Biodegradable plastic made from bean products

E.M. Salmoral

a,*, M.E. Gonzalez

b, M.P. Mariscal

aaDepartment of Chemistry,Engineering Faculty,Buenos Aires Uni6ersity,Paseo Colon850 (C.P.1063),Buenos Aires,Argentina bTechnological and Agricultural Unit,Ezeiza Atomic Center,National Atomic Energy Commission,Argentina

Accepted 8 October 1999

Abstract

The aim of the present work was to explore the suitability of two kinds of bean with typical protein quality and different starch structure to produce moulded specimens by compression. In this work we analysed the possibility of forming new plastic materials from two kinds of bean preparations; with different protein content, in the presence or absence of inherent cellulose material and other biopolymer such as starch. Significant differences were determined in the fine structure of glucopolysaccharides isolated from the different types of bean. Complete moulding of the specimens took place at 20 MPa at a temperature not higher than 140°C, for 7 min. The mechanical properties of the moulded plastics based on soluble protein black bean (BP) were superior in elongation, tensile strength and low water absorption than the soluble protein white bean (WP) variety. However, the addition of boric acid 3% (w/w, in total batch basis) to white bean plastic materials was effective in improving slightly the mechanical properties in the case of their whole flours products (WWF). The gamma radiation was effective to reduce water absorption only in plastics materials with cellulose – starch content (BWF, WWF) and improved their mechanical properties. The gelatinization process of the moulded material was influenced by the predominant lineal structure of the carbohydrate content. © 2000 Elsevier Science B.V. All rights reserved.

Keywords:Biodegradable plastics; Agricultural plastics; Bean protein; Gamma-irradiation

www.elsevier.com/locate/indcrop

1. Introduction

The use of renewable natural polymers in the manufacture of plastics grows in impulse and importance in the last years of the 20th century. Many major chemical companies are becoming increasingly interested in developing technologies

for the manufacturing of products from crops. Among the products derived from the legumi-nous studied for manufacturing plastics, are the soy isolate prepared by precipitation at pH 4.5, with 90% protein; the soy concentrate, prepared by eluting soluble components from defatted soy flour with 70% protein and about 18% carbohy-drate and soy flour with lower protein content, from 50 to about 34% (Kinsella 1979; Salt et al., 1982).

In the present work we employed as raw mate-rial two leguminous varieties like Phaseolus 6ul -* Corresponding author. Tel.:+54-11-43430891; fax:+

54-11-43121191.

E-mail addresses:[email protected] (E.M. Salmoral), [email protected] (M.E. Gonzalez)

garis L., from which there is evidence about their prehistoric existence in South America. Their greatest production is in the North West of Argentina.

The black bean used is a cultivar noticeable for its high resistance to viral diseases of warm areas and it is eventually of high yield (Vizgarra, 1995). We have utilised the white bean cultivar be-cause it is commercially important and has also been submitted to phyto-improvement by agro-nomic experiments.

The seeds, which are typical of Argentina, were defatted; their polysaccharides, proteins and fiber isolated, purified and quantified.

Starch is a mixture of two polysaccharides: amylose (in which predominates linear a-1,4

glu-can), and amylopectin (highly brancheda-1,6

glu-can with branching points occurring through

a-1,6 linkages).

The two components: amylose and amylopectin are present in varied ratios, depending on the vegetal source (Salmoral et al., 1993). In our case, the starch was used in addition to glycerol as plasticizers and was selected in order not to re-duce the biodegradability of biopolymers.

Boric acid is reported to be able to react with glycerol and starch forming a network among starch chains and glycerol molecules. It has been suggested the existence of crosslinks among starch, glycerol and boric acid. Crosslinks be-tween OH- of the components caused by boric acid would enlarge the molecules and so prevent the segments for easy moving (Yu et al., 1998).

In the present work, the addition of boric acid to the blend in a dose non toxic was studied. We examined the effect of gamma radiation on blends of proteins and defatted whole flour with respect to the mechanical properties and the water ab-sorption of the molded plastics.

Gamma radiation has been reported to be use-ful in the crosslinking of proteins (Ressouany et al., 1998), which would mean an increase in the tensile strength of the product.

On the other hand, ionizing radiation acts on polysaccharides by breaking C – C bonds and forming acid and reductive groups (Pruzinek and Hola, 1987)

The objective was to compare two different varieties of crop products of legumes ofPhaseolus 6ulgaris L.

2. Materials and methods

2.1. Materials

2.1.1. Culti6ation

Phaseolus 6ulgaris L., black bean Tuc 500 and white bean Alule 91 were obtained from the Ex-perimental Station of the National Institute of Agricultural Technology (INTA), from Tucuma´n and Salta, Argentina.

2.1.2. Soluble protein preparation

Black bean soluble protein (BP) and white bean soluble protein (WP) (patent pending) were pre-pared in the laboratory using pulverized seeds; ground in a mill and defatted by the Soxhlet method. After treatment with 0.001M NaHSO3

and the homogenization at pH not higher than 6. The material was filtered to separate the cellulose material. The supernatant was decanted and the rest of the suspension was concentrated by evapo-ration and finally lyophillized. It was kept at 4°C, and the protein content determined (50%).

2.1.3. Whole flours

Black bean whole flour (BWF) and white bean whole flour (WWF) were prepared in the labora-tory by crushing the seeds, defatting the powder by the Soxhlet method and pulverizing the mate-rial with help of a mill until it could be sieved through a 230 ASTM mesh. It was kept at 4°C and the protein content determined (BWF; 32%, WWF; 30%).

2.1.4. Glucopolysaccharides

In the process of isolation the pulverized seeds were soaked in 0.005 M NaHSO3, homogenized

and squeezed in cheesecloth thus obtaining a su-pernatant that was decanted. The precipitated was submitted to several washes with: NaCl in aqueous solution, NaCl in aqueous solution/

washed, dried and defatted by the Soxhlet method.

The purification process: the a1,4 –a1,6

gluco-polysaccharides were purified in Biogel P6 (100 – 200 mesh) before analysing its structural characteristics (the wavelength of maximum ab-sorption and the polysaccharide spectra were analysed in a UV-VIS Beckman spectro-photometer).

The structural analysis of the a1,4-a1,6 linked

glucopolysaccharides, was described in a previous paper (Tolmasky and Krisman, 1987; Salmoral et al., 1993).

The proteins were quantified by Kjeldhal method and in the washing solutions by the Lowry method ( Lowry et al., 1951).

2.2. Preparation and plasticization of mixtures

2.2.1. Blend

The starch (11.7%) of total weight gelatinized with water and the glycerol (21.7%) of total weight were incorporated to either the protein soluble fraction or the whole flour material. The water content of these blends was 28%. All pro-portions are w/w in total batch basis. The blends were kept at 4°C for 24 h in closed containers for stabilisation previously to the compression process.

2.2.2. Treatment with boric acid

The blend was prepared with the addition of boric acid 3% (w/w in total batch basis).

2.2.3. Specimen preparation

Specimens were prepared from bean products (soluble protein preparation and whole flour preparation) following the same technique em-ployed for soybean products described elsewhere (Salmoral et al., 1998).

The carefully homogenised blends were left to stand to reach a temperature of 23°C in closed containers and were immediately submitted to compression-moulding under the following condi-tions: compression load, 20 MPa; molding tem-perature, 120 – 130°C and molding time 7 min. Plates 0.7 mm thick were obtained. Specimens for microtensile tests according to ASTM D-1708

(ASTM 1984) were cut out of the plates and conditioned at 23°C, 70% relative humidity for 48 h.

The borders and edges were polished as well as the surfaces with abrasive sandpaper. This kind of specimens was chosen in order to be able to prepare large numbers of specimens with rela-tively small amounts of material, for each kind of composition tested. The mechanical properties were measured in this work only for comparative purposes among the different materials employed, not intending to define basic properties of the materials.

2.3. Irradiation

Irradiation of some of the blends was carried out with gamma beams from a Co-60 source, at a dose rate of 9.5 kGy/h to a total dose of 50 kGy. The samples were packed in polyethylene flasks in the presence of air. The temperature in the irradi-ation chamber never surpassed 30°C. The dosime-try was performed by means of dichromate dosimeters for high doses. The homogeneity of dose within the samples was of 30%.

Irradiation was always performed after 24 h of blend preparation. The time from irradiation to compression moulding was also of about 24 h. In all cases irradiated and non-irradiated samples were processed and tested in the same batch.

2.4. Water absorption

Water absorption was measured according to ASTM D 570 95 (ASTM, 1995). Samples 8.0 mm×15 mm and 1.5mm thick were conditioned in an oven for 24 h at 5093°C, then cooled in desiccator and weighed to a nearest 0.001 g. The samples were immersed in distilled water for 2 h at 23°C and immediately weighed to determine the absorbed water; process utilised for materials having a relatively high rate of absorption.

2.5. Mechanical testing

and percent elongation at breakage were mea-sured using at least five specimens for each com-position or treatment tested. The reported results are averages of the experimental values. Due to the limitations pointed by ASTM D-1708 we did not intend to measure the modulus. Tensile tests were performed after temperature and relative humidity of stabilisation of specimens.

It was necessary to measure the moisture con-tent of samples before mechanical testing below 1% because of the R.H. conditioned was different from the standard condition of 50%.

2.6. Statistic results

The results were analysed by means of the Student’s t-test.

3. Results

In each case the starch employed was obtained from the same vegetal species and purified. The characterisation of the chemical structure showed that the white bean starch has a ratio of amylose to amylopectin structure of 70/30, while for the black bean the ratio is 95/5. The degree of branching points in the black bean starch was found to be 2.9. It was obtained from the rela-tionship between thelmax and the percentage of

a1,6- linked glucose. The 2.9 value founded in the

black bean can be more accurately interpreted by comparison with the value of the degree of branching points of rabbit liver glycogen 9.4,

phytoglycogen 7.1, amylopectin 5.7 and amylose of sweet corn maize 1.4 (Tolmasky and Krisman, 1987). This relations suggest the presence of an amylose with a relatively high degree of branching points.

The absorption spectrum of the predominant glucopolysaccharide presents l max=580 nm in the presence of CaCl2– I2– KI reagent in both

cultivars. The preparation of blends for molding from defatted soy whole flour black and white bean whole flour was performed under the same conditions and proportions used for the protein preparation.

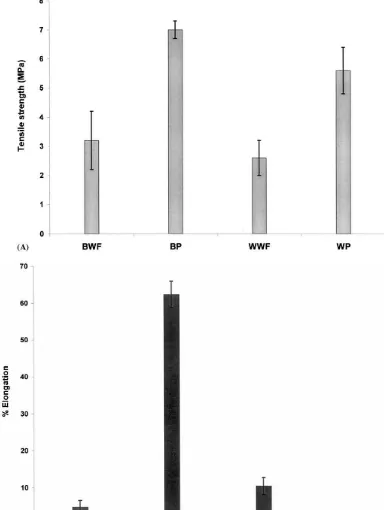

When ultimate tensile strength of the plastic materials from whole flours of black and white beans are compared with those from the protein soluble fractions, it is found that the tensile strength (MPa) is significantly higher for protein materials (BP, PB B0.001) and (WP,PB0.001) with respect to the whole flour materials (BWF) and (WWF). This effect was common to both varieties of beans ( Fig. 1A).

When elongation at breakage is analysed, a notable difference between both varieties of beans can be observed. While the protein plastic com-pound of black bean (BP) reaches a high elonga-tion respect of BWF, PB B0.001, the white plastic bean variety shows better elongation in their whole flour compound WWF, PB B0.001 than the protein plastic compound (WP) (Fig. 1B).

Moreover, the % elongation in the BP com-pound is seven times higher than WP comcom-pound, 0.01BPB0.001. The water absorption of these

Table 1

Water absorption of materials %a

Blend Blend ba Blendi

s

s s

0.70

Black bean BWF 27 1.00 31 0.91 17

BP 22 0.45 22 1.50 21 0.40

White bean WWF 29 2.00 30 3.00 20 0.06

0.69 18 1.20 21 0.70

WP 21

aBlack bean whole flour (BWF); black bean protein preparation (BP); White bean whole flour (WWF); White bean protein

Fig. 2. Effect of boric acid. Mechanical properties of soluble protein preparation of black bean (BP), soluble protein preparation of white bean (WP), black bean whole flour (BWF) and white bean whole flour (WWF). Tensile strength expressed in MPa.: Elongation %. Blend. isolate or defatted whole flour+11.7% starch+21.70% glycerol +3% boric acid.

same materials can be seen in Table 1. Whole flour materials BWF, 27% (s=1.0); WWF, 29% (s=2.0) absorb 2095% more water than protein materials BP, 22% (s=0.45); WP, 21% (s= 0.69); in all cases water absorption was below 30%.

3.1. Boric acid treatment

The effect on mechanical properties, tensile strength and elongation by the addition of boric acid in a concentration of 3% to the blends con-taining 11.7% starch and 21.7% glycerol are shown in Fig. 2.

The result obtained show that neither the ten-sile strength nor the % elongation favourably influenced in plastic compounds based on black bean. There is also no positive influence in water absorption of these materials, as can be seen in Table 1.

When the results of mechanical properties of white bean plastics materials are analysed, a dif-ferent behaviour can be appreciated. The tensile strength only increases in the whole flour material from WWF, 2.5 – 4.5 MPa (PB B B0.001). The % elongation resulted improved in the WWF from 1.8 to 5.6 (PB B0.001); in WP from 2.5 to 3.5 (PB B B0.001), as can be seen by comparing Fig. 1B and Fig. 2. There was no positive influ-ence in water absorption.

3.2. The gamma radiation

Regarding percentage of elongation, only WWF was improved from 2.5 to 10.5, PB B 0.001.

The water absorption was reduced in both whole flour plastic compounds BWF, 17%, and WWF, 20%.

4. Discussion

It has been demonstrated in Fig. 1 that the protein black bean compound (BP) reaches the higher percentage elongation and the higher ten-sile strength, which are not attained by the other materials studied. These results can be attributed to the chemical characteristics inherent in the cultivars under study.

The interpretation requires having into account the remarkable difference in chemical composition

existing between the soluble protein preparations BP, or WP and the defatted whole flours com-pounds BWF or WWF. These latter materials have 21.3 and 18% of cellulose content respec-tively, which is absent of the BP and WP materi-als. It should be remarked that the protein quality inherent to the vegetal species would have an influence on the gelatinization process considering that among proteins, the properties of hydration dampness or absorption and retention of water depend on the interactions protein – water which depend also on pH and ionic strength.

The much higher elongation in BP can be un-derstand by the improved protein-protein interac-tions with better possibility of plasticization when the cellulose content is absent. However, the im-proved tensile strength, also suggests the influence of the typically quality protein of each cultivar, because of the WP compound has similar but reduced behaviour.

Moreover, the presence of lecithin in the solu-ble protein fraction based on black bean seeds would be contribute to the plasticization process (actually in study at the laboratory).

It is known besides, that the starch structure determines the properties of starch material, such as stability, degradability, texture, mechanical and thermal properties. There is a diversity of molecu-lar and supramolecumolecu-lar structures in processed starch materials depending on starch source, par-ticularly amylose/amylopectin ratio, moisture and plasticizer content (Van Soest, 1996).

The starches in study possess different ratio of amylose/amylopectin, 70/30 and 95/5, in white and black bean respectively.

This work shows a highly hydrophilic carbohy-drate chains in the case of predominant amylose structure that would have better influence on the gelatinization process in the presence of water and consequently in the mechanical properties of the BP plastic material.

Irradiation of blends produced an appreciable effect regarding tensile strength and water absorp-tion capacity of whole flour products. We did not found an effect of plasticization that would have resulted in case of degradation of starch molecules. This effect would have been noticeable as an improvement in elongation.

The cellulose material present in the defatted whole flour could be affected by radiation through breaking of chains and introducing radi-olytic products. Both effects would enhance the reactivity of the cellulose material (Stepanik et al., 1998).

The improvement in tensile strength and water absorption observed could be attributed to inter-actions among cellulose chains, proteins and the amylopectin starch structure.

Fig. 2 shows that boric acid only has chemical effect on materials based on white beans; this effect improves the mechanical properties, which was associated with the presence of different kind of starch.

The plastic products of beans studied absorb not more than 30% of water. These values are four times lower than that of the soy whole flour and two times lower than the protein soy isolate respectively, treated in similar conditions. (Salmoral et al., 1999).

At the moment of this presentation biodegrad-ability essays have begun at our laboratory. Fur-ther experiments with the purpose to improve the presented plastics are to be carried on, among them the elucidation of the protein quality of the beans.

5. Conclusion

Black and white bean leguminous under study proved to be potential raw materials for manufac-turing biodegradable plastics by compression moulding.

The plastic materials obtained from soluble protein preparations without cellulose content and those formed by whole flours have different mechanical properties in some cases. This result may be attributed to the association protein – glu-copolysaccharide (amylose or amylopectin) in presence of glycerol and water as plasticizers.

So, the plastic material based on black bean, made with a glucopolysaccharide characterized by its prevailing amylose structure, is outstanding because its elongation as well as its tensile strength are higher than all the studied materials and because of its low ability to absorb water.

It could be said that, in the conditions em-ployed in this study, black bean produced plastic materials with better properties than all soybean materials, such as protein isolate and whole soy flour.

On the other hand, plastics based on white bean with glucopolysaccharide characterised by having higher amylopectin content had poorer mechanical properties and higher water absorption.

Nevertheless, the mechanical properties could be improved, the same as water absorption, by including boric acid in the blends of black bean legume. However there was a slight improvement in the mechanical properties of whole flour white bean.

The protein soluble fractions resulted better than the defatted whole flours in both bean varieties.

The economic advantage is that we can utilise in the plastic moulding process, the destroyed seeds which are habitually rejected as wastes.

Acknowledgements

Research and Doctorate Department, Engineer-ing Faculty of Buenos Aires University,for finan-cial support. For provision of seeds: to Eng. L.F. Medina and Experimental Stations of National Institute of Agricultural Technology ( INTA). For lyophillization of samples to National Institute of Seeds and Matias Langan.

References

ASTM, 1984. ASTM Standard D-1708 Standard test method for microtensile tests of plastics, American Society for Testing and Materials, Philadelphia.

ASTM, 1995. ASTM Standard D-570 Standard test method for water absorption of plastics, American Society for Testing and Materials, Philadelphia.

Kinsella, J.E., 1979. Functional properties of soy proteins. Am. Oil Chem. Soc. 56, 242 – 258.

Lowry, O.H., Rosebrough, N.J., Ferr, A.L., Randall, R.J., 1951. Protein measurements with the Folin phenol reagent. J. Biol. Chem. 193, 265 – 275.

Pruzinek, J., Hola, O., 1987. Starch degradation by irradia-tion. J. Radioanal. Nucl. Chem. Lett. 118 (6), 427 – 431. Ressouany, M., Vachon, C., Lacroix, M., 1998. Irradiation

dose and calcium effect on the mechanical properties of cross -linked caseinate films. J. Agric. Food Chem. 46, 1619 – 1623.

Salmoral, E.M., Cura, J.A., Pagano, E., Tolmasky, D., Lepek, V., Favret, E., et al., 1993. Comparative studies of the

a-1,4a-1,6 glucopolysaccharides from crops of commercial

interest. An. Asoc. Quim. Argent. 81 (2 – 3), 179 – 187. Salmoral, E.M., Gonzalez, M.E., Mariscal, M.P., Medina,

L.F., 1998. Plastic compound of soy. Fifth Latin American Symposium of Polymers, Chile.

Salmoral, E.M., Gonzalez, M.E., Mariscal, M.P., Medina L.F. 1999. Biodegradable plastics made from chickpea and soy. Fourth European Symposium on Industrial Crops and Products together with the Sixth Symposium on Renew-able Resources for the Chemical Industry, Bonn, Germany.

Salt, D.J., Leslie, R.B., Lillford, P.J., Dunhill, P., 1982. Fac-tors influencing protein structure during acid precipitation. A study of soy proteins. Eur. J. Appl. Microbiol. Biotech-nol. 14, 144 – 148.

Stepanik, T.M., Rajagopal, S., Ewing, D., Whitehouse, R., 1998. Electron processing technology: a promising applica-tion for the viscose industry. Rad. Phys. Chem. 52, 505 – 510.

Tolmasky, D., Krisman, C.R., 1987. The degree of branching ina-1,4a-1,6 linked glucopolysaccharides is dependent on

intrinsic properties of the branching enzymes. Eur. J. Biochem. 168, 393 – 397.

Van Soest, J., 1996. Starch plastics:structure, property rela-tionship. Thesis, University Utrecht.

Vizgarra, O., 1995. Tuc 390 and Tuc 500: two new varieties of black bean for the Northwest of Argentina. J. Ind. Ag. Tucuma´n 72 (1 – 2), 81 – 85.

Yu, J., Che, S., Gao, J., Zheng, J., Lin, T., 1998. A study on the properties of starch/glycerine blend. Starch/Starke 50 (6), 246 – 250.