Drying temperature and added sugar content significantly (p ≤ 0.05) affected moisture loss and drying of marula fruit leather. Consumer sensory evaluation was also conducted to assess the acceptability of fruit leathers.

General Introduction

- Introduction

- Problem statement

- Justification

- Objectives

- References

In South Africa, indigenous fruit drying has received little attention in the world of scientific research and development (Akinnifesi FK, 2009, Du Preez et al., 2012). Indigenous marula fruit is a highly perishable commodity due to its characteristic high moisture content (Dube et al., 2012).

Literature Review - Perspectives in the Processing and Utilisation of Indigenous

Introduction

- Overview of indigenous fruits processing

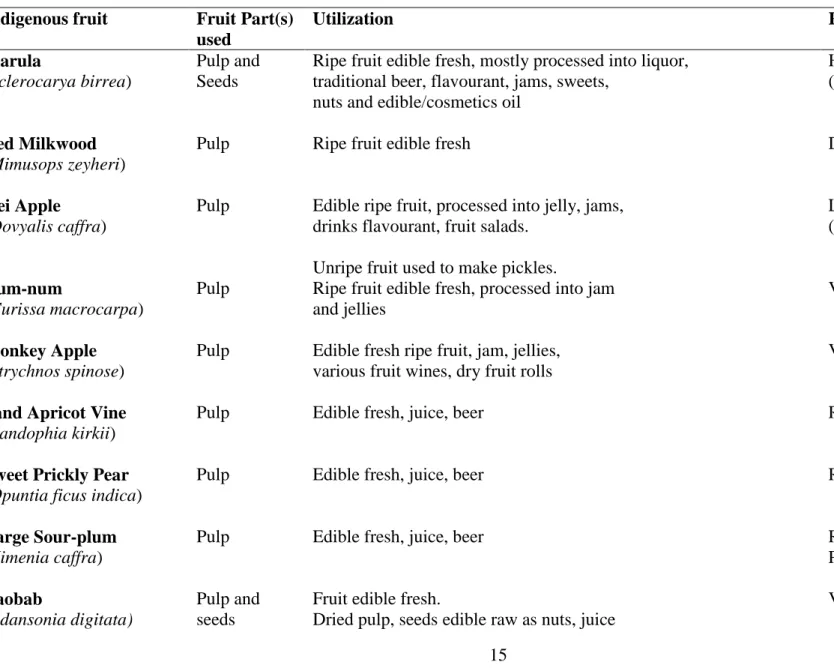

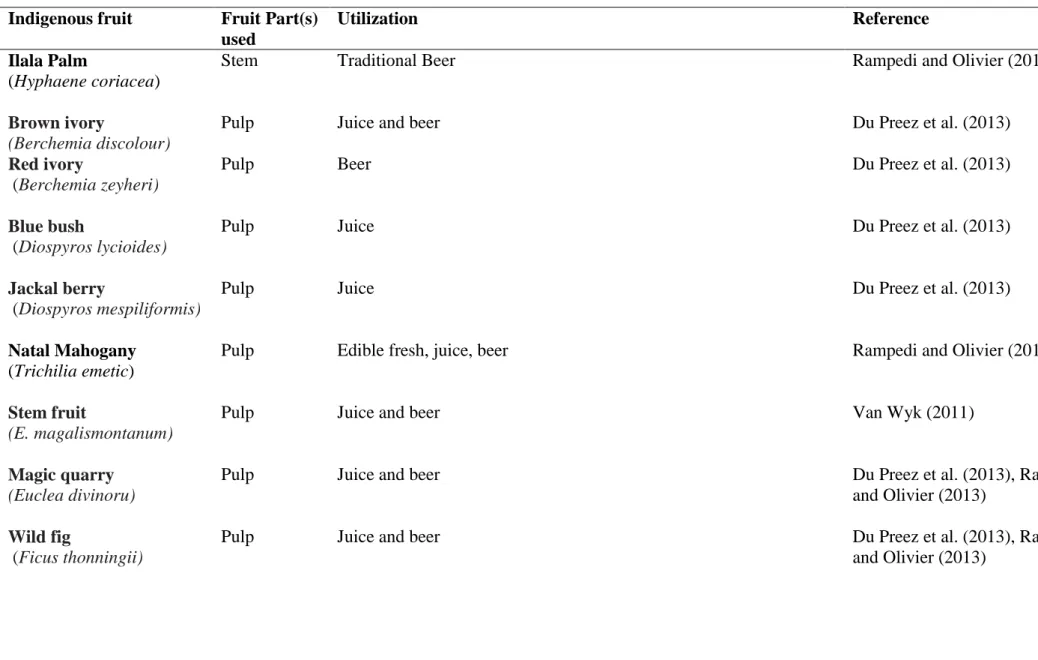

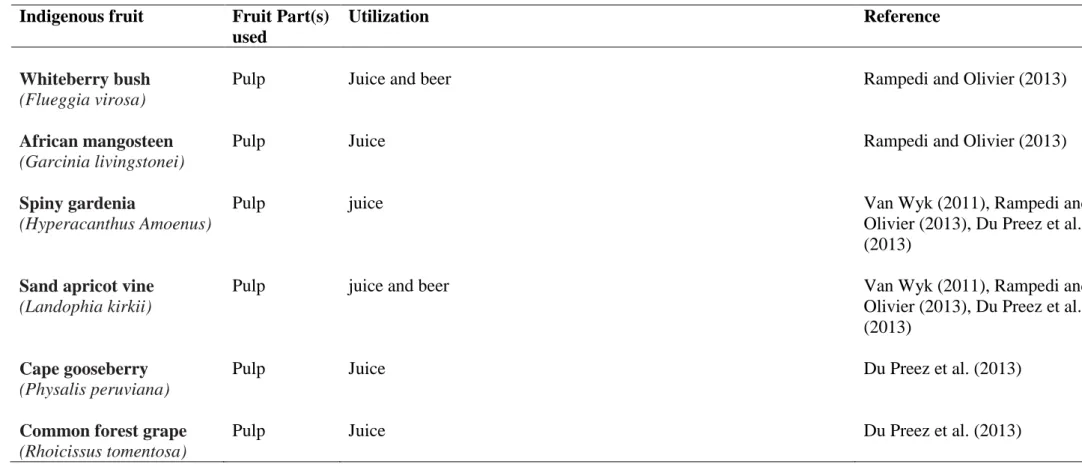

As stated by Schreckenberg et al. 2006), indigenous fruits are considered a number of species that are truly traditional or native to the region. Several fruit species are included in the category of native fruits with great variation in sizes, tastes, shapes and colors (see Figure 2.1.2 for examples). 2013) and Rampedi and Olivier (2013) on native fruit use (Table 2.1.1), indicate that the pulp is overwhelmingly the most commonly used part of native fruits (Table 2.1.1).

The Marula fruit

- Ecology and taxonomy

- Fruit Description

- Nutritional composition

- Uses and socio economic importance of marula fruit

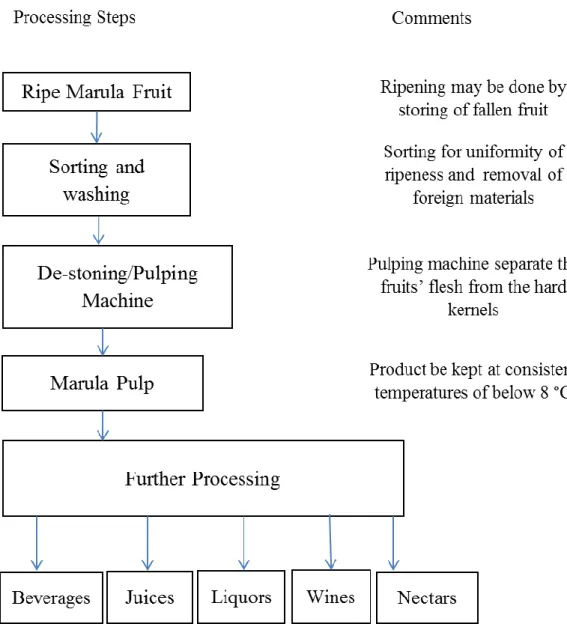

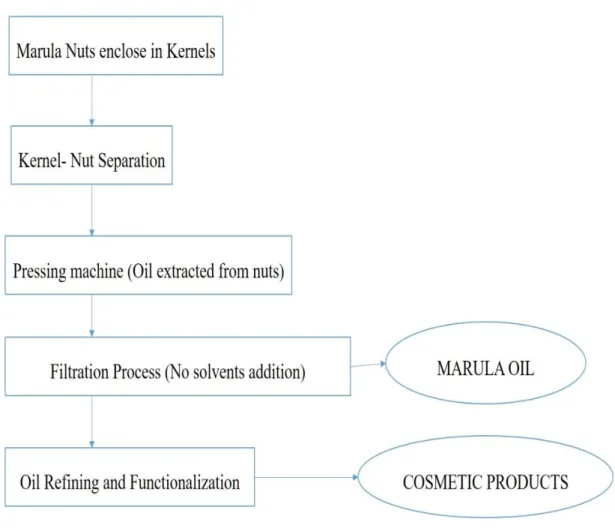

- Common processing methods for marula fruit and various indigenous fruits in some

- Common processing methods for marula fruit and various indigenous fruits in South

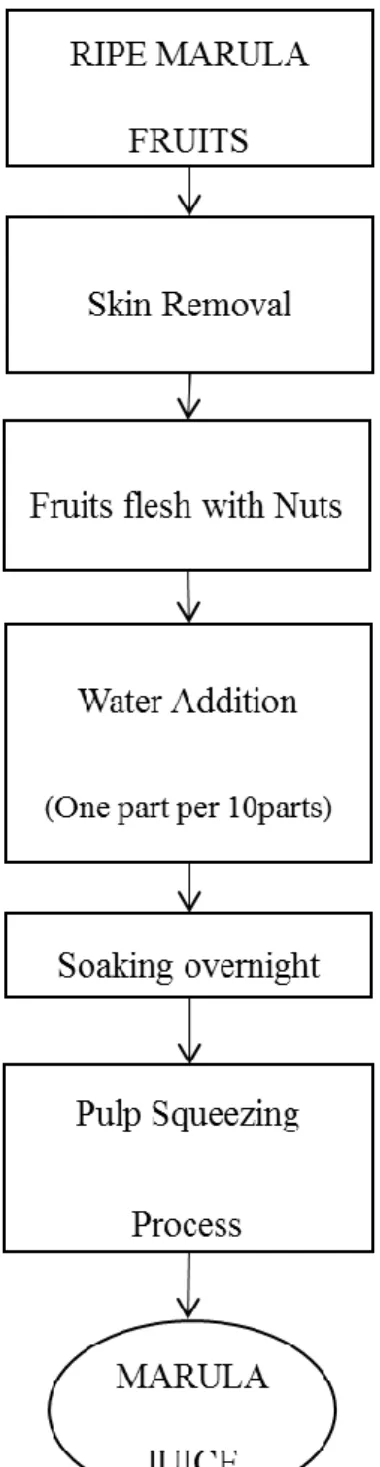

- Marula Juice

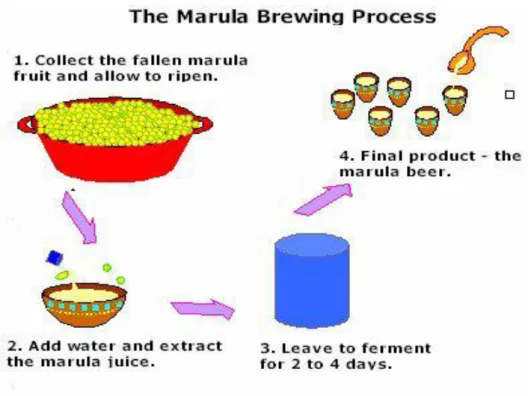

- Traditional Marula Beer

- The processing of Marula Liqueur (Amarula Cream)

- Other marula derived products

The commonly processed products from these fruits are jams and jellies (shown in Figure 2.1.2), juice, traditional and commercial wines (Shackleton, 2004, Saka et al., 2008, Rampedi and Olivier, 2013). Saka et al. 2011) describes methods used in Malawi and Tanzania for preparing juice and jam from native fruits of marula (Sclerocarya birrea), monkey orange (Strychnos cocculoides), stinkberry (Vitex mombassae), wild loquat (Uapaca kirkiana ) and baobab (Adansonia digitata).

Drying: A potential processing technique for indigenous fruits

- Theory and principle of drying

- Factors affecting the drying process

- Air temperature

- Relative humidity

- Airflow rate

- Measuring the drying process through mathematical modelling

- The advantages of drying indigenous fruits

- Indigenous fruits based fruit leathers

- Marula fruit leather processing procedures

- Drying techniques and their influence on product quality

- Sun/solar drying

- Hot air drying (conventional methods)

- Microwave drying

- Freeze drying

- Heat pump drying (HPD)

- Combined/ Hybrid drying

- Other mild processing methods

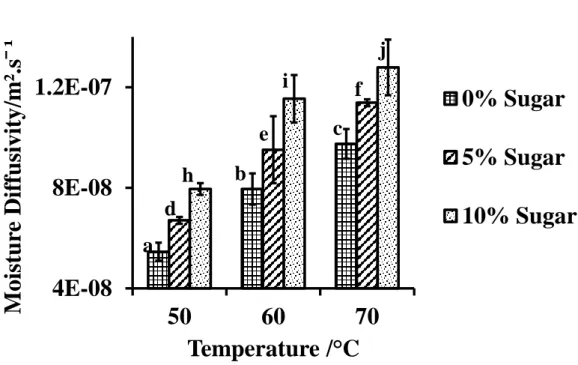

These are the effective moisture diffusivity (Deff) and activation energy (Ea) (Erbay and Icier, 2010, Kucuk et al., 2014). It uses reduced temperatures compared to the conventional superheated steam drying (Fernandes et al., 2011).

Conclusion and Future Remarks

In a study by Amellal and Benamara (2008) on vacuum drying of dates, reported that a decrease in moisture content from 15% to 6% on dry basis produced good quality in terms of color. In a comparative study between vacuum drying and intermittent LPSSD of dried banana, Thomkapanich et al. 2007) reported that LPSSD-dried banana had a higher vitamin C retention than vacuum-dried banana. They concluded that the low oxygen environment was related to this high nutrient retention in LPSSD dried bananas. 2007) in an investigation of foam drying of alphanso mango pulp found higher vitamin C retention.

They also reported that foam mat drying results in a higher drying rate, thus shorter drying time. Drying is recognized for improving post-harvest shelf life of perishable products, however, few studies have reported on the drying of indigenous fruits.

Effect of storage temperature on post-harvest quality, ripening and marketability of marula (Sclerocarya birrea subsp. . caffra) fruits. Genetic management of indigenous fruit trees in southern Africa: a case study of Sclerocarya birrea based on nuclear and chloroplast variation. Drying of porous material during periods of constant and decreasing velocity: a critical review of existing hypotheses.

Less is often more: management of the non-timber forest product, marula (Sclerocarya birrea subsp. caffra) in southern Africa. Recent developments in microwave drying of vegetables, fruits and aquatic products - Drying kinetics and quality aspects.

Effect of Drying Temperature and Sugar Concentration on the Drying Kinetics

Introduction

Native fruits of the species Sclerocarya birrea, commonly known as marula, are recognized as important sources of dietary food in many African countries (Shackleton, 2004, Hillman et al., 2008). Furthermore, it contributes both to household food security and farm diversity, especially for small farmers (Bille et al., 2013). With these aforementioned valuable assets, marula fruits are therefore considered a major contributor to improving and sustaining the livelihoods of various rural households (Wynberg et al., 2002).

Fruit leathers are common products that can be produced from the pulp of marula fruit by applying the drying technique (Mitrevski et al., 2013). Sugar is the most common and abundantly added ingredient during fruit leather processing (Orrego et al., 2014).

Materials and Methods

- Fruit Material and Preliminary Characteristics

- Sample Preparation

- The Drying Procedure

- Marula fruit leather drying kinetics

- Marula fruit leather effective moisture diffusivity

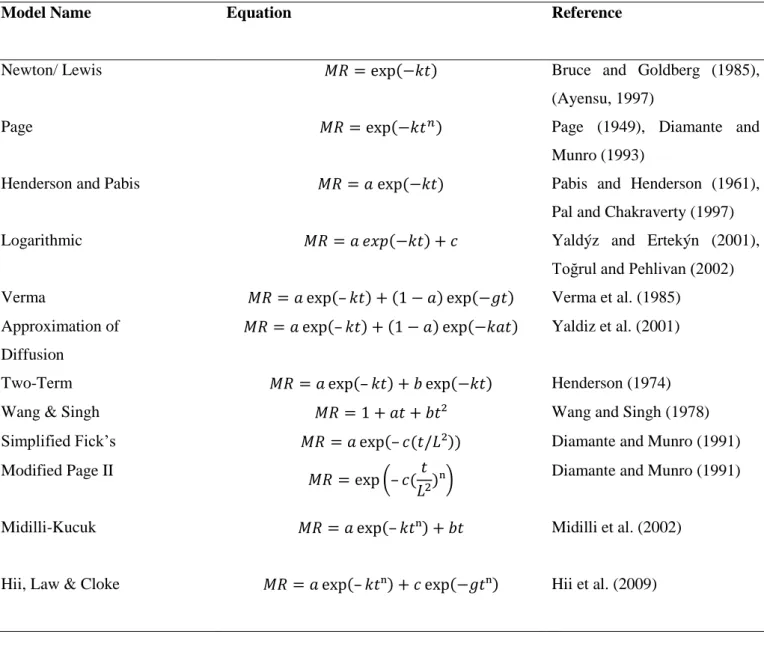

- Marula fruit leather mathematical modelling

- Marula Fruit Leather colour attributes evaluation

To predict and describe the drying kinetics of marula fruit leather, it is essential to model its drying behavior. The dimensionless moisture ratio (MR) of marula fruit leather during drying experiments was calculated by means of Eq. The dimensionless moisture ratio (MR) of marula fruit leather was calculated by means of Eq.

The marula fruit leather surface color was determined using a reflectance chromameter (CR-400, Konica Minolta Sensing, INC, Japan). The data obtained were used to calculate Chroma (C*), Yellowness Index (YI) and Browning Index (BI) for marula fruit leather.

Results and Discussion

- Effective moisture diffusivity (D eff ) of marula fruit leathers

- Activation energy (E a ) of marula fruit leathers

- Marula fruit leather drying kinetics

- Mathematical modelling of the drying kinetics of marula fruit leather

- Colour properties of marula fruit leathers

- Chroma (C*)

- Yellowness Index (YI)

- Browning Index (BI)

Moreover, the drying rate during this period is controlled by the diffusion of moisture from the inside to the outside of the material (Kashaninejad et al., 2007). During hot air drying of oyster mushrooms (Kotwaliwale et al., 2007), it was observed that the yellowness index of dried mushrooms increased with increasing temperature. However, increasing pectin was reported to increase the yellowness of pineapple fruit leather (Phimpharian et al., 2011).

Heat treatment can also result in caramelization of sugar to produce brown pigments during drying of the products (Perera, 2005, Pathare et al., 2013). During hot air drying of litchi, Mahayothee et al. 2009) reported that the addition of 0.5% Trehalose and 0.5% Glycerol reduced the coloration of the dried product.

Conclusion

Selection and evaluation of thin-layer drying models for infrared radiative and convective drying of onion slices. The effect of drying methods on the characteristics of thin-layer drying of non-skinned pumpkin (Cucurbita pepo L.). Effect of air drying temperature on the physicochemical properties, antioxidant capacity, color and total phenolic content of red pepper (Capsicum annuum, L.

Effect of air drying temperature on the quality of rehydrated dried red pepper (var. Lamuyo). The effect of air temperature on the drying kinetics and quality characteristics of octogenarian giant squid (Dosidicus gigas).

Effect of Drying Temperature and Sugar Concentration on the Texture Attributes

Introduction

Fruit leather is made by drying a very thin layer of fruit puree/pulp mixed with other ingredients or additives to produce cohesively dried leather sheets with varying degrees of integrated textural and sensory properties (Vijayanand et al., 2000; Huang and Hsieh, 2005 , Vatthanakul et al., 2010, Phimpharian et al., 2011). Fruit leathers are considered healthy snacks with greater nutritional value than fresh fruits because all nutrients are concentrated in one dried form (Orrego et al., 2014). As with any other processing technique, several biochemical reactions take place during drying (Niamnuy et al., 2014), and these result in desirable or undesirable changes in texture and sensory properties (Gujral and Khanna, 2002) and also change with the microstructural system. of the final product (Niamnuy et al., 2014).

In the context of the new product development process, such as that of lettuce fruit skin, the evaluation of textural properties provides a systematic approach to ensure that the properties of new products match the characteristics of already existing products of a similar nature (Al- Hinai et al., 2013). Sensory evaluation analysis during product development also aims to express consumer preferences, satisfactions and general acceptances of the quality of products to better improve the production process (de Wijk et al., 2003, Vatthanakul et al., 2010 ).

Materials and Methods

- Fruit Materials

- Fruit Leather Sample Preparation

- Marula Fruit Leather Preparation: The Drying Procedure

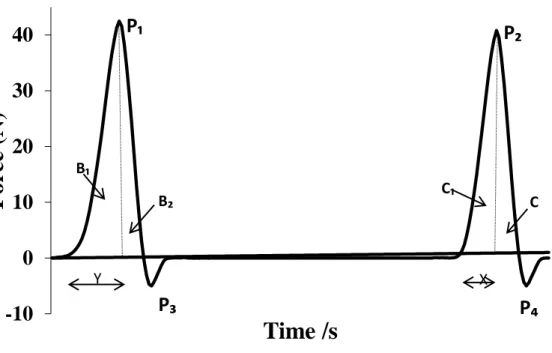

- Marula fruit leather textural attributes

- Texture Analysis Profile (TPA)

- Tensile test

- Consumer Sensory Evaluation of Marula Fruit Leathers

- Statistical Data Analysis

The results of this part of the research can be used as a baseline for better quality control during the processing of marula fruit leather. Moreover, these results can provide guidance to processing industries interested in the production of maroela fruit leather or any other native fruit leather. A total of nine kg of maroela fruit pulp was measured using a weighing scale (CFW-150, Adam Equipment Co Ltd, Dunbury, USA, min 0.01 kg).

The marula fruit leather was obtained and was immediately packed in high density polyethylene bags, heat sealed to prevent further moisture loss and stored at 5 °C for further analysis. The marula fruit leather samples (3 x 3 cm) were evaluated for color, texture (i.e. hardness and chewiness), flavor, taste and overall acceptability using a 9-point hedonic scale (please see index).

Results and Discussion

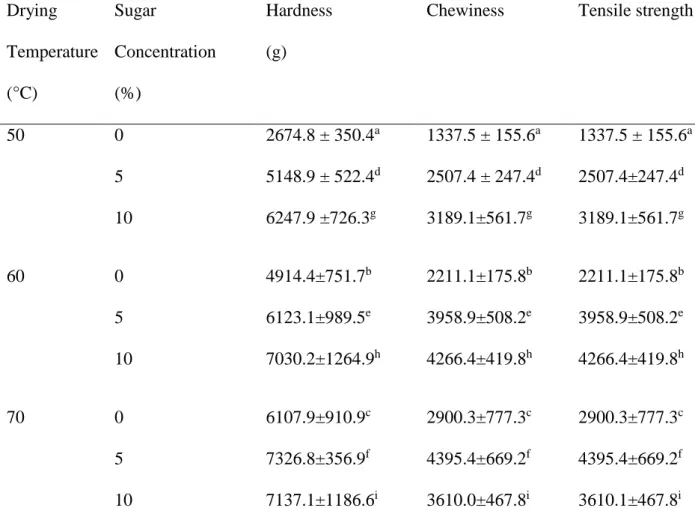

- Texture profile analysis (TPA) properties of marula fruit leathers

- Tensile Strength of Marula Fruit Leathers

- Marula Fruit Leather Consumer Sensory Acceptability Testing

- Correlations between Sensory Evaluation Parameters and Treatments (Temperature

TPA was used to determine different sets of textural properties of fruit leather (Al-Hinai et al., 2013). Among many, it gives the impression of hardness and chewiness of the products in the dried state (Argyropoulos et al., 2011). The hardness and chewiness of oyster mushrooms have been reported to increase with increasing temperature (Kotwaliwale et al., 2007).

It was reported that stress failure in pumpkin increases with increasing temperature (Mayor et al., 2007). The taste of fruit leather is largely determined by the amount of sugar in the fresh pulp (Ashaye et al., 2005).

Conclusion

Effect of air-drying temperature on physicochemical properties of dietary fiber and antioxidant capacity of orange (Citrus aurantium v. Canoneta) by-products. Effect of skimmed milk powder, soy protein concentrate and sucrose on the dehydration behaviour, texture, color and acceptability of mango leather. Effect of heating on the stability of grape and blueberry pomace procyanidins and total anthocyanins.

Effect of osmotic pretreatment on hot air drying kinetics and quality of Chilean papaya (Carica pubescens). Effect of concentration and drying processes on color change of grape juice and leather (pest).

General Discussion, Conclusion and Future Research Recommendations

General Discussion and Conclusion

These results also showed that adding additives such as sugar plays a crucial role during the processing of marula fruit leather. The results also showed that marula fruit leather prepared with high sugar concentration were softer products and this was demonstrated by the instrumental texture analysis results which revealed a decrease in hardness, chewiness and tensile strength of marula fruit leather prepared with 10% w/w added sugar. This was reflected in a decrease in overall acceptance and willingness to purchase the fruit leather by panel members.

This was shown by the increased acceptance and general willingness to buy fruit skins. The addition of sugar appears to have improved texture attributes, color properties, flavor and aroma, overall acceptability and willingness to purchase lettuce fruit skins.

Future Research Recommendations

From this chapter, the drying temperature (50 °C) and 10% w/w sugar addition were recommended for drying marula fruit leather and for producing a more preferred product by consumers. In conclusion, the results obtained from this entire study indicated that the introduction of a new variety of marula fruit (i.e. marula fruit leather) to the market should be accompanied by critical product quality attribute assessment required by consumers. How much do you like or dislike the sample in terms of the features provided.

Please tick (√) your level of like/dislike. Chewy hardness Sweet and sour taste Marula fruit aroma. likeability/acceptability Would you buy this. Chewy hardness Sweet and sour taste Marula fruit aroma. Chewy hardness Sweet and sour taste Marula fruit aroma. Would you like to be involved in the next sensory assessment: Yes/No (Please circle) Thank you very much for your time and participation.