Page 1 of 88

Semesters

1439 H – 2018 G

TECHNOLOGY DIPLOMA Curriculum for Department of

Construction Technology

Major

Civilization Construction

Training Plans For Technical Colleges

Page 2 of 88

Introduction

Praise be to Allah who taught (the use of) the pen, Taught man that which he knew not. Peace and blessings upon our Prophet, instructor and role model, Muhammad Ibn Abdullah, who is sent as a teacher and guide to people and caller to Allah to bring people out of the darkness of ignorance and misguidance to the light of knowledge and guidance.

The Technical and Vocational Training Corporation seeks to qualify trained national cadres who are able to fill technical, technical and vocational jobs available in the Saudi labor market. This interest comes as a result of the directions requested by the leaders of this country. All these jobs seek to obtain an integrated homeland that depends first on Allah's success, then on its resources and the strength of its youth, which has knowledge and faith. Everyone strives for the sake of continuing to reach developmental progress, so that, by the grace of Allah, the country becomes one of the highest industrialized countries.

The Director General for curricula has taken a positive step in line with advanced international experiences to build training programs, according to modern scientific methods that are compatible with the requirements of the labor market in all its specialties to meet these requirements. This step consisted of the National Professional Standards Preparation Project, then the National Professional Qualifications Project. Both projects are the main pillar in building training programs. Standards and qualifications depend on the formation of specialized committees representing the labor market and the General Organization for Technical and Vocational Training. The scientific vision must be compatible with the practical reality imposed by the requirements of the labor market, so that these committees ultimately come out with an integrated view of a training program more relevant to the labor market, and more realistic in achieving its basic requirements.

This training plan deals with the "Civilization Construction plan" in the Department of Construction Technology for trainees of technical colleges to describe the courses of this specialization. This plan needs to include vital topics that deal with how to acquire the necessary skills for this specialization so that their skills are to assist them in their practical life after graduating from this program.

The Director General for curricula hopes that this training plan will be a direct contribution to the study of necessary skills, in a simplified manner free of complication.

We hope that Allah will grant success to those who prepare the training plan and its beneficiaries, for what Allah wants and pleases.

Director General for curricula

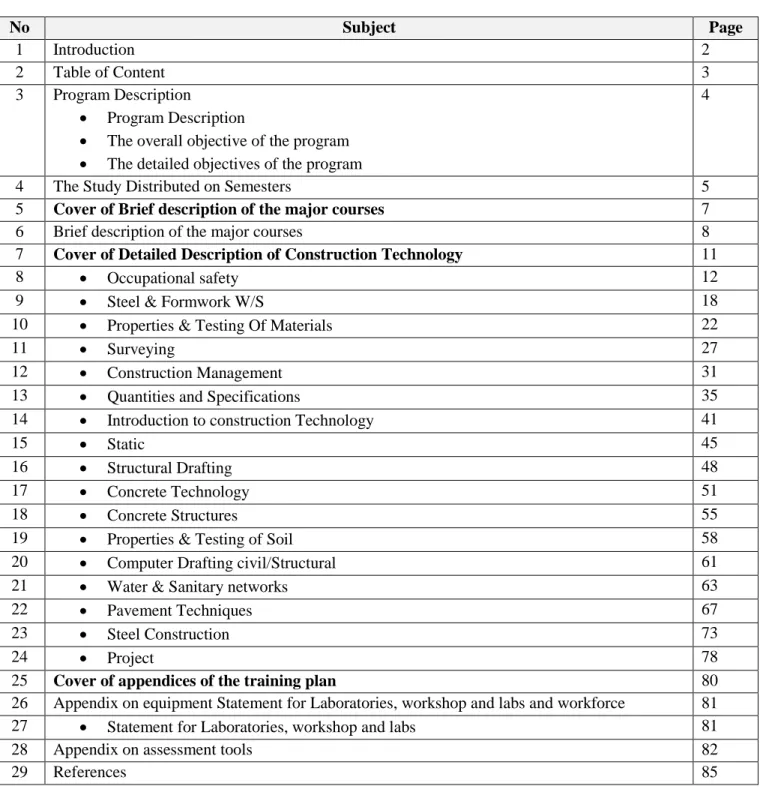

Page 3 of 88 Table of Content

No Subject Page

1 Introduction 2

2 Table of Content 3

3 Program Description

Program Description

The overall objective of the program

The detailed objectives of the program

4

4 The Study Distributed on Semesters 5

5 Cover of Brief description of the major courses 7

6 Brief description of the major courses 8

7 Cover of Detailed Description of Construction Technology 11

8 Occupational safety 12

9 Steel & Formwork W/S 18

10 Properties & Testing Of Materials 22

11 Surveying 27

12 Construction Management 31

13 Quantities and Specifications 35

14 Introduction to construction Technology 41

15 Static 45

16 Structural Drafting 48

17 Concrete Technology 51

18 Concrete Structures 55

19 Properties & Testing of Soil 58

20 Computer Drafting civil/Structural 61

21 Water & Sanitary networks 63

22 Pavement Techniques 67

23 Steel Construction 73

24 Project 78

25 Cover of appendices of the training plan 80

26 Appendix on equipment Statement for Laboratories, workshop and labs and workforce 81

27 Statement for Laboratories, workshop and labs 81

28 Appendix on assessment tools 82

29 References 85

Page 4 of 88 Program Description

It covers the civil construction diploma in the Construction Technology Department in line with the needs of the local labor market for specialization. Training in this specialization is carried out in technical colleges, in five semester training classes; the duration of each training semester is eighteen training weeks, with (1696) training hours. This is in addition to (490) hours of practical training in the labor market, equivalent to (79) credit hours.

Training in this program is on specialized skills in wrenching and reinforcing workshops, structural drawing, computer structural drawing, static, material properties and exams, construction technology, surveying, concrete technology and work. Training is carried out on soil properties and exams, quantities and specifications, construction management, water and sewage networks, road technologies, mineral construction in addition to general skills in Islamic culture, Arabic, English, mathematics, computer applications, and getting to know the business world or (my course Career guidance, excellence, career behavior and communication skills).

Graduates from this program are granted an intermediate university certificate in the civil construction specialization from the Department of Construction Technology, and it is expected that they will work in the fields (road controller, civil construction superintendent, cartographer, surveyor, assistant coach in the specialty, technical specifications and standards in the specialty, technician industrious Specialization, Assistant Civil Engineer).

The overall objective of the program

This program aims to provide the trainee with the skills and information necessary to practice work in the field of civil construction, and he obtains the fifth level in the national qualifications framework.

The detailed objectives of the program

By the end of this program, the trainee will be able and efficiently to:

The trainee receives the job site

The trainee adheres to occupational safety procedures at the work site

The trainee draws engineering drawings

The trainee reads the engineering drawings

The trainee exams the quality of the civil materials.

The trainee supervises the implementation of civil works

The trainee supervises the implementation of construction works

The trainee receives the finishing works for the buildings

The trainee uses types of insulators in the buildings

The trainee exams the insulation works in the buildings.

The trainee learns about the science of stillness

The trainee learns the principles of structural analysis

The trainee uses surveying devices for surveying and lifting works

The trainee learns about the physical and mechanical soil properties.

The trainee performs laboratory and field exams on the soil.

The trainee calculates the quantities of the project.

The trainee prepares the technical specifications of the project.

The trainee learns about the types of water supply networks, torrents and sewage.

The trainee creates a horizontal and vertical layout of the methods to create them.

The trainee learns about steel construction systems, components and design.

The trainee learns about the old and modern structural systems.

The trainee defines the structural system.

The intern trains the project through the executive drawings and technical reports.

The Study Distributed on Semesters

1 st Semester

No Course

Code Course Name Prerequisites Equivalent No of unites

CRH L P T CTH

3 CCIV 101 Occupational safety CIV 9150 2 2 0 0 2

2 MATH101 Mathematics MAT8101 3 3 0 1 4

4 ICMT 101 Introduction to Computer

Applications CMT 101 2 0 4 0 4

5 ENGL 101 English Language -1 ENG 8101 3 3 0 1 4

6 PHYS 101 Physics PHY 8101 3 2 2 1 5

7 VOCA

101 Vocational Guidance & Excellence VOC 107 2 2 0 0 2

1 ISLM 101 Islamic Studies ISL 101 ISL 102 2 2 0 0 2

8 CCIV 102 Steel & Formwork W/S CIV 151 2 0 4 0 4

Total Number of Units 19 14 10 3 27

CRH: Credit Hours L: Lecture P: Practical T: Tutorial CTH: Contact Hours

2 st Semester

No Course

Code Course Name Prerequisites Equivalent No of unites

CRH L P T CTH

1 ARAB101 Technical Writing ARB 101 2 2 0 0 2

2 ENGL 102 English Language -2 ENGL 101 ENG8102 3 3 0 1 4

3 CCIV111 Properties & Testing Of Materials CIV9153 3 2 2 0 4

4 CARC131 Introduction to construction

Technology ARC9253 2 1 2 0 3

5 CCIV112 Static MATH101 CIV 155 3 3 0 2 5

6 CCIV122 Computer Drafting civil/Structural ICMT 101 CIV9253 2 0 4 0 4

7 CCIV 121 Structural Drafting CIV9152 4 2 4 0 6

Total Number of Units 19 13 12 3 28

CRH: Credit Hours L: Lecture P: Practical T: Tutorial CTH: Contact Hours

3 st

Semester

No Course

Code Course Name Prerequisites Equivalent No of unites

CRH L P T CTH

1 ENGL 103 English Language -3 ENGL 102 ENG 8103 3 3 0 1 4

2 CCIV 241 Surveying MATH101 CIV 9154 2 1 2 1 4

Page 6 of 88

3 CCIV 232 Concrete Technology CCIV 111 CIV 156 3 2 2 0 4

4 CCIV 233 Concrete Structures CCIV 112 CIV 251 4 4 0 1 5

5 CCIV 213 Properties & Testing of Soil CIV 252 3 2 2 0 4

6 CARC 214 Quantities and Specifications MATH101 ARC 250 3 2 2 0 4

Total Number of Units 18 14 8 3 25

CRH: Credit Hours L: Lecture P: Practical T: Tutorial CTH: Contact Hours

4 st Semester

No Course Code Course Name Prerequisites Equivalent No of unites

CRH L P T CTH

1 ETHS 101 Professional Ethics & Comm.

Skills VOCA 101 ETH 101

2 2 0 0 2

2 LEAS 101 Learning Skills 2 2 0 0 2

3 CCIV 251 Construction

Management CIV 9250 3 2 2 0 4

4 CCIV 252 Water & Sanitary networks CIV 9254 3 3 0 1 4

5 CCIV 261 Pavement Techniques CIV 4252 CIV 9255 3 2 2 0 4

6 CCIV 271 Steel Construction CIV 4155 CIV 256 3 3 0 1 4

7 CCIV 281 Project CIV 9260 4 2 4 0 6

Total Number of Units 20 16 8 2 26

CRH: Credit Hours L: Lecture P: Practical T: Tutorial CTH: Contact Hours

5 st

Semester

No Course Code Course Name No of unites

CRH

1 CIV 4299 Co-operative Training 4

Total Number of Units 4

CRH: Credit Hours L: Lecture P: Practical Hours T: Tutorial CTH: Contact Hours

Total Number of Semesters Credit Unites CRH L P T CTH

79 57 38 11 106

Total of training Hours (16x106 )+ Cooperative training Hours (490)

2186

Brief description of the major courses

Page 8 of 88 Course

Name Occupational safety Course

Code CCIV 101 CRH 2

Description

This course examines the rules and procedures for occupational safety and security and the responsibility of the employer and its employees. The course addresses the safety and security standards and procedures necessary to achieve them on site and in the workshop, and to ensure that all employees adhere to the applicable safety and security procedures, achieve an appropriate work environment that is safe from accidents, and provide safety for all workers.

Course

Name Steel & Formwork W/S Course

Code CCIV 102 CRH 2

Description

This course deals with the definition of Construction Technology and its fields of work in addition to the executive side. Woodwork works for each of the bases, tables, ceilings, beams, ladders, retaining walls and methods of receiving these works. The course deals with training in the implementation of rebar works for these structural elements, and knowing the number and tools used for both wood and metal formwork and rebar work.

Course Name

Properties & Testing Of Materials

Course

Code CCIV111 CRH 3

Description

This course deals with the definition of the mechanical, physical and chemical properties of the various materials used in building technology, the extent of the presence of these materials in the environment in which the building is executed and their conformity with local and international standards, and carrying out the necessary experiments for construction materials exams.

Course

Name Surveying Course

Code CCIV 241 CRH 2

Description

This course deals with introducing space science and its basic principles. It includes training in the use of various surveying devices for the work of lifting and surveying, taking measurements, preparing budgets in the stages of project implementation and matching drawings on the ground within the use of modern techniques in surveying science.

Course

Name Construction Management Course

Code CCIV 251 CRH 2

Description

The course deals with the definition of the types of engineering contrworks, tenders and their procedures, to organize and manage construction project contrworks. It deals with the stages of the project, the parties involved in it, and the tasks of the technical management of the project in reviewing the project documents, from quantitative tables, executive plans and specifications, and their approval by the consultant, preparing reports, writing records, and methods of managing the project resources. The course deals with training in planning and scheduling methods used in project management for materials, labor, equipment and subcontractors during the various project stages as well as preparing detailed programs for implementation stages and how to determine the time to implement various project activities with the use of computers in planning and scheduling the project.

Page 9 of 88 Course

Name

Quantities and Specifications

Course

Code CARC 214 CRH 3

Description

This course deals with the skills of studying contract documents, the concept of insurance assays and the list of quantities, in addition to carrying out quantitative work, excavation and backfilling, ordinary and reinforced concrete and building works. The course deals with isolation work, stating the specifications and business items, the method of making periodic and final works for the executed works, and using specialized software.

Course Name

Introduction to construction Technology

Course

Code CARC131 CRH 2

Description

This course covers the review of old, modern and advanced construction systems and to determine the appropriate construction system, testing the quality of sanitary and electrical works and finishes and insulation works implemented in buildings and receiving them according to Saudi specifications. The course deals with the definition of the importance of energy and ways to conserve it using different types of insulators and methods of installing and testing them.

Course

Name Static Course

Code CCIV112 CRH 3

Description

This course covers the review of ancient, modern and advanced structural systems, how this statics deals with principles of structural analysis such as force analysis, reaction calculation, and internal forces of simple structural elements. As well as drawing the shape of shear and bending torque in addition to finding the value of strain and stress in the simple structural elements.

Course

Name Structural Drafting Course

Code CCIV 121 CRH 4

Description

This course deals with the basics of drawing architectural and structural plans (concrete and metal), in addition to drawing details and sections for all the different structural elements of concrete and metal installations, the course deals with how to read the details of the plans and ensure that the engineering drawings are matched with what is implemented on the site.

Course

Name Concrete Technology Course

Code CCIV 232 CRH 3

Description

This course deals with the stages of concrete manufacturing, starting from mixing, transporting, pouring and mixing it to finishing and treating it. The course also deals with ways to speed up the resistance of concrete, in addition to emphasizing the procedures and precautions to be taken according to climatic conditions. The course includes the necessary experiments to ensure the quality of fresh concrete on site and hardened concrete in the facility.

Course

Name Concrete Structures Course

Code CCIV 233 CRH 4

Description

In this course, the trainee learns about the types of concrete structures, the foundations of structural analysis and the basics of design for tiles, beams, columns, bases and supporting walls, with application and use of standard specifications and the use of software for structural analysis and design.

Page 10 of 88 Course

Name

Properties & Testing of Soil

Course

Code CCIV 213 CRH 3

Description

The course introduces the study of all types of soils and their physical and mechanical properties, their classification and how they behave under the influence of loads; The course includes standard specifications for earthworks according to international regulations and a number of laboratory exams on soil.

Course Name

Computer Drafting civil/Structural

Course

Code CCIV122 CRH 2

Description

This course covers the skills of preparing structural drawings with a computer, which includes structural panels for columns, axes, foundations, tiles and various construction sectors with printing and drawing boards and how to use computer drawing orders to prepare architectural and structural forms.

Course

Name Water & Sanitary networks Course

Code CCIV 252 CRH 3

Description

The course deals with the types of water feeding networks, sewage networks, torrents, the necessary initial studies for them, the types of pipes used in each network, the parts that comprise them, the way of implementing, maintaining, testing them, and reading their executive plans. The course includes water sources and hydraulic laws for the movement of fluids in open channels and pipes and calculating their diameters in different types of networks in addition to studying population density and determining consumption rates for current and future water and the use of floor and upper tanks.

Course

Name Pavement Techniques Course

Code CCIV 261 CRH 3

Description

This course deals with the scientific and technical foundations related to road construction, which include horizontal and vertical planning of roads, elements of the road cross section, types and forms of road intersections, and then detailing the technical aspects necessary for implementation. This course deals with supervision of road projects, from the work of compacting the soil to the construction of the asphalt layer of the road, and then briefly addresses methods for designing flexible paving, how to evaluate the pavement surface, identifying paving defects, and determining the ideal method for maintenance of pavements and the technical bases for receiving road projects according to specific specifications

Course

Name Steel Construction Course

Code CCIV 271 CRH 3

Description

This course deals with the types of steel installations, their components, and structural systems for them, in addition to the principles of designing various steel members, types of connections between members with nails and welding, design, drawing, and methods of implementation. The course includes manufacturing methods in the workshop, construction on site, monitoring the quality of work and receiving works in addition to reading and extracting various data from the plans used in steel plant projects.

Course

Name Project Course

Code CCIV 281 CRH 3

Description

The project is applied in one of the specializations of civil technology, and it may be in more than one specialization where the skills that have been trained in the curricula are employed in an integrated manner and in a practical manner similar to what is done in the labor market. The topic deals with producing the project with a technical report, executive drawings, or both.

Page 11 of 88

Detailed Description of the specialization courses

Page 12 of 88 Course

Name Occupational safety Course

Code CCIV 101 Prerequisite

Training semester 1 2 3 4 5

Credit hours 2

Collaborative training Contact hours

(Hour/ week)

Lecture 2

Practical 0 Training 0

Course Description

This course addresses the safety and occupational safety rules and procedures and the responsibility of the employer and its employees. The course addresses the safety and security standards and procedures necessary to achieve them on site and in the workshop, and to ensure that all employees adhere to the applicable safety and security procedures, achieve an appropriate work environment that is safe from accidents, and provide safety for all workers.

The general objective of the course:

This course aims to provide the trainee with the skills and preventive measures that must be followed in the workplace to avoid accidents.

The detailed objectives of the course: The trainee should be able and efficient to:

1. The trainee adheres to the safety and security rules.

2. The trainee makes sure that the employees abide by the safety and security rules.

3. The trainee verifies the availability of first aid.

4. The trainee verifies the powers of the fire extinguishers.

5. The trainee verifies the presence of security guards at the site.

6. The trainee learns ways to implement barriers.

7. The trainee organizes the movement inside the project to avoid accidents.

8. The trainee identifies the types of warning signs and guidance.

9. The trainee identifies medications and tools that should be put in first aid boxes.

10. The trainee studies the emergency plans prepared for similar sites.

11. The trainee prepares security reports and statistics for the project.

Page 13 of 88

Units (theoretical and practical) Training hours Theoretical Practical

Occupational Safety Policy 2 0

Training and raising awareness of occupational safety matters 2 0

Risk analysis and management 6 0

Security on site 4 0

Accident investigation, reporting and statistics 2 0

Periodic inspection of work sites to discover hazards 2 0

Safety rules and guidelines and safe work systems 4 0

Safety and firefighting equipment 2 0

First aid and medical services 2 0

Occupational Safety and Health and performing site-specific

measurements 4 0

Specialized programs in occupational safety and health 2 0

Total 2 0

32

Procedures of Safety Requirements:

In this course, safety instructions must be adhered to in the halls of the health session, and the body should be in the proper position when transporting or using devices and equipment, and following safety procedures in field work sites by wearing a protective helmet, gloves, and appropriate clothing for work.

Page 14 of 88

The detailed curriculum (Theoretical and practical)

Hours Content Assessment tools

2

Occupational Safety Policy:

Define the general policy for occupational safety

Introduce the facility's policy

The occupational safety regulations for the facility o Safety program objectives

o The concept and philosophy of the program o Responsible for the safety program

o General responsibilities of all employees of the facility

o Ways to follow up on the occupational safety program

The objectives of public safety laws in the countries of the Gulf Cooperation Council

Oral exams Written exams Practical performance

2

Training and raising awareness of occupational safety matters:

Information required to implement the training and awareness-raising program

Training new employees in the facility

Training old employees in the facility:

o Cases of the need to conduct training for old workers and its components

o Occupational Safety Awareness Program:

o Prepare periodic newsletters o Install the stickers

o Publish statistics, pictures and how-to phrases

The important elements to be covered by the training and its fields

Oral exams Written exams Practical performance

6

Risk analysis and management:

Definition of the concept of hazards and disasters, and mentioned the most important sources and classification o Natural hazards and disasters

o Human hazards and disasters o Industrial hazards and disasters

Work site assessment and risk detection

Risk assessment and analysis

Oral exams Written exams Practical performance

Page 15 of 88

The detailed curriculum (Theoretical and practical)

Hours Content Assessment tools

Preparing for emergencies and contingency plans:

o The emergency cases expected to happen in the facility

o Emergency plans, which include measures to address sudden situations

o Important elements included in emergency plans such as plans: (evacuation, firefighting, prevention of leakage of dangerous materials, dealing with severe injuries, etc.)

Experiments to ensure the efficiency of the emergency plan

Manage available resources and provide risk response plan equipment

Elements and procedures of the risk response plan

4

On-site security:

The importance of security guard

Security guard places on the site

Site security procedures

Self-inspection

Items inspection

Verify the tasks entering the site

How to deal with and record events

Oral exams Written exams Practical performance

2

Accident investigation, reporting and statistics:

Identify and investigate risks to be reported

Determine the methods of reporting, the recipient and who is to investigate

Reporting and investigation forms for injuries and accidents

Statistics to be prepared on accidents and injuries and how to benefit from them

Oral exams Written exams Practical performance

2

Periodic inspection of work sites to discover hazards:

The importance of periodic inspection to identify risks

Inspection forms for inspection

Preventive and corrective actions to avoid risks

Self-inspection and inspection of belongings and proof of the tasks entering the site

Employment structure and distribution of responsibilities:

Oral exams Written exams Practical performance

Page 16 of 88

The detailed curriculum (Theoretical and practical)

Hours Content Assessment tools

o The responsibilities of all employees of the facility o Responsibilities of supervisors

o Facility management responsibilities o Responsibilities of safety officials

Occupational Safety and Health Committee:

o Its responsibilities o Formed

o Its agenda

4

Safety rules and guidelines and safe work systems:

Site safety instructions and guidelines (laboratories, workshops, warehouses, offices)

Instructions for applying occupational safety instructions

Safe working methods for all activities in the facility

Provide first aid

Oral exams Written exams Practical performance

2

Safety and firefighting equipment:

Safety equipment for personal protection:

o The importance of safety equipment to maintain the safety of workers

o Description of personal protective equipment and features

o Choose the right equipment for the type of risk o The proper way to use

o Maintenance, storage and maintenance methods

Firefighting and extinguishing equipment and means of preventing fire

o Causes and types of fires

o Types of fire extinguishers and their importance o Distribution of fire extinguishers

o Ensure the use of extinguishers is valid

o Civil Defense Administration instructions for fire resistance

o Preventive methods for granting fire and modern devices for this purpose

Oral exams Written exams Practical performance

Page 17 of 88

Hours Content Assessment tools

2

First aid and medical services:

Definition of first aid, its importance, and who will do it

Locating first aid boxes and medical aid

Choose people who are trained in first aid on site

Explanation of first aid methods provided to workers:

o Ambulance for different fractures o Ambulance puppy

o Ambulance suffocation cases o Relief of various bleeding cases o Ambulance for burn cases

Oral exams Written exams Practical performance

4

Occupational safety and health and workplace measurements:

Assessing the work environment and identifying chemical and physical hazards

o Chemical hazards:

o Harm to workers

o It damages the machines

o Rates are as high as: smoke, gas fumes, liquids, and dust

Physical hazards: their definition and the permissible rates for them (temperature, airflow speed, noise, radiation, light intensity, atmospheric pressure, humidity)

Carrying out the necessary measurements for work sites periodically, identifying devices and methods of using and calibrating them

Oral exams Written exams Practical performance

2

Specialized programs in occupational safety and health:

Specialized Safety Programs (OSHA) as required by the US Occupational Safety and Health Administration:

o Program for communicating information about dangerous materials

o Warning machines and warning signs isolation program

o Preserving the audio system o Respiratory Protection Program o Indoor entry program

Oral exams Written exams Practical performance

References

Crisis management, disaster response and decision making, Naif Arab University for Security Sciences, Riyadh, Al-Dweik, Abdul Ghaffar (2013)

Use of modern technology in the field of civil defense activities, Naif Arab University for Security Sciences, Riyadh, Dweik, Abdul Ghaffar (2014)

Civil Defense Regulations, General Directorate of Civil Defense, Ministry of Interior, Kingdom of Saudi Arabia

Page 18 of 88 Course

Name Steel & Formwork W/S Course

Code CCIV 102 Prerequisite

Training semester 1 2 3 4 5

Credit hours 2

Collaborative training Contact hours

(Hour/ week)

Lecture 0

Practical 4 Training 0 Course Description

This course deals with the definition of civil and architectural technology and its fields of work in addition to the executive side of wooden formwork work for each of the bases, tables, ceilings, beams and ladders, retaining walls and methods of receiving these works. The trainee trains in the implementation of rebar works for these structural elements and knowledge of the number and tools used for both wood and metal wrenches and rebar works.

The general objective of the course:

This course aims to provide the trainee with the skills of formulating and reinforcing the necessary construction works and supervising their implementation in buildings, roads, bridges, sidewalks and sewage lines.

The detailed objectives of the course: The trainee should be able and efficient to:

1. The trainee distinguishes between the fields of civil and architectural construction.

2. The trainee uses wooden wrenches.

3. The trainee performs the carpentry work in the construction.

4. The trainee does armed blacksmithing in construction.

5. The trainee performs metal wrenches in construction.

6. The trainee performs paving layers.

7. The trainee works to extend the sewage pipes inside a trench.

Units (theoretical and practical) Training hours

Theoretical Practical

Unit 1: Definition of civil and architectural technology and its fields of

work 2 0

Unit 2: tools and materials for wooden wrenches and reinforcing steel 0 2

Unit 3: The Axes Business (Axes) 0 4

Unit 4: Casting (carpentry + reinforcing steel) 0 8

Unit 5: Configuration (carpentry + reinforcing steel) 0 8

Unit 6: Columns (carpentry + armature) 0 4

Unit 7: Ceilings and Beams (carpentry + armature) 0 10

Unit 8: Stairs (carpentry + reinforcing steel) 0 6

Unit 9: Retaining walls (carpentry + reinforcing steel) 0 8

Unit 10: advanced and metallic formwork 0 4

Unit 11: Works of pavements, sidewalks and cold 0 4

Total 0 4

62

Page 19 of 88 Procedures of Safety Requirements:

The health session inside the training halls and the body is in the proper position when transporting or using devices and equipment, wearing the protective helmet, gloves, and clothes appropriate for work and following the safety instructions mentioned in the manuals for the use of devices and equipment, and uses engineering tools for what was assigned to him.

The detailed curriculum (Theoretical and practical)

Hours Content Assessment tools

2

Introduction to civil and architectural technology and its fields of work:

Definition of civil technology

Definition of architectural technique

Civil technology work fields

Architectural technology work fields

Elements of different installations

Construction materials

Oral exams Written exams Practical performance

2

Wrench and reinforcing tools and materials:

The number and tools used

Types and sectors of wood used

Types of rebar and its sizes

Oral exams Written exams Practical performance

4

Axes work (hedging)

The purpose of the precaution

Reading the axes and columns panel

Sign the building on the public site

Executing precautionary works

Signature of horizontal and vertical axes

Receiving the hubs business (hedging)

Oral exams Written exams Practical performance

8

Concrete bases:

Types of rules and get to know their drawings

Read grammar diagrams

Woodwork for reinforced bases

Receiving the work of the rules' hardships

Arm the separate bases

Calculation of steel reinforcement lengths in separate bases

Receive the rebar

Oral exams Written exams Practical performance

8

The bars:

Benefits of women in buildings

Types of females as they relate

Wooden formwork for bars

Receive wooden wrenches for the bars

Arm the women

Oral exams Written exams Practical performance

Page 20 of 88

Calculating the lengths of the reinforcing iron of the welders

Receiving the iron reinforcing bars

4

Columns:

Types of columns and learn about their drawings

Read column charts

Wood formwork for columns

Receiving the works of formworks

Types of steel reinforcement bars

Calculate the lengths of the reinforcing bars

Receive the steel reinforcement bars

Oral exams Written exams Practical performance

10

Ceilings and beams:

Types of roofs and beams and learn about their drawings

Read the ceiling diagrams

Wooden formwork for roofs and beams

Receiving works of roofs and beams

Types of reinforcement in the ceilings

Types of reinforcing beams

Oral exams Written exams Practical performance

6

the stairs:

Types of stairs and learn about their drawings

Read the stairs diagrams

Works of stairs intensity and receipt

Oral exams Written exams Practical performance

8

retaining walls:

Types of retaining walls

Wrenching works for retaining walls of road ferries

Receive the works of wall formwork

Oral exams Written exams Practical performance

4

Metal and advanced formwork works:

Materials and equipment used in metal formwork

Metal parts, bridges, scaffolding, vertical uprights

Disconnect installation and connection

Metal formwork for no roof and beams

Metal formwork for large holes

Employment and productivity rates in metal formwork

Types of advanced wrenches:

o Tunnel wrenches o Sliding wrenches o System wrenches

Oral exams Written exams Practical performance

4

Works of pavements, sidewalks and curbs:

The tools and tools used inside the road and sidewalks workshop

Road planning inside the workshop

Create pavement layers (below foundation and

Oral exams Written exams Practical performance

Page 21 of 88 foundation)

Create sidewalks and install curbs

Surface layer works

4

Works of laying sewage pipes inside a trench:

Digging a trench 80 - 90 cm wide with a side sides support

Extension of a sewage pipeline to a suitable diameter

Create a manhole with the necessary openings

Oral exams Written exams Practical performance

References

Architectural construction --- For Dr. Muhammad Abdullah

Implementation work --- Arab Contractors Company

Engineering Encyclopedia --- Mr/ Abdul Latif Al-Zubari

Modern methods for the restoration, strengthening and protection of concrete structures, Dr. Kamal Mustafa, Dr. Aziz Shenouda

Building construction (building technology) by Dr. Mohamed Abdullah - The Anglo Egyptian Library

Page 22 of 88 Course

Name Properties & Testing Of Materials Course

Code CCIV111 Prerequisite

Training semester 1 2 3 4 5

Credit hours 3

Collaborative training Contact hours

(Hour/ week)

Lecture 2

Practical 2

Training 0

Course Description

This course deals with the definition of the mechanical, physical and chemical properties of the different materials used in building technology, the extent of the presence of these materials in the environment in which the building is executed and their conformity with local and international standards, and carrying out the necessary experiments for construction materials tests.

The general objective of the course:

This course aims to provide the trainee with the basic skills to learn about the properties of different construction materials through conducting field and laboratory tests to be able to control their quality.

The detailed objectives of the course: The trainee should be able and efficient to:

1. The trainee continues to supply construction materials on site.

2. The trainee verifies the quality of the materials used.

3. The trainee tests the quality of the materials used.

4. The trainee makes sure that the materials are well mixed.

5. The trainee is acquainted with the specifications brochure.

6. The trainee is familiar with the international specifications of the materials.

7. The trainee studies the brochures and flyers attached with the materials 8. The trainee determines the types of tests required for the materials.

9. The trainee determines the means of examination and inspection.

Units (theoretical and practical) Training hours Theoretical Practical

Natural stones and rubble 4 6

Cement 2 6

Mixing water and additives 2 2

Concrete 4 10

Bricks and blocks 4 2

Lime and plaster 4 2

Mineral and non-metallic materials 4 8

Paints and insulation 4 0

Total 28 35

64

Page 23 of 88 Procedures of Safety Requirements:

The health session inside the training halls and the body is in the proper position when transporting or using devices and equipment, wearing the protective helmet, gloves and clothes appropriate for work and following the safety instructions mentioned in the manuals for the use of devices and equipment, and uses engineering tools when assigned to it. Keep the documents in a suitable place.

The detailed curriculum (Theoretical and practical)

Hours Content Assessment tools

10

Natural stones and aggregates:

Rocks:

o Rock formation

Cumulus:

o confiscation o Its types o Its uses o Its properties

Marble:

o confiscation o Its types o Its uses o Its properties

Building stones:

o confiscation o Its types o Its uses o Its properties

Aggregate tests:

o Specific and volumetric weight o Granular gradient

o Organic impurities

Oral exams Written exams Practical performance

8

Cement:

Made it up

Its types

Its properties

Store it

Quality control

Cement and mortar tests

Smoothness

Oral exams Written exams Practical performance

Page 24 of 88

The detailed curriculum (Theoretical and practical)

Hours Content Assessment tools

Specific and volumetric weight

Set standard textures

Set the primary suspicion time and final suspicion time

Resistance to compression, tensile and bending of cement mortar samples

4

Mixing water and additives:

water:

o Occupation o Its properties

Types of additives o Its types

o Its properties

Mixing water tests:

o Percentage of salts o Alkaline degree (PH)

Oral exams Written exams Practical performance

14

Concrete:

Concrete mixing

Soft concrete properties

Properties of hardened concrete

Elements influencing concrete resistance

Transfer and pour concrete

Your blood and concrete treatment

Fresh and hardened concrete tests:

o Landing, flow, compacting factor, air content of fresh concrete

o The pressure resistance of standard cubes o Compression resistance of standard cylinders o Schmidt hammer test on structural elements o Concrete heart test on structural elements o Structural loading test

o Determination of bending resistance of hardened concrete

o Non-destructive tests on concrete using ultrasound:

(Determination of concrete quality, detection of steel reinforcement positions and diameters, measurement of the thickness of the surface cover layer, measurement of the depth and direction of the surface cracks).

Oral exams Written exams Practical performance

Page 25 of 88

The detailed curriculum (Theoretical and practical)

Hours Content Assessment tools

6

Brick:

Its types

Its components

Its uses

Its properties

Brick tests:

o Pressure resistance o Water absorption ratio

o Visual examination (dimensions, angles, flatness, straightness)

Oral exams Written exams Practical performance

6

Lime and plaster:

Lime:

o Lime industry o Its uses o Its properties

Gypsum:

o Gypsum industry o Its types

o Its uses o Its properties

Lime tests:

o Smoothness, operability

Gypsum and aloe gypsum tests:

o Softness o Operability o Time of doubt o Bending resistance

Oral exams Written exams Practical performance

12

Mineral and non-metallic materials:

Metal material:

o Iron types o Structural steel o Stainless iron

o The effect of carbon ratio on structural steel o The relationship between stress and emotion o Aluminum and its uses and mechanical properties

Mineral materials tests:

o Tensile iron and aluminum o Shock on iron and aluminum o Bending over iron and aluminum

Non-metallic materials:

o Wood: its sources, types, defects and damage, methods of protecting and treating wood

Oral exams Written exams Practical performance

Page 26 of 88

o PVC: its types, components, uses, properties o Glass: its types, components, uses, properties

Non-metallic materials tests:

the woods :

o Moisture content o Compression resistance

o Shear, bend and stretch in a direction parallel to the fibers

PVC:

o Internal pressure o Chemical resistance

o Visual examination (diameter - thickness - straightness)

4

Paints and insulation materials:

Types of paints:

o Its components o Their uses o Its properties

Insulating materials:

o Its components o Their uses o Its properties

Oral exams Written exams Practical performance

References

Engineering materials resistance and tests, d. Ahmed Ali Al-Arian, d. Abdel Karim Atta, Cairo, the world of books

Concrete Technology (Properties of Concrete and Mixture Design), Dr. Ahmed Ali El-Erian, Dr. Abdel Karim Atta, Cairo, Book World

Saudi standard specifications for building materials

American Code for Design and Implementation of Concrete Structures (Appendix for Laboratory Testing of Concrete Materials)

Page 27 of 88 Course

Name Surveying Course

Code CCIV 241 Prerequisite MATH121

Training semester 1 2 3 4 5

Credit hours 2

Collaborative training Contact hours

(Hour/ week)

Lecture 1

Practical 2

Training 1

Course Description

This definition deals with surveying science and its basic principles, in addition to training in the use of various surveying devices for the work of raising and surveying, taking measurements and preparing budgets in the stages of project implementation and matching drawings on the ground within the use of modern techniques in surveying science.

The general objective of the course:

This course aims to provide the trainee with the skills of using surveying devices to carry out the required surveying work in the stages of project implementation, lifting work, budgeting, and matching drawings on the ground.

The detailed objectives of the course: The trainee should be able and efficient to:

1. The trainee receives a zero point level at the site.

2. The trainee determines the dimensions of the site.

3. The trainee identifies directions on the site.

4. The trainee shall restrict excavation and backfilling.

5. The trainee uses technical terms.

6. The trainee performs the measurement.

7. The trainee uses civil surveying devices.

8. The trainee uses modern electronic measuring devices.

9. The trainee performs satellite positioning.

Units (theoretical and practical) Training hours

Theoretical Practical

Geodesy 2 0

Measuring horizontal distances 2 4

Electronic measurement 2 4

Measuring angles and directions 2 2

budget 2 4

Survey applications 4 4

Calculate the spaces 3 0

Calculation of volumes and land leveling 3 0

Spatial maps and their use 2 2

Satellite positioning 2 4

Introducing all types of space devices used 2 4

An application project for survey works to construct a building 2 8

Total 28 36

64

Page 28 of 88 Procedures of Safety Requirements:

The health session inside the training halls and the body is in the proper position when transporting or using surveying devices and equipment, wearing a protective helmet, gloves and appropriate clothes for work and following the safety instructions mentioned in the manuals for the use of devices and equipment.

The detailed curriculum (Theoretical and practical)

Hours Content Assessment tools

2

Geodesy:

Basic terms and definitions

Types of space

Major steps to surveying

Area measurements and their units

Methods for recording survey observations

Scale of drawing

Direct observation Oral exams Studies cases Written exams

6

Measuring horizontal distances:

Methods for measuring distances

Tape measure

Measuring horizontal distances with modern, funded electronic devices

Errors in measuring and correcting lengths

Raise the space with tape

Direct observation Oral exams Studies cases Written exams

6

Measurement with electronic devices:

Measurement with Total Station

EDM Measurement

Direct observation Oral exams Studies cases Written exams

4

Measuring angles and directions:

Direction of the lines

The horizontal angle between the lines

Angle measuring devices

The unit of measurement of the angle and the relationship between it

Calculate the coordinates

Oral exams Written exams Practical performance

6

budget:

Trigonometric adjustment

Balance adjustment

Leveling applications

Contour lines

Oral exams Written exams Practical performance

Page 29 of 88

The detailed curriculum (Theoretical and practical)

Hours Content Assessment tools

8

Survey applications:

Horizontal accreditation of buildings

Vertical approval of buildings and columns

Road adoption

Approval of water and sewage networks

Oral exams Written exams Practical performance

3

Calculate the spaces:

Calculation of the area of land and flats

Methods used to calculate the spaces

Oral exams Written exams Practical performance

3

Calculation of lands size and settlement:

Volumes in the cross sections

Volumes in the network budget

Volumes from elevation lines

Land settlement

Oral exams Written exams Practical performance

4

Spatial maps and their use:

Flat area maps

Guidelines and terminology

Oral exams Written exams Practical performance

6

Satellite positioning:

GPS components

The number of satellites for the GPS device

Calculation of female coordinates by satellite

Oral exams Written exams Practical performance

6 Practical identification of all types of space devices used

Oral exams Written exams Practical performance

10

An application project for survey works to construct a building with different stages:

Receive the project site and create the network budget for the land

Oral exams Written exams Practical performance

Page 30 of 88

Calculation of required drilling quantities

Receive drilling and horizontal tuning works

Signing the location of the building, making the pig and adjusting its horizons, and defining the main axes of the building

Drop the points of intersection and locate the columns

Receiving the wrenches of the wings, adjusting their horizontal and matching the axes

Receive the column headers and confirm them after casting

Determine the level of the roofing formwork and receive its horizontal

Determine the level of the windows sessions, door sills and the level of electrical switches on the walls of the buildings inside the building

Determine the level of tiles work inside the building and receive the tile work

2 Satellite positioning:

Calculate the coordinates by satellite

Oral exams Written exams Practical performance

References

Page 31 of 88 Course

Name Construction Management Course

Code CCIV 251 Prerequisite

Training semester 1 2 3 4 5

Credit hours 3

Collaborative training Contact hours

(Hour/ week)

Lecture 2

Practical 2

Training 0

Course Description

The course deals with the definition of types of engineering contracts and tenders and their procedures, to organize and manage construction project contracts. It deals with the stages of the project, the parties involved in it, and the tasks of the technical management of the project in reviewing the project documents from quantities tables, executive plans and specifications and their approval by the consultant, preparing reports and writing the damages and methods of managing the project resources.

The course deals with training in planning and scheduling methods used in project management for materials, labor, equipment and subcontractors during the various project phases as well as preparing detailed programs for the implementation stages and how to determine the time of implementation of various project activities with the use of computers in planning and scheduling the project.

The general objective of the course:

This course aims to provide the trainee with technical and administrative skills to prepare engineering contracts and project management during its various stages.

The detailed objectives of the course: The trainee should be able and efficient to:

1. The trainee learns the procedures for approving the plans from the owner, the consultant and the official authorities.

2. The trainee checks the contract documents and the general and special conditions.

3. The trainee verifies the availability of services on site.

4. The trainee performs the required tests on site.

5. The trainee prepares contractor and consultant offices, warehouses, workshops and laboratories.

6. The trainee submits periodic reports (monthly - weekly - daily).

7. The trainee applies safety and security measures on site.

8. The trainee sets a timetable for the project.

9. The trainee distributes work and responsibilities according to schedule.

10. The trainee learns the systems for project licenses.

11. The trainee arranges the works in a way that suits the implementation plan.

12. The trainee learns about the work of machines, their sizes and types.

13. The trainee supervises material storage, employment, and equipment management.

14. The trainee prepared technical reports for the project

15. The trainee documents the project's work, and depicts it periodically.

Page 32 of 88

Units (theoretical and practical) Training hours Theoretical Practical

Project stages 2 2

Construction contracts 8 8

Technical management of the project 12 12

Project Resource Management 2 2

Monitoring project time and analyzing performance rates 2 2

Computer applications in the field of project management 6 6

Total 32 32

64 Procedures of Safety Requirements:

1. Avoiding the presence of electronic devices near liquid materials such as drinks while drawing 2. Following the safety instructions in the manuals attached to the computers

The detailed curriculum (Theoretical and practical)

Hours Content Assessment tools

4

Project stages

Study stage

Design preparation stage

The stage of the project tender

Contracting stage

Site preparation stage

The implementation stage

Project handover stage

Oral exams Written exams Practical performance

16

Construction contracts:

Its definition

Contents of the contract

Contract documents

Parties to the contract Contract types:

Contract classification

Price contracts

Cost contracts

Quantity contracts

Turnkey contracts

Other contracts Tenders and bids

Open tenders

Oral exams Written exams Practical performance

Page 33 of 88

Limited Tenders

Multiple tenders

Direct attribution

Organization and management of construction contracts:

Determining the need for employment

Site supervisory employment

Employment control

Monitor production rates

Professional performance development

24

Technical management of the project:

The role of technical management in the project

The project parties and the responsibility of each party

Project manager responsibilities

Method of modifications in the diagrams

Executive drawings and their approval by the consultant

How to write a technical report

Manage project meetings and write a lecture

Prepare and save files and charts

On-site supply and operating systems Project cost estimate:

Approximate costing methods

Detailed methods for estimating the cost

Bid processing

Estimated budget for the project Project planning:

Divide the project into activities

Determine the relationship between activities

Representing activities and relationships Shorten the project time

Project time compression method

Shorten the project time without cost

Shorten project time at an additional cost

Oral exams Written exams Practical performance

4

Project Resource Management

Employment management

Equipment management

Material management

Subcontractors management

Oral exams Written exams Practical performance 4 Monitoring project time and analyzing performance rates Oral exams