Hollenberg to be identified as the editor of this work is asserted in accordance with the law. This work is sold with the understanding that the publisher is not engaged in rendering professional services.

Author’s Biography

About the Editor

Preface

I hope this book will fill the need that exists for these new cosmetic chemists in the industry. It contains information on the basic topics involved in the use of color in cosmetics and toiletries.

Acknowledgments

Fred LaFaso, American Glitters, Inc., for data, samples and education provided on glitter pigments.

Introduction

Third, once regulatory and stability considerations are met, color selection based on the desired color aesthetic can be considered. In today's highly competitive market, there is always pressure on formulators to develop formulas in the most economical way, and the choice of colorants used can dramatically affect the overall cost of the formula.

Color Basics

It’s a Colorful World

It is often worn by brides in the Western Hemisphere (although, interestingly, it is a mourning color in certain parts of Asia). Yellow is thought to draw attention, so it is often the color of choice in writing pads.

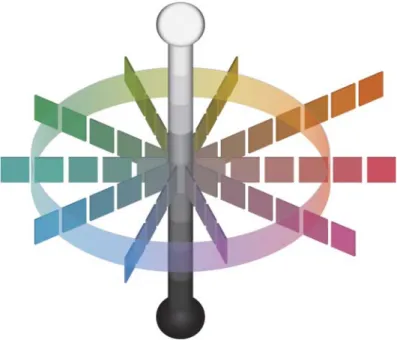

Color Theory and Color Space

Purple: The color of royalty, symbolizing wealth and sophistication, and also of passion, whether artistic, emotional or spiritual. Brown: The color of earth (ie earth, dirt, soil) and, like earth, carries the connotation of stability and reliability.

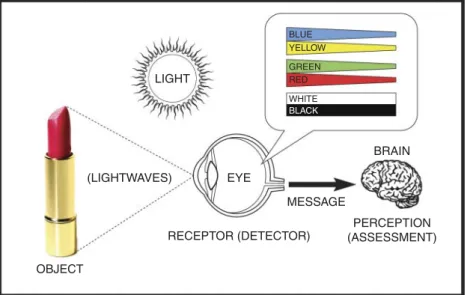

Human Color Physiology

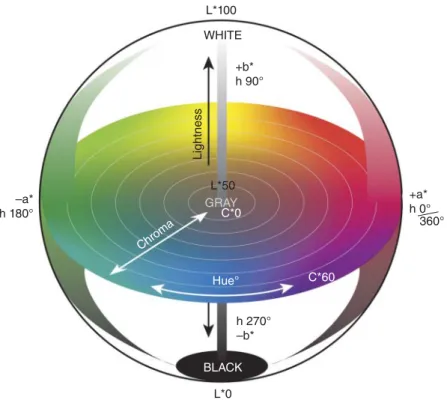

The rods allow the eye-brain connection to perceive the difference between light and dark colors (i.e. brightness), while the cones separate color into its components of hue and assess its intensity. Second, it helps to reinforce Munsell's color characteristics and explain how modern color measurement works.

Color Physics

As can be seen in Figure 1.5, visible light is the narrow part of the electromagnetic spectrum that can be seen by the human eye. For example, the lipstick shown in Figure 1.7 absorbs wavelengths in the 400-600 nm region and reflects those in the 600-700 nm region, thus producing the perceived red color of the lipstick.

Color Chemistry

Color cosmetics, on the other hand, are designed to cover the skin, so they take advantage of the opacity that pigments exhibit. There is no chemical bond between the dye and the substrate; the dye simply assumes the insoluble character of the substrate and thereby creates a pigment.

Color Properties

Color Nomenclature

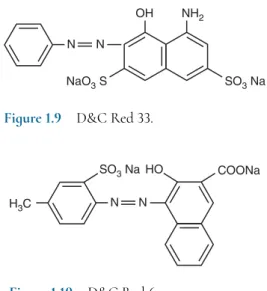

For example, according to American nomenclature, the most common organic toner used in decorative cosmetics is D&C Red 7, which is a calcium salt. A more detailed nomenclature of color additives used in cosmetics and toiletries will be discussed in Chapter 2.

Organic vs. Inorganic

First, each individual chemical color unit is assigned a five-digit number (for toners, a sixth digit may be added at the end, followed by a colon to indicate the precipitating metal salt). Second, each dye is assigned a color name and number, corresponding to this five- (or six)-digit Color Index number.

In these applications, its designation as D&C Red 7 is meaningless, but users can easily identify the dye by its name and Color Index system number, which are Pigment Red 57:1 and 15850:1, respectively.

Color Selection – Regulations

Regulatory changes are underway in the United States, European Union, Japan and China.

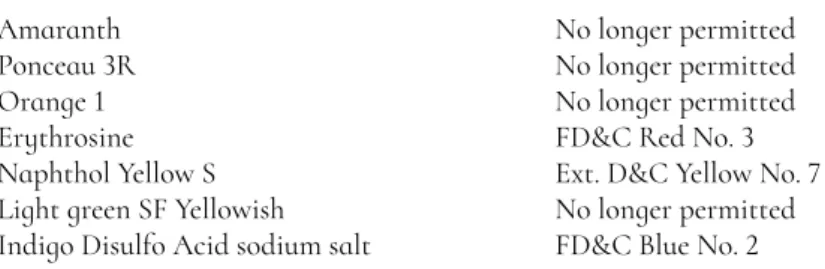

The Regulatory History in the United States

As a result of the dramatic increase in the number of end uses and the amount of dyes in foods, drugs, and cosmetics, Congress passed the Food Drug and Cosmetic Act (FD&C Act) of 1938. Disagreements developed between industry and the FDA over safe levels of use and the definition of the term "harmless". The FDA was of the opinion that a color additive must be safe regardless of its level of use.

The Current Regulatory Landscape in the United States

6 Not for use in the area of the eye In accordance with GMP D&C Red No. 21 Not for use in the eye area. In accordance with GMP D&C Red No.

The State of Regulations in the European Union, Japan, and China

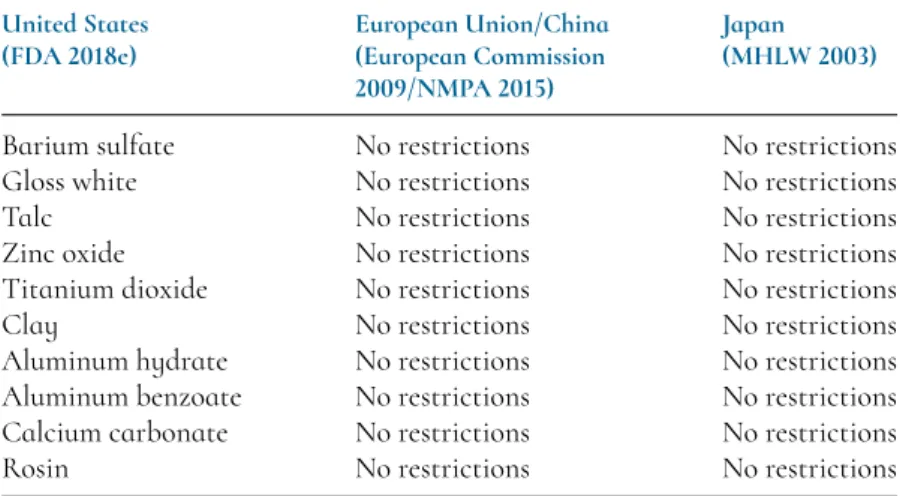

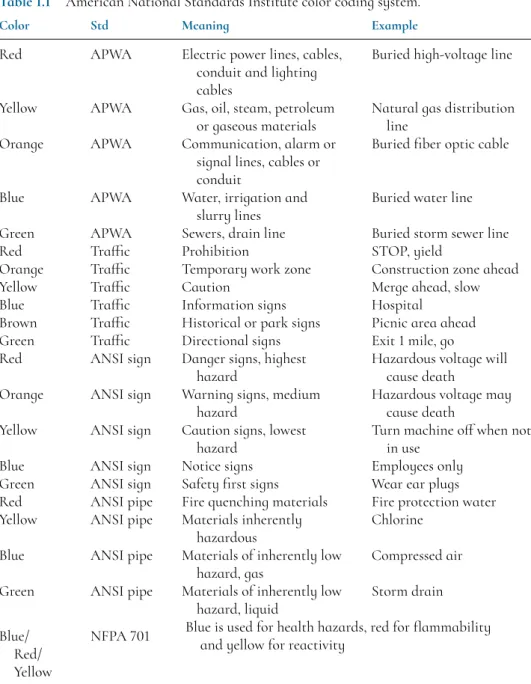

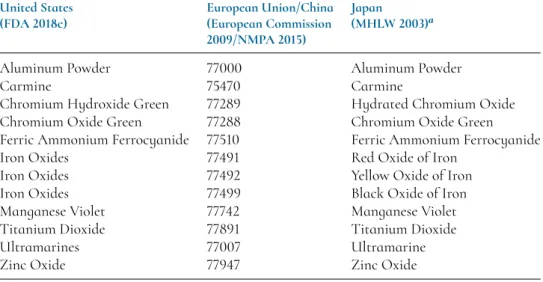

All cosmetic products for sale in the United States must use certified color additives. This shows the most common certifiable dyes used in the US market, along with their legal status in the European Union/China and Japan.

Regulatory Changes in China, the United States, and the European Union

As a result, there have been some regulatory updates on titanium dioxide in the European Union and the United States. The use of pigmentary titanium dioxide as a colorant in accordance with Annex IV to Regulation (EC) No 1223/2009 should also be allowed, with specific use restrictions added to Annex III (List of Restricted Substances) as a result of this SCCS opinion .

The businesses involved in the manufacture of final products are responsible for conducting risk and exposure assessments to determine if Proposition 65 labeling is required on the packaging of products supplied to California. Therefore, the information presented here may have been revised by the various regulatory bodies in the interim between this writing and your reading. https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/. https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/. https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/.

Color Selection – Stability

Certifiable (Synthetic Organic) Colorants

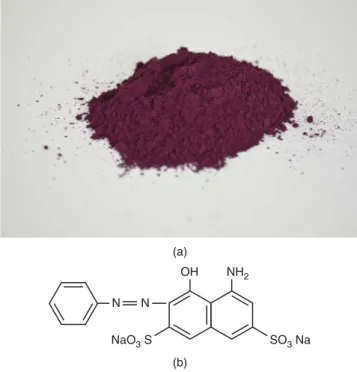

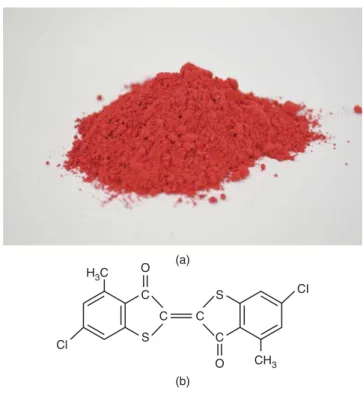

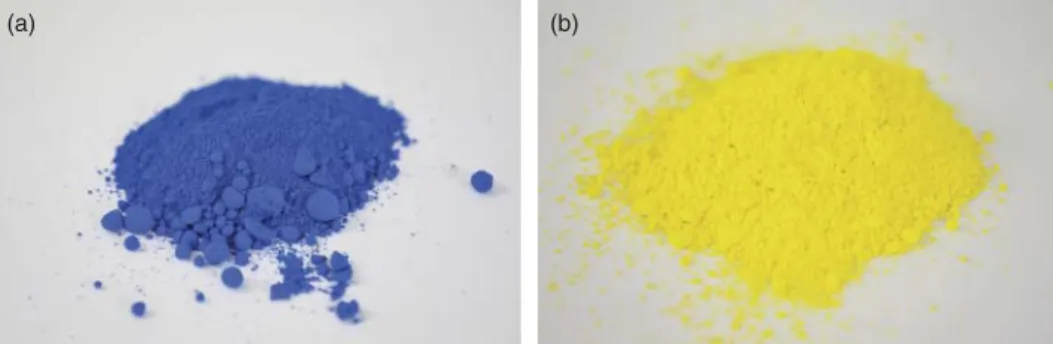

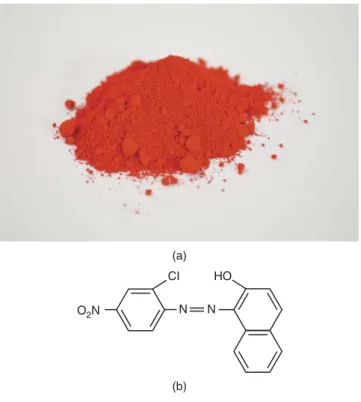

Some other important dyes in the soluble azo category are FD&C Yellow No. A photograph of the pure pigment is shown in Figure 3.9a, while its chemical structure is shown in Figure 3.9b.

Exempt Colors

Caramel Soluble in water; insoluble in organic solvents; fast to light, weak acids and weak alkalis. Ultramarine Insoluble in water; insoluble in organic solvents; not stable in acids; insoluble in alkalies; excellent lightfastness.

Color Selection – Color Esthetics

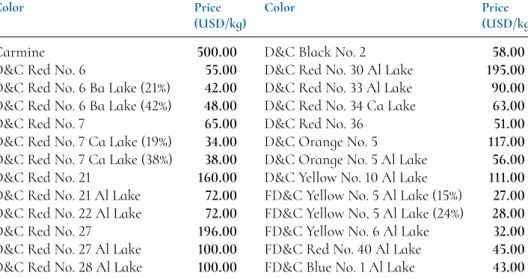

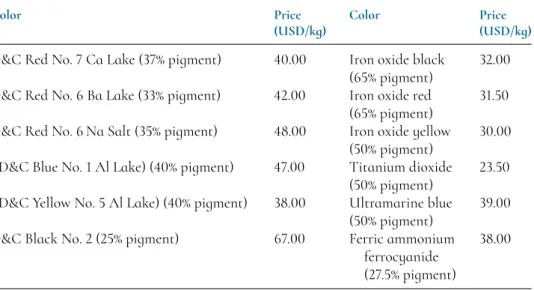

Color Combinations: There are wide variations in the prices of color additives, based on their production costs and the cost of the raw materials used to produce them. The chemist must be aware of these differences to choose the appropriate additive that meets the color and physical requirements of the product being formulated.

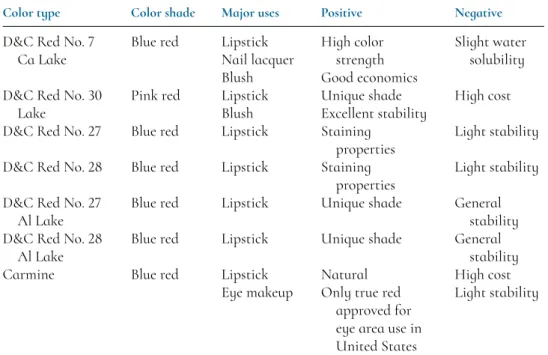

Color by Shade: Organics

27 is the free acid of tetrabromotetrachlorofluorescein (tetrabromo=four bromine atoms), while its cousin, D&C Red No. 28, is the sodium salt of the same molecule. It has the same chemical structure as D&C Red No. 7 Ca Lake, the difference is that the blue shade is the calcium salt, while it is the barium salt.

Color by Shade: Inorganics

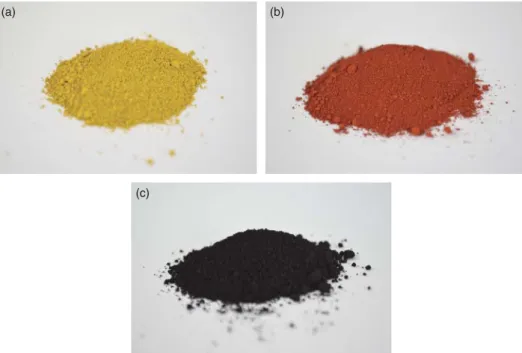

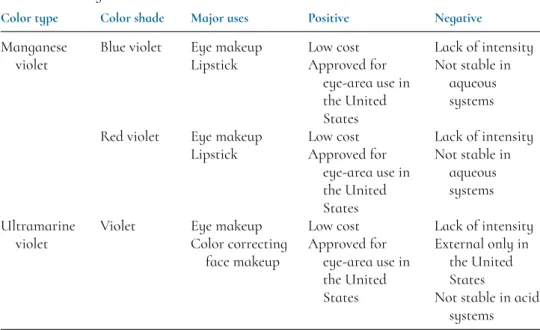

Like manganese violet, it is used in lipsticks and nail polish to soften the bright organic colors in products formulated for darker skin types and is a common colorant for eye makeup and lip color, especially in earth tones. It is available in a standard (black) shade that is used with red and yellow to formulate a variety of skin tone foundation shades and earth tones for eye shadow.

Color by Product Application

2 can be used in place of black iron oxide to produce dark shades of brown. 7 Ca Lake are the main colors used, for the same reasons they are commonly used in lipsticks: bright shades and good value D&C Red No.

Color Selection – Economics

With these figures in mind, it is now possible to review the economics of the use of colors in decorative cosmetics.

Dye Content

Effectiveness of Dispersion

Dry Pigments vs. Predispersed Pigments

Thus, when all the calculations are done, a dry color will always turn out to be cheaper than a prefabricated dispersion, because the price of the dispersion will include the manufacturer's conversion costs and the profit margin. But like the microwave meal, the convenience and consistency of the dispersion brings enormous value to the table.

Jet Black Iron Oxide vs. Brown Black Iron Oxide

2 is several times more intense and "blacker" than black iron oxide, but unfortunately its cost ($50.25/kg) compared to the cost of oxide ($9.75/kg) exceeds the scale greater strength by quite a large margin. As a way to have the best of both worlds - aircraft and an economical formula - a mixture of the two blacks is often used.

Blended Iron Oxides vs. Neat Iron Oxides

Therefore, unless the formulator absolutely needs the special color properties of the former, he or she should always "grab" a container of the latter off the shelf when starting work on a new product that requires a yellow pigment.

Chromium Hydroxide Green vs. Chromium Oxide Green

Package Sizes

In the case of generally more expensive organic paints, this premium does not add a significant percentage to the price per kilogram of the product, so in most cases it makes sense for smaller consumers to buy smaller packages. However, if a premium is applied to inorganic colors, especially titanium dioxide and iron oxides, the price of the pigment can increase by 50% or more, as shown in Table 5.2.

Pigment Dispersion

The Importance of Dispersion

The pair on the right are shades – prepared by diluting the masstone with zinc oxide. The ability to add shine to the skin is an important property of such cosmetics in terms of consumer appeal.

Pigment Particle States

Aggregates: These are pigment particles formed when the flat surfaces of primary particles are brought together and cemented tightly together by pressure and heat. Agglomerates: These are pigment particles formed in the production process when primary particles and aggregates gather at the points instead of at their crystal surfaces.

The Dispersion Process

Again, this ensures a more effective separation/dispersion in the next step of the distribution process. Once the pigment is thoroughly wetted, it is time to move on to the second part of the spreading process: separation/dispersion.

Color Measurement and Pigment Testing

Pigment Testing

Taking into account such differences, color additives should be tested in the same system in which they will be used in production. Therefore, just like testing in a real system, it is also necessary to test color additives at the level at which they will be used in an actual production situation.

Test Methodologies: Three Basic Methods

The tint is used to assess the color and strength of the test batch against the standard (Figure 7.8). This masstone display is used to make a visual assessment of the test batch against the standard.

Color Measurement

A final point of note in the area of preparing a color test screen involves setting up the sample and standard. One of the most influential organizations in the development of today's color measurement systems was the Commission Internationale de l'Eclairage (CIE).

CIEL*a*b*, A Detailed View

DL*: This is the difference in brightness, expressed in terms of lighter (+) or darker (−) than the standard. De*: This is the total difference in intensity (chroma), expressed in terms of stronger (>1) or weaker (<1) than the standard.

Sample Preparation

Surface Treated Pigments

Origins of Surface Treated Pigments

In order to overcome these shortcomings, in 1977, metal soap treatment was introduced to the Japanese market. As an added benefit, metallic soap-treated pigments and foundations feel smooth and soft when applied to the skin.

Benefits of Surface Treatment of Pigments

Tactile properties: Most surface treatments impart a smooth, soft and creamy feel to the cosmetic products in which they are incorporated. Hydration: Many of the surface treatments add a softening and hydrating quality to both pigments and substrates.

Commercial Surface Treatments

Lauroyl Lysine: It is similar to the amino acid treatment in most of its properties. Esters: Isostearyl sebacate is used to treat pigments and substrates primarily for powder applications because it provides a wet feel payoff when applied to the skin while maintaining good skin adhesion and wear properties.

Surface Treatment Mechanisms

Electrostatic: Electrostatic forces between the treatment active and the surface of the pigment or substrate bond the two materials together. Precipitation: A soluble form of the treatment active is precipitated on the surface of the pigment or substrate, often by a di- or trivalent metal ion.

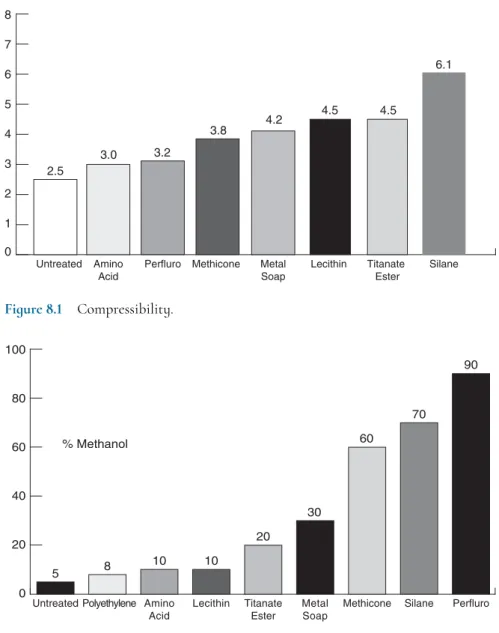

Performance Testing of Treatment Types

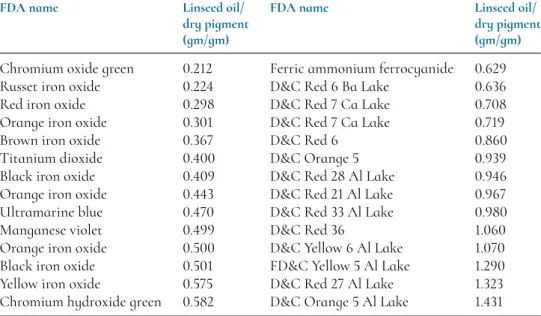

The reader is referred to Table 6.1 to see the large differences in oil absorption between different types of pigments. The results shown in Table 8.4 show that the overall appearance after six hours of wear is improved compared to the control treated with metallic soap, perfluor and methicon, although less product remains with the latter.

Intellectual Property Surrounding Surface Treatments

Using Treated Pigments and Substrates

For example, to prevent the settling of inorganic pigments in nail polish, it is necessary to treat only those pigments, and none of the organic pigments or other ingredients. Conversely, to achieve a good skin feeling with a pressed powder, it is normal to treat all dry components in the formulation.

Choosing Treatments

It is possible – and in some cases desirable – to use more than one surface treatment in the same formulation. By using multiple treatments, the benefits of different treatment types can be realized in the final product.

Effect Pigments

General Properties of Light

Absorption of Light: Based on the physical and/or chemical properties of a substance, the wavelengths of light that strike it and pass through that substance are said to be absorbed. Reflection of light: Based on the physical and chemical properties of a substance, the wavelengths of light that strike it that are not absorbed are said to be reflected from the surface of that substance.

General Light Interference Properties of Effect Pigments

Smooth surfaces: The smoother the surface of the effect pigment, the less diffuse reflection (scattering of light) there will be. Refractive index: The higher the refractive index of the effect pigment, the more light will be split, increasing the brilliance of the effect.

Traditional Commercially Available Effect Pigments

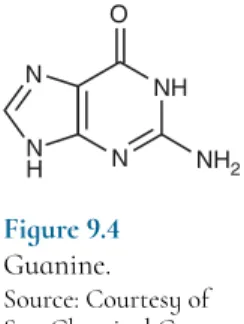

Of the synthetic effect pigments, it comes closest to guanine in this respect, at a significantly lower cost. Smooth Shine: The type of shine that BiOCl exhibits is very smooth compared to the sparkling shine of many of the metal oxide coated effect pigments (see later).

Usage of Oxide Coated Pigments in Decorative Cosmetics

Acid stability: Enhanced interference or two-tone effect pigments made with carmine are not stable in acid systems because the carmine is not stable in those systems. Heat stability: Enhanced interference or two-tone effect pigments made with carmine are not stable above 60∘C, because the carmine is not stable above that temperature threshold.

Regulatory Considerations When Using Oxide Coated Pigments in Decorative Cosmetics

Alkaline stability: Enhanced interference or bicolor pigments made from ferric ferrocyanide are not stable in alkaline systems because blue iron is not stable in these systems. This Regulation does not apply to pigments based on borosilicate, alumina, silica or fluorophlogopite.

Other Effect Pigments

Economics of Oxide Coated Micas and Other Effect Pigments

The information in Table 9.4 is an approximation of the relative costs of the different types of effect pigments. It follows that finer pigments will be priced lower and larger pigments higher.

Specialty Pigments

Metallic Pigments

Figures 10.6 and 10.7 are comparisons between two types of metallic pigments and two types of oxide coated effect pigments. Effects observed by applying the pure dry powders to an inner arm (Figure 10.6) predict performance in powder products, such as eye shadow, highlighter or blush.