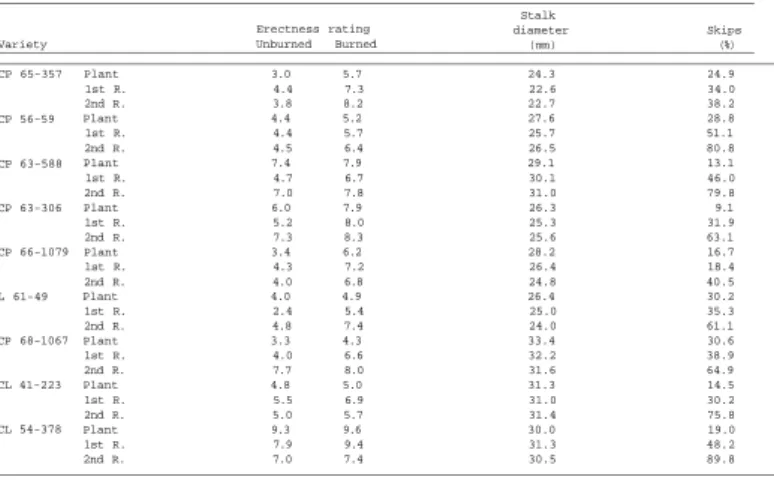

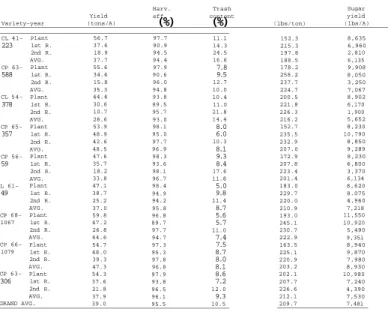

Measurements of stem diameter and skip length were taken in the row before the harvester passed. The varieties yielded better than expected in terms of the amount of dormant crop.

DATE

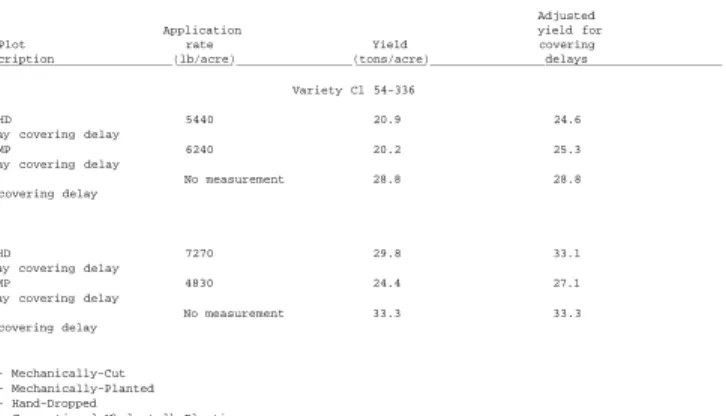

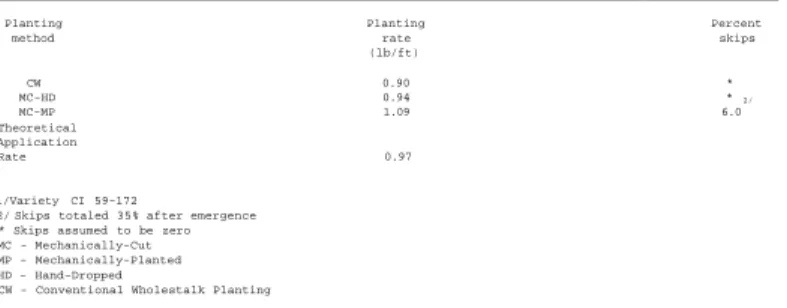

Seventy-three biparental crosses (Table 1) were made in the cubicles of the tall sugarcane nursery. One mechanically planted sugarcane treatment (Plot 5) was comparable in yield to conventional whole-stem planting, while the other mechanically planted treatment (Plot 4) was lower.

Damage

Consumption was determined daily by subtracting back weight of the remaining bait from the original amount. Consumption of the alternative food, lab chow, was inversely related to corn and oat grass consumption (except by water rats during pretreatment). Breaux (1) evaluated 95 random F sugarcane clones for uprightness at each of four stages of the Louisiana breeding program.

The parents were complex hybrids of the Saccharum species used commercially in Florida and Louisiana. An estimate of the heritability of laying was obtained from these variances using the formula h = (variance within F1 populations minus variance within parental clonal populations) / variance within F1 populations. Most of the lodging in this experiment was caused by stem bending, but there was also some uprooting.

It should be emphasized that the pH meter will be used to determine the endpoint of the titration, not the pH of the juice.

ROLLER MILL

2 stalks

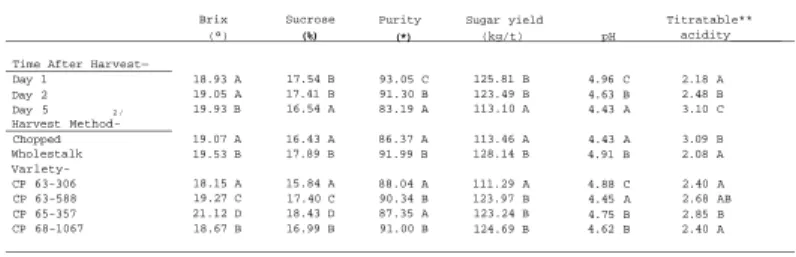

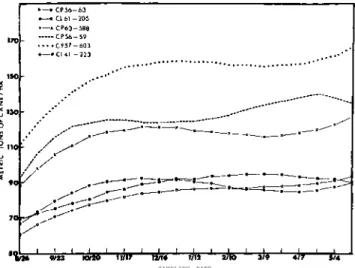

Stems were cut into three equal segments and manual refractometer brix was obtained at the midpoint of the segments. Brix at the center of the stem was a better indicator of sucrose content early in the season than top or bottom brix. After mid-January, brix of the different segments was not significantly different from whole stable brix.

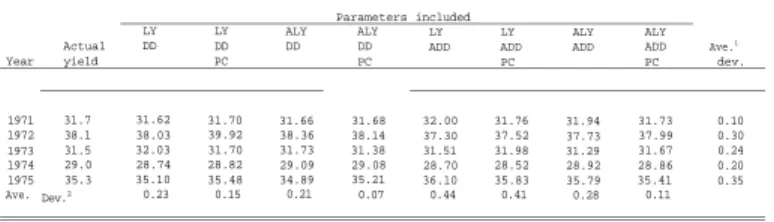

Varieties matured within 2 weeks of the time when the difference in brix in the lower segments minus the upper stem was zero. Hand-held refractometer mid-stem brix was the best estimate of whole-stem brix early in the season (Table 1. Hand-held refractometer brix of the upper segment was a better indicator of recoverable sugar per ton throughout the season than brix of each bpttom or middle segment.

These correlations do not give an indication of maturity status on a given day, but they do show a close correlation between brix of the stem segments and recoverable sugar per tonnes throughout the harvest season.

Bottom

Bottom

Bottom

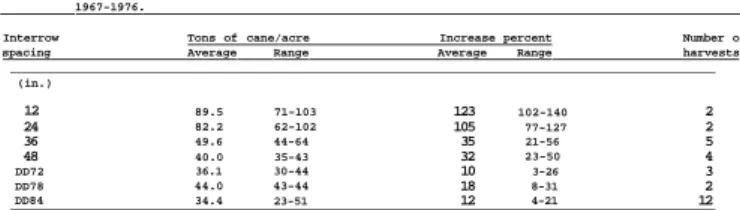

- A significant row width x variety interaction was evident in this test and was probably due to the severe rat damage that occurred only In CP 56-63

- No significant difference in tons of cane per acre for different row width means within the same crop year

- LSD - Least significant difference between any 2 values

- LSD = Least significant difference between any 2 values

- W. Scott, Jr

- R. Thomas Agricultural Research Service

The average sugarcane yield estimates (tons per hectare) for six varieties at each of the twenty sampling dates are shown in Figure. Therefore, there was little actual difference in maturity time of the mid-season and late-maturing varieties in this test. The development of the flat burner, which uses liquid petroleum gases (L-P) and produces a relatively short, flat flame that remains close to the surface, has greatly expanded the use of the flame cultivator (5).

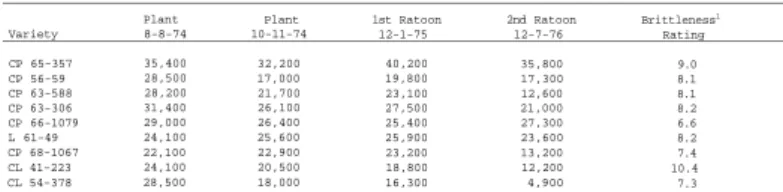

All varieties averaged less sugar per ton of cane in the second stubble crop than in the planting cane and first stubble crops due to the severe freeze in January 1977. A different row was observed in each of the three crops (planting cane, first, and second stubble );. Variety CP 63-588 averaged 217 lb of sugar per ton of cane in the average of the second stubble data and therefore outperformed all other varieties in this category (Table 3.

A review of the literature (2, 3) showed that cane and sugar yields per hectare increased with decreasing species width.

SOIL WATER, cm/30cm

1st rtn 13.6

1st rtn 16.4

1st rtn 82.9

As can be seen in the physical chronogram (Fig. 1) and the order of assembly (Fig. 2), the schedule for the construction of the building and the mill tandem was as follows: The history of the Santa Elisa new mill tandem in particular and that of this Usina (sugar factory) itself and its directors is just an example of what is currently happening in Brazil and in the Brazilian sugar industry in particular. Now, with the addition of the new Zanini-Farrel tandem, the subject of this presentation, the mill's milling capacity has been increased to 15,000 tons.

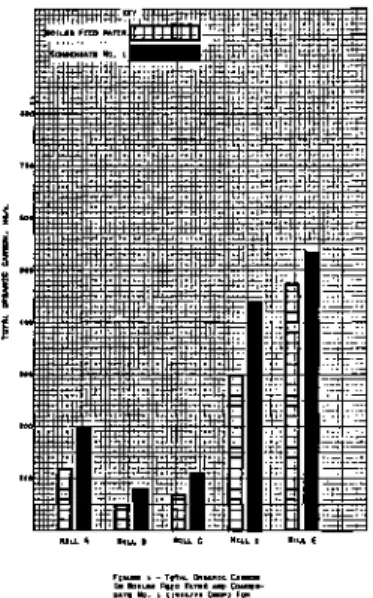

The presence of these volatile, non-sugary contaminants can seriously limit the efficient operation of the boilers, and it becomes imperative that their concentrations in the boiler water are kept to a minimum. We chose the measurement of total organic carbon for this purpose because of its ability to provide a direct measurement of the organic contaminant and its simplicity of operation compared to the indirect oxidation-titration procedures. Figures 1 and 2 show that significant levels of organic contamination are present in all sampled plants, as measured by total organic carbon.

The difference indicates that the majority of the organic contamination in the condensate No.

CONDENSATE NO. 2

Turn Sample Select Valve to desired position (Total Carbon or Inorganic Carbon)

Fill syringe (20 ul)

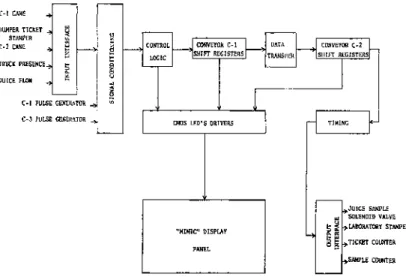

System maintenance is limited to cleaning the C-l switch and juice strainer at the first mill. The value of the sugarcane by-product is critical to the prospects of sugarcane, but is unknown. In 1976, Battelle made some preliminary estimates of the cost of ethanol from sugarcane juice, assuming a giant plant capable of producing about 25% U.

This by-product results from the evaporation and drying of the solids obtained from the bottom of the still. If the cooling from the molasses process has value (Fig. 6), the net cost of ethanol drops significantly. In the case of batch-fired furnaces, this increases the frequency of the cleaning cycle.

Reducing chimney gas losses and recovering this heat is a very obvious approach.

Heat the boiler feed water in finned tube economizers

Limiting the excess air to the amount required for complete combustion is the first step, as the greater the volume of the stack gases, the most heat is stolen from the steam. So every bit of extra air brings in 80% of this inert material, which absorbs heat without providing any benefit. The solution here is to tighten the air supply to the combustion chamber and closely monitor the composition of the chimney gas, mainly for oxygen.

The carbon monoxide and carbon dioxide content will of course also be useful when analyzing the furnace operation. Much of this waste heat can be recovered by using the hot stack gases to:.

Preheat the combusion air

Dry the bagasse

Fugitive emissions are difficult to control

The dry bagasse and fines constitute a fire hazard

The main engines (turbines for the mills and turbo generators) required most of the live (high pressure) steam, with a small amount required by the steam jet ejectors (for the vacuum units) and other miscellaneous uses. The exhaust steam from the main engines is used for heating in the juice heaters, evaporators, vacuum pans and the boiler feed water discharge. An ideal steam balance is one where all the steam required to operate the factory can be obtained from the available bagasse.

Ideally, all the exhaust produced by the prime movers is consumed by the boiler house so that there is no excess to be vented (thereby losing heat and good condensation for boilers). Thus, it is necessary to provide auxiliary fuel for boilers, a live steam composition for exhaust and an exhaust vent to atmosphere (or surface condenser) to prevent breakdowns in one stage from affecting all stages of plant operation. . In Florida, the use of high-pressure steam leads to lower direct steam requirements in the prime movers.

In Louisiana, few mills generate electric power, so the use of live steam is less than indicated in the table, and exhaust requirements are often restrictive.

Proportional to the potential heat or enthalpy drop in the steam. The potential (ideal) heat drop increases with steam pressure and steam superheat, and decreases with increasing

Assuming we have done everything we can to maximize steam production from the bagasse, we will look at what changes can be made to reduce steam consumption. A small amount is used for mass heating, process water heating and other miscellaneous applications. The need for exhaust steam in Florida is also lower, and in good balance with steam production, thanks to quadruple effect evaporation combined with vapor extraction for pans and heaters.

The former abundance of cheap natural gas led to the installation of low-pressure steam generators and triple effect evaporators. In practice, it is the steam condition at the turbine ring (available steam at the turbine blade) that controls the steam consumption of the turbine. Therefore, for minimum steam consumption, the turbine hand valves must be controlled so that the annulus pressure is only slightly less than the pressure in the steam collector (if the annulus pressure reaches the pressure in the header, the turbine may stall).

Reduction of boiler exhaust steam requirements: Boiler steam requirements can be reduced by the following methods:

Increase the number of evaporator effects

Bleed vapor from the evaporator effects to operate heaters and/or the vacuum pans

The recovery of heat from boiler blowdown, by flashing this hot water to produce exhaust steam

The flashing of hot evaporator condensates to produce additional vapor

Using excess exhaust to deaerate boiler feedwater

The optimum insulation of live steam, exhaust, and condensate return lines; and the insulation of the boiler feed water storage tank

The proper sizing of live steam and exhaust lines to reduce power-robbing pressure drop

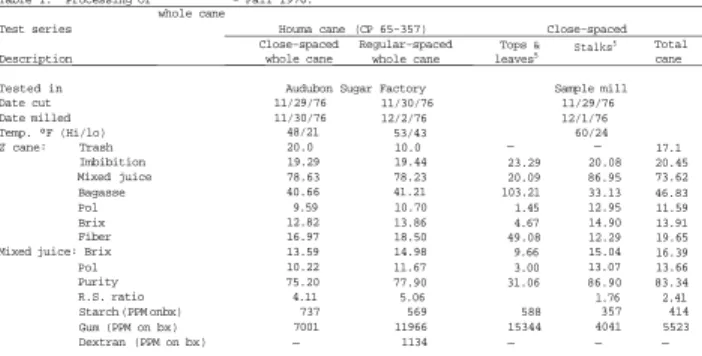

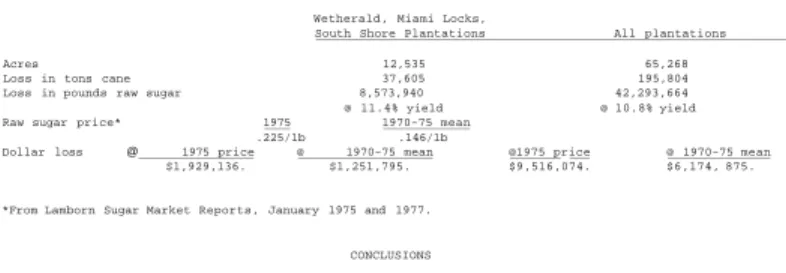

The work described herein was part of the Energy from Crops program sponsored by the U. On the other hand, the cane harvested on November 29 was actually processed in the mill on the morning of the hard freeze. In addition, a test mill run (100 lb load) was made on each of the pooled cane samples.

This procedure resulted in the reduction of starch content, as shown in the data in Table 1. It is clear that the buds and leaves are very poor from the point of view of sap production and pollen content - the latter only 1.45%. The results on total cane (see third column) are slightly worse than those on the clean stems, as you would expect due to the inclusion of the buds and leaves.

Accordingly, it is predicted that very high sucrose yields per acre can be obtained through the factory treatment of the closely spaced cane.