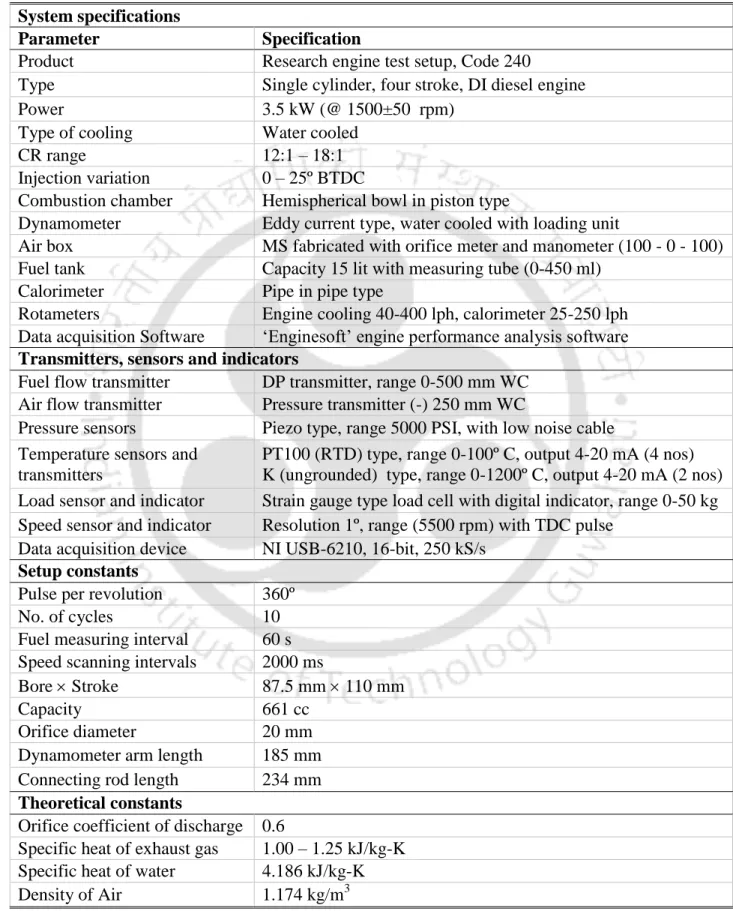

It has been proven that the work included in the thesis entitled Experimental and Theoretical Routes towards Evaluating the Potential of Emulsified Palm Biodiesel as an Alternative to Diesel Fuel, by Biplab Kumar Debnath (Registration No. as a student of the Department of Mechanical Engineering, Institute Indian Institute of Technology Guwahati, India, for the award of Doctor of Philosophy degree was carried out under our supervision and this work has not been submitted elsewhere.Therefore, the initial part of this investigation aims to find the performance characteristics of 100% POME in a diesel engine with variable compression ratio (VCR) 3.5 kW in different combinations of compression ratios (CR and 18) and injection timing (IT ºBTDC).

Nomenclature

ATDC after Top Dead Center (degrees) PM Particulates BSEC Brake Specific Energy Consumption (kJ/kW-s) POME Palm Oil Methyl Ester BSFC Brake Specific Fuel Consumption (kg/kW-h) RPM RPM.

73 5.9 Changing ID with engine load for different CR and IT for proper operation of POME. 78 5.14 Variation of HC with engine load for different CR and IT for smooth operation of POME.

List of Tables

One of the viable solutions that has gained popularity in recent decades is the use of fatty acid methyl esters, also known as biodiesels, as an alternative diesel fuel. Finally, the chapter concludes with the objectives of this research and the design of the dissertation.

Introduction

- Preface

- Alternative Fuels

- Biodiesel

- Emulsified Fuel

- Emission Control Norms

- Objectives

- Organization of the Thesis

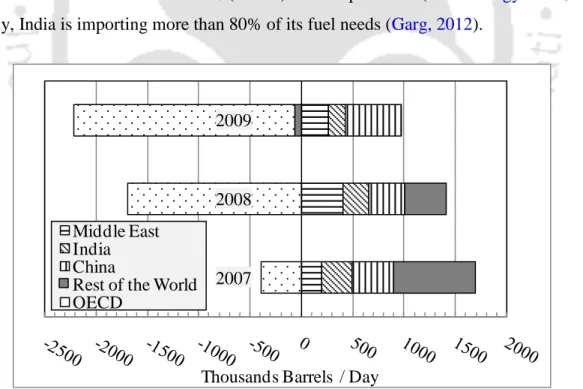

A report published by "The International Energy Outlook in 2011" shows that the world's energy consumption will increase by about 53% between 2008 and 2035. The results of the experiments help to optimize the aforementioned design parameters to achieve optimal performance. , combustion and emission characteristics of pure POME in the diesel engine.

Literature Review

Preface

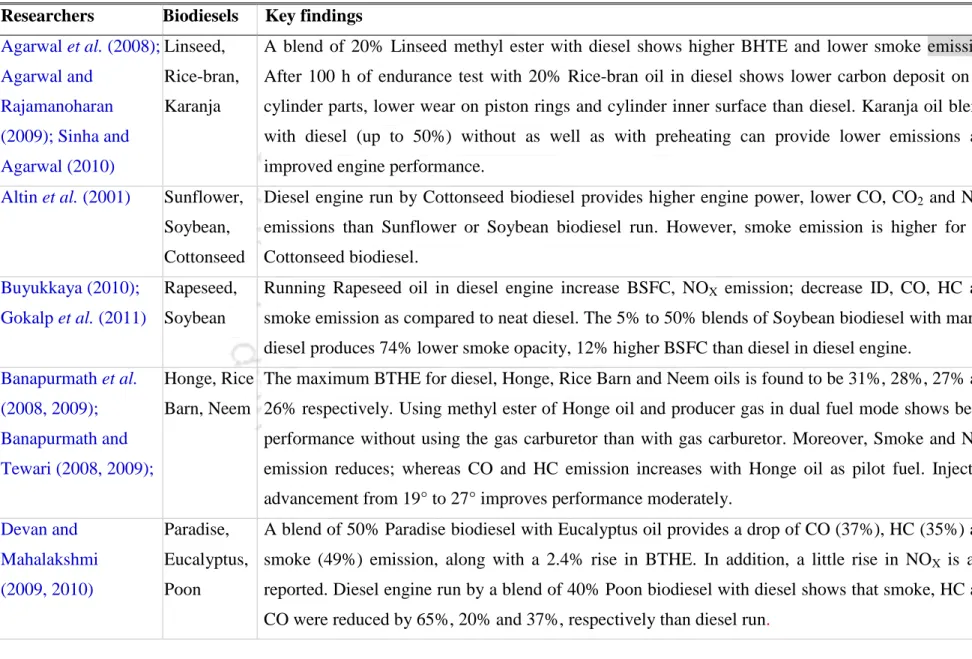

More focus is on biofuel methyl esters, mainly palm oil methyl ester (POME) and its emulsion in diesel engines. Side by side, a detailed review of performance, combustion and emissions studies of variable compression ratio (VCR) diesel engines has also been prepared.

Biodiesel from Palm Oil

Running canola oil in diesel engine increases BSFC, NOX emission; reduce ID, CO, HC and smoke emissions compared to pure diesel. The addition of palm oil and corrosion additives in diesel has resulted in a better combustion of the liquid fuel in the diesel engine.

Emulsified Fuel

- Surfactants and HLB Number

Kalam and Masjuki (2002) revealed that addition and increase of palm oil in diesel engine increased the BP and reduced NOX, CO and HC emissions. Therefore, they finally concluded that the palm oil is suitable for diesel engines comparable to its competitors such as soy or rapeseed biodiesels.

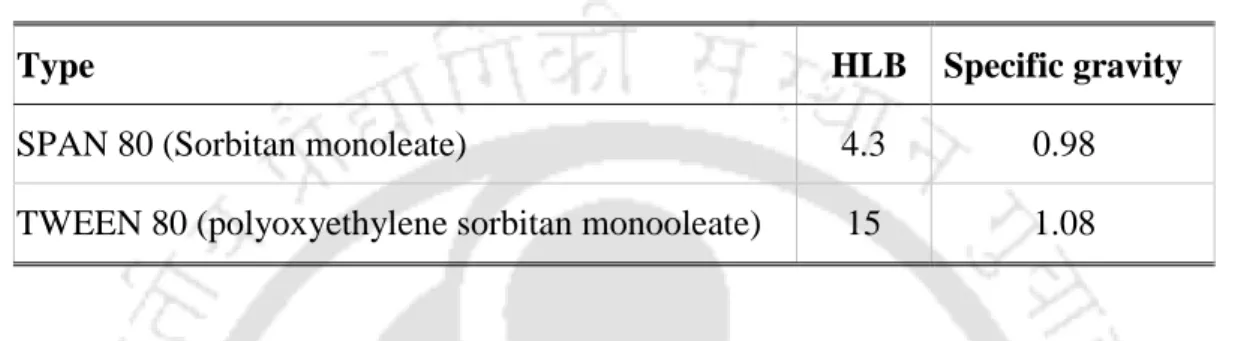

These dual characteristics, called amphipathy or amphiphilicity, result in a dual affinity of polar or nonpolar substances, mixing them through stable interfaces (Schwartz et al., 1977). Based on their affinity for polar or non-polar liquids, each surfactant is assigned a certain number; called hydrophilic-lipophilic number or HLB.

Surfactants or surfactants are substances that contain both polar and non-polar groups in their molecules.

8.6), TRITON X-35 (7.8)

11), TWEEN 21 (13.3)

- Types of Emulsion

- Based on Droplet Size

- Based on Phase

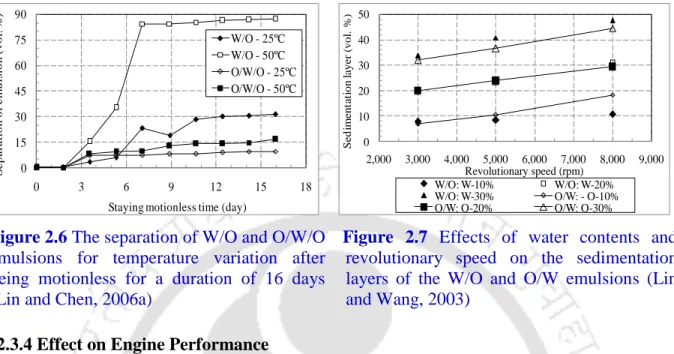

- Emulsion Characteristics

- Surfactant and Hydrophilic Lipophilic Balance (HLB)

- Additives

- Mixing Parameters

- Criteria of Effective Emulsion

- Effect on Engine Performance

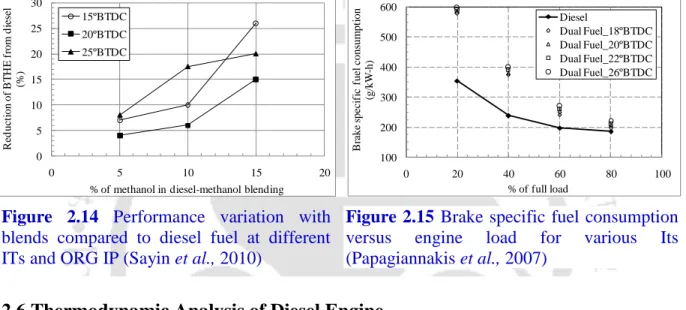

- Brake Power

- Brake Thermal Efficiency

- Brake Specific Fuel Consumption

- Effect on Engine Combustion

- Ignition Delay and Combustion Duration

- Cylinder Pressure

- Heat Release Rate

- Effect on Engine Emission

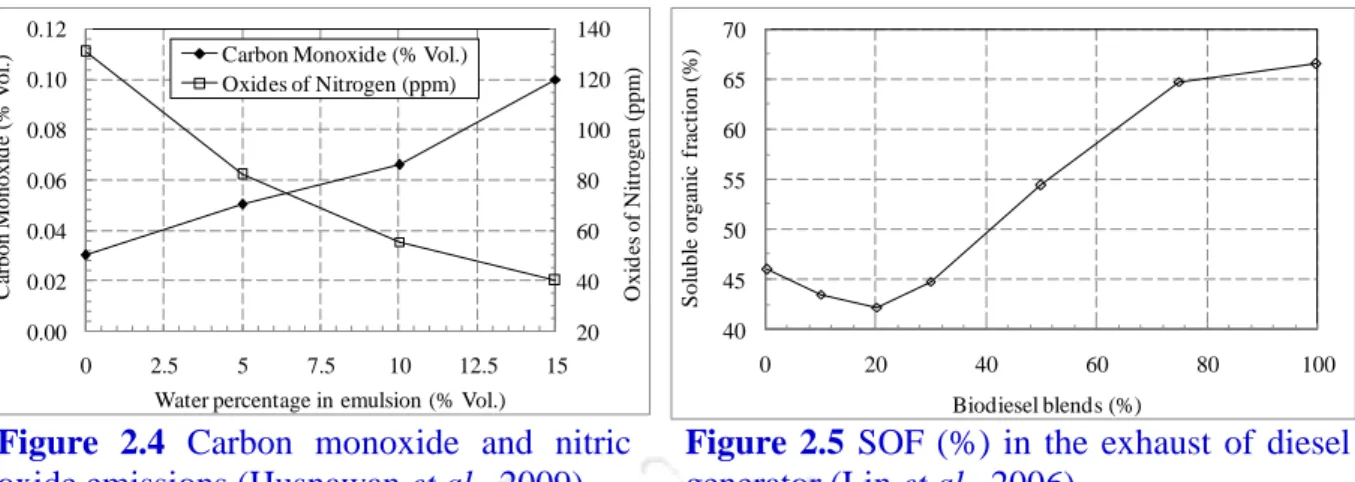

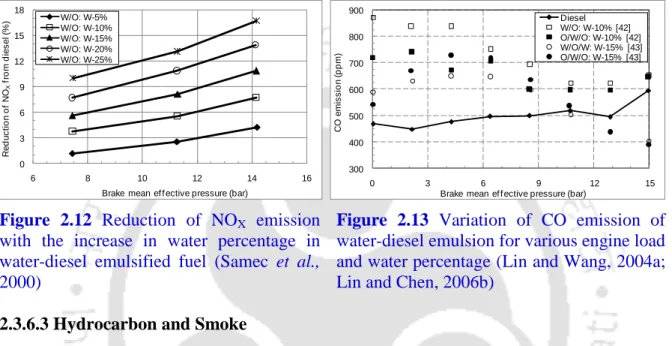

- Oxides of Nitrogen

- Oxides of Carbon

- Hydrocarbon and Smoke

- The VCR Engine

- Brief History

- Earlier Work on VCR engine

- Recent Work on VCR Engine

- Effect of Load

- Effect of Compression Ratio

- Effect of Injection Timing

- Thermodynamic Analysis of Diesel Engine

- Scope of Work

- Summary

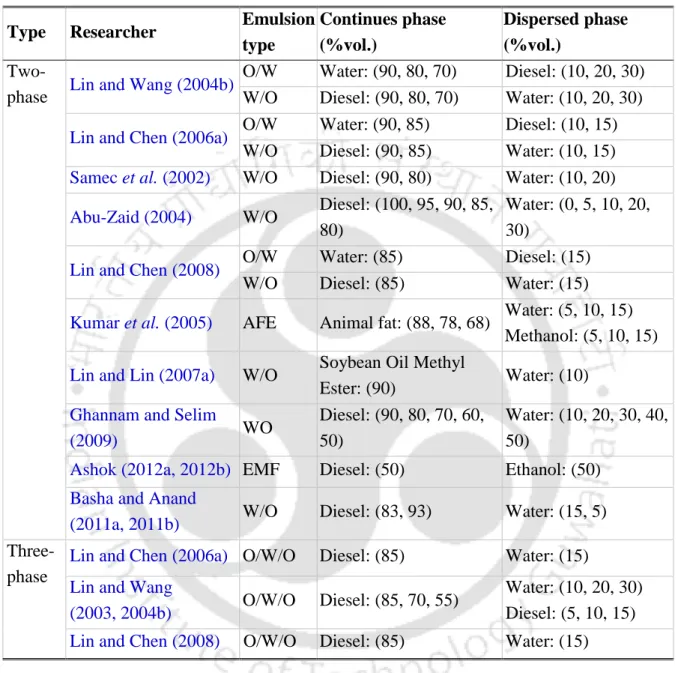

In this regard, the frequently used apparatus and the two essential parameters - the speed of rotation and the time of emulsifications are shown in Table 2.10. This is because increasing the amount of ethanol reduces the energy content of the emulsified fuel (Likos et al., 1981).

Characterization of Emulsified Palm Oil Methyl Ester

Preface

In an emulsion (WIP) used as motor fuel, the water must be evenly distributed and stable for a suitable period of time. However, the application of biodiesel as an emulsified fuel is very rare and should be explored exclusively.

Characteristics of Emulsion

- Surfactant and Hydrophilic Lipophilic Balance

- Ratio of Emulsifying Fluids

HLB can be defined as a measure of the degree to which a liquid molecule is hydrophilic or lipophilic. The ratio of liquids has a huge effect on the stabilization of the emulsion to be produced.

Emulsified POME Preparation and Stability Study

- Ultrasonic Bath Sonication Machine

- Emulsion Preparation Procedure

- Measurement of Droplet Diameter

- Stability Study

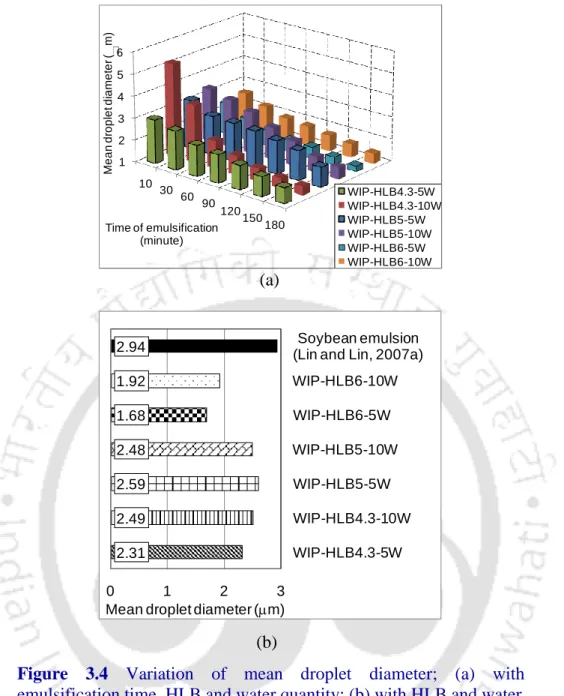

The figures show that with longer emulsification time, a lower mean droplet diameter of the emulsion is achieved. Figures 3.5(a) and 3.5(b) show that although the emulsion is prepared with the presence of a single surfactant, SPAN 80 (HLB 4.3), the dispersion of the water droplets is uniform. Probably this is the reason why the average droplet diameter of the dispersed water is slightly higher for HLB 5 emulsions than for.

Variable Compression Ratio Engine Test Setup

- Preface

- The VCR Engine Setup

- Instrumentations for Measurements

- Performance Measurement

- Air and Fuel Flow Measurement

- P- Measurement

- Temperature Measurement

- Compression Ratio Variation Control

- Injection Timing Variation Control

- Emission Measurement

- Experimental Design and Procedure

- The Neat Diesel Test

- The Neat POME and Emulsified POME Tests

Details of the engine and instrument specifications are included in this chapter. The density and calorific value of the fuel in question are included as required. After the clean diesel test is completed, the engine's diesel tank is drained and filled with B100.

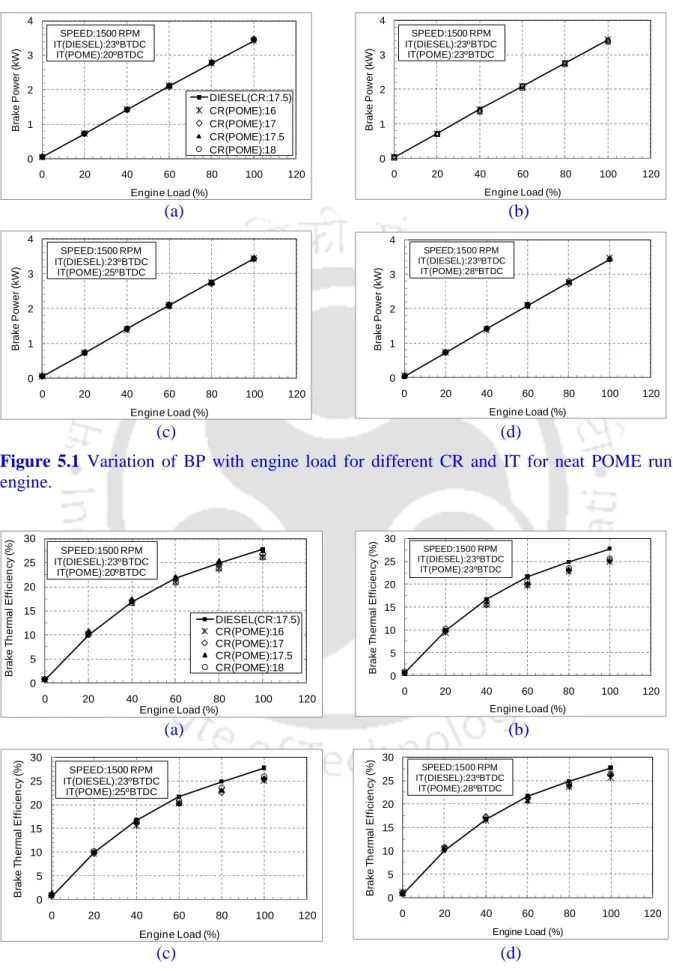

Results and Discussion: Neat Palm Biodiesel Run Engine

- Preface

- Performance Analysis

- Effect of Compression Ratio

- Effect of Injection Timing

- Combustion Analysis

- Effect of Load

- Effect of Compression Ratio

- Effect of Injection Timing

- Emission Analysis

- Effect of Load

- Effect of Compression Ratio

- Effect of Injection Timing

- Uncertainty Analysis

- Summary

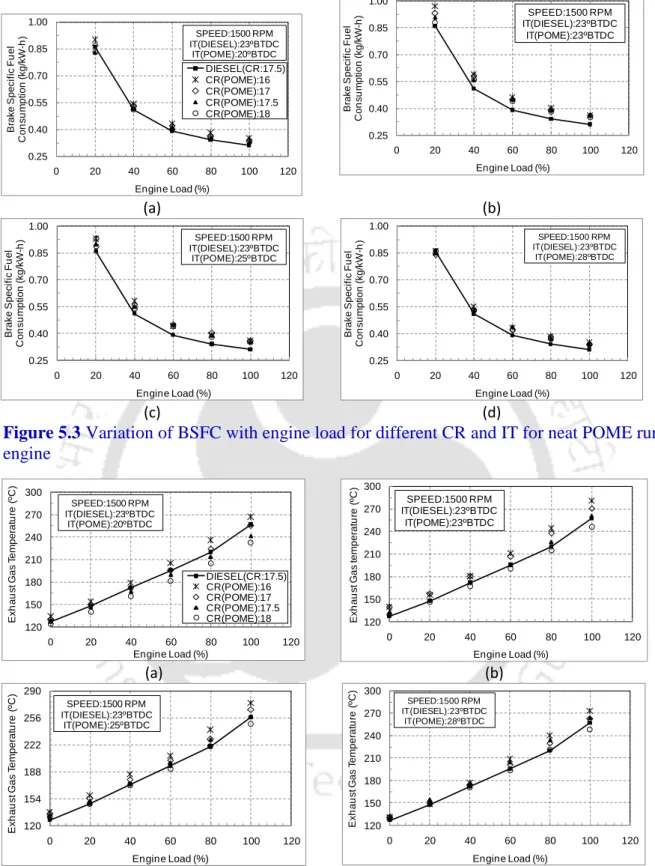

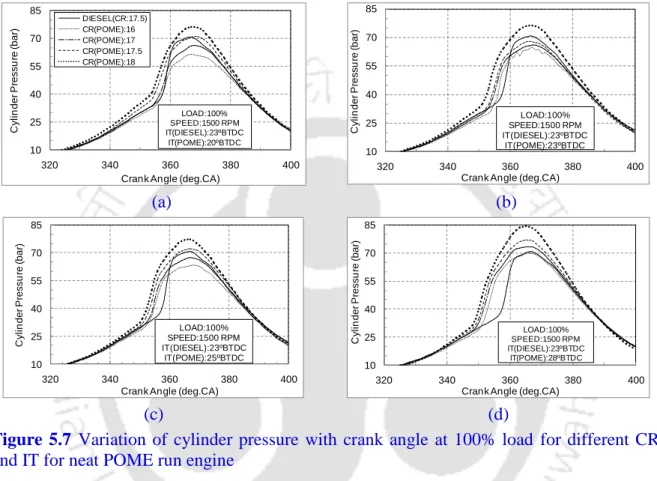

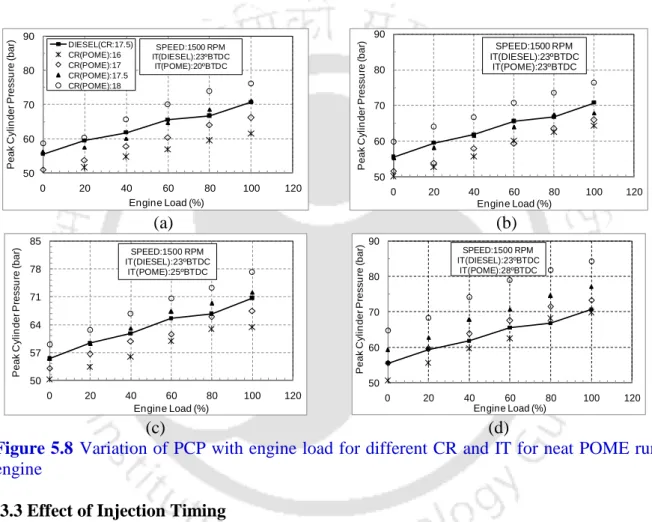

Although the use of POME results in higher fuel intake than base diesel (Figure 5.3), increasing CR from 16 to 18 showed a drop in BSFC. The same cause attributes the increase in CO2 emissions to the increase in CR (Figure 5.12). The emission of HC in the exhaust gases is the result of incompletely burned fuel particles (Figure 5.14).

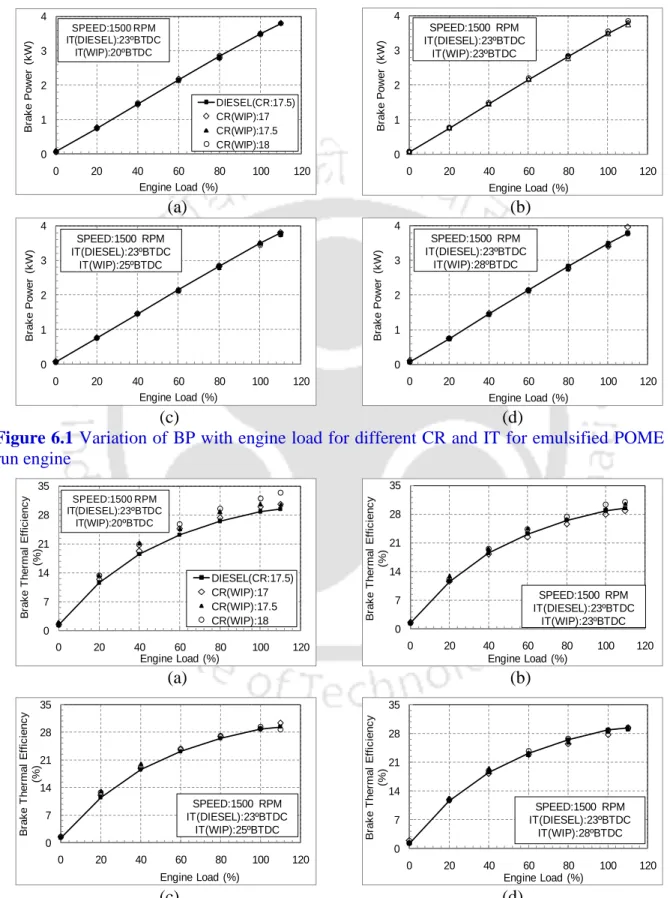

Results And Discussion: Emulsified Palm Biodiesel Run Engine

- Preface

- Performance Analysis

- Effect of Compression Ratio

- Effect of Injection Timing

- Combustion Analysis

- Effect of Compression Ratio

- Effect of Injection Timing

- Emission Analysis

- Effect of Load

- Effect of Compression Ratio

- Effect of Injection Timing

- Uncertainty Analysis

- Summary

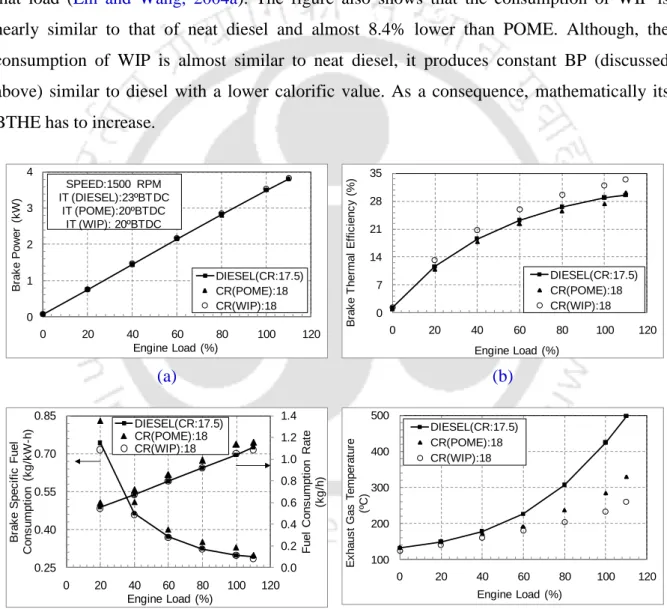

The reduction in PCP (Figure 6.8) at delayed IT is due to splashing of WIP, when the piston reaches closer to TDC. CO2 reduction is a result of BSFC results (Figure 6.3) 4.6% decrease in BSFC of WIP was found than with diesel. This fact is also responsible for the increase in CO2 emission with increasing CRs as observed in the plots (Figure 6.12).

Analysis at Optimized Operating Condition

- Preface

- Performance Analysis

- Combustion Analysis

- Emission Analysis

- Summary

The results show nothing but a clear presence of the occurrence of "micro-explosion." The immediate and intense evaporation of the water droplets in the POME droplets breaks the large POME droplets into several smaller droplets. The comparison of cylinder gas pressure for WIP, POME and pure diesel is shown in Fig. The variations of CO emission for WIP, POME and clean diesel are shown in fig.

Thermodynamic Potential Study

Preface

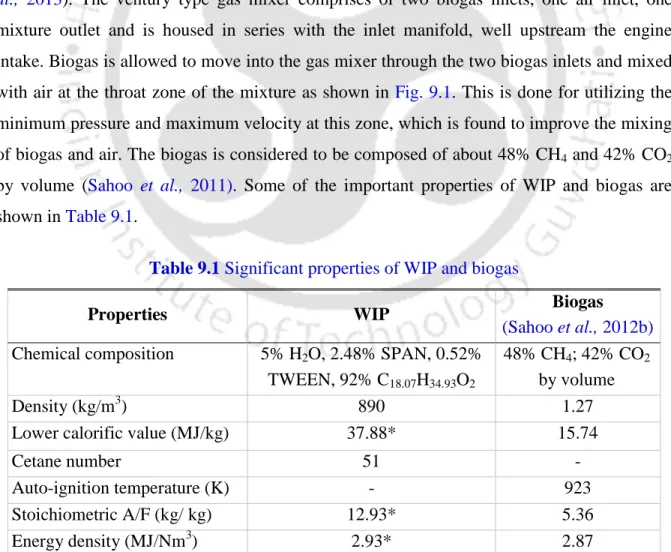

Rakopoulos and Kyritsis (2001) discovered a method to calculate combustion irreversibility and working medium availability for a diesel engine. Canakci and Hosoz (2006) performed energy and exergy analyzes of a turbocharged diesel engine operating with soybean methyl ester. Therefore, the objective of this work includes a combined first and second low analysis of a VCR diesel engine operating with emulsified POME and pure POME.

Thermodynamic Potential of Neat POME

- Energy Analysis

- Exergy Analysis

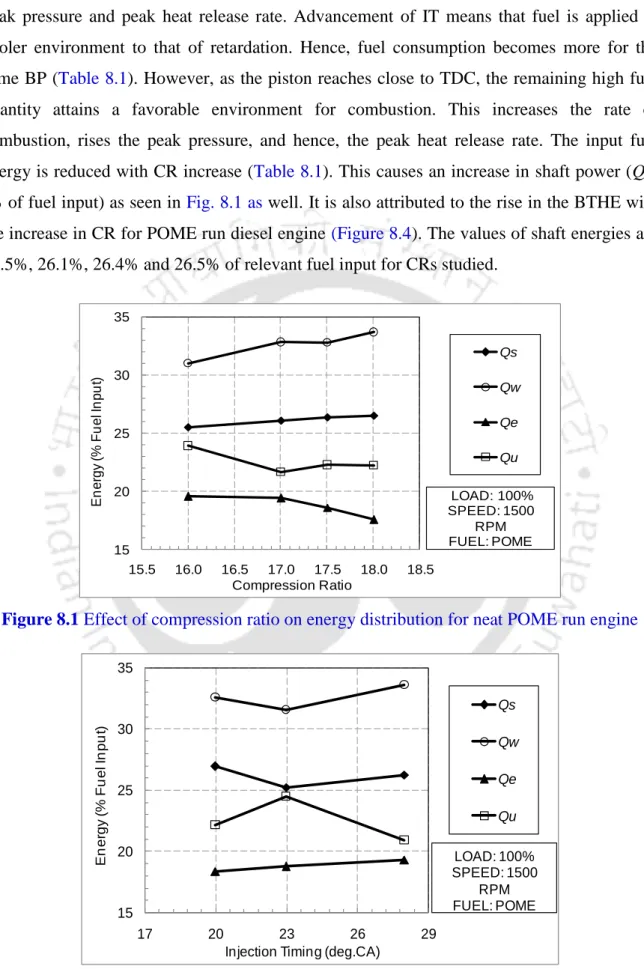

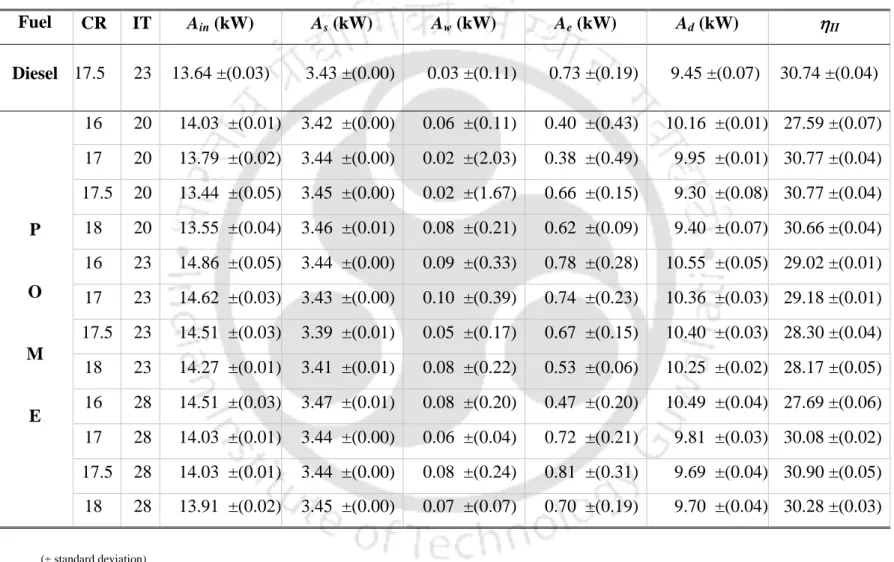

However, in the intermediate range of CR (17 and 17.5), combustion can be described as fully premixed combustion and partially premixed combustion (Laguitton et al., 2007). The trend of shaft availability for CR variation (Figure 8.6) is almost the same as the trend of shaft power as described in the figure. The effect of IT on the availability balance shows (Figure 8.7) that shaft availability increases as IT advances and lags.

Thermodynamic Potential of Emulsified POME

- Energy Analysis

- Exergy Analysis

On the other hand, for the calculation of the cumulative availability, i.e. the total availability that can be harnessed, the cooling water and outlet availability must be taken into account (Sahoo et al., 2011). Remaining 60% of the input availability is destroyed in various ways for the WIP run engine studied. Certainly, the fuel input value for the WIP run engine is the lowest for retarded IT.

Summary

The average values of availability destruction and entropy generation for WIP engines are 7.03 kW and 0.024 kW/K. The second law analysis of the WIP engine shows that approximately 40% of the available fuel can be captured. Furthermore, with the advent of CR, the percentage of shaft availability with respect to fuel-energy input increases for engines running on WIP.

Influence of Emulsified Palm Biodiesel in Dual Fuel Mode

- Preface

- Setup Modification and Approach

- Performance Analysis

- Combustion Analysis

- Summary

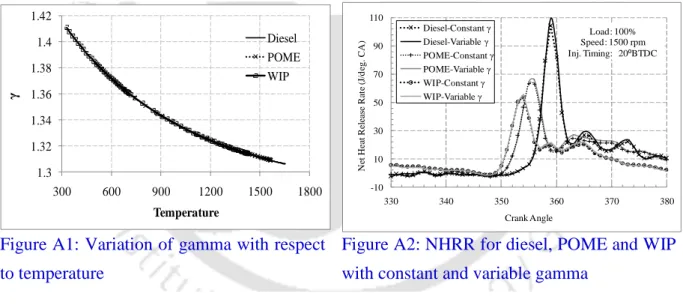

In dual fuel mode, biogas and air are premixed in the inlet manifold and fed into the engine. This is attributed to a 44% reduction in EGT for the dual fuel mode with emulsified biodiesel than that of pure biodiesel as the pilot fuel (Figure 9.2c). This is a significant breakthrough for dual-fuel operation of renewable fuels and the use of emulsified biodiesel as a pilot fuel.

Conclusions and Future Scopes

- Preface

- Contribution of the Present Work

- Neat POME

- Emulsified POME

- Analysis at Optimized Operating Characteristics

- Thermodynamic Potential Study

- Influence of Emulsified Palm Biodiesel in Dual Fuel Mode

- Application Probabilities

- Future Scopes

The use of emulsified POME in a diesel engine causes a micro-explosion that increases the fuel burn rate. A diesel engine driven by WIP can recover almost 30% of the fuel energy supplied as shaft power. These two methods occur simultaneously during the combustion of water-emulsified biodiesel in a diesel engine.

Basha SJ and Anand RB, (2011a), Experimental investigation of a diesel engine using carbon nanotubes with mixed water-diesel emulsion fuel, Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, Vol. Ozzezen AN, and Canakci M, (2010), Determination of performance and combustion characteristics of a diesel engine fueled with canola methyl esters and waste palm oil. Park SH, Youn IM and Lee CS, (2011), Effect of Ethanol Blends on Combustion Performance and Exhaust Emission Characteristics of a Four-Cylinder Diesel Engine at Different Engine Loads and Injection Timings, Fuel, Vol. 2005), Effect of heat transfer on diesel cycle performance and exhaust gas flow exergy in LHR diesel engine at optimal injection timing, Energy Conversion and Management, Vol.

Equations for Performance and Combustion Analysis

Performance Analysis

APPENDIX-A

The crank angle encoder, connected to the motor shaft, detects each degree of crank rotation for each cycle. Although combustion in a CI, DI engine is quite heterogeneous, the contents of the combustion chamber are assumed to be homogeneous in heat release calculations. The parameter uncertainties are calculated using the well-known theory of the sequential perturbation technique introduced by Kline and McClintok (1953) and Moffat (1982).

APPENDIX-B

Equations for Thermodynamic Potential Study

Energy Analysis

APPENDIX-C

Exergy Analysis

The availability can be described as the ability to perform useful amount of work by the supplied energy (Heywood, 1988). In the CI engine, the availability of fuel (Ain) supplied is converted into different types of exergy, namely ash availability (As), cooling water availability (Aw), exhaust gas availability (Ae) and destroyed availability (Ad) in the form of friction, radiation , heat transfer to the environment, operating auxiliary equipment, etc. These forms of energy are calculated according to the following analytical expressions as described in the literature (Flynn et al., 1984; Kotas, 1985; Van Gerpen and Shapiro, 1990; Stepanov, 1995).

List of Publications