polyurethane coatings on material specimens and 2934,74 cm-1, 2870,40 cm-1 for PU-PPG / MMT is the absorption of CH alkane groups, and in the uptake of 816.57 cm-1, 816.01 cm-1 and 816.72 cm-1 aromatic CH groups of the MDI compound. The uptake in the region of 1310.78 cm-1, 1311.38 cm -1 and 1313.75 cm-1 is the absorption of the C = N group of isocyanate compounds. Comparative spectrum of commercial polyurethane FT-IR and synthetic polyurethane show almost the same absorption region.

Table 1. Numokomposit Polyurethane Waves

Functional

Groups Wave Number

(cm-1)

PU Commercial PU-PPG PU-PPG/MMT

-N-H 3311,86 3315,80 3316,21

-CH 2942,56 2926,63:2855,51 2934,74: 2870,40

-C=O

C=N 1310,78;1226,88 1311,38;1229,42 1313,75;1232,02

3.2. Thermal Characterization

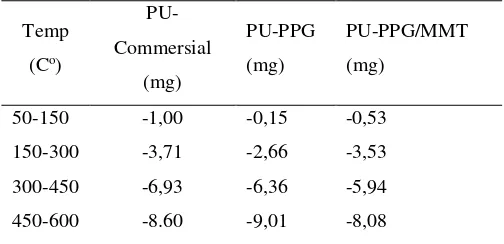

The thermogravimetric analysis (TGA) of Commercial PU, PU-PPG and PU-PPG / MMT is shown in Table 2. Termogravimetry can be used to characterize any material that indicates changes in material weight during heating, and to detect changes due to the decomposition process. Weight reduction in the early 50-150 oC of evaporated water for Commercial PU, PU-PPG and PU-PPG / MMT with weight loss of -1.00 mg, -0.15 mg and -0.53 mg or about 5 %. decomposition of commercial PU at a temperature of 380 oC of the remaining sample of 1.40 mg or about 14%. For PU-PPG decomposition and PU-PU-PPG / MMT weight reduction at the beginning of 150-200 oC at 5% and decomposition at 490 oC. This proves that the nanocomposite PU-PPG / MMT has increased thermal stability

.

Table 2 Losing weight on temperature variations

Temp

3.3 Characterization of Adhesive Classification

Table 3 shows that commercial PU and PU-PPG fall into classification 2, it states that the material specimens applied with Commercial PU and PU-PPG / MMT damage rate of about 15%.

55

MMT fall into classification 1, it states the level of damage PU-PPG / MMT about 5% (ISO 2409). The addition of MMT to the polyurethane of propylenaglycol may increase the adhesion strength. The adhesiveness of the coating film and the media may be caused by bonding forces, hydrogen bonding forces, dispersion forces, and mechanical gluing (pores) or a combination thereof. Adhesive power is highly dependent on the surface properties of the media with the resin. To get a good bond media and polymer must be compatible and can build several kinds of bonding style. Based on the above, good adhesion strength of the polyurethane film layer in the material specimen medium is caused by the formation of bond forces between the material specimen and the polyurethane film. The strength of polymide coating adhesives with 3% clay additions increases with polymide coating adhesives without clay (Kishore, 2012).CONCLUSIONS

Based on the thermal test, it is obtained that the polyurethane coatings added with montmirillonit isolation result underwent an increased heat in comparison with polyurethane without addition of montmorillonite. The decomposition of Polyurethane commercial occurred at 380 oC while the polyurethane with the addition of 5%

monmorillonit local

ACKNOWLEDGMENT

Acknowledgments are submitted to Kemenristek Dikti for grant aid through Applied Product Research program no. 503 / PL20 / R15 / BAP.PPT / PL / 2017

REFERENCES

1. Ahmed Rehab, Nehal Salahuddin, 2005,

”Nanocomposite materials based on polyurethane

intercalated into montmorillonite clay”, Materials

Science and Enginering A, 368-376

2.

Charu, S.,”Studies on Development of Polypropylene-Clay Nanocomposite for Automotive, Thesis, School of Physics and Material Science, Thapar University, India, Applications, 2008.

3. Diego Piazza, Debora S. Silveira, Natalia P. Lorandi,

2012,” Polyester-based powder coatings with

montmorillonit nanoparticle applied carbon steel”,

Progress in Organic Coatings, 73, 42-46

4. Fisli,A. 2008,Isolasi dan Karakterisasi dari Bentonit Sukabumi (Indonesia), Indonesia Journal of Material Sience, 10 (1), 12-17

5. Gultom,F, Basuki Wirjosentono, Thamrin, Hamonangan Nainggolan, Eddyanto, 2016, Prepaeation and characterization of North Sumatera natural zeolite polyurethane nanocomposite foams for light-weight engineering materials, Procedia Chemistry,19, 1007-1013

6. Harjono, Purwatiningsih Sugita, Zainal Alim Mas’ud,

2012, “Synthesis and Application of Jatropha Oil based Polyurethane as Paint Coating Material”, Makara

Journal of Science 16/2,134-140.

7. Kishore K. Jena, K.V.S.N. Raju.Ramanuj Narayan,

2012, “Sodium montmorillonit clay loadedorganic-inorganic hybrid composites: Synthesis and

characterization”, Progress in Organic Coatings 75, 33 -37.

8.

Nayani.M, Gunashekar.S, Nidal.A., “ Synthesis andCharacterization of Polyurethane-Nanoclay

Composites”, 2013, Polymer Science, Research

Article, Hindawi

.

9. Rihayat, T. and Suryani, 2013, Morphology properties of polyurethane/clay nanocomposites base on palm oil polyol paint, Advanced Materials Research, 647, 701-704

10. Rohaeti.E., Suyanta. 2011. Analisi Sifat Termal Poliuretan Berbasis Minyak Jarak dan Toluena Diisosianat Dengan Teknik DTA dan TGA.Universitas Negeri Yogyakarta

11. Mihail Ionescu, 2005, “Chemistry and Technologi of

Polyol for Polyurethanes”, Rapra Technologi.

12. Petrovic, Z.S; DooPyo, H; Javni, I; Erina, N; Zhang,

F;Ilavsky, J. 2013,”Phase structure in segmented

polyurethanes having fatty acid-based soft segment” Polymer 54, 372-380

13. Suman,T and N. Karak, 2013,”Castor oil-based hyperbranhed polyurethanes as advaned surface coating materials”. Prog’. In Organic Coating 76,157-164

14. Suryani, Zaimahwati, 2014, Fourrier Transform Infrared and Gel Permeation Chromatography Evaluation to Prepared Polyurethane Paint from Polyol Palm Oil Based, Applied Mechanics and Materials, Vol. 525, 162-165