One of the well problems the operation faces is formation damage in the wellbore. The damage to the formation can have several causes, one of which is due to the formation of wax and asphaltene deposits. This formation of organic deposits will cause the flow of the well to be disrupted and suddenly depleted.

The study of the effect of temperature on the formation of the precipitate will provide a solution to the operation in order to manipulate the production to minimize the formation. The study will cover the effect of temperature on raw properties and also determine the temperature range where precipitation tends to form. The raw sample will be placed under several temperature ranges to observe the change that may occur in its properties and also any precipitate formation.

The result of the study will be used to manipulate the current operating practices to minimize the formation of the precipitate and thus improve the production of crude oil. T who had showered his immense blessing and wisdom on the author throughout his life as a student. Thank you for taking the time to guide and supervise the author through it all.

Special thanks are also extended to the last year's Chemical Engineering Project Committee and the technicians involved in ensuring that this project is successful.

CHAPTER 1 INTRODUCTION

To determine the temperature range where oil tends to form waxes and asphaltene precipitates. The study on the influence of temperature changes on the extraction of waxes and asphaltenes from crude oil will be completed within a period of one year (2 semesters). There are 2 main phases of the study; phase 1, literature review and phase 2, laboratory experiment.

The study will include 2 main parts which is the study of the effect of temperature on the change of raw properties and also the study of the temperature range that will form the crude from the wax and asphalt precipitate.

CHAPTER 2 LITERITURE REVIEW

The increase is influenced by the increase in asphaltene particle concentration in the area near the wellbore as the oil converges radially toward the wellbore. There are highly condensed polyaromatic structures or molecules, containing heteroatoms (S, 0, N) and metals (Va, Ni), which exist in petroleum in an aggregated state in the form of suspension and surrounded and stabilized by resins as peptizers. Whether or not asphaltenes cause problems is independent of the amount of asphaltene in the oil.

Light oils with small amounts of asphaltenes are more likely to cause problems during production than heavy oils with larger amounts of material in the asphaltene fraction. Any injection of fluids and chemicals near the wellbore during production and variation of fluid saturations can change the temperature, pressure and composition of the fluids in the near wellbore area and tubing. Wax before separation it can cause or magnify a number of problems in the treatment of petroleum.

It can help emulsify crude oil during crude oil production and refining as well as during oil spills. As the wax precipitates at low temperatures, it can cause clogging of drilling equipment and pipelines underwater and in the Arctic. When waxy crude oil is cooled, it gels due to the formation of a network of wax crystals, which exhibit strong physical interaction and affinity that precipitates in the formation of stable wax crystals that interlock to form a solid network.

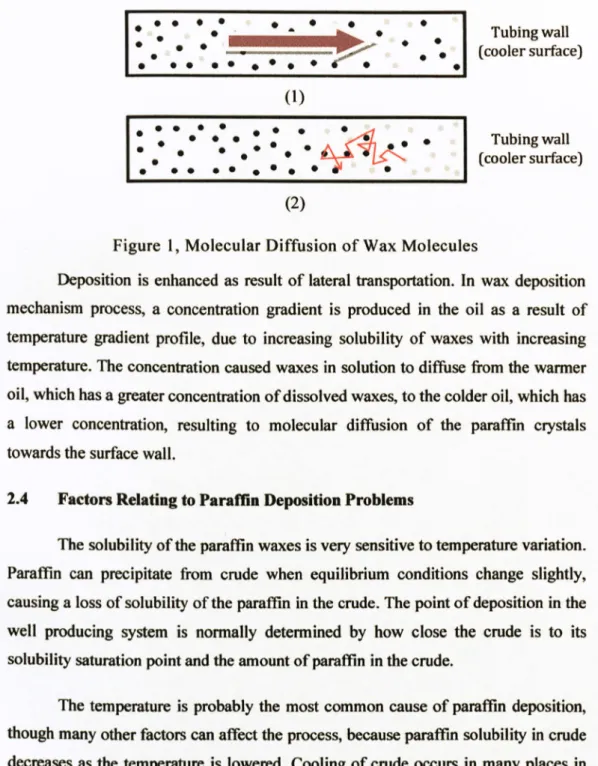

At high temperature and pressure, similar to reservoir conditions, the solubility of these compounds is sufficiently high to keep them completely dissolved in the mixture and the crude oil behaves as a Newtonian fluid with low viscosity. The wax particles appear in the crude oil when the oil temperature drops below the solubility limit. In the process of wax deposition mechanisms, a concentration gradient is produced in the oil due to the temperature gradient profile, due to the increasing solubility of waxes with increasing temperature.

Paraffin can precipitate from crude oil if equilibrium conditions change slightly, causing loss of solubility of the paraffin in the crude oil. Injecting cold fracturing fluids or acidifying fluids into the brown oil reservoir for maintenance work can cause significant cooling of the crude oil. However, methods of detecting wax deposition in the field include visual observation of produced crude oil in the stock tanks and abrupt drop in production rate.

CHAPTER 3 METHODOLOGY

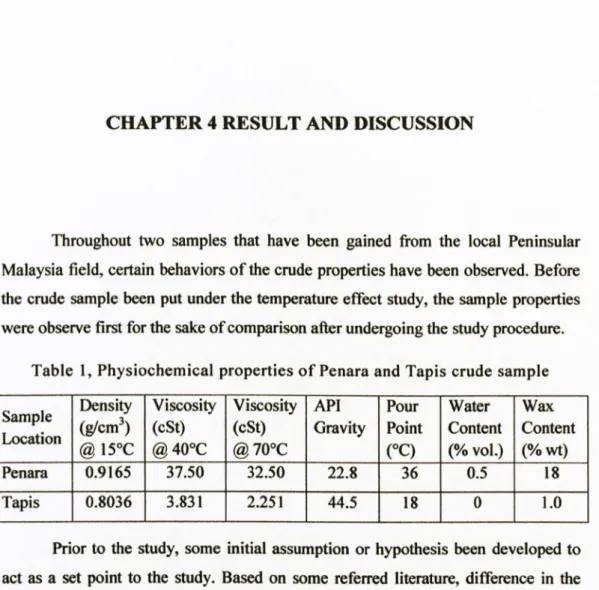

In general, the procedures refer to the laboratory scale experiment where most of the research will be carried out. It is identified that the formation of the wax and asphaltene precipitation in the wellbore occurs due to various reasons. For this study, API gravity values were obtained by calculating them from the value of the density of the crude oil.

A viscometer was used to measure the viscosity represented by each crude oil sample. The effect of crude oil precipitation was also closely related to the wax content value. The wax content measurement can be done by first weighing the empty sample bottle and also the sample bottle with the crude sample.

This is to ensure that all the wax that was in the sample to settle at the. The remaining sample in the bottle was then weighed to obtain the weight of the wax in the crude oil. From the calculation, the wax content value will then be compared with the other data obtained on the properties of the raw sample to obtain a.

From obtaining the different wax contents, the sample is then heated to ensure that the wax will dissolve back into the crude oil. The main part of the research is the study of the temperature effect on the precipitation formation. It is claimed that the temperature is one of the most important parameters that promote the precipitation formation.

The pressure applied to the raw sample was done by pumping the water into the column. After this period, all samples were taken for observation of precipitation analysis formation. This is to gain a better understanding of the behavior of the crude oil and how the effect of temperature will affect its properties.

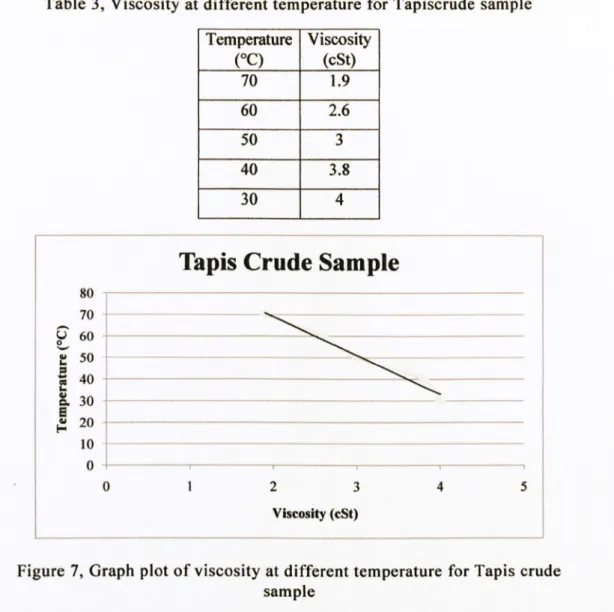

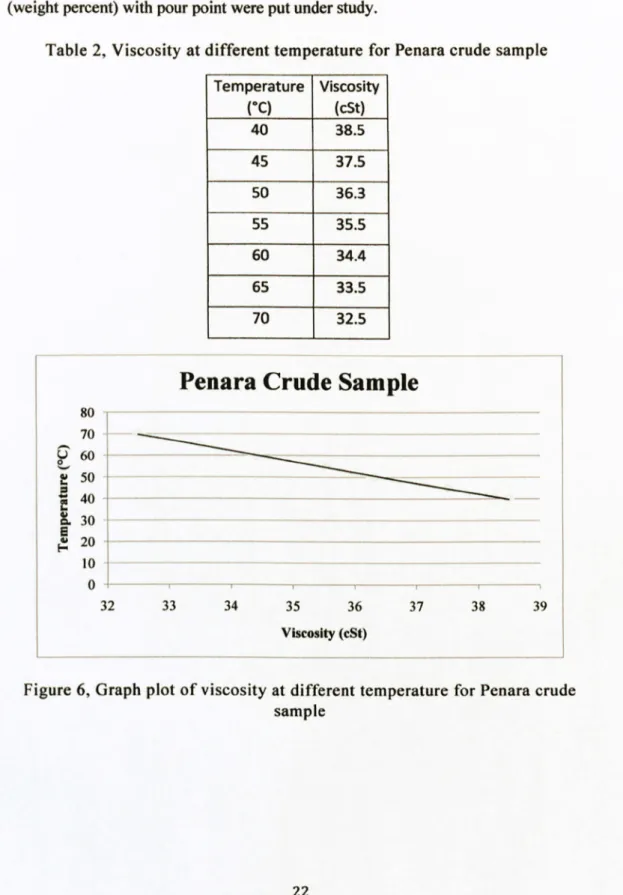

For this first part of the data interpretation, the crude oil properties data were taken within a certain range. The result and analysis of the data are presented in the form of a table and a graph.

CHAPTER 4 RESULT AND DISCUSSION

The viscosity of the crude oil sample for both fields tends to increase with decreasing temperature. Although the magnitude of the viscosity is different between the two samples due to the different properties of the crude oil, it still shows a similar interaction with respect to the temperature change. The temperature was lowered on the raw sample just like during production to see the effect the sample would be subjected to.

The result obtained shows that the same trend can be seen in both samples: increasing the temperature cooling interval will result in an increase in precipitation formation. The greater the temperature gradient between the simulated reservoir temperature and the ambient temperature, the greater the proportion of crude oil that will tend to form precipitation. Although the viscosity value and rate of change differed between both crude samples due to the different properties of the crude oil, it exhibits the nature of viscosity decrease as temperature.

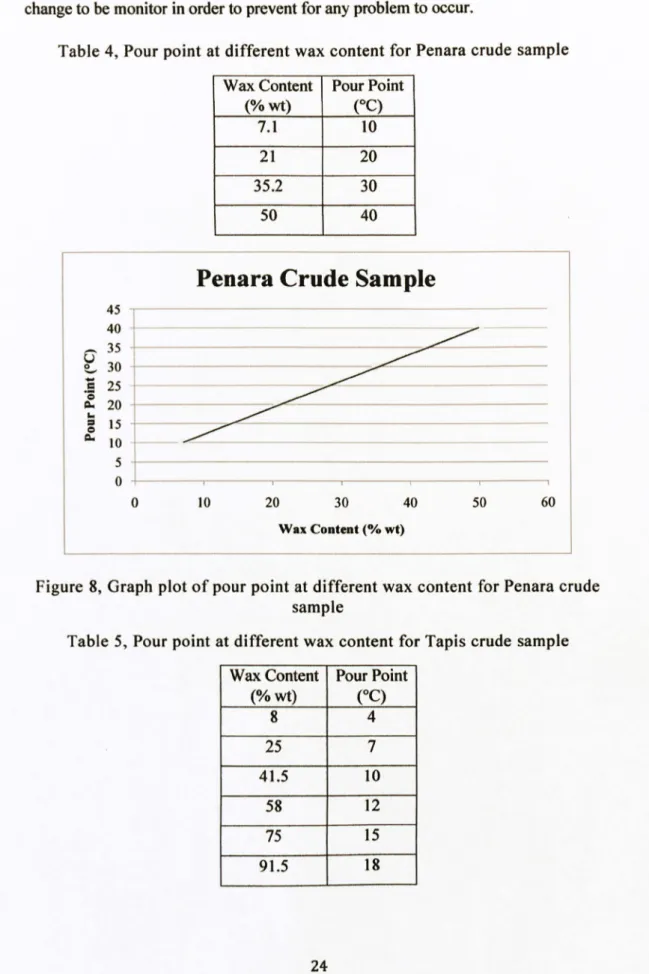

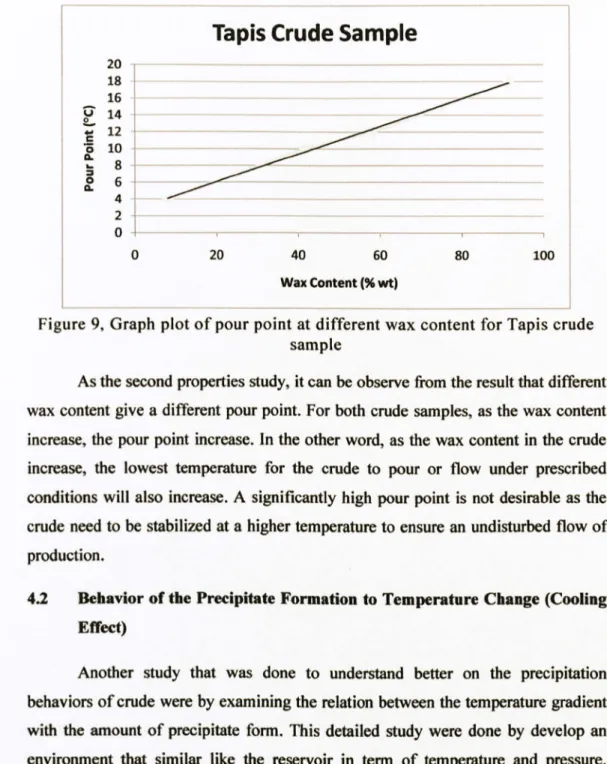

This will result in the increase in viscosity as the interaction between the crude oil particles acts as a resistance to the flow. Regarding the relationship between the wax content and the pour point, the pour point of the oil will show a significant increase as the wax content of the crude oil increases. High pour points were not desired for the production of crude oil, as it appears to be a problem to flow at a high temperature.

The temperature can be easily manipulated as it is by controlling the heat to ensure that the production temperature does not drop to the pour point of the crude oil. Although it is said that the formation of precipitate can be controlled by controlling the wax content, but up to the current production technology, trying to control the wax content seems to be impossible as it is highly related to the raw properties of the various fields themselves. . The study has shown that as the temperature gradient increases, the crude oil precipitate content will gradually increase.

This may be because the faster the cooling of the crude oil, the more precipitate will form. To ensure that the same does not happen in the production well, proper control of the gradient must be considered to control the additional sediment formation. From the overall study, it is proven that the temperature change plays a major role in the formation of the precipitate in the crude oil.

CHAPTER 5 CONCLUSION

If the effect can be modeled together with the temperature change, a better set of results showing the reservoir condition will be obtained. 34; To consider the effect of the high-temperature cooling on the formation of wax and asphaltene precipitation. The studies have provided a comparison between the different cooling temperature gradients and the formation of precipitation.

To prove that it is the properties that really influence the formation of precipitation, it was necessary to establish the effect of high-temperature cooling.