This is confirmed by the analysis of the elemental distribution in the ITZ of the received composition (Figure 12). Also, its structure becomes more homogeneous due to the reduction of large pores in the ITZ. Non-destructive testing (NDT) methods are widely used to investigate the mechanical properties and integrity of concrete structures.

Introduction

Extreme weather conditions and changes in humidity have a significant impact on the development of the compressive strength of concrete. On the other hand, the low temperature drying condition is a very common problem affecting the strength development of concrete. It is well documented that if concrete freezes in the plastic phase, approximately 50% strength reduction is expected and loss of durability is inevitable [2].

These phenomena negatively change the compressive strength and the vulnerability to crack propagation, showing that the water-cement ratio is one of the most important factors in the strength development of the concrete [15, 16]. In addition, the freezing of concrete in the initial stages of strength development negatively reduces the ability of the cement matrix to maintain the integrity of the mixture against freeze-thaw cycles [16, 17]. The outcome of this chapter is to understand the behavior of concrete under different ambient conditions as the most commonly used material for construction and residential buildings.

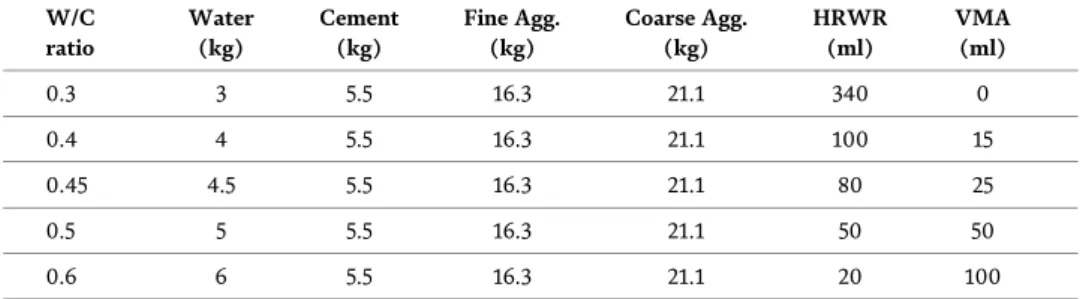

Material properties used for compressive strength investigation To elaborately indicate compressive behavior of the concrete, the results for

Another problem at low ambient temperature is the expansion of water in concrete, especially in mixes with a high water-cement ratio, leading to spalling and general strength degradation [1, 7, 8]. The durability of concrete against freeze-thaw cycles has previously been investigated as a major factor indicating weathering ability [9–11]. A review of severe weather concreting is presented in detail with treatment of compressive strength, maturity index and freezing and thawing tests.

Material properties used for compressive strength research To indicate the compressive behavior of the concrete in detail, the results for. Four cements with low and high water-cement ratio are taken into account to understand the compressive behavior of the concrete under different environmental effects. It should be noted that the mixing procedure is based on the ASTM manuals [14–16] for simulating the actual behavior of the concrete under cold, mild and moderate temperature conditions.

Investigation of cement matrix compressive strength development under various temperature conditions

Roding is done for each layer uniformly on the cross-sectional area with rounded end. The number of strokes varies depending on the type of molds used, which is based on ASTM standards [14]. Next, the samples are demolded after curing for 24 hours, and the compressive strength is monitored for and 28 days curing time based on the ASTM recommended procedure [14-16].

It is noted that samples remain at temperatures shown in Table 1 for one week and are then moved to room temperature range with the same humidity thereafter. In general, for each injection mortar type, at each time interval, three cubic and two cylinders as well as two large rectangular samples have been made for freeze-thaw durability index tests for investigations of compressive strength development.

Investigation of curing process and strength development of concrete with maturity method

It is noted that the rate of compressive loading based on the ASTM manuals [14-16] should be consistent for all the samples, as the rate of loading has a significant effect on the ultimate compressive strength. In general, there are many common methods of achieving concrete maturity level. It has been shown that environmental influences such as very dry conditions can noticeably change the strength development of the concrete; however, the change may not be as great as temperature variations.

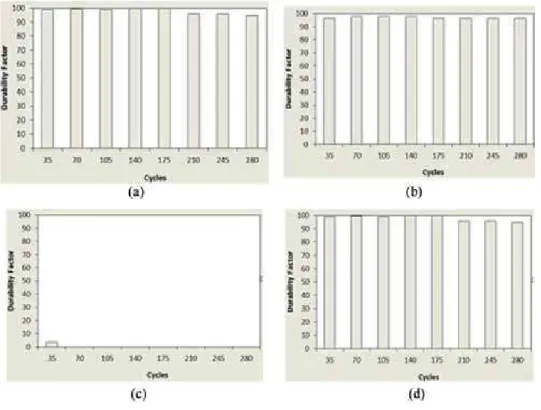

In other words, the concrete would not develop the expected final strength regardless of the curing time interval. In general, there are limitations to the implementation of the maturity method in estimating concrete strength. Durability of the concrete under cyclical environmental conditions The durability of cement mix is defined as its ability to withstand.

Durability of the concrete under cyclic environmental conditions The durability of cement mix is defined as the ability for resistance against

Fourth, the size of the concrete piece is usually larger than the samples, which means that the hydration process produces more heat and higher temperatures inside. The durability of concrete is highly dependent on the cement content, water-cement ratio, drying process, coverage, sufficient compaction and proper mix design. To evaluate the durability of concrete, ASTM C666 [17] provides an equation shown in Eq.

For further investigations, the behavior of the concrete samples for freeze-thaw cycles is monitored. From this experiment, it is shown that the durability of concrete is highly dependent on the cement matrix, water-cement ratio, exposure to harmful chemicals, extreme weathering and concrete mix design. It is concluded that cement type and water-cement ratio have a significant effect on the concrete's resistance and durability.

Conclusion

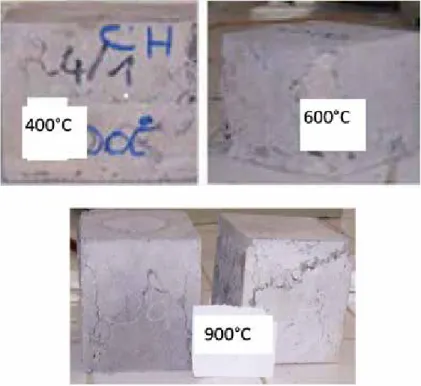

Effect of cold weather during pouring and curing on the stiffness and durability of concrete. In these extreme conditions, significant degradations of concrete structures can be observed (peeling, cracking, breaking of the structure). Therefore, a fire can strongly modify the behavior of concrete and endanger the durability of concrete.

High strength of concrete is achieved by reducing porosity, inhomogeneity and microcracks in the hydrated cement paste and the transition zone. The importance in the behavior of concrete at a high temperature stems mainly from the many cases of fires that occur in buildings, high-rises, tunnels and drilling platform structures [3]. Important factors are also the rate of heating and the time of concrete exposure to high temperature.

Effect of curing temperature on cement hydration

When concrete is heated under fire conditions, the increase in temperature in the deeper layers of the material is gradual, but because this process is slow, significant temperature gradients are created between the surface of the concrete element and the core, causing additional damage to the element. Fundamental questions related to the effect of high temperature on concrete include the identification of the complex changes that occur in concrete during heating. This concerns the physical and chemical changes that take place in the cement matrix, as well as the phenomena associated with mass movement (gases and liquids) [4].

The analysis is complicated due to the fact that cement concrete is a composition consisting of two essentially different ingredients: cement paste and aggregates. The consequences of the various changes that take place in heated concrete are the changes of its physical, thermal and mechanical properties [5]. Much research has shown that changes in the strength of concrete as a function of temperature are related to, among other things, concrete composition, the type of aggregate used, the water/cement ratio, the presence of pozzolana additives, etc.

Effects of high temperature on the residual performance of concretes The increase in temperature results in water evaporation, C-S-H gel dehydra-

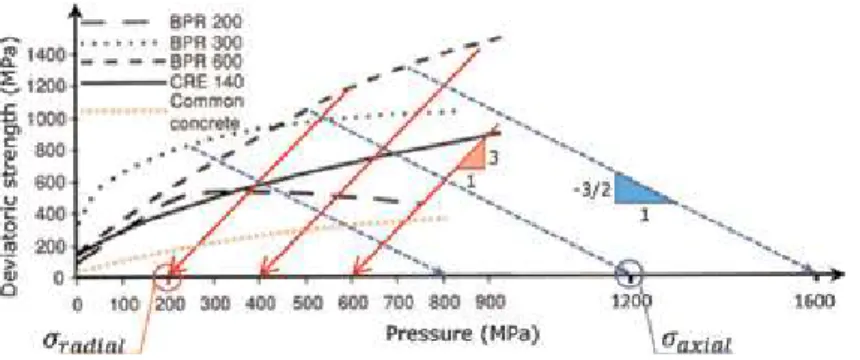

However, another variable is believed to play a key role, influencing the early hydration kinetics and the properties of the cured cement paste: that variable is temperature [6]. About 50% of cement paste strength is believed to come from cohesive forces (major C-S-H gel sheet area); therefore, the evaporation of water between CSH gel plates strongly influences the mechanical properties of the cement paste [15, 16]. The nature of the phase transitions depends on the mineralogical composition of the cement, the C/S ratio (mole lime per mole silica; CaO/SiO2), the amount of fine particles (quartz or silica fume) and the temperature and pressure levels reached.

In this state, the structure of the cement paste is partially damaged due to dehydration at a temperature of 105°C, which is standard for drying materials. Hager observed that the CaO produced in this reaction renders the Portland cement elements virtually redundant after cooling. The dehydration process of the C-S-H gel reduces its volume, which in turn increases the porosity of the cement matrix.

Effect of temperature on durability of slag concrete, fly ash concrete, and silica fume concrete

According to Bingöl et al., between 150 and 300 °C there are no significant losses in the compressive strength of lightweight aggregate concrete. The effect of thermal cycling on the compressive strength of high volume fly ash concrete has been studied by Srinivasa Rao et al. There was a significant reduction in strength above 210°C and the loss of compressive strength was 8% [27].

GGBFS can contribute to some extent to the residual compressive strength of concrete at elevated temperatures. Furthermore, a significant reduction in their compressive strength was observed at temperatures between 300 and 600°C [30]. Researchers noted that the changes in the color tone component and compressive strength show similarities.

Tebbal et al.’s research on the effect of temperature on high-performance concrete

- Materials and methods

- Mixture design

- Results and discussion

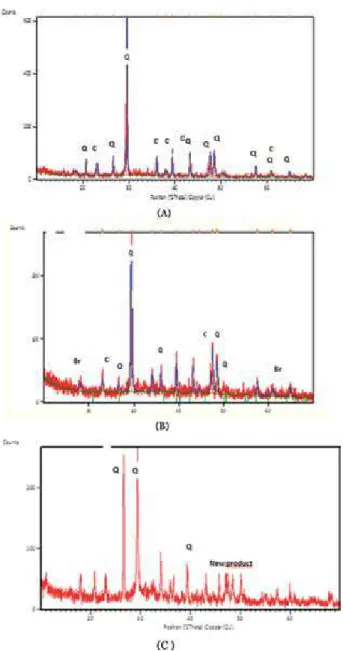

- Internal structure, ATG, and ATD of concrete

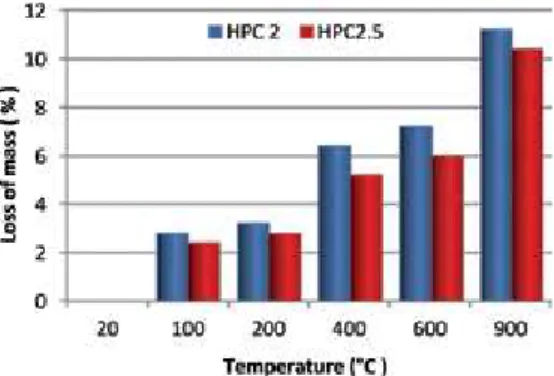

This study investigates the effect of the additions of silica fume and super plasticizer on the mechanical performance of high performance concrete at high temperatures. The physical and mechanical properties of the concrete with and without the addition of silica fume were compared. The role of the super plasticizer in the dispersion of cement particles in improving the compactness of concrete is highlighted.

In this part of the study, we want to highlight the influence of silica on the mechanical behavior of HPC. After heating to 600°C, the compressive strengths of CR were lower than those of HPC2.5 concretes. This is partly due to the internal breakdown of the C-S-H gel structure during the dehydration process [49].

Conclusions

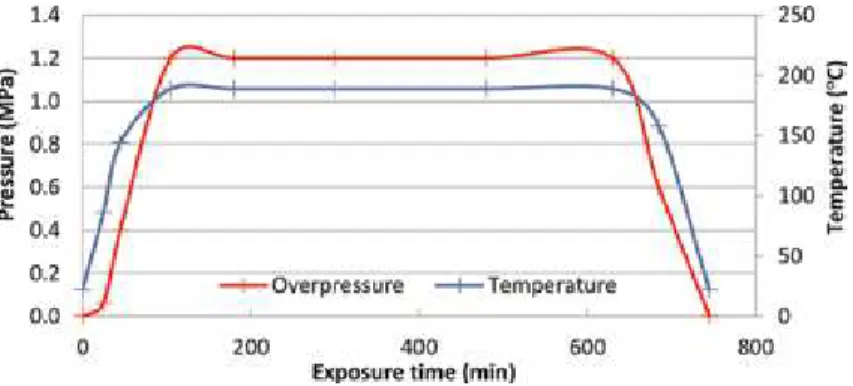

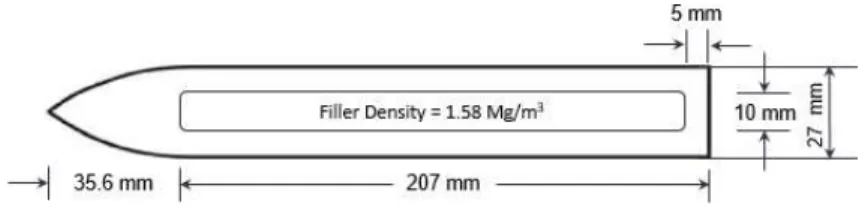

The global annual production of cement accounts for about 5% of total anthropogenic CO2 emissions [1]. The durability of concrete based on steel slag was tested under conditions of higher temperature and pressure. The effect of sulphate action on the expansion of the mortars is depicted in Figure 5.

The presence of CH was not recognized in the HC mortar in water and Na2SO4 exposure. The minimal presence of calcite CaCO3(Cc) is also negligible in terms of mortar damage. PC mortar is characterized by visible thickening of the pore structure after 4 years of exposure to sodium sulfate. Visual and microscopic observations support the earlier finding that the sulfate resistance of H-cement is the same as that of sulfate-resistant Portland cement.

![Table 3 showcases some of the different equations generated by researchers in the last decades to predict compressive strength of concrete, fc, in terms of UPV [15].](https://thumb-ap.123doks.com/thumbv2/1libvncom/9201430.0/63.765.117.651.86.343/showcases-different-equations-generated-researchers-compressive-strength-concrete.webp)

![Table 3 showcases some of the different equations generated by researchers in the last decades to predict compressive strength of concrete, fc, in terms of UPV [15].](https://thumb-ap.123doks.com/thumbv2/1libvncom/9201430.0/64.765.113.650.203.420/showcases-different-equations-generated-researchers-compressive-strength-concrete.webp)