When looking to improve business performance, a company may consider implementing Theory of Constraints. In the multi-project environment, Theory of Constraints is applied as Critical Chain methodology, using the same principle of resource with limited capacity.

Theory of Constraints

In South Africa, as everywhere in the world, original equipment manufacturers are coming under ever-increasing pressure to improve deliveries, be more flexible and innovative, serve customers better, and at the same time improve company results in terms of profits. Goldratt (Goldratt & Cox, 1986) first formulated the Theory of Constraints in the manufacturing environment and published it as a novel that was described as “The most successful attempt at management-as-fiction” (Tibben-Lembke, 2009).

Critical Chain

Measurements

Action research

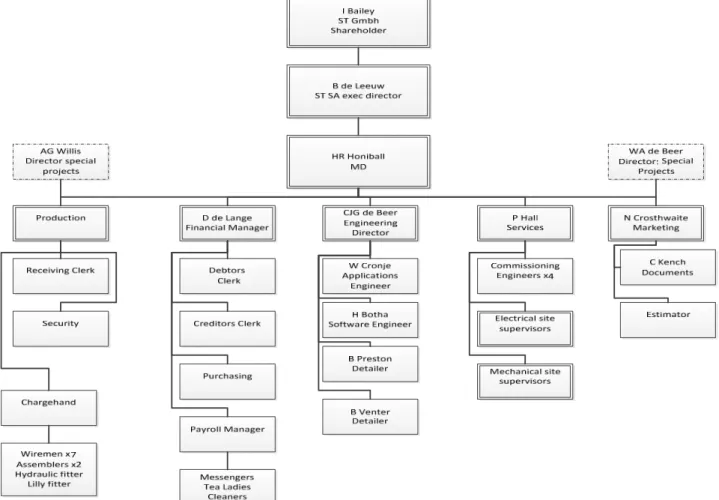

Choice of company

Summary

This literature review will present the theoretical basis that will be applied during action research, namely the Critical Chain (CC), which is the Theory of Constraints (TOC) as applied to project management. The main focus will be on the areas to be covered by action research.

Introduction to Theory of Constraints (TOC)

Since its introduction and first application to manufacturing, Goldratt demonstrated how TOC can be used in project management in a follow-up novel called Critical Chain (Goldratt E. M., 1997). In the project management application, the concept of critical chain (CC) is introduced and it corresponds to the bottleneck in the production process.

The systems approach of TOC

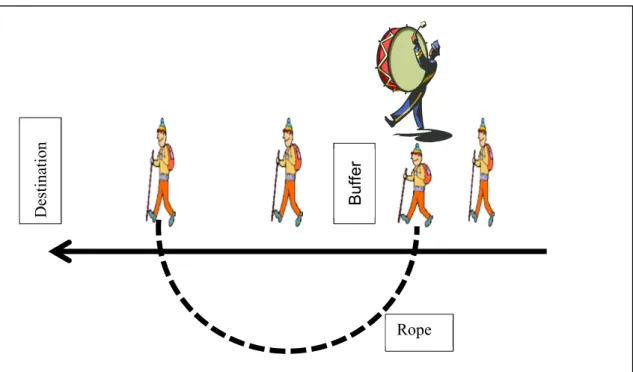

Buffer refers to the amount of time anyone can hold off the slowest scout before starting to hold the slowest scout: the bottleneck. Even the slowest Scout's load is distributed to speed it up.

The business case for TOC

A common method of using cost to make decisions is to determine cost per unit by assigning overhead to each unit produced by dividing the overhead by the number of units. This can even be done per process or machine, and then management can use figures obtained by this method to measure efficiency or to manage according to this cost per unit.

Management philosophy of TOC

Bottleneck exploitation is achieved by ensuring that the bottleneck is never idle by ensuring an adequate buffer size in front of the bottleneck. Goldratt did not specify a specific size or method of calculation except to state that the bottleneck should not be left idle (Goldratt & Cox, 1986).

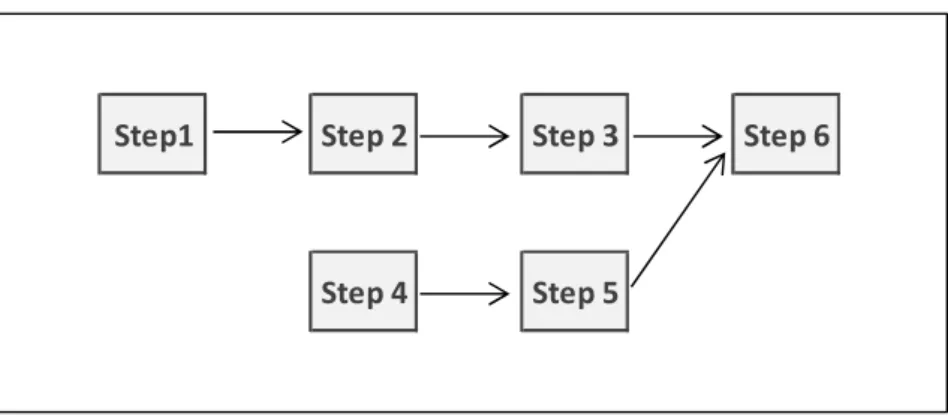

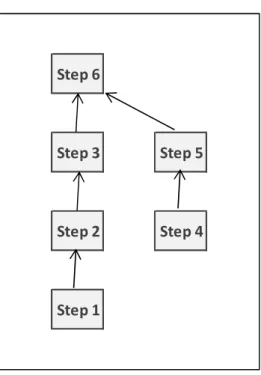

The five focussing steps

- Identify the constraint

- Exploit the constraint

- Subordinate to the constraint

- Elevate

- Repeat the process

Barrier utilization is the process by which current capacity is increased while reducing waste. It was first checked whether the product was actually to be processed by the strait.

Critical chain overview

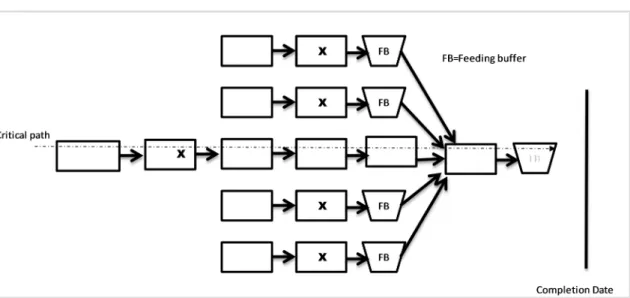

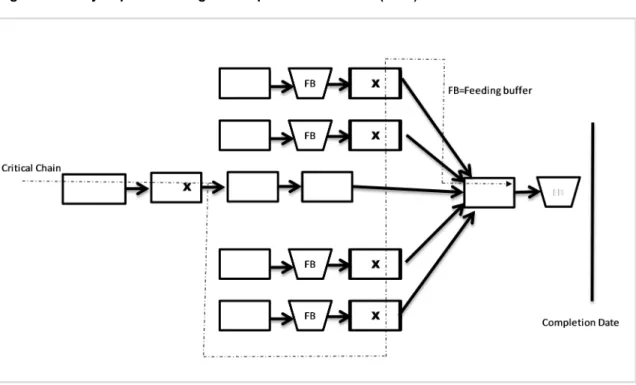

In TOC, the bottleneck determined the performance of the system, while in CC it is the critical chain that determined the performance of the project. Exploiting the bottleneck involved removing fat from task estimates and placing reduced aggregated fat at the end of the critical path as a project buffer to protect the critical chain from delays.

Management practices

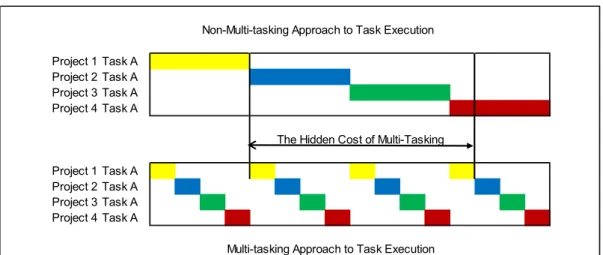

Elimination of multi-tasking

The solution to this situation is to avoid multitasking as much as is practically possible.

Procrastination or the student syndrome

Failure to report early completion

Management may reduce the time given to a task in the future based on past performance, which may lead to an overrun and more punishment. The impact on the project plan is clear: because the task is not shown as completed on the project plan, the next one will not be started, and the result is another delay in the critical path.

The critical chain concept

Reducing suppliers’ lead time

The lost sales would have brought in profit, which is money flowing into the business. The stock is not useful if it is not sold, as high-tech products are, and the lost market share is due to over-stocking.

The practical application of CC

Criticism of TOC and CC

Criticism of TOC's contribution to project management: Although there are differing opinions on the originality of the ideas, both critics and promoters admitted that it was a breakthrough at the time and that TOC presented an innovative new way of project management. Even a small business can implement the full CC process as there is software available even for USD250 (Stratton, 2011). It should also be noted, as Lechler, Ronen, and Stohr (2005) suggested, that there are CC management practices that are highly beneficial to be implemented without having to implement the entire CC process.

The major criticism of CC and TOC then centered on refereeing, the originality of ideas and theoretical problems where other methods produced better results.

Summary

Practical application: Critical chain is used by large companies such as Hitachi (Umble, Umble and Murakami, 2006), ABB, Boeing, Hewlett Packard and others (Stratton, 2011) for project management. What are the improvements in business performance due to the implementation of the critical chain methodology; and. What are the contributing and inhibiting factors that will determine the success or failure of a critical chain methodology implementation.

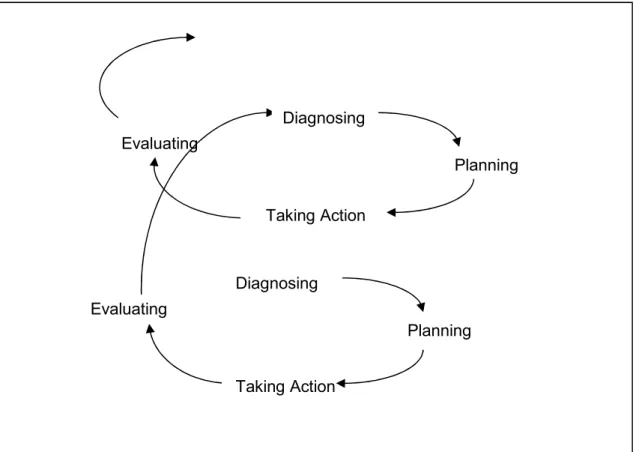

Action research, a term coined by Lewin, (O'Brien, 1998) was chosen as the most appropriate research method for investigating the implementation of CC methodology.

Why action research

Organisational change

Based on implementing theory

Used in problem solving

General action research methodology

Human knowing

Collaborative process

Local context of this action research

Action research cycle time

System and population

Personal Context

Personal bias

The researcher is an engineer and previously headed an engineering department in a similar organization. Another source of confirmation bias is that the researcher wants to effect an effective change in the organization and will look for positive evidence to bring about such change.

Mastering of theory by study group

Reading

Playing the die game

Structuring the cycles

- Discovery

- Measureable action

- Reflection

- Next steps

Specific cases will be reflected on and the group will determine what has been learned from these incidents and consider whether any change in behavior or thinking has resulted. This heading covers the basic measurements agreed upon by the research group. The team must plan specific actions that will be taken in the next week or fortnight.

These interventions will be designed using Theory of Constraints in general, but Critical Chain scheduling specifically to design the interventions.

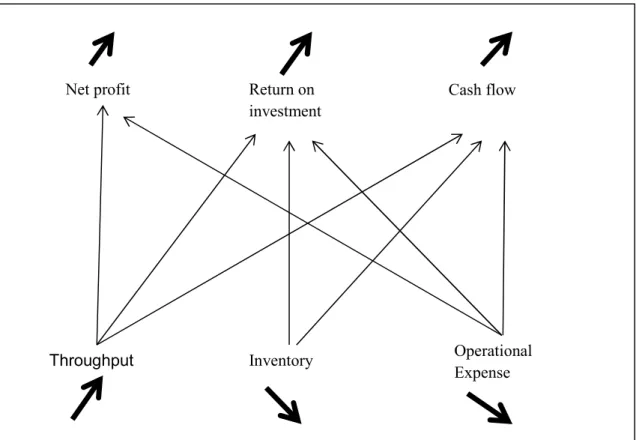

Financial Measurements

How do these ideas go with or contrast with what you have read in the literature on this topic. This is again a group activity, and the research group plans what actions will be taken during the next week. The idea is to check what worked and what didn't in the past week.

Action research learning

Action research group composition

The direct costs are subtracted from revenue and then all operating costs are subtracted.

Potential research limitations

Structuring the action research group

On the introduction of theory

- General comments

- Net profit

- Return on investment

- Cash flow

- Order Intake

This was done to comply with the requirements of the company for the release of financial results for research purposes. In flow accounting, the cash position of the business is considered if the main purpose of business is to. In the case of the foreign investor, that investor would have put money into the business and the return in dividends would be his return on investment.

Tenders without a concrete date, such as verbally accepted tender requests, would be "green" - the lowest priority.

Summary on business performance improvement

Action research cycles

- Implementing the five focussing steps

- Interventions in the first cycle

- Interventions during the second cycle

- Interventions during the third cycle

AG Willis (personal communication, February 2012) noted that in the past such discussions would have been met with strong resistance and denial and that it was surprising to see the cooperation of Engineering and Design. It has been decided to implement E-Plan™ as standard drawing package for use by Engineering and Design. However, a QA inspector was present in the organization and the action research group decided that this particular task could be performed by the QA inspector.

It was also decided to include a representative from Engineering and Design in the morning production meeting.

Indentifying the primary contributing and inhibiting factors to CC methodology

Interruptions

It was also decided to equip the purchasing system software with a facility whereby the parts list could be loaded in spread sheet format directly into the system. Attempts to change processes and eliminate at least some of these disruptions all ultimately failed. This inhibitor was so prominent that no other contributing or inhibiting factors could be found in the time available for this research.

Because there was no change in financial indicators, no change mentioned in the working groups to working methods, it is found that the CC practices were not implemented due to the massive resistance to change.

Resistance to change

This was mentioned in cycle one, but at the end of cycle three only one project had been outsourced, and only a relatively small project.

Learnings identified by the action research group

Success of CC

The action research group unanimously expressed at every meeting that CC worked and contributed to the business. Gut feeling: Twice it was quoted at meetings that members in the group had a gut feeling that CC works and contributes to the company. This should not be confused with an inhibitor during the implementation of CC, as it is proven above that CC was not implemented.

This could also be called a passive form of resistance, as it will create the perception that CC is being implemented, while no change can occur in the background.

Changes in behaviour

By secondary inhibitor in this case is meant a factor that supports the identified primary inhibitor.

Implementation errors

Inhibiting and contributing factors

Embedded culture

If a director has been in a position for more than ten years and has been doing the same job for more than ten years, we can assume that there may be some culture embedded in the way of working and managing. This director also personally mentored the senior application engineer, another participant in the action research group. It would be fair to assume that his behavior, at least professionally, will follow that of his mentor.

This is reinforced by the fact that his mentor is well known in the industry and represents a legend to live up to.

Remuneration motivation

Add to that the fact that he has been working in the same company since 1976 and has always had to work a certain way, and there can be some resistance to change. This application engineer started his career at Winder Controls and progressed from test technician to application engineer. His mentor rightly offers a model of behavior as Ashforth and Humphrey (1997) stated: "The main task of senior management is to create and maintain a system of shared meanings that provides a basis for coordinated behavior", p.46.

Incorrect CC application

These steps then become a cycle that feeds and sustains itself and will inhibit the implementation of CC.

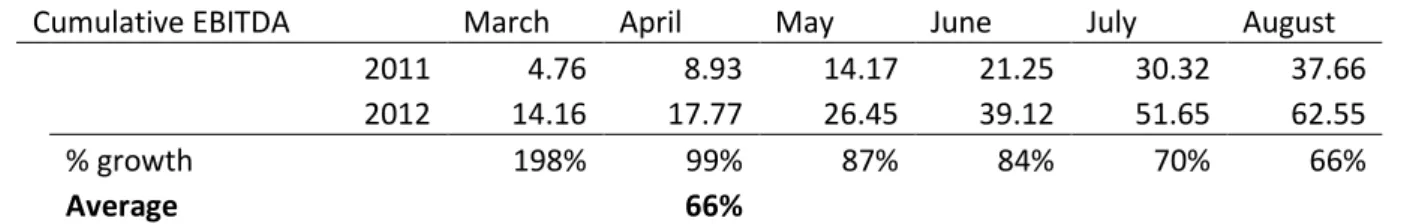

Improvements in business performance

Business performance

Contributing and inhibiting factors

Suggestions for further research

Implications to management

Conclusion

An introduction to the Theory of Constraint and how it can be applied to medical management. Queuing network analysis approach for time buffer size estimation in theory of constraints controlled production systems. Implementing theory of constraints in a traditional Japanese production environment: the case of Hitachi Tool Engineering.

Can the Toyota Way Overcome the Recent Toyota Backlash - A Study Based on the Theory of Constraints.