Many lessons and experiences that I have gained in the implementation and preparation of this thesis, thank you for the help, motivation and support from various parties so that the thesis can be successfully completed. Thank you for your guidance and knowledge from the first day of my studies at this university until today;.

INTRODUCTION

- Problem Background

- Problem Statement

- Objective

- Scope

- Assumptions

- Research Outline

How to identify cumulative trauma disorders - low back pain and tinea pedis disease in the area of leak testing. To identify cumulative traumatic disorders - low back pain and tinea pedis disease in the area of leak testing.

STUDY LITERATURE

Ergonomics

Manual Material Handling

- Manual Material Handling Assessment

Anthropometry

- Anthropometry Data

Cumulative Trauma Disorders

- Cumulative Trauma Disorders: Lower Back Pain

Tinea Pedis disease

Rapid Entire Body Assessment (REBA) Analysis

- REBA Analysis Process

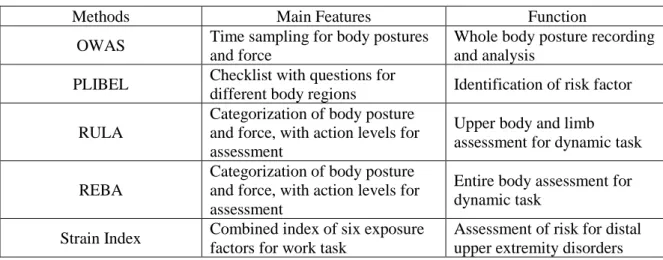

Differences between REBA Other Methods

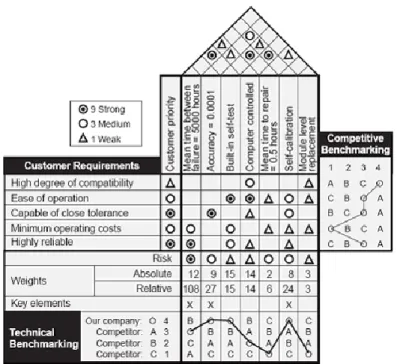

Quality Function Deployment Method

- House of Quality

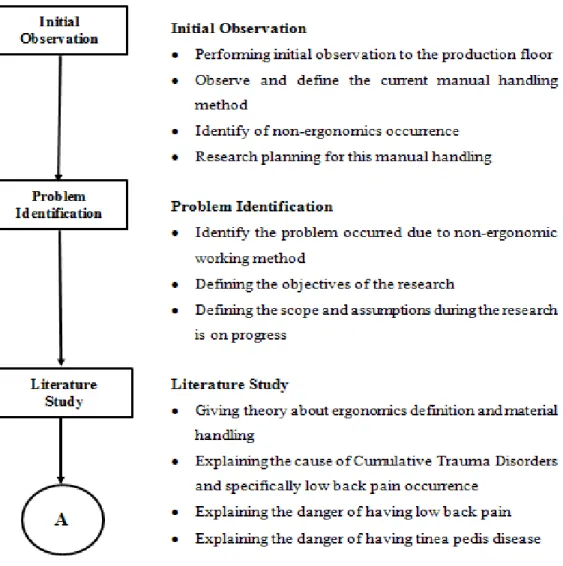

RESEARCH METHODOLOGY

- Initial Observation

- Problem Identification

- Literature Study

- Data Collection & Analysis

- Conclusion & Recommendation

- Detailed Framework

The first thing to do is the initial observation, where the initial observation is made and how the activity is adopted as a non-ergonomics activity explains why it can create the danger of cumulative trauma disorders - low back pain and tinea pedis- disease.

DATA COLLECTION & ANALYSIS

Initial Observation

- Workplace Overview

- Non-ergonomic Activity

In PT.FRS there is a big machine producing plastic packaging such as oil bottle, beverage bottle, tank for motorcycle radiator etc., in work station in leak tester of AHZ tank is next to AHZ tank making machine itself. The temperature of the workplaces is in accordance with the standard and does not require improvement. The problem occurs when the operator performs the activity of leak testing, in this workstation of leak tester, the material handling is still done manually.

It requires the operator to repeatedly test the tightness of the AHZ tank with his hand in the water box, and in 4 hours of work, the operator's frequency of testing the tightness of the AHZ tank can reach 4 bags of AHZ tank, in which one bag contains 400 pieces of AHZ tank, the operator needs 1 hour to test the leakage of 1 bag of the AHZ reservoir, which will eventually cause cumulative traumatic disorders - low back pain and tinea pedis disease. This activity is carried out daily as long as the AHZ tank is still producing in PT.FRS. After observing the leak testing on the AHZ reservoir, the risk of the activity in the leak testing process was identified.

The activity of leak testing is very dangerous and non-ergonomic, as the operators force themselves to bend their body when they sit and perform the leak test.

Data Collection

- Specification of Tools and Personnel

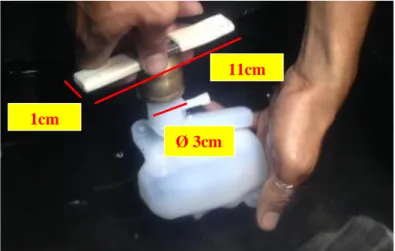

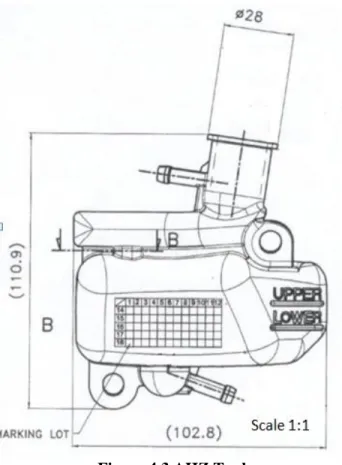

- Specification of AHZ tank

The data required to perform this observation are data operators, AHZ tank, anthropometric data and so on. Following are the details for tools required for the activity when the operator performs the leak test in PT. FRS and also the data operators which consists of the information about gender, body weight and height.

The length of the box is 54 cm, width 30 cm, height 41 cm and weight 1.5 kg. Each operator will work in 2 different shifts, the company has 8 hours of working time per shift, the first shift will work from 08:00 to 17:00, the second shift will work from 17:00 to 01:00, the operator has only 4 working hours time to complete 4 bags of AHZ tank and when the operator finishes the leak testing activity they have another job. AHZ tank is a motorcycle air radiator tank, AHZ tank is required by the number one motorcycle industry in the world, and AHZ tank must be completed in perfect condition without rejection in all aspects, such as leakage, and this is the last activity. in the AHZ tank is AHZ tank tightness testing, this activity is done manually and.

Data Analysis

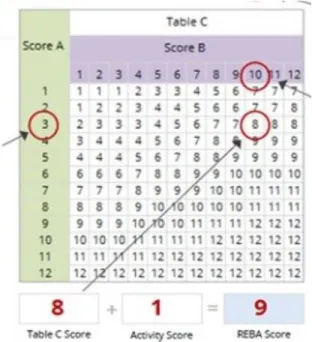

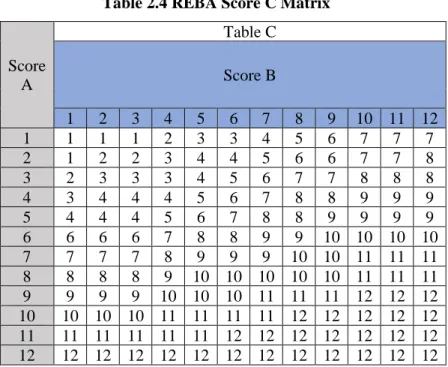

- Rapid Entire Body Assessment Analysis (REBA)

- Anthropometry Data

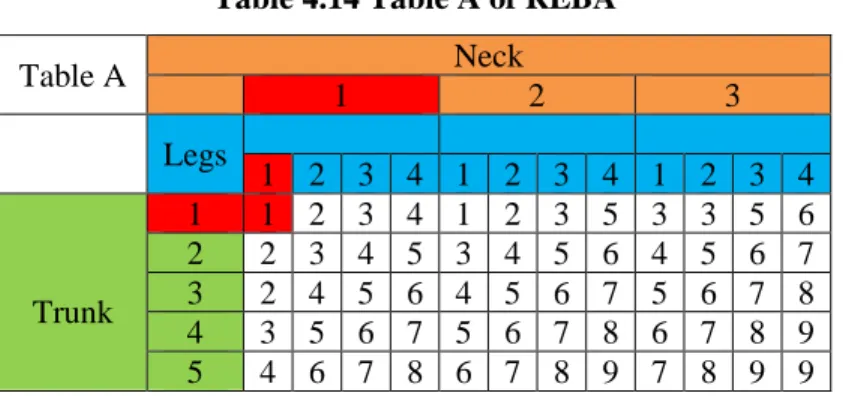

In the current state of the activity, it is clear that the operator has to bend his trunk, while the AHZ tank leak testing is not ergonomic. In the current condition the operator's legs bending the leg while performing the AHZ tank leak test. This score is then added to the REBA score of the Force/Load in the activity.

As shown in figure 4.7 below, in the current state of the activity, it shows that the operator is performing leakage test activity with both hands. The load REBA score is then added to the group A body part REBA score. This score is then added with the REBA score for the link in the activity.

From the observation, the actual condition of the operator's hands during the AHZ tank leak testing is categorized as a straight joint. The REBA score of the joint is then added to the REBA score of the body parts of group B.

Proposed Improvement

- Product Selection

- Product Selected Specification

- Quality Function Deployment

These criteria are then used as the parameter to assess the product in the selection process. 0 = product has neutral value in these criteria - = product has weakness in these criteria The product selection process is shown in table 4.8 below. And the last aspect is safety all the product got the plus point. For the total score of each product has a different score, the total score of the first product is 4, followed by the second product got the total score of 2 and the third product has score which is 2.

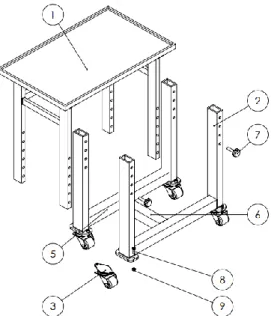

5 Strong and durable The product is built from strong material The product has a storage box. The product has a steering wheel with bearings and the product has a hand break are connected to each other due to the ease of use of the holding tools. The product can be adjusted up to one meter as the technical specification in the supporting tools has a strong connection with the other technical specification which is the product has wheels and breaks.

The product has a modification table with the technical specifications and has the highest weight score, which is 94.59. The product has customization meets both needs of user-friendly and easy to move, then it will multiply by these two relationship scores.

Product Specification

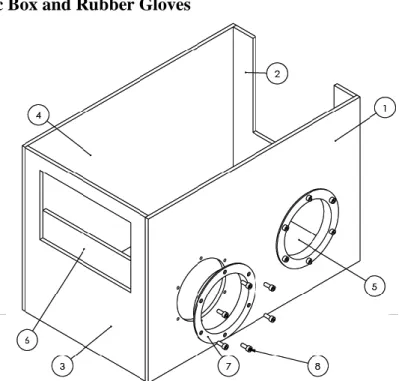

66 The first is a table adjustment table designed so that the operator can easily set the table size down and up according to the operator's preference and posture, the second is a transparent colored acrylic box to make it easy for the operator to see AHZ Deposits in performing a leak testing activity. The third is a rubber glove that can keep the operator's hand out of the water in the acrylic box used to perform the AHZ tank leak test activity. The fifth is a conveyor, which is provided by PT.FRS, whose function as a transferred AHZ tool of the tank that wants to take the leak testing process, does not force the operator to do the manual handling of the material to transfer AHZ reservoir.

67 In Figure 4.23, showing a transparent colored acrylic box, this tool is made to make it easier for the operator to see the AHZ tank while performing a leak test activity. Figure 4.25 shows sliding metal, sliding metal made of iron, sliding metal built into acrylic box, which serves to facilitate the operator to move the AHZ tank that has passed the leakage test into the finishing container, the specification of sliding metal is 500mm x 300mm x 10 mm. In figure 4.26 shown Raw AHZ tank container box which is made of acrylic which serves to contain the AHZ tank before the leakage test process, the specification dimension of raw AHZ tank container box number 1 is 350mm x 350mm x 15mm for the bottom is 350mm x 100mm x 15mm, number 2 is 700mm x 50mm x 25mm made of hollow steel and number 3 is screw with 15mm made of steel.

Figure 4.27 shows a well-finished AHZ tank container box, which is made of strong material, namely an iron plate, which serves to house the AHZ tank after the leak testing process. In the simulation, the operator does the leak test activity with the future leak test tools by using an adjusting table, an acrylic clear box, rubber gloves, sliding metal, a conveyor belt, a container box and using safety shoes in the leak test area. not doing leak testing of the AHZ tank in the awkward position, this tool will reduce and eliminate the non-ergonomic activity.

Future Leak Testing Cost

71 Figure 4.28 Design of a proposed improvement to future leak testing tools Figure 4.28 above shows a proposed improvement in the field of leak testing.

Before-After Analysis

Since the AHZ tank leak test condition is already adapted to the anthropometric elbow height standard. It is assumed that the operator during the AHZ tank leak testing is in the standing position as shown in figure 4.30. In this case, when performing the leak test activity, the AHZ tank is connected with an acceptable but not ideal hand hold.

The final REBA score is then used to define the risk level and the action required for the assessed activity. Final REBA score for leak testing of AHZ tank activity after the operator uses supporting tools in PT. This proposed improvement significantly addresses the safety risk of leak testing AHZ tank activity.

To identify cumulative trauma disorders - low back pain using REBA, The result of the total REBA score is 8, the score is categorized as high risk level activity. Based on the results of REBA calculations, AHZ tank leak test activities are categorized as non-ergonomic activity that may cause operators to be affected by cumulative trauma disorders - low back pain in the future.

CONCLUSION AND RECOMMENDATION

Conclusion

By using the following leak testing tools, the operator will not leak test the AHZ tank in the awkward position, this tool will reduce and eliminate non-ergonomic activity, may reduce the potential for Cumulative Trauma Disorders - Pain back and tinea pedis in the future.

Recommendation

Akao, Y., Pengembangan Produk Baru dan Jaminan Kualitas: Sistem QFD, Standardisasi dan Kontrol Kualitas, Japan Standards Association, vol. Clausing, D., dan Pugh, S., Peningkatan implementasi fungsi kualitas, Prosiding Konferensi Internasional tentang Produktivitas Desain (hlm. 15-25). Kejadian dan pola jamur penyebab Tinea pedis di rumah Brimob Semarang Ilmu Kesehatan Kulit dan Kelamin FK Undip.