The 5

th

Indonesia

Biotechnology

Conference

An Interna tiona l Forum

The 5

th

Indonesia

Biotechnology

Conference

An Internationa l Forum

P R O C E E D I N G S

Ma ta ra m , July 4th-7th 2012

The 5

th

Indonesia

Biotechnology

Conference

An Internationa l Forum

P R O C E E D I N G S

July 4

th-7

th2012

Sa ntosa Ho tel, Seng g ig i Bea c h

M a ta ra m , Lo m b ok Isla nd

Provinc e of We st Nusa Teng g a ra , Ind o nesia

Hosted by:

7

Invited Spea kers (Plenary Session)

... 27Lunch Symposia ... 57

Concurrent Session & Post er Present at ions ... 60

Agricult ure & Forest ry Biot echnology ... 61

Energy & Environm ent al Biot echnology ... 463

Healt h & M edical Biot echnology ... 702

Indust rial Biot echnology ... 919

LIST OF PARTICIPANT ... 1009

LIST OF THE 5

thIBC COMMITTEE... 1047

9

The 5th Ind o nesia Bio tec hno lo g y C onferenc e

M a ta ra m , July 4-7th 2012

Foreword from Cha irma n of Orga nizing

Committee

11

The 5th Ind o nesia Bio tec hno lo g y C onferenc e

M a ta ra m , July 4-7th 2012

Foreword from Rector of Universita s

Indonesia

13

The 5th Ind o nesia Bio tec hno lo g y C onferenc e

M a ta ra m , July 4-7th 2012

Genera l Sche dule : Da y 1

15

The 5th Ind o nesia Bio tec hno lo g y C onferenc e

17

The 5th Ind o nesia Bio tec hno lo g y C onferenc e

M a ta ra m , July 4-7th 2012

Genera l Sche dule : Da y 2

19

The 5th Ind o nesia Bio tec hno lo g y C onferenc e

21

The 5th Ind o nesia Bio tec hno lo g y C onferenc e

23

The 5th Ind o nesia Bio tec hno lo g y C onferenc e

469

The 5th Ind o nesia Bio tec hno lo g y C onferenc e

M a ta ra m , July 4-7th 2012 << Back t o t able of cont ent s

O 30

The Utilization of Palm Oil M ill Effluent (POM E) for

Bioenergy through W ild Algae Treatment

Hadiyant o

Cent er of Biom ass and Renew able Energy (CBIORE), Depart m ent of Chem ical Engineering, Facult y of Engineering, Diponegoro Universit y,

Jl. Prof. Sudhart o, SH-Tem balang Sem arang 50239 hady.hadiyant o@gmail.com filt ered and m easured as dry w eight . Result indicat ed t hat Chlorella sp at 50% POM E 1gr/ L urea show ed higher specif ic grow t h rat e (0.066/ day). Fact or affect ing grow t h rat e of m icroalgae is CNP rat io, POM E concent rat ion, and urea concent rat ion

1. Introduction

Table 1. Com m odit ies of Indonesia agricult ure 2010-2014

471

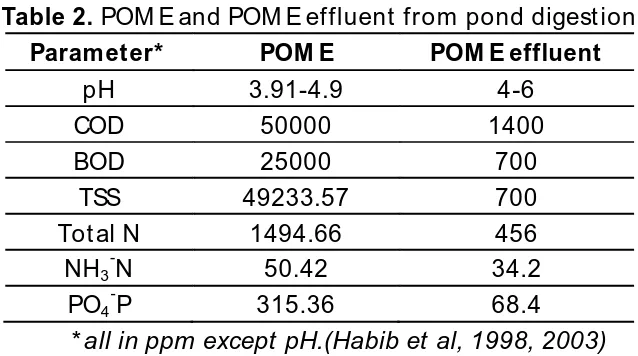

can not be avoided because wit hin 15 years, t he oil reserve w ill be dim inished; t he exploring of new renew able energy resources is a vit al. M icroalgae can be considered as t he one w hile POM E w hich has high COD is also pot ent ial as biogas sources. To be used as nut rient of m icroalgae, POM E m ust have low BOD cont ent s.2.2. Algae cult ure

Wild algae was obt ained from pond area in PTPN VII Lam pung and Bioprocess Laborat ory, Diponegoro Universit y.The w ild algae

w ere ident ified for t heir species at Bioprocess Laborat ory. Chlorella

sp and Spirulina w ere collect ed from BBPAP Jepara and cult ivat ed w hich w as cont aining Spirulina and Chlorella.

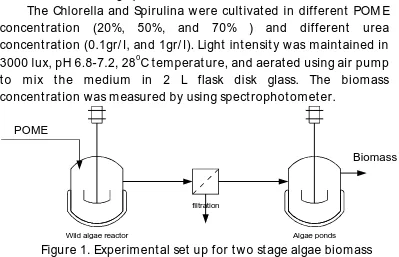

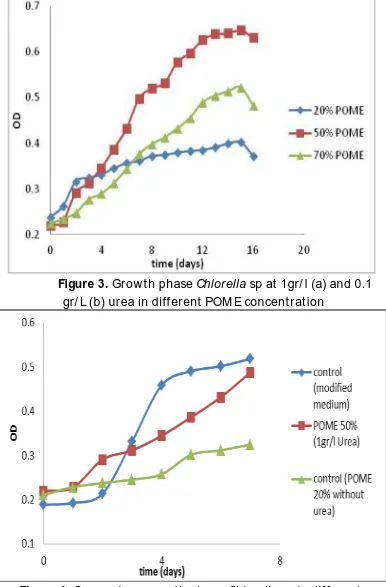

The Chlorella and Spirulina w ere cult ivat ed in different POM E concent rat ion (20%, 50%, and 70% ) and different urea concent rat ion (0.1gr/ l, and 1gr/ l). Light int ensit y w as m aint ained in 3000 lux, pH 6.8-7.2, 280C t em perat ure, and aerat ed using air pum p t o m ix t he m edium in 2 L flask disk glass. The biom ass concent rat ion was m easured by using spect rophot om et er.

473

w as calculat ed using biom ass produced divided by cult ivat ion t im e.3. Result and Discussion

3.1. Wild algae

The wild algae w as grow n w ildly in an open t ank, w it hout addit ion of ext ernal nut rient s. The m ost species appeared in t he cult ure w ere Chlorella and Scenedesmus. The grow t h of w ild algae

w as evaluat ed under POM E m edium (Table 3) Chlorella and Scenedesm us have been recognized as

m icroalgae t hat produce lipid cont ent bet w een 20-30%.

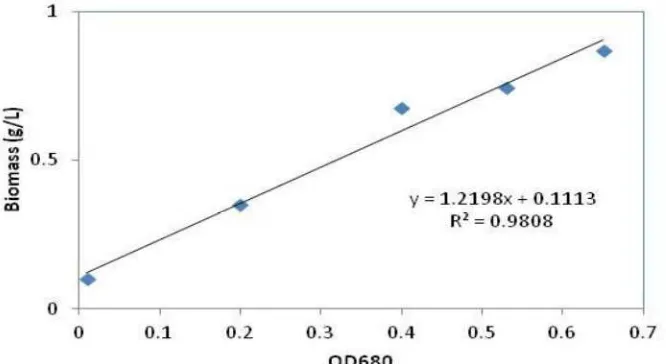

3.2. Biomass vs Opt ical densit y for algae

Figure 2. Correlat ion bet w een OD and Dry M ass Chlorella sp

475

The 5th Ind o nesia Bio tec hno lo g y C onferenc e

M a ta ra m , July 4-7th 2012 << Back t o t able of cont ent s

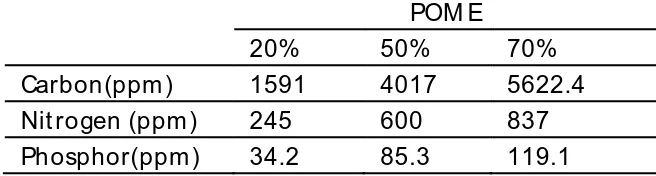

Table 5. Concent rat ion carbon, nit rogen, and phosphat e in POM E

in dif ferent concent rat ion POM E 1980) w it h recom mended rat io of 56:9:1. According t o equat ion of POM E aft er adding urea, CNP rat io has changed (Table 6):

Table 6 CNP ratio in POM E after additional urea

Figure 3. Grow t h phase Chlorella sp at 1gr/ l (a) and 0.1

gr/ L (b) urea in diff erent POM E concent rat ion

477

vulgaris, Chlorella pyrenoidosa, Bot rycoccus sudet icus, Tet raselmis sp). The result s in Specific grow t h rat e were 0.099/ day, 0.084/ day,0.048/ day, 0.083/ day and 0.065/ day, respect ively. In t he research, dilut ed POM E could have low er t annic acid, so it did not inhibit phot osynt het ic react ion. Com pared by biom ass product ion, t he result show ed t hat highest biom ass can reached in 8.0 m g/ l/ day. In t his experim ent , highest biom ass w as reached in 58.4 m g/ l/ day. POM E concent rat ion m ay lim it in biom ass form ing, due t o high carbon, nit rogen, and phosphor source.

According t o t his research, higher urea concent rat ion also influences in specific grow t h rat e of Chlorella sp. Urea influences in Chlorella `s grow t h (El Sayed et al., 2011) and t he concent rat ion

also inf luences in biom ass product ion (Choochot e et al., 2010, M andalam & Palsson, 1998). W ijanarko (2011) in his research also st udied influences urea as nit rogen source and conclude t hat urea has pot ent ial nut rient for Chlorella t han nit rat e. It also can increase

grow t h rat e and biom ass product ivit y. The biom ass form ing

Chlorella vulgaris based t he research is:

Wijanarko (2011) also report ed t hat high urea concent rat ion t hat concent rat ion, and urea concent rat ion.

Acknow ledgement

This research is part of project Indonesian Aquat ic Biom ass, w it h consort ium mem bers: PT Wirana, M aris Project BV and KU Leuven belgium

References

Cheirsilp, Benjam as and Torpee, Salw a. 2012. Enhanced grow t h and Lipid product ivit y of m icroalgae under m ixot rophic cult ure condit ion: Eff ect of light int ensit y, glucose concent rat ion and fed-bat ch cult ivat ion. Bio resource Technology 110 pp. 510 516

Choochot e, W eena., Paiboonsin, Kerkkiat ., Ruangpan, Siripong., and Pharuang, Akkaphop. 2010. Effect s of Urea and Light Int ensit y on t he Grow t h of Chlorella sp. The 8t h Int ernat ional

Sym posium on Biocont rol and Biot echnology.

ht t p:/ / w w w.science.km it l.ac.t h/ downloads/ proceeding_2/ 22%2 0page127-134.pdf

Dept an. 2009. Rancangan Rencana St rat egis Kem ent rian Pert anian Tahun 2010-2014 w w w .dept an.go.id.

Edw ards, P., O.A. Sinchum pasak and Ouano, E.A.O.. 1980. A st udy of a sew age fed highrat e st abilizat ion pond in Thailand. Wast ew at er and Resources Recovery (IDRC-15e). Int ernat ional Developm ent Research Cent re, Ot t aw a, Canada. p. 42.

479

nut rient s of agro indust rial effluent s in M alaysia. Asian Fisheries Science 11(3): 279-286.Habib, M .A.B., Yusoff, F.M ., Phang, S.M ., Kam arudin, M .S. and M oham ed, S. .2003.Grow t h and Nut rit ional Values of M olina m icrura Fed on Chlorella vulgaris Grow n in Digest ed Palm Oil

M ill Effluent . Asian Fisheries Science 16 : 107-119.

M andalam , R.K., Palsson, B.Ø., 1998. Elem ent al balancing of biom ass and m edium com posit ion enhances grow t h capacit y in high-densit y Chlorella vulgaris cult ures. Biot echnol. Bioeng. 59,

605e611.

Puangbut , M ut iyaporn and Leesing, Rat anaporn. 20120. Int egrat ed Cult ivat ion Technique for M icrobial Lipid Product ion b y Phot osynt het ic M icroalgae and Locally Oleaginous Yeast . World Academ y of Science, Engineering and Technology 64.

Put ri, E.V., Din, M .F.M ., Ahm ed, Z., Jam aluddin, H., and Chelliapan, S. 2011. Invest igat ion of M icroalgae for High Lipid Cont ent using Palm Oil M ill effluent (POM E) as Carbon Source.Int ernat ional