To gain a better understanding of microbes, microfluidic approaches were innovatively introduced to the field with the potential to revolutionize high-throughput biological assays. As another practical application of the microfluidic approach, for high-throughput screening (HTS) application, a fluidic array will be developed using immiscibility between water and oil for microbial incubation, analysis, selective extraction, recovery process and demonstration of practical applications. The fluid array device not only showed demonstrations of high-throughput screening, but also advanced screening applications were also demonstrated with higher mutant library screening with 106 and C2C communication screening system.

Also, the proposed C2C screening approach enabled high-throughput compartmentalization and resulted in 10 possible mutants exhibiting higher extracellular biomolecule secretion efficiency. 8. instruments, 2) lightweight potentials to enable multiplex quantitative analysis in a high-throughput manner, and 3) selective, direct, and convenient measurement without pre- or post-treatment of sample solutions, the entire processes could be fully automated in the near future. Therefore, microfluidic devices have knocked a new door for high-throughput screening application for synthetically produced microorganisms and quantitative approaches for microbial biosensors.

Introduction

From basic microbiology to microfluidics

Motivation of microfluidic approaches 1 : Integrative microbial biosensors

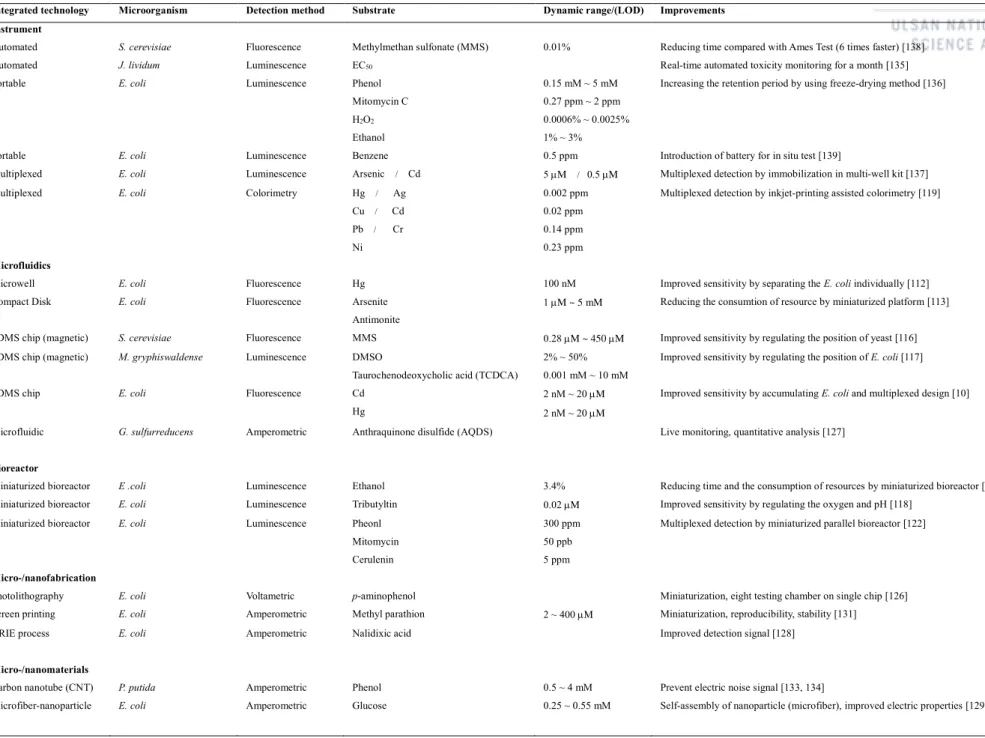

The optical or fluorescent signals produced by the microbes can be directly quantified during incubation of the microbes with test solutions, thereby enabling the detection of target analytes with unknown concentrations. They found that higher growth rates and/or dilution rates improved the performance of microbial biosensors [ 30 ]. They immobilized microbial biosensors in the multiple wells and then applied a sample solution containing various heavy metals to utilize them.

For further miniaturization, several research groups have developed microfluidic devices and combined them with microbial biosensors for the detection of toxic compounds and HMIs. Essentially, serial mixing of microbes and target analytes in closed solution not only limits maximal cell growth due to nutrient depletion, but also progressively reduces the number of target analytes available for further induction over time. For this reason, a continuous cultivation and induction environment is essential to improve detection sensitivity, because the continuous supply of nutrients and target analytes (target HMI) helps to improve gene expression in the microbial biosensor.[10]

![Figure 1. Fundamental mechanism of heavy metal ion biosensor. (a) Whole-cell bioreporters for the detection of bioavailable metals [20]](https://thumb-ap.123doks.com/thumbv2/123dokinfo/10522660.0/16.892.147.779.226.492/figure-fundamental-mechanism-biosensor-bioreporters-detection-bioavailable-metals.webp)

Motivation of microfluidic approaches 2 : High-throughput screening

These approaches easily generate large mutant libraries, making a high-throughput screening (HTS) process inevitable for the selection of desired mutants. Therefore, an efficient HTS technology is inevitably needed to achieve the selection of target cells from the mutant libraries [36]. Over the past decade, microfluidics has achieved great improvements with the potential to revolutionize high-throughput biological testing.

Since this microfluidic technique is a suitable platform for patterning of liquid with a fully compartmentalized environment and high-throughput performance, many applications have been developed to be a suitable candidate for a biological assay, for example droplet-based microfluidics [47-50] , small bioreactors using complex pneumatic valves [51] and liquid patterning of aqueous phase by immiscible oil separation [52–54] . Due to the advantages listed above, some researchers have developed new microfluidic devices for liquid patterning, in other words, digitizing sample [ 52 , 54 ], self-complementary [ 55 , 56 ] and droplet patterning. Since these liquid pattern technologies meet many requirements of the directed evolution by random mutation method, the device can provide a high-throughput screening technique as well as a fully compartmentalized environment for the detection of microbial secreted chemical products [36].

![Figure 3. Representative microfluidic devices for various biological applications. (a) Long-term monitoring of bacteria undergoing programmed population control in a microchemostat environment for a small microbial bioreactor [51]](https://thumb-ap.123doks.com/thumbv2/123dokinfo/10522660.0/20.892.135.766.135.752/representative-microfluidic-biological-applications-monitoring-undergoing-microchemostat-environment.webp)

Theory : Microbial Biosensors in Micro-/Nanofluidic Technologies

- Introduction of microbial biosensors

- Microbial biosensors in recent decades

- Conventional detection methods

- Micro/nanotechnological detection methods

- Micro/nanotechnological platforms for microbial biosensors

- Conclusion and future perspectives

Finally, recent biological technologies to improve the performance of microbial biosensors and several future perspectives are discussed [1]. Currently, micro/nanotechnologies are rapidly being used and integrated into electrochemical detection technologies using microbial biosensors. Novel micro/nanometer structures and materials to improve electrochemical detection performance of microbial biosensors. a).

In this review, the integration of micro/nanotechnologies with microbial biosensors and their applications have been previously discussed. At the same time, micro/nanotechnologies have revolutionized the electrochemical detection sensitivity and selectivity of microbial biosensors. Finally, integration with advanced micro/nanotechnology heralds the beginning of a new era for microbial biosensors.

Quantitative Analysis of Microbial Biosensors for Heavy Metal Ion

- Importance of heavy metal ion detection

- Integration of microbial biosensor with microfluidic device

- Experimental methods

- Ratchet microstructure-based microfluidic device

- Detection of heavy metal ion by microbial biosensors in microfluidic device

- Conclusion

For visualization and quantification of the microfluidic channels, green, red and yellow dyes and 50 mM fluorescein isothiocyanate (FITC) were mixed with deionized water, respectively. However, the fluorescence intensities, although only indirectly representing the growth rate of the cells in each chamber, changed significantly over time in each chamber. These microbial biosensors were integrated into the ratchet structure-integrated microfluidic device to provide a chemostat-like environment for enhancing the sensitivity of the sensors.

After five hours of cell culture, the fluorescence intensities showed a linear dependence on the concentration of the Pb2+ ion; a higher concentration was associated with a stronger fluorescence intensity. Therefore, the combination of the microfluidic device and the microbial biosensors improved the sensitivity and dynamic range for HMI detection. The detection performance for HMIs using the microfluidic device was compared with that of the conventional detection method using batch culture under the same microscopic image acquisition conditions.

However, the batch-type induction did not produce sufficient fluorescence signal to allow differentiation of the control signal due to the lower cell density and limited supply of Pb2+ ions. Therefore, the microbial biosensors with a continuous chemostat-like environment improved the sensitivity and dynamic range of the microbial biosensors by about three orders of magnitude compared to the conventional beam induction method for the detection of HMIs [86]. The improved performance can be attributed to the continuous expression of the engineered genes and the increased number of cells in the detection chamber.

Even with a low concentration of HMI (e.g. 2 nM), the genes seem to be continuously activated over time by continuous replenishment and/or intracellular accumulation of the target HMI, leading to over-expression of GFP in the cells [ 19]. -flow characterization of the selectivity and crosstalk of the two microbial biosensor cells, respectively HK621 and HK622, using the microfluidic device. Using this chemostat-like microfluidic platform, two sets of microbial biosensors were used for HMI detection by a transformation of the plasmid pCadC1945, pCadC640 in DH5 strain and newly developed plasmid pT7cadO1945 and pT7cadO640-H in train.

These results can be a direct proof of the improvement of microbial biosensors mainly caused by two factors 1) T7 promoter amplification and 2) internal growth rate.

Development of Fluid Array for Screening of Small Mutant Microbial Library

- Microfluidic approaches for high-throughput microbial applications

- High-throughput screening methods for a microbial library

- Microfluidic HTS methods

- Experimental methods

- Fluid array device characterization

- Demonstration of high-throughput screening application

- Discussion

- Conclusion

Red food dye and 50 M fluorescein isothiocyanate (FITC) solutions were used to visualize and characterize the fluid pool. Then, the fluorescence intensity of the images was analyzed using a custom-made m-file in MATLAB R2014a (Mathworks, Natick, MA, USA). Different aspects of the fluid array were characterized for potential HTS applications as shown in Figure 15 and Figure 16 .

The lighter hexadecane oil retained the aqueous fluid array at the bottom, completely preventing dehydration of the microwells. The oils used in all experiments were fully hydrated to minimize dehydration of the fluid array. Furthermore, Figure 16 shows the effect of PDMS hydration on the dehydration of the fluid array.

Fluorescence intensities were compared to those of cells grown in the liquid array device for 14 h. b) Quantitative results of fluorescence images. On the other hand, when the fluid array device was immersed in oil to provide anaerobic conditions for the PDMS device, cells appeared to be concentrated near the perimeter of the microwell. The possibility of extracting target cells was also investigated using a commercially available capillary tube or an insulin syringe needle.

Above all, it seems simple that the fluid array platform can be combined with all the methods mentioned above. The fluid array device consisted of microwells for growing microbial cells and a fluorinated oil container for high-throughput cell division. In addition, extraction and recultivation of target cells from the liquid array device allowed repeated cycling screening.

Therefore, the combination of the liquid array device and target cell extraction method developed in this study offers tremendous advantages over conventional HTS techniques.

Advanced High-throughput Screening Applications by Fluid Array

- Microbial platform for fatty acid production

- Rationally designed engineering of TesA for improved microbial fatty acid production

- C2C communication screening for extracellular fatty acid production

- Fluid array applied to two screening applications

- Experimental methods

- Screening of larger mutant library : Increased throughput of 10 6 TesA mutants

- C2C communication based screening : New type of screening application

- Conclusion

To induce the expression of thioesterase, 0.3 mM isopropyl-β-D-1-thiogalactopyranoside (IPTG) was added at OD600 of 1 [175]. Therefore, the experiment carried out the screening of approx. 1.8 106 samples on the fluid array devices, which statistically covered over 95% of the 106 entire mutation library by following the above equation (Eq. 1). From the throughput perspective, the 20 fluid array chips in parallel preparation were therefore used and covered more than 95% of 106 of the 'TesA mutant library.

After the process of incubation in the fluid array platform and data analysis, capillary extractions were performed in a descending order of fluorescence signals from each chamber. Mutants exhibiting higher fluorescent signals also showed increased FFA production as the results of GC analysis (Figure 25). To see the device efficiency variation of the batch of liquids, 20 arbitrarily selected extractions were also analyzed for their FFA production by GC analysis.

To see a relativity between the screening performance of the liquid array and the FFA production yield, the extracted mutant samples were categorized into two distinct groups. Through the hybrid screening process, several genetic mutants of 'TesA were revealed and analyzed by DNA sequencing of the extracted cells. The dynamic detection range of the exFAB biosensor is defined from 0.05 to 0.4 g/L, which closely matches the expected production yield of DCs.

We then tested the response of the exFAB biosensors to the extracellular produced fatty acids from three different control microbial groups within the fluid array platform (Figure 29). We then selected outstanding 10 mutants that showed higher fatty acid secretion performance and identified sequences of the transposon insertion regions from each of selected samples. The concentration of intra/extracellular fatty acids was measured from ten mutants screened by C2C communication based screening of the fluid array platform.

In the near future, identification of these screened mutants will be performed as well as further advanced genetic analysis of the mutations.

Summary and Future Outlook

Summary of findings

Overall, the microfluidic approaches introduced in this thesis were successfully used for the quantitative analysis and high-throughput screening of synthetically engineered microbes. It is strongly believed that the bioMEMS technologies, including such microfluidic approaches, would be a practical step to realize a fully integrated total analysis system for various biological applications that have been limited by conventional approaches.

Future outlooks and perspectives

Rocaboy-Faquet, E., et al., New bacterial bioassay for a high-throughput screening of 4-hydroxyphenylpyruvate dioxygenase inhibitors.