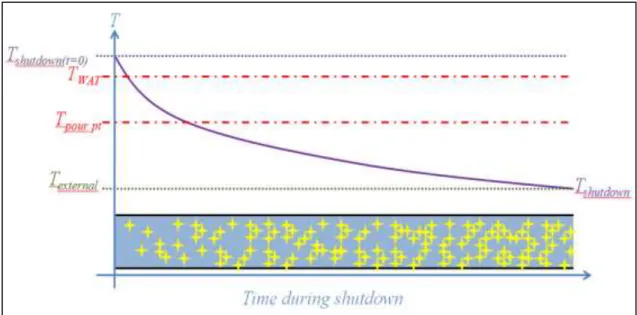

During an emergency or maintenance shutdown, crude oil in the pipelines undergoes thermal contraction, so a high start-up pressure is required to restart crude oil flow. Subsequently, the presence of PPD in the crude slows down the thermal shrinkage and gassing process. In the oil and gas industry, approximately 20% of produced and pipelined petroleum reserves are crude oil.

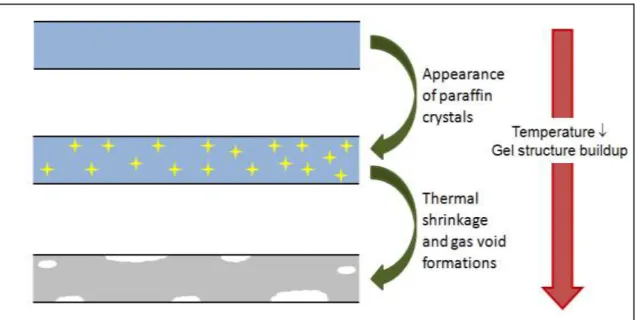

However, during non-operating period or maintenance shutdown, thermal shrinkage and formation of gas voids occur resulting in waxy crude oil. Thermal shrinkage and gas voids formed during cooling increase the restart pressure and thus affect the transport process of the crude oil. The main objective of this project is to study the thermal shrinkage and gas void formation of waxy crude oil.

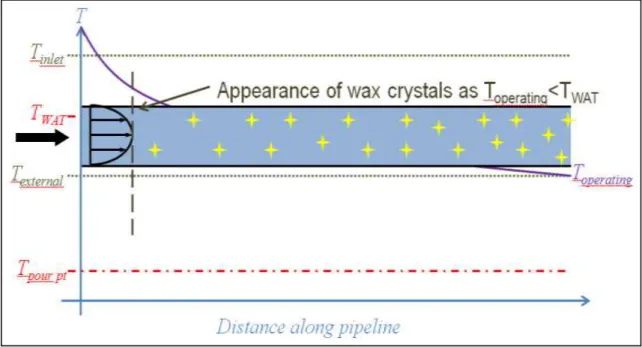

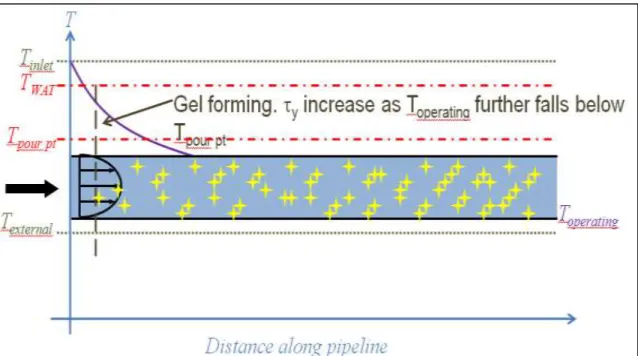

Custom bubble line flow rig to simulate the thermal shrinkage of waxy crude oil in the pipeline. The solubility of wax decreases drastically as the temperature drops and wax molecules begin to precipitate out of the crude oil. Basically, waxy crude oil undergoes thermal shrinkage as the pipeline temperature approaches the pour point.

PPD alters the wax crystallization process and blocks the extensive growth of wax matrices in the crude oil.

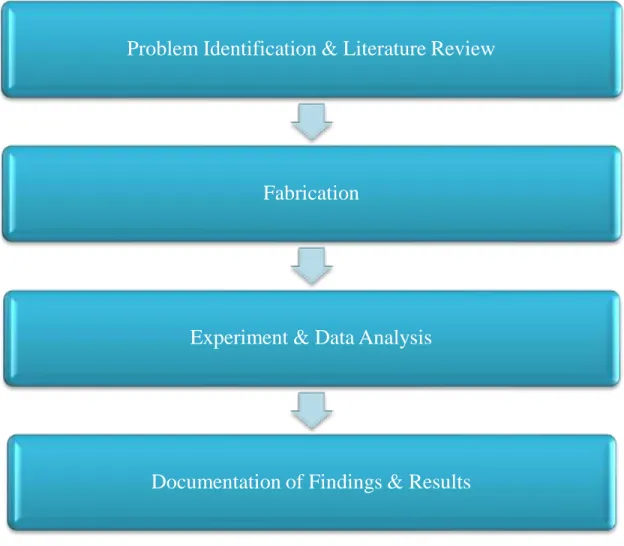

METHODOLOGY 9

- Research Methodology 9

- Apparatus 11

- Project Activities 11

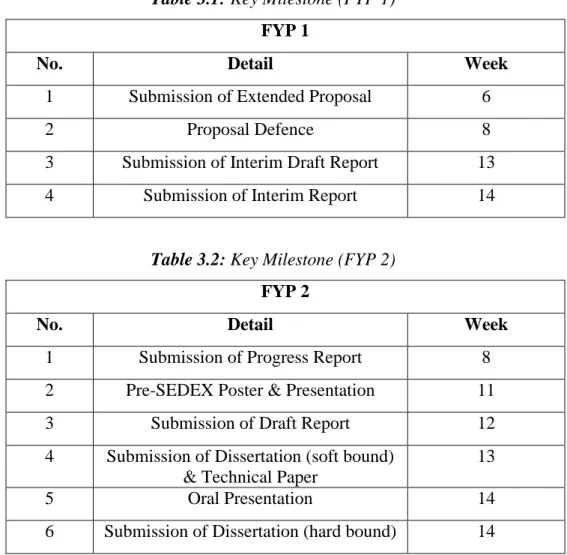

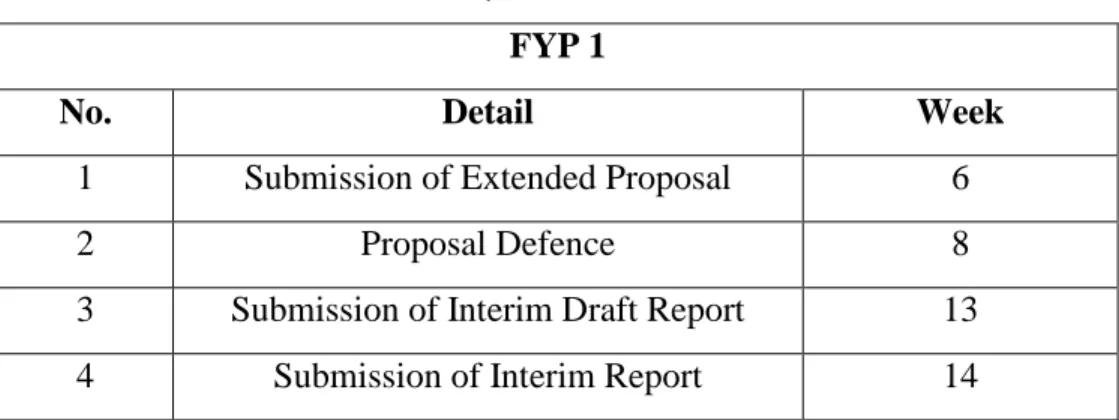

- Key Milestone and Gantt Chart 15

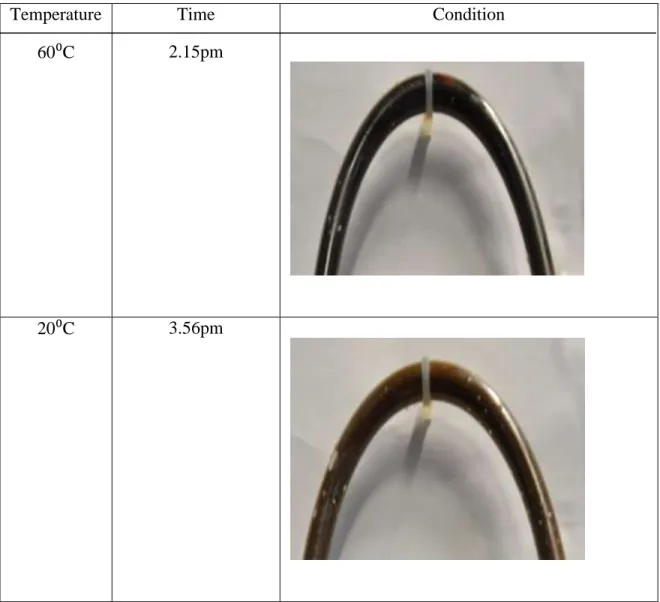

The mixture is then cooled from 60°C to 10°C. 3) Gas void formation is then observed for every 5°C interval. The condition of the crude oil inside the pipe is recorded and its picture is taken for further analysis. A new frame to hold the crude oil pipe is created based on the previous frame.

The new frame was manufactured taking into account that the tube must be completely immersed in the water bath so that the formation of the gas void at the apex is not affected. The crude sample is heated for 30 minutes at 60⁰C to enable good mixing of the particles. The syringe is then tapped at the top of the tube where the gas cavities are located due to pressure difference.

Finally, measure the volume of the solid headspace and scale back to the original ratio. Before analyzing the composition of the headspace using the gas chromatography machine, the headspace should be extracted from the tube without any contamination. Below are details about the method that can be used to extract the gas void without any contamination.

Once the gas void is formed at the top of the tube, tap both syringes and slowly release the helium gas, withdrawing the gas void at the same time. Aspirate the gas from the tube and seal it before transferring it to the Gas Chromatography machine.

RESULTS AND DISCUSSION 18

Pour Point Analysis 18

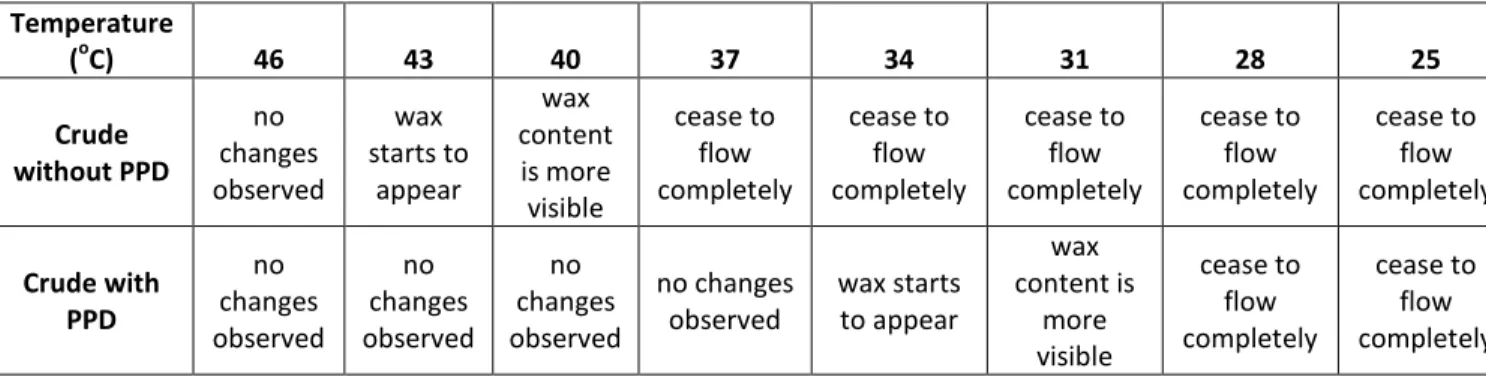

The formation of gas pockets with and without the presence of pour point depressant (PPD). Based on the experiments performed and the results obtained, few conclusions can be drawn regarding the thermal shrinkage and the formation of gas voids. In addition, the effect of pour point depressant (PPD) on thermal shrink gas void formation was also studied.

However, the gas void tends to expand more in the crude oil without PPD and fills the tube as the temperature drops. However, the addition of PPD does not completely stop the gas void formation process, but rather slows it down. Regarding the study on aging process, the result shows that the volume and pressure of the gas void increases slightly during the aging process.

Based on the observation, the gas void expands and begins to fill the tube during the aging process. As the crude oil is allowed to cool further, larger volume of gas void is observed. The result produced is not accurate because the gas cavity can be contaminated during the extraction process.

Thermal shrinkage and gas voiding occur when waxy crude oil undergoes a cooling process below the solidification temperature. First, the volume and pressure of the gas void increase with the cooling rate. On the other hand, the aging process increases the volume and pressure of the gas void.

Use special syringes to draw out the gas void so that the gas void is not contaminated. The study of parameters other than volume, pressure and composition of crude oil can provide a better understanding on thermal contraction and gas void formation. Syuaib Mohd, (2012) “Thermal Shrinkage and Gas Void Formation of Additive Waxy Crude Oil”, Tronoh, Perak.Universiti Teknologi PETRONAS.

Experiment: Variation of Final Temperature 19

- Experiment 2 20

Experiment: The formation of gas void without the

Experiment: The formation of gas void with the

Experiment: The aging process of the gas void 29

Cooling Rate 32

Gas Void Pressure Measurement 33

Gas Void Volume Measurement 34

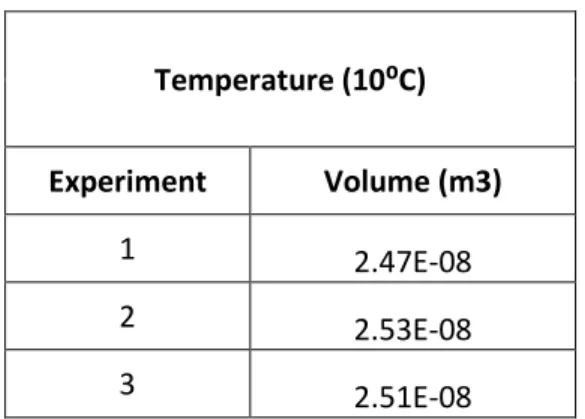

From the variation of final temperature experiment carried out to investigate the effect of cooling rate on the gas void formation, it is found that the volume and pressure of the gas void increases with the cooling rate. As the final temperature decreases and the time taken for cooling process increases, higher percentage of gas void along the tube is observed. This is because at lower temperature and higher cooling rate the gas void can expand more and fill the tube.

Crude oil with and without PPD was cooled to a temperature of 10⁰C. The results show that the gas void starts to form at the top of the pipe at a temperature of 25⁰C (below the melting point of crude oil) for both experiments. When PPD is added to crude oil and then cooled, a smaller gas void volume is formed compared to crude oil cooled without the presence of PPD.

This is because the addition of PPD helps reduce wax precipitation and lowers the melting point of the wax.

Gas Void Composition 40

CONCLUSION AND RECOMMENDATION 41

Conclusion 41

New approaches to waxy crude restart: Part 1: Thermal shrinkage of waxy crude and its implications for pipeline restart, Journal of Petroleum Science and Engineering (2010), doi: 10.116/j.petrol.2010.009 6. Comparison of waxy crude Appearance Temperatures of Crude Oils by Differential Scanning Calorimetry, Thermomicroscopy and Viscometry”. Nazmi Mohd, (2012) “Thermal Shrinkage and Gas Cavity Formation of Waxy Crude Oil”, Tronoh, Perak.Universiti Teknologi PETRONAS.

Before transferring the image to Catio, it is necessary to mark two red lines and measure the original parameter between the two red lines. Based on the sketch, draw a solid pipe structure and determine the scale of the parameters.

Recommendation 41