Evaluation of fine aggregate morphology by imaging method and its effect on microsurface skid resistance. The wet abrasion test was used to measure the skid durability for the feasibility verification of single microsurfaces.

Results and Discussions

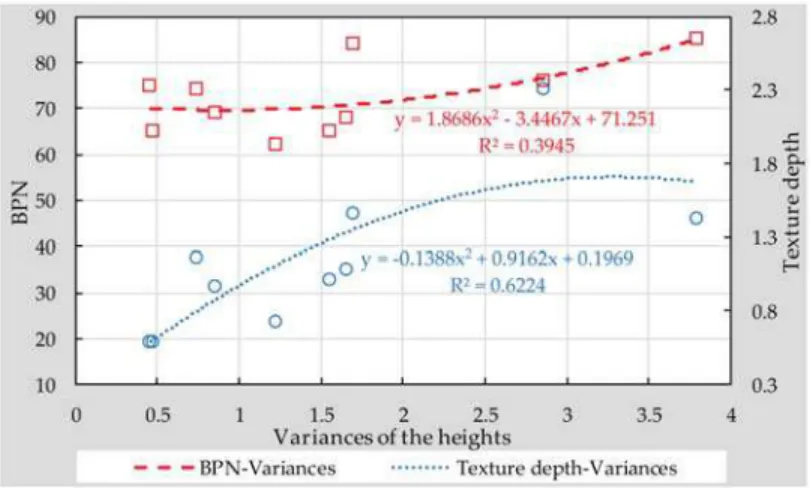

The variances of the heights were used to represent the surface texture of micro-surface. The results also indicated that single-grade micro-surfaces can increase the sliding resistance of micro-surfaces.

Conclusions

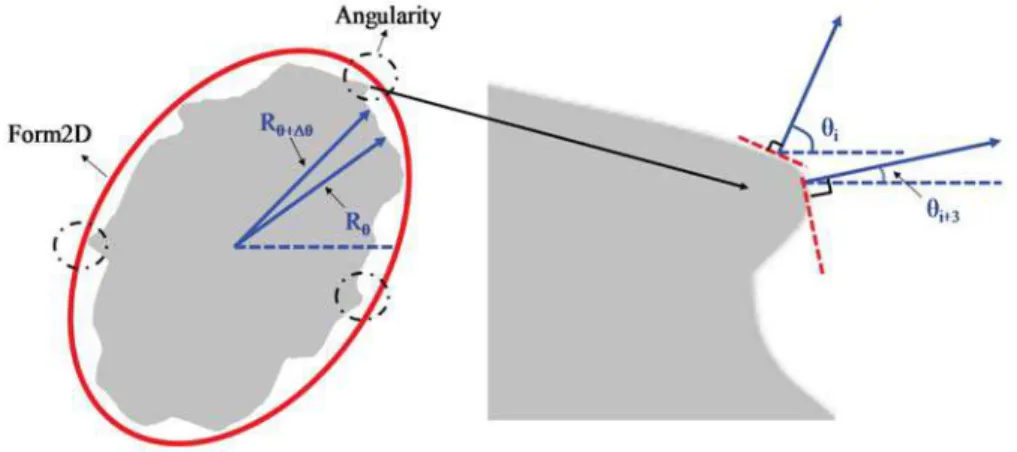

This indicates that the effect of smoothness on the slip resistance of the micro-surface is weaker than that of Form2D. The research results showed that the effect of Form2D on the skid resistance of the microsurface is much stronger than that of smoothness.

Influence Analysis and Optimization for Aggregate Morphological Characteristics on High- and

Low-Temperature Viscoelasticity of Asphalt Mixtures

Introduction

According to existing research on the evaluation of aggregate morphology, many researchers studied the influences of aggregate morphological characteristics on the performance of asphalt mixtures. Thus, the morphological characteristics of the aggregate have significant direct influences on the performance of the asphalt mixture.

Materials and Experimental Methods 1. Raw Materials

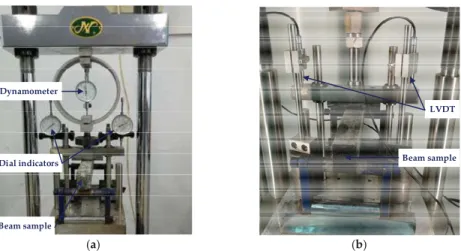

The beam samples of asphalt mortar and mixture were placed in an environmental chamber for at least 4 hours and the test temperature is -5◦C. Then the strain versus time in the beam bending creep could be obtained and the creep compliance of asphalt mortar and mixture was also calculated by Equation (1).

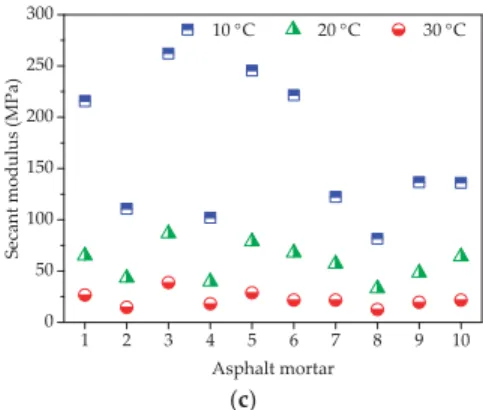

Results and Analysis for High-Temperature Creep Properties of Asphalt Mixes

Thus, fine aggregate with complex morphological characteristics can improve the anti-deformation performance of asphalt mortar. Figure 8 shows the influence of the morphological characteristics of fine aggregate on the lag time of asphalt mortar.

Results and Analysis for Low-Temperature Relaxation Properties of Asphalt Mixes 1. Conversion between Relaxation Modulus and Creep Compliance

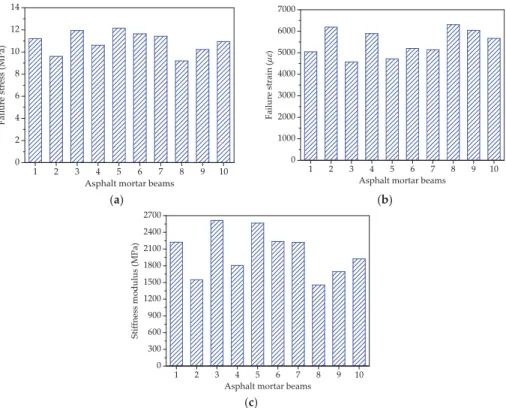

Beam bending Creep test results of asphalt mortar (1) Elongation results of low temperature creep test. Beam bending Creep test results of asphalt mixture (1) Elongation results of low temperature creep test.

Optimization of Aggregate Morphological Characteristics for High- and Low-Temperature Viscoelasticity

Based on the optimum values of single response, the total proportion for asphalt mixture considering high and low temperature viscoelastic properties was designed as: basalt:andesite:pebble. When the morphological properties of coarse aggregate are CR= 1.5666, CPI= 1.1918, CEDR= 0.828, asphalt mixture has the best viscoelastic properties at high and low temperature.

Conclusions

Analysis of aggregate morphological characteristics for viscoelastic properties of asphalt mixtures using simplex grid design.Materials. Research on characteristics of mineral aggregate and its effect on high and low temperature viscoelastic performance of asphalt mixture.

Analysis of Aggregate Morphological Characteristics for Viscoelastic Properties of Asphalt Mixes Using

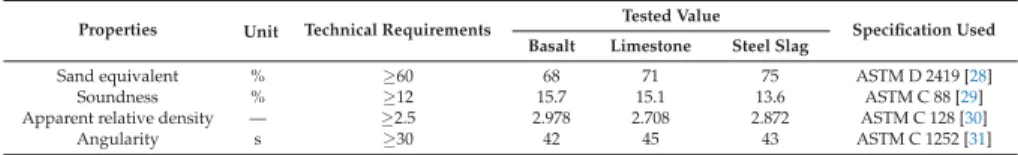

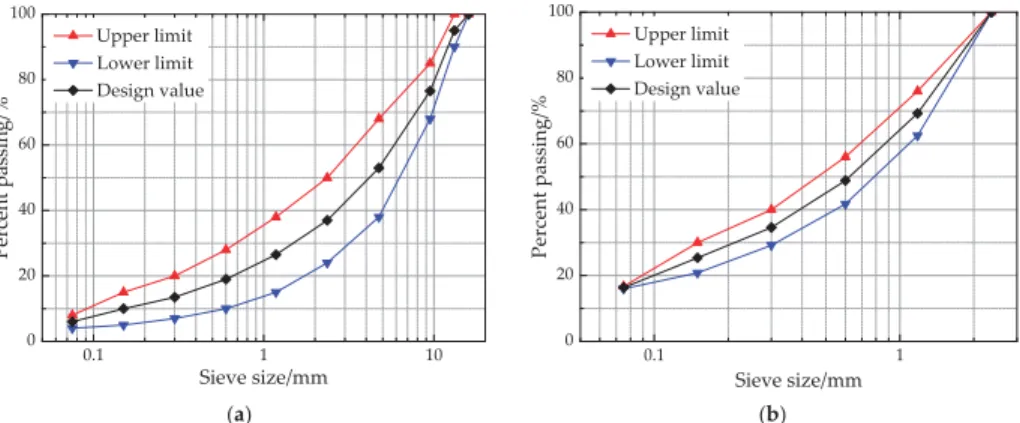

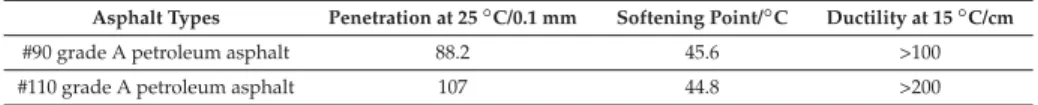

Materials and Methods 1. Raw Materials

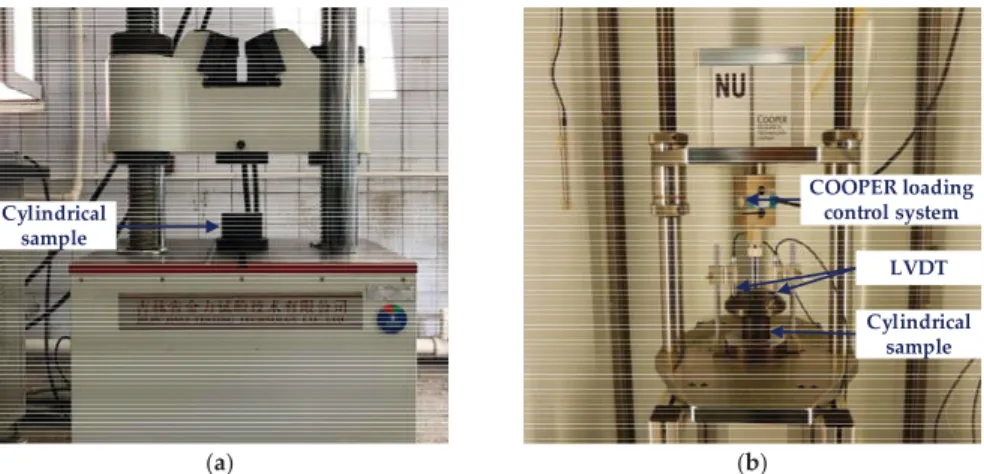

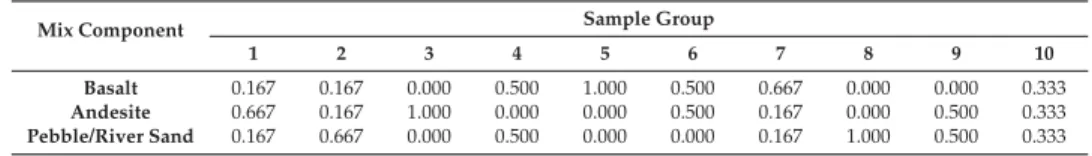

In this study, the uniaxial compression failure tests of asphalt mortar and mixture were conducted in accordance with previous research [25,26]. The samples of asphalt mixtures can be prepared by mixing the three ingredients in different proportions.

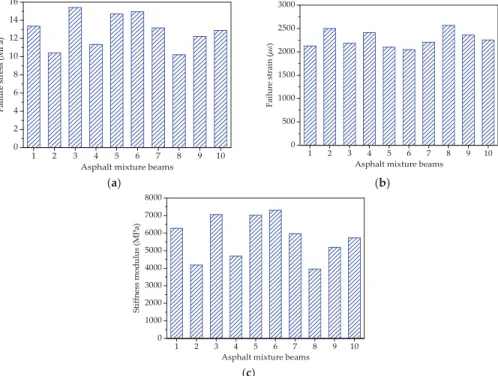

Results and Discussion

Thus, fine aggregates with complex morphological properties could improve the anti-deformation performance of asphalt mortar. Thus, coarse aggregates with complex morphological properties could improve the anti-deformation performance of the asphalt mixture.

Study on the Effect of Demulsification Speed of Emulsified Asphalt Based on Surface

Characteristics of Aggregates

- Materials and Methods 1. Materials

- Aggregate Characteristics

- Results and Discussion 1. Orthogonal Design

- Conclusions

The relationship between the specific surface area of limestone aggregates and the particle size is established, as shown in Figure 11. As shown in Figure 11, the specific surface area of the three aggregates decreases with increasing particle size. Then, factors B (material factor) and D (particle size factor) were used to analyze the influence of surface energy and specific surface area of aggregate on the fracture rate of emulsified asphalt.

The greater the surface energy and the specific surface area of the aggregate, the faster the emulsion breaking speed of the emulsified asphalt.

![Table 1. Emulsified asphalt performance properties [22,23].](https://thumb-ap.123doks.com/thumbv2/1libvncom/9201273.0/71.723.119.604.144.830/table-emulsified-asphalt-performance-properties.webp)

Improvement of Asphalt-Aggregate Adhesion Using Plant Ash Byproduct

- Testing Materials

- Adhesion Evaluation Using Conventional and Modified Stripping Tests 1. Conventional Stripping Test

- Contact Angle Test

- Microstructure Analysis with SEM and EDS

A series of image processing techniques, including contrast enhancement and thresholding, were performed to convert the original photographs into binary images as shown in Figure 7 . a) (b) (c) (d) (e) (f) Figure 6. Specimens after modified peeling test: (a–c) control samples with granite, base rock and limestone and (d–f) treated samples with granite, base rock and limestone. The test results showed that plant ash lixivium can increase adhesion at the asphalt-aggregate interface at both temperatures. The modified removal test results showed that plant ash lixivium can effectively prevent the peeling of the asphalt binder from the aggregate.

The effectiveness of plant ash lixivium treatment varied depending on the type of asphalt and aggregate.

Diffusibility Enhancement of Rejuvenator by Epoxidized Soybean Oil and Its Influence on the

Therefore, the regeneration of aged bitumen in RAP is significantly dependent on the diffusion of the rejuvenator [15]. Therefore, it is necessary to develop new methods to increase the diffusibility of the rejuvenator. Therefore, the diffusibility of the rejuvenator can be increased by simultaneously reducing the asphaltene content and increasing the fluidity of the aged bitumen.

Consequently, the property recovery of aged bitumen is intensified, which significantly contributes to the improvement of the low-temperature crack resistance of RHMA.

Effect of Rejuvenator Containing Dodecyl Benzene Sulfonic Acid (DBSA) on Physical Properties,

Chemical Components, Colloidal Structure and Micro-Morphology of Aged Bitumen

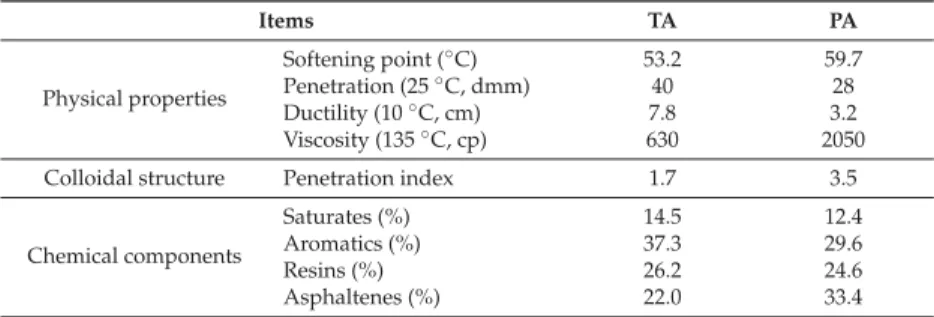

Results and Discussions 1. Characterization of TA and PA

Surface micromorphology of regenerated TFOT bitumen aged with 10 wt. % CR and SR, is described in Figure 5a,b. It can be seen from Figure 5 that the TFOT surface of the aged bitumen becomes smooth with the introduction of 10 wt. % CR and SR. Figure 6a,b shows the micromorphology of regenerated PAV aged bitumen with 10 wt. % CR and SR.

The physical properties of regenerated TFOT-aged bitumen with 8 wt% CR and SR can approximate the properties of virgin bitumen before aging.

Evaluation of Thermal-Mechanical Properties of Bio-Oil Regenerated Aged Asphalt

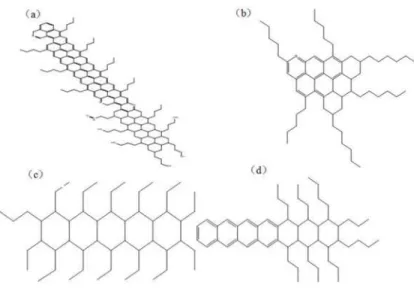

Molecular Models and Methods 1. Modeling and Simulations Details

The following processes were performed to simulate the physical condition of asphalt systems and to calculate the thermal-mechanical properties. In this research, asphalt systems were relaxed to equilibrium at the same pressure (1.0 atm) and different temperatures (223 to 448 K). In this research, asphalt systems were relaxed to equilibrium at different temperatures (223 to 448 K) to simulate the heating process of asphalt.

After the asphalt systems relaxed to an equilibrium state, the elastic constants of systems were calculated using the Mechanical Property tool of the Forcite module.

Results and Discussions 1. Thermal Properties of BRAA

In conclusion, we conclude that the CTEα of aged asphalt could be improved and Cp reduced with the addition of bio-oil. Supplement 5 wt. % or 10 wt. % of bio-oil could restore the ductility of aged asphalt to some extent. The addition of bio-oil would soften the aged asphalt, which would reduce the possibility of asphalt cracking.

When the addition of bio-oil was over 15 wt. %, the ductility of aged asphalt would instead decrease.

Further Research Work

Performance evaluation of asphalt binder modified by bio-oil generated from waste wood sources.Int. An extensive laboratory study on the use of bio-oil modified bitumen in road construction.Constr. Preparation of bio-bitumen by bio-oil based free radical polymerization and optimization of the production process.J.

Diffusion and rheological properties of asphalt modified by bio-oil regenerant derived from waste wood.J.

A Comprehensive Evaluation of Rejuvenator on Mechanical Properties, Durability, and Dynamic

Materials and Experimental 1. Materials

Before testing, the aged and rejuvenated samples were kept in the test device at 60◦C for 6 hours. Before testing, the aged and rejuvenated samples were kept in the test device at 60◦C for 4 hours. Three-point bending test was used to evaluate the low temperature performance of the aged and rejuvenated asphalt mixtures according to JTG E20 T0715 [27].

Four-point bending tests were performed to evaluate the fatigue performance of the aged and rejuvenated asphalt mixtures according to JTG E20 T0739 [27].

Result and Discussion

With the inclusion of rejuvenator, the rejuvenated asphalt mixture showed comparable Marshall stability and MSR value to the unaged mixture. It can be concluded that the softening effect of the rejuvenator worsens the high-temperature stability of the asphalt mixture. However, it should be noted that the stiffness modulus of the rejuvenated asphalt mixture was still greater than that of the unaged.

Prolonged aging improves the stiffness of the asphalt mixture, while the rejuvenator softens the aged asphalt mixture.

Assessment on Physical and Rheological Properties of Aged SBS Modified Bitumen Containing

Rejuvenating Systems of Isocyanate and Epoxy Substances

Experimental 1. Raw Materials

Table 2 presents related experimental results regarding the physical properties and recovery rates of aged SMBs incorporating rejuvenation systems. Figures 1–4 show the physical properties of ductility, softening, penetration and viscosity of aged SMB containing Rband Rc. The viscoelastic properties of aged SMB with built-in rejuvenation systems are shown in Figure 5.

The complex modulus and phase angle of aged SMB with rejuvenating systems are shown in Figure 7.

Investigation of the Potential Use of Calcium Alginate Capsules for Self-Healing in Porous Asphalt Concrete

Experimental Method 1. Materials

The porous asphalt mixture used in this study was based on the standard PA 0/11 mixture (Table 1). Thus, in this work, capsules were added to the porous asphalt mixture replacing 7% volume of bitumen [9]. The porous asphalt test specimens used in this study include cylinders for indirect tensile stiffness modulus (ITSM) tests and semicircular specimens for semicircular bending (SCB) tests.

This indicated that the SCB tests were capable of generating brittle fracture in the porous asphalt samples.

Results and Discussion 1. XCT

In this way, the calcium alginate capsules have a healing effect when used in construction. This study shows that addition of calcium alginate capsules with encapsulated rejuvenator increases the healing effect of porous asphalt mix. In XCT images, the presence of capsules in the porous asphalt mixture shows that calcium alginate capsules can survive the asphalt production process.

From the ITSM test results, application of these calcium alginate capsules shows strengthening effect by improving the stiffness modulus of the porous asphalt mixture;.

Microfluidic Synthesis of Ca-Alginate Microcapsules for Self-Healing of Bituminous Binder

The effect of the inner and outer diameters of quartz glass tubes on the size of Ca-alginate microcapsules was analyzed. It also showed that the addition of Tween80 significantly reduced the size of the microcapsules (Figure 6). Table 3 shows the relationship between the size of the microcapsules and the velocity of continuous and dispersed phase.

Three-dimensional experimental image (a) and fitting image (b) of the diameter of the microcapsules versus the flow rate of continuous phase (oil) and dispersed phase (alginate emulsion).

Self-Healing Property of Ultra-Thin Wearing Courses by Induction Heating

Materials

The data points for steel slag were higher than those for basalt when the angular index was lower than 3700. The cumulative number of steel slag particles was higher than that of basalt when the Form2D value was below 10. It suggested that the proportion of steel slag with circular shape and moderately circular shape was higher than basalt.

Therefore, the steel slag used in this study had a more rounded shape and a higher angularity than basalt.

Research Program 1. Mixture Design

Average temperature rising rate of the materials after induction heating was investigated to indicate induction heating property. A FLIR infrared camera was used to record the infrared image of samples after induction heating. Induction heating property of the materials was therefore concluded by testing the average temperature rise rate of the mixtures during the induction heating period.

A description of the semicircular patterns and the infrared image after induction heating is shown in Figure 5.

Result and Discussion

Four self-healing cycles were performed on each sample to investigate the self-healing durability of the asphalt mixtures.