2018

5th International Conference on

Industrial Engineering and Applications

ICIEA

2018

April 26-28, 2018

Singapore

ISBN: 978-1-5386-5748-5

The 5th International Conference on Industrial Engineering and Applications (ICIEA 2018)

Copyright ©2018 by the Institute of Electrical and Electronics Engineers, Inc. All rights reserved.

Copyright and Reprint Permission:

Abstracting is permitted with credit to the source. Libraries are permitted to photocopy beyond the limit of U.S. copyright law for private use of patrons those articles in this volume that carry a code at the bottom of the first page, provided the per-copy fee indicated in the code is paid through Copyright Clearance Center, 222 Rosewood Drive, Danvers, MA 01923.

Other Copying, reprint, or reproduction requests should be addressed to IEEE Copyrights Manager, IEEE Service Center, 445 Hoes Lane, P. O. Box 1331, Piscataway, NJ 08855-1331.

Compliant PDF Files

IEEE Catalog Number: CFP18L08-ART ISBN: 978-1-5386-5748-5

Conference CD-ROM Version

IEEE Catalog Number: CFP18L08-DVD ISBN: 978-1-5386-5746-1

Print Version

IEEE Catalog Number: CFP18L08-PRT ISBN: 978-1-5386-5747-8

Additional copies of this publication are available from

Curran Associates, Inc. 57 Morehouse Lane Red Hook, NY 12571 USA +1 845 758 0400

+1 845 758 2633 (FAX)

x iv

Conference Committees

International Advisory Committee

Zhe George Zhang, Western Washington University, USA

Conference Chairs

Felix T. S. Chan, The Hong Kong Polytechnic University, Hong Kong

Shey-Huei Sheu, Department of Statistics and Informatics Science, Providence University, Taiwan

Local Organizing Chair

TANG Loon Ching, National University of Singapore, Singapore

Organizing and Program Committees

Seoung Bum Kim, School of Industrial Mangement Engineering, Korea University

Usik Lee, Inha University, Korea

Maode Ma, Nanyang Technological University, Singapore

Finance Chair

Minghan Xi, Dalian Maritime University, China

International Technical Committees

Cheng-Feng Hu, National Chiayi University, Taiwan

Dong-Yuh Yang, National Taipei University of Business, Taiwan

Mario Hirz, Graz University of Technology, Austria

Amr Eltawil, Egypt Japan University of Science and Technology (E-JUST), Egypt

Po-Hsiang Liu, College of Business and Management in St. John's University, USA

Taesu Cheong, Korea University, Korea

Tien-Lun Liu, Chung Yuan Christian University, Taiwan

Wei Cai, Wuhan University of Technology, China

Jinguo Huang, Huazhong University of Science and Technology, China

Yu-Chung Tsao, National Taiwan University of Science Technology, Taiwan

Yip Mum Wai, Tunku Abdul Rahman University College, Malaysia

x v

Bonivasius Prasetya Ichtiarto, Mercu Buana University, Indonesia

Elita Amrina, Andalas University, Indonesia

Ren-Jieh Kuo, National Taiwan University of Science and Technology, Taiwan

Nguyen Thi Phuong Quyen, National Taiwan University of Science and Technology, Taiwan

Xuan Qiu, The Hong Kong University of Science and Technology, Hong Kong

Mohamad Zairi Bin Baharom, Universiti Malaysia Pahang, Malaysia

Anand Jayakumar Arumugham, SVS College of Engineering, Coimbatore, Tamil Nadu, India

Byung Do Chung, Yonsei University, Korea

M. Mujiya Ulkhaq, Diponegoro University, Indonesia

Marek Kocisko, Technical University of Kosice, Slovakia

Sandeep Singhal, National Institute of Technology, India

J. W. Wang, The University of Hong Kong, Hong Kong

Ching-Chang Kuo, National Taichung University of Science and Technology, Taiwan

Kuo-Hsiung Wang, Providence University, Taiwan

Ismail Musirin, Universiti Teknologi MARA, Malaysia

Sangbok Lee, Hansung University, Korea

Adrian E. Coronado Mondragon, Royal Holloway University of London, UK

Chin-I Lee, Ling Tung University, Taiwan

S. H. Choi, University of Hong Kong, Hong Kong

Shang-Juh Kao, National Chung-Hsing University Taichung City, Taiwan

Wei Cai, Wuhan University of Technology, China

Hashibah Hamid, Universiti Utara Malaysia, Malaysia

T. M. A. Ari Samadhi, Bandung Institute of Technology, Indonesia

Zainal Abidin Akasah, Universiti Tun Hussein Malaysia, Malaysia

Pi-Chun Hsu, Chaoyang University of Technology, Taiwan

Mu-Chen Chen, National Chiao Tung University, Taiwan

Murat Kucukvar, Qatar University, Qatar

Chaudry Bilal Ahmad Khan, Institute of Space Technology, Pakistan

Tsu-Wei Yu, Chaoyang University of Technology, Taiwan

Lingyun Wei, Beijing University of Posts and Telecommunications, China

Hamdi Bashir, University of sharjah, United Arab Emirates

Lerdlekha Sriratana, Ramkhamhaeng University, Thailand

LIU Hai-peng, Kunming University of Science and Technology, China

Elfira Febriani, Trisakti University, Indonesia

Yu-Hsiang Hsiao, National Taipei University, Taiwan

Chien-Chih Wang, Ming Chi University of Technology, Taiwan

x vi

Roberto Montemanni, Istituto Dalle Molle di Studi sull'Intelligenza Artificiale (IDSIA - USI/SUPSI), Switzerland

Bambang Suhardi, Universitas Sebelas Maret, Indonesia

Ssu Han Chen, Ming Chi University of Technology, Taiwan

M’d Gapar M’d Johar, Management and Science University, Malaysia

Fazeeda Binti Mohamad, Universiti Malaysia Pahang, Malaysia

Augustina Asih Rumanti, Bandung Institute of Technology, Indonesia

Maheshwar Dwivedy, BML Munjal University, India

Zhichuan Guan, China University of petroleum (East China), China

Iwan Aang Soenandi, Krida Wacana Christian University, Indonesia

Amelia Kurniawati, Telkom University, Indonesia

Anas Ma’ruf, Bandung Institute of Technology, Indonesia

Gabriel Lodewijks, The University of New South Wales’ Australia

Yenming J. Chen, National Kaohsiung University of Science and Technology, Taiwan

Ardyono Priyadi, Institut Teknologi, Sepuluh Nopember, Indonesia

Tuanjai Somboonwiwat, King Mongkut’s University of Technology Thonburi (KMUTT), Thailand

iii

2018 5th International Conference on Industrial

Engineering and Applications

ICIEA 2018

Table of Contents

Decision Analysis and Methods

Towards a Decision Support Approach for Selecting Physical Objects in Collaborative Supply Chain Processes for Cyber Physical System-Transformation ...1

Endric Hetterscheid, Florian Schlüter

Decision Support System for Inventory Control of Raw Material—(Case Study : PT Suwarni Agro Mandiri Plant Pariaman, Indonesia) ...6

Difana Meilani, Amelia Andiningtias, Dicky Fatrias

Integration AHP and TOPSIS in Shipyard Location Selection ...11

Ali Parkhan, Aldrin Daeng Vatimbing, Imam Djati Widodo

E-Business and E-Commerce

Inventory Management in E-commerce Supply Chain with Lateral Transshipment and Quick Response...17

Xueqing Yu, Lingyun Wei

Impact of Recommender Systems on Unplanned Purchase Behaviours in e-Commerce ...21

Zhang Ying, Chen Caixia, Gu Wen, Liu Xiaogang

Evaluating and Analyzing the Effectiveness of Online Advertising...31

Huini Zhou, Li Li, Xiaoguang Gu

Micro Enterprise and e-Commerce Platform: Literature Review and Agenda for Future Research ...38

Clara Linggaputri, Isti Surjandari, Akhmad Hidayatno

Preface………...………...………...……….xiii

iv

Global Manufacturing and Engineering Economics

Optimal Manufacturing Outsourcing Decision Based on the Degree of Manufacturing Process Standardization...49

PingYu Chang, Thi Thanh Nhan Phan

A Functional Design of a Cost Benefit Analysis Methodology for Transport Infrastructure Projects ...54

Tiep Nguyen, Stephen Cook, Indra Gunawan

Demand Management Practices in the Manufacturing Industry: An Empirical South African Perspective ...60

Eric Bakama Mikobi, Eveth Nwobodo-Anyadiegwu, Charles Mbohwa

Healthcare Systems and Management

A Study on Healthcare-product Supply Chain with a Group Purchasing Organization...67

Yin Han, Lingyun Wei

A Study on Shortage of Hospital Beds in the Philippines Using System Dynamics ...72

Josephine D. German, John Karlo P. Miña, Claudine Mae N. Alfonso, Kang-Hung Yang

Research on Health Monitoring Mechanism Based on Service Invocation* ...79

Xuan Mei, Xinming Tan

Business Process Reengineering for the Saline Management in Hospitals...84

Sith Vilasdechanon, Apichat Sopadang

The Acceptance Model of Hospital Information Systems in Thailand: A Conceptual Framework Extending TAM ...89

Paneepan Sombat, Wornchanok Chaiyasoonthorn, Singha Chaveesuk

Human Factors

An Experimental Study to Investigate Personality Traits on Pair Programming Efficiency in Extreme Programming ...95

Ramlall Poonam, Chuttur M. Yasser

Intention of Opening Up the Network of Personal Data... 100

Mao-Sung Chen, Tung-Kuan Liu, Ming-Tien Tsai

The Differences of Individual Spatial Strategy on Their Solving Performance ... 105

v

Understanding the Model of User Satisfaction in Using Cloud Storage Systems of Employees in Thailand: A Conceptual Framework... 110

Kulapa Najantong, Singha Chaveesuk, Wornchanok Chaiyasoonthorn

Evaluating Variables That Affect Job Satisfaction of Bank Customer Contact Centre Agents in South Africa ... 116

Eveth Nwobodo-Anyadiegwu, Charles Mbohwa, Nokukhanya Ndlovu

Information Processing and Engineering

Real-time Localization and Navigation in an Indoor Environment Using Monocular Camera for Visually Impaired ... 122

Kruthika Ramesh, Nagananda S. N., Hariharan Ramasangu, Rohini Deshpande

Experiment and Optimization of Magnetostrictive for Long Time Operation to Find Amplitude of Vibration and Thermal Limit... 129

Nuttakorn Pukseesang, Samran Santalunai, Thanaset Thosdeekoraphat, Chanchai Thongsopa

Some Methods for Measuring the Efficiency of Firms Utilizing Different Technologies... 134

Soobin Choi, Jaedong Kim, Hanjun Lee

Core Challenges to Cloud PLM Adoption in Large Manufacturing Firms ... 141

Shikha Singh, Subhas Chandra Misra

Intelligent Systems

Visual and Hearing Detection Capabilities to Discriminate whether a UAV Invade a Campus Airspace ... 146

S. J. Chang, K. W. Li

Reflections on Facilitating the Development of “Internet Plus” Intelligent Manufacturing in China... 150

Yong Tao, Gang Zhao, Qiushi Li, Wen Zhao

A Study of Small Complicated Axisymmetric Parts Manufacturing in Industry 4.0... 158

Chengcheng Zhu, Shengdun Zhao, Shuaipeng Li

Voltage Stability in DC Micro Grid by Controlling Two Battery Units with Hybrid Network Systems... 163

Adhi Kusmantoro, Ardyono Priyadi, Mauridhi Hery Purnomo

Design and Implementation of IoT Based Smart Laboratory ... 169

vi

Analysis of Microwave Precipitation in the Topographic Barrier for the Lifting Condensation Level of Clouds Formation... 174

Supawat Kotchapradit, Thanaset Thosdeekoraphat, Samran Santalunai, Chanchai Thongsopa

Improved Efficiency of Insect Pest Control System by SSPA... 179

Phanupong Saeung, Samran Santalunai, Thanaset Thosdeekoraphat, Chanchai Thongsopa

Manufacturing Systems

Optimized Information Exchange Process between CAD and CAM—Enhanced Data Exchange in the Field of Joining Technology from the Viewpoint of an Automotive Supplier ... 184

Alexander Kreis, Mario Hirz, Severin Stadler

Efficiency Improvement of Door Frame Manufacturing Process in Wood Product Manufacturing Industry ... 189

Lerdlekha Sriratana

The Structural Design of 3D Print Head and Execution of Printing via the Robotic Arm ABB IRB 140... 194

Martin Pollák, Jozef Török, Jozef Zajac, Marek Kočiško, Monika Telišková

Micro-fabrication Method of Au Micro-wire Structures on Substrate by Chemical Printing and Peeling Process ... 199

Potejana Potejanasak

Evaluation of Thermal Comfort Room Garment Workshop in Textile Vocational School... 203

Anastasia Febiyani, Bambang Suhardi, Eko Pujiyanto

Modular Measuring System for the Force Distribution in Forming Processes ... 208

W. Zorn, L. Hamm, R. Elsner, W. G. Drossel

Gravity Filling System of Slurry for Rod Mill Sand with High Concentration and Research on Technical Transformation in Jinchuan Mine ... 214

Li Li-Tao, Yang Zhi-Qiang, Gao Qian, Wang Yong-Ding

Defect Reduction in the Board Front Door Trim Manufacturing Process... 220

Punyisa Kuendee

Operations Research

Integrated Railway Timetable Scheduling Optimization Model and Rescheduling Recovery Optimization Model: A Systematic Literature Review ... 226

vii

A Comparative Analysis about the Balance Design of the Assembly Line by Branching & Bound Method and Lingo Method... 231

Jia Shuyuan, Huang Li, Li Qin, Gu Yonghu

The Optimal Routes and Modes Selection in Multimodal Transportation Networks Based on Improved A* Algorithm... 236

Yan Liu, Lingyun Wei

Industrial Cluster Optimization Based on Linear Programming ... 241

Roberto Montemanni, Jafar Jamal

Multi-objective Joint Optimization of Batch-discrete Hybrid Flow Shop Scheduling Integrated with Machine Maintenance... 247

Yangyang Fei, Huimin Ma

Investigating the Interrelationship between Stochastic Aircraft Routing of Airlines and Maintenance Staffing of Maintenance Providers ... 254

Felix T. S. Chan, Abdelrahman E. E. Eltoukhy

An Modified Relax-and-fix Algorithm for the Multi-level Lot-sizing Problem with Replaceablility ... 262

Mingyuan Wei, Yifei Yuan, Canrong Zhang

Height-Based Heuristics for Relocating Containers during Loading Operations... 268

Yifei Yuan, Canrong Zhang, Ting Huang

A Record-to-Record Travel Algorithm for Multi-product and Multi-period Inventory Routing Problem... 274

Fadillah Ramadhan, Arif Imran, Afrin Fauzya Rizana

Developing Tabu Search with Intensification and Diversification for the Seriation Problem... 279

Pimprapai Thainiam

A Comparative Study of Mixed-Integer Linear Programming and Genetic Algorithms for Solving Binary Problems... 284

Punyisa Kuendee, Udom Janjarassuk

Production Planning and Control

Concurrent Optimization of Job Shop Scheduling and Dynamic and Flexible Facility Layout Planning... 289

Ryota Kamoshida

Makespan Minimization on Single Batch-processing Machine Considering Preventive Maintenance ... 294

viii

Customer Kansei-Oriented Restaurant Location Evaluation Using Kansei Engineering... 299

Yu-Hsiang Hsiao, Guan-Ting Chen

An Improvement Scheme for the Overall Line Effectiveness of a Production Line: A Case Study ... 304

Jieli Li, Yuhui Jia, Binbin Xu, Fei Chen, Zhaojun Yang, Xiaodong Li

An Adjustment Method for Material Inventory Control Decision Considered in Product Life Cycle ... 310

Jiun-Shiung Lin, Jen-Huei Chang, i-Yan Yang

Application of a Hidden Markov Model for Consistency Checking of Process Plant Facility Tag Numbers—A Case Study ... 314

Jayaram Sivaramakrishnan, Gareth Lee

Analyzing Circadian Rhythms for Breaktime Schedulling on Night Shift Work ... 321

Lovely Lady, Ansor Firdaus

Resource-Reconfigured Flow Shop Scheduling and Lot-Sizing Problems in Semiconductor Test ... 326

Yige Zhang, Yuangen Lu, Cangrong Zhang

Process Flow Improvement in Production of Noise Filter Products through Lean Manufacturing Technique ... 333

Rattarak Moonpragarn, Rungchat Chompu-inwai

Waste Reduction in the Shoe Sewing Factory ... 340

Pongpat Phetrungrueng

The Joint Replenishment Problem with Resource Restriction: A Note ... 345

M. I. M. Wahab, Y. Chen

Aggregate Planning in Canned Pineapple Production Lines ... 349

Datepard Charoenponyarrat, Tuanjai Somboonwiwat

Applications of Data Mining

A Research Study on Unsupervised Machine Learning Algorithms for Early Fault Detection in Predictive Maintenance ... 355

Nagdev Amruthnath, Tarun Gupta

The Analysis of Matching Learners in Pair Programming Using K-Means ... 362

Naladtaporn Aottiwerch, Urachart Kokaew

Machine Learning Based Approach for Demand Forecasting Anti-aircraft Missiles ... 367

ix

Quality Control and product lifecycle Management

Simultaneous Prediction Interval-Based Multiobjective Solution Approach for Multiple Quality Characteristics Optimization ... 373

Abhinav Kumar Sharma, Indrajit Mukherjee

The TQM Integration in Procurement Function Performance ... 378

Bisalyaputra, K.

Safety Analysis at Weaving Department of PT. X Bogor Using Failure Mode and Effect Analysis (FMEA) and Fault Tree Analysis (FTA) ... 382

Prima Fithri, Nidi Annisa Riva, Lusi Susanti, Berry Yuliandra

Success Determinants to Product Lifecycle Management (PLM) Performance ... 386

Shikha Singh, Subhas Chandra Misra

Company Performance Measurement for Automobile Companies: a Composite Indicator from an Environmental Perspective ... 391

Qinqin Zeng, Wouter W. A. Beelaerts van Blokland, Sicco C. Santema, Gabriel Lodewijks

Loss Time Reduction for Improve Overall Equipment Effectiveness (OEE) ... 396

Kamolchanok Krachangchan, Natcha Thawesaengskulthai

Service Innovation and Management

Estimating Diffusion of Technology Using User Perceptual Values: A Conceptual Model ... 401

Chaudry Bilal Ahmad Khan

Implementation of Innovative Digitalization Methods in Reverse Engineering ... 406

Monika Telišková, Martin Pollák, Jozef Török, Jakub Kaščák, Petr Baron, Viktoria Mezencevova

Topological Evolution of Public Transportation Network: A Case Study of Bangkok Rail Transit Network ... 410

Pijaya Na Bangxang, Pisit Jarumaneeroj

A Design of Automated Parking System for Shopping Centers in Metro Manila ... 415

Ma. Janice J. Gumasing, Charles Aaron V. Atienza

Design of an Ergonomic Classroom Chair and Desk for Preschool Students of Selected Public Schools in Cabuyao City, Laguna ... 420

Ezrha C. Godilano, Mark Kevin G. Galang, Hazel Elaine O. Ramilo, Kristian Roi F. Velayo

Design of an Ergonomic Wheelbarrow to Reduce Physiological Demands of General Users ... 424

x

Ergonomic Intervention Addressing Musculoskeletal Disorders among Poultry Layer Workers ... 429

Ma. Janice J. Gumasing, Rex Aurelius C. Robielos

Wristwatch Development Based on Kansei Engineering ... 435

Imam Djati Widodo, Heavy Zerry Novibrilliawan

Innovative Product Development of Fabric Glass Interlayer ... 440

Ploynaplus Thanasiritham, Natcha Thawesaengskulthai, Prasert Akkharaprathomphong

Systems Modeling and Simulation

A Simulation Study of Multi-dimensional Clearing Function Considering Degradation for Semiconductor Manufacturing ... 448

Jianqiu Huang, Jingying Huang, Liya Wang

Productivity Improvement of Tapioca Packing Process through Simulation Modeling Analysis ... 453

Nara Samattapapong

Modelling the Barriers for Mass Adoption of Electric Vehicles in Indian Automotive Sector: An Interpretive Structural Modeling (ISM) Approach ... 458

Surya Prakash, Sameer Sharma Poudel, Maheshwar Dwivedy, Dilesh Raj Shrestha

Diagnostics of the Wire Coating Production Line by Implementation of Computation Methods ... 463

Ivan Kuric, Miroslav Cisar, Ivan Zajacko, Tomas Gal

District Model with Two Types of Vehicles for Transporting Sugarcane ... 468

Rujirat Patcharamethanon, Kanchala Sudtachat

Experiment of Induction Heating Application for Heating Multilayer Metallic Hollow Altered Cylinder ... 475

Jakkarin Srituvanont, Thanaset Thosdeekoraphat, Chanchai Thongsopa, Samran Santalunai

A Framework for Analyzing and Developing Dashboard Templates for Small and Medium Enterprises ... 479

Wasinee Noonpakdee, Thitiporn Khunkornsiri, Acharaphun Phothichai, Kriangsak Danaisawat

An Economic Order Quantity Model with Continous Quantity Discount and Probabilistic Demand ... 484

Ardian Rizaldi, Ashaeurizky Dilianaputri, Fitri A. Anugrah, Riska Ummaya, Senator Nur Bahagia

Technology and Knowledge Management

Analyzing Interdependencies in a Project Portfolio Using Social Network Analysis Metrics ... 490

Helal Al Zaabi, Hamdi Bashir

Sentiment Analysis of Twitter Corpus Related to Artificial Intelligence Assistants ... 495

xi

Artificial Neural Neural Network Approach for Technology Life Cyle Construction on Patent Data ... 499

Muhammad Hanif Ramadhan, Vialli Ibrahim Malik, Teddy Sjafrizal

A Systematic Literature Review on Knowledge Sharing for Innovation: Empirical Study Approach ... 504

Augustina Asih Rumanti, T. M. A. Ari Samadhi, Iwan Inrawan Wiratmadja, Indryati Sunaryo

Belief Representation of Design Mental Model Based on Design Rationale ... 510

Chen Ying, Jing Shikai, Wang Yedong, Cheng Dada

Study on Teaching Methods of Fundamental Electrical Courses in Engineering Education ... 515

Jianpei Chen, Fei Gao, Lingling Kong, Lin Cui

Supply Chain Management

Supply Chain Model for Renewable Energy Resource from Biomass in Vietnam ... 520

Duy Nguyen Duc, Narameth Nananukul

Exploring the Implementation of Green Supply Chain with Cluster and Discriminant Analysis—Case Study: Furniture Industry at Central Java Semarang ... 526

Aries Susanty, Diana Puspita Sari

Systematic Literature Review and Improved Model for Mitigating Bullwhip Effect in Low Shelf Life Food Supply Chain ... 531

Nia Novitasari, Dida Diah Damayanti

Supply Chain Management Performance and Partial Least Square-Structural Equation Model An application to Thai Tourism Supply Chain ... 536

Daraka Palang, Korrakot Yaibuathet Tippayawong

An Economic Competitiveness Analysis of Power Generation Plants ... 543

Ndala Yves Mulongo, Pule Kholopane

Supplier Selection Considering Sustainablitity Criteria by Using A Hybrid Evaluation Method in Printing

Business ... 548

Onsiree Mananawigapol, Chorkaew Jaturanonda, Tuanjai Somboonwiwat

Barriers and Drivers of eBIZ Adoption in the Fashion Supply Chain: Preliminary Results ... 555

Bianca Bindi, Virginia Fani, Romeo Bandinelli, Gilda Massa, Gessica Ciaccio, Arianna Brutti, Piero De

Sabbata

A Simulation Analysis on Regional Logistics Development Based on System Dynamics: The Case of Yunnan

Province ... 560

xii

A Sustainability Assessment of Electricity Supply Systems ... 565

Ndala Yves Mulongo, Pule Kholopane

(Case Study : PT Suwarni Agro Mandiri Plant Pariaman, Indonesia)

Difana Meilani

Industrial Engineering Department Andalas University Padang e-mail: [email protected]

Amelia Andiningtias

Abstract—PT Suwarni Agro Mandiri Plant Pariaman is a company which produces fertilizer. This company has a problem related to raw material inventory. The inventory can be overstock or stock out. It is due to their working which is not guided by an information system. Therefore, this research proposes a decision support system for controlling the inventory of the raw material. The system uses Material Requirement Planning (MRP) approach and is designed in three sub-systems. They are OLTP database for managing the daily activities, MRP for determining the lot size and the raw material ordering time, and OLAP with data warehouse for analyzing the raw material data.

Keywords-inventory; inventory control; online analytical processing; online transaction processing

I. INTRODUCTION

In enhancing effectiveness and efficiency in handling inventory, companies must have inventory control system of firms (5). This system can avoid the financial burden caused by the overload inventory or the production disturbant caused by the run out of stock (5). Furthermore, practicing and embracing the effectiveness of management will improve the competitiveness among the companies (8).

To reach this achievement, the company named PT Suwarni Agro Mandiri Plant which is located in Pariaman must overcome their problems such as the overstock of urea (raw material) and the shortage of Rock Phospate Egypt (RPE). The overstock happens since the urea is ordered in massive amounts in the beginning but are used in some small amounts in the production process, while the RPE shortages happens when there was a stop production due to the small amount of order, but high amount in using the material. This happend around March 2017.

The problems occur because the numbers of raw materials ordered are not determined and the optimal time of ordering is not decided. Facilities for getting information quickly and for giving summary of information relating to

the current status of raw material are also not provided. This condition becomes worse since the management of the company is still using manual way like using worksheet to other divisions of raw material inventory. More time is needed to process the data into a decision maker. In addition, the long duration of the time is also the caused of mis-schedule in ordering the raw material and the delay of delivering raw material to the company. Therefore, a decision support system for inventory control of raw material is developed.

II. METHODOLOGY

This research starts with the process to determine the Material Requirement Planning (MRP) for all raw material. MRP is a method to schedule the purchased planned orders and manufactured planned orders [3],[11]. It is based on

custumers’ orders, sales forecasts, and manufacturing policy

[2].

The company has a production target for each product which the target is for one-year period. This production target is derived as the Master Production Scheduled (MPS) for each product by using disagregate method. After MPS is known, the need for each raw material can be determined by using this MPS. MRP system uses MPS which explodes into a bill of material (BOM) [4]. Generally, MRP uses the following notations, which may vary in some application. They are [9] :

GRi : gross requirements during time period i, SRi : scheduled receipts during time period i, OHi : on hand inventory during time period i, NRi : net requirements during time period i, POi : planned orders during time period i.

Based on the MPS, the amount of raw material and the time to order is determined by using MRP approach. The steps are as followed. Firstly, the netting process is conducted in order to determine the net requirement for each material. Secondly, the lotting process is conducted in order

6

2018 5th International Conference on Industrial Engineering and Applications

Decision Support System for Inventory Control of Raw Material

to determine the optimal lot size for each raw material. In this research, Algorithma Wagner Within (AWW) is used as the lot sizing technique. The last, the offsetting process is conducted to determine the time to release the order plan. The results of those processes are arranged and become a MRP report.

While, the Decision Support System (DSS) is designed with three sub-systems using Waterfall Method. Decision Support System (DSS) is a system to support non-routine decision making for middle management [6]. The steps of designing the DSS are: the first sub-system is determining the Online Transaction Processing (OLTP). This sub-system is designed to help users in managing the daily data using database. It uses PHP as the framework and XAMPP as local server. The second system is MRP application. This sub-system is designed to help users to determine the lot size and time to order, and it also uses PHP as the framework as the first one. The last sub-system is Online Analytical Processing (OLAP). OLAP is the used of graphical tools that allow users to use multidimensional data and allow users to analyze data with a simple graphical interface. [1], [7]. This sub-system is designed to analyze all data of raw material. It helps users to make a decision for inventory control of raw material. This sub-system uses Pentaho Data Integration (PDI) to build a data warehouse. This data warehouse is the source for OLAP to analyze data in multidimensional. Data warehouses are subject-oriented, integrated, time-dimensional data, and the collections are used to support decision-making processes by managers at every level [12].

III. FINDING AND RESULT

A. Determining MPS and MRP

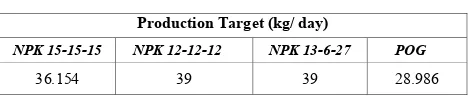

There are two types of fertilizer produced by the company. They are NPK and POG. NPK consists of NPK15-15-15, NPK 13-6-27 and NPK 12-12-12. The production fractions are 0,998; 0,001; and 0,001. The company states that the production target for NPK, is 10.000 ton/year or 833,333 kg/month and for POG is 8.000 ton/year or 666,667 kg/month. Based on the production target, the MPS is derived as the Table I. The horizon of planning is for April 2017.

TABLE I. MPSFORAPRIL 2017

Production Target (kg/ day)

NPK 15-15-15 NPK 12-12-12 NPK 13-6-27 POG

36.154 39 39 28.986

The company has eight types of raw materials. By using the composition for each product, the Gross Requirement (GR) can be determined. The GR which is determined from multiplying the composition of raw material with the amount of product production is needed to calculate the Net Requirement (NR). The NR is the difference between GR and inventory on hand (POH) and Scheduled Receipts (SR). The example of determining the urea, one of the raw materials, NR and POH for day 1 is as followed:

NR = Max (0, GRt– POHt-1- SRt)

This net requirement is needed for determining the lot size using AWW. AWW is chosen since it gives the optimal solution for lot sizing. The steps for calculating the lot size using AWW are as followed:

Step 1. Calculate the cummulative demand (Qce)

for each raw material for each day using the following equation

Step 2. Calculate the total inventory cost (Oen)

using the following equationg q

(2) Note that A is the ordering cost and h is the holding cost.

The Oenfor urea for day 4 is :

Fn is an optimal cost for alternative of ordering policy

until the n period. The Fenfor urea for 4 days ordering are :

F4 = min (F14,F24,F34, F44)

= min(Rp13.419,Rp23.413,Rp22.556,Rp21.700) = Rp13.419

F14 is the cost for ordering raw material from day 1

until day 4 which is calculated as follows :

F14= O14+ F0

= Rp13.419 + Rp0 = Rp13.419

Step 4. Transform the Fn as the lot size

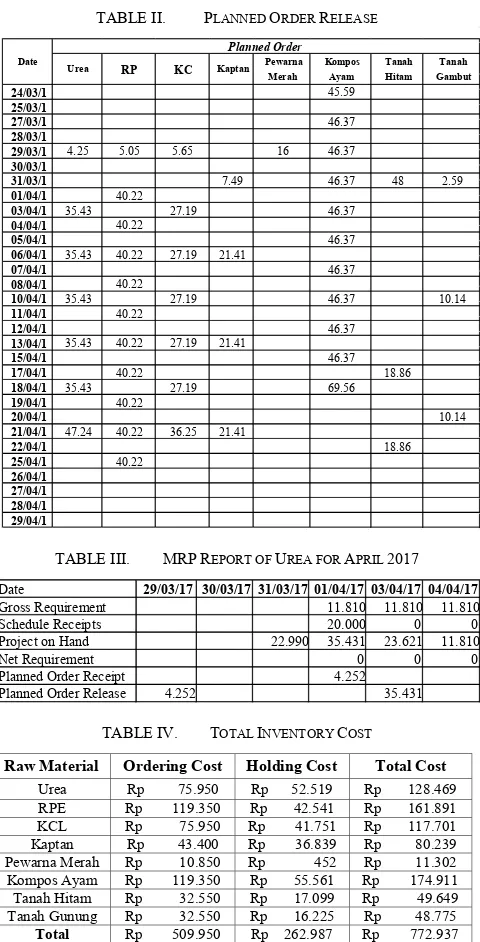

Finally, the planned order release is determined by offsetting process using lead time for each raw material. The lot size is the result of AWW method that has been calculated. The lot size and planned order release for each raw material are as shown in Table II.

All of the results from the processing of determining the MRP is summarized in the form of MRP report. MRP report for urea is shown in Table III.

MRP approach gives information not only about the lot size and time to order raw material, but also the information about the total inventory cost. The total inventory cost is as followed

B. System Design

By analyzing the system, the functional and non-functional needs can be identified. The non-functional needs are: :

TABLE II. PLANNED ORDERRELEASE

TABLE III. MRP REPORT OFUREA FORAPRIL 2017

TABLE IV. TOTAL INVENTORY COST

Raw Material Ordering Cost Holding Cost Total Cost

Urea Rp 75.950 Rp 52.519 Rp 128.469

1. There is an application for calculating the amount of raw material needed based on production rate. Furthermore the Production Planning and Inventory Control (PPIC) division can also control the inventory of raw material.. PPIC which is an integrated application is required to create a raw material inventory report.

2. In the production division, an integrated application is required to record data production.

3. In the logistic division, there is an application that can record the amount of raw material that comes in and out from the warehouse.

4. In the marketing division, an application is required to

manage ordering data of raw material and product

demand

5. For the head of the factory, OLAP application which contains analytical data is required. The data are the amount of raw material usage and raw material entered per period

Meanwhile, the non-functional needs of the system are : 1. Applications can be used by multiple users at the same

time and using different computers.

2. The interface of the application is easy to be understood and operated.

3. The application uses a username and password for users’

authentication.

After analysing the need of system, the system concepts is built. Unified Modelling Language (UML) is used as the language for system concept using visual paradigm software. UML consists of business process diagram, use case diagram, class diagram, and entity relationship diagram. This system concept is executed by programming the program using PHP. The result of programming is the users interface for OLTP sub-system as shown in Fig. 1. This OLTP sub-system is

connected to bahan bakudatabase.

Figure 1. OLTP user interface.

The MRP application is designed after running the OLTP. The MRP application is the model management sub-system which is the design of mathematical models used in the program. This study applies MRP by using WWA method for determining the optimal lot size. The user interface for MRP application is shown in Fig. 2.

Figure 2. MRP application user interface.

Urea RP KC Kaptan Pewarna Merah

29/03/1 4.25 5.05 5.65 16 46.37

30/03/1

31/03/1 7.49 46.37 48 2.59

01/04/1 40.22

03/04/1 35.43 27.19 46.37

04/04/1 40.22

05/04/1 46.37

06/04/1 35.43 40.22 27.19 21.41

07/04/1 46.37

08/04/1 40.22

10/04/1 35.43 27.19 46.37 10.14

11/04/1 40.22

12/04/1 46.37

13/04/1 35.43 40.22 27.19 21.41

15/04/1 46.37

17/04/1 40.22 18.86

18/04/1 35.43 27.19 69.56

19/04/1 40.22

20/04/1 10.14

21/04/1 47.24 40.22 36.25 21.41

22/04/1 18.86

Date 29/03/17 30/03/17 31/03/17 01/04/17 03/04/17 04/04/17

Gross Requirement 11.810 11.810 11.810

Schedule Receipts 20.000 0 0

Project on Hand 22.990 35.431 23.621 11.810

Net Requirement 0 0 0

Planned Order Receipt 4.252

Planned Order Release 4.252 35.431

The last sub-system is OLAP application. It is designed using data warehouse. Data warehouse is obtained from

bahan baku database, after going through the Extract, Transform, and Load (ETL) process. This ETL process is conducted using Pentaho Data Integration (PDI) to get the

uniform data from bahan baku database. The data from ETL

process is loaded to a new database named data warehouse. This data warehouse is non-volatile, and will be used further using OLAP tools named SAP lumira. The OLAP user interface using SAP lumira is shown as Fig. 3.

To make sure this system is running well, a testing is conducted to this system. The testing is to verify that this system is no error and gives the same value for MRP calculation. The testing which validates the system is fit with the user needs of the system. This system is verified and validated.

Figure 3. OLAP application user interface.

IV. DISCUSSION AND ANALYSIS

A. Actual System and Propose System Analysis

The decision support system is designed to help users in PT Suwarni Agro Mandiri such as the head of factory, PPIC division, production division, logistic division, and also marketing division to manage their data of daily activities. By using this system, the data is easier to be collected, processed, and transformed into information. As a decision maker, the PPIC division can calculate the amount of raw material easily and the time to order the raw material from supplier using the MRP application.By using MRP approach, the company will save Rp348.901 in April 2017 if they order the raw material based on planned order release from MRP. Table V shows the different cost between actual system and the proposed system.

TABLE V. TOTAL INVENTORY COST

Actual Propose Actual Propose Actual Propose Urea Rp 119.350 Rp 75.950 Rp 127.909 Rp 52.519 Rp 247.259 Rp 128.469

Raw Material Ordering Cost Holding Cost Total Cost

B. The Advantage and Disadvantage of The System

There are some advantages of the decision support system, such as :

1. The flow of information is clear

The forms contained in the application is based on the activities performed by each user. As in the design of business process diagrams and use case diagrams, information flowing from one user to another user occurs according to the information needs of the user and the information can be known by looking at the usefulness of the information.

2. Friendly user interface

The appearance of the designed application has been adjusted to the needs of users of the system. In addition, the display is designed to be attractive and to be understood and utilized easily by the user.

3. Data Security

The system is designed to have different access rights, based on the needs of users and the role of users in the system. The head of the factory can only see the data of raw material usage, while the PPIC division can input data and see the data of raw material usage.

4. Able to perform the calculation of inventory control

The ability of inventory control calculation feature facilitates the division of PPIC in determining raw material inventory policy that must be done. PPIC division can know the quantity and time of ordering of raw materials.

Beside, there are some disadvantages of this decision support system, such as :

1. The proposed system has not been able to display

the user interface for OLAP.

The proposed system only at the stage of building a data warehouse for OLAP. As for displaying the output of OLAP, additional software such as SAP Lumira to display analytical data in the form of graph is still needed

2. There is still a process of inputting manually in determining the inventory control of raw material. In the process of calculating raw material inventory control, the application still needs the user translating the tables of the calculation of costs into the lot size of ordering at the lotting stage. This is because at this stage, there are two variables that must be determined simultaneously, namely the amount of order and order time. To determine the amount and the time of ordering can be done through trial and error stage by following algorithm rule wagner within in determining lot size. With such limitations, the system is designed only to the limit of displaying the calculation results, while the process of translation of raw material size and ordering time is done using the user knowledment.

V. CONCLUSION

The conclusions obtained from the results of this study are as follows:

1. The proposed system for inventory control of raw

material in PT Suwarni Agro Mandiri Plant Pariaman is conducted by using Material Requirement Planning (MRP) approach. Based on the results of lotting using AWW method, it is

known that the total cost of inventory for one planning period is Rp772.937. The output obtained from this method is the optimal order quantity and ordering time for each raw material.

2. The proposed decision support system for inventory control of raw material in PT Suwarni Agro Mandri Plant Pariaman with MRP method has performed inventory control, input data that related with raw material, and reported inventory which is integrated to each other. In addition, this system has a data warehouse that can be used to perform the process of inventory data analysis.

ACKNOWLEDGMENT

Authors would like to thank to Engineering Faculty, Andalas University for providing publication grant 2018.

REFERENCES

[1] A Cravero and S. Sepulveda,“Methodologies, Techniques and Tools for OLAP Design: A Systematic Mapping Study”, IEEE Latin America Transactions,Volume: 14 Issue: 2, 2016. DOI: 10.1109/TLA.2016.7437244.

[2] Farrington, B., & Lysons, K. Purchasing and Supply Chain Management. London: Pearson Education, 2006.

[3] H. Stadtler,“Supply Chain Management and Advanced Planning -Basics, Overview and Challenges, European Journal of Operational Research, Vol 163, Issue 3, P 575-588, 2005.

[4] Jacobs, F. R., Berry, W. L., Whybark, D. C., & and Vollmann, T. E. Manufcturing planning and control for supply chain management. New York: McGraw, 2011.

[5] Kennedy M. M., Margaret o., Walter O., Effect Of Inventory Control Systems On Operational Performance Of Tea Processing Firms, Kenya, Volume 1 Issue 5, 2013.

[6] Loudon, K. C., & Loudon, J. P., Managing The Digital Firm. 12th

Edition. Prentice-Hall, 2012.

[7] Mohamed L, Stefano R, Rachid C, Exodus: Exploratory OLAP over Document Stores , Information Systems, 2017.

[8] Rajeev, N. An Evaluation of Inventory Management in Indian Machine Tool SMEs: An exploratory. 4th IEEE International Conference on Management of Innovation and Technology (pp. 1412-1417). Bank, Thailand: bank, 2008 pp.1412-1417.

[9] Ramen Sadeghian, Continuous Materials Requirements Planning (CMRP) Approach When Order Type is Lot for Lot and Safety Stock is Zero and Its Applications, Elsavier, 2011.

[10] Rushton, A., Croucher, P., & Baker, a. P. The Handbook of Logistics and Distribution Management. London: Kogan page ltd, 2011. [11] Thomas E.. Vollmann, William L.. Berry, DC Whybark,

Manufacturing and Control System, Irwim/McGraw-Hill 2, 1997. [12] Vishal Gour, S. S. Sarangdevot, et. al, Improve Performance of

Extract, Transform and Load (ETL) in Data Warehouse. International Journal on Computer Science & Engineering, Volume 2 No. 03, 2010.