The construction of water supply infrastructure shall comply with the Water Services Association of Australia publication 'WSA 03-2011 Version 3.1 - Water Supply Code of Australia' (the 'Code'), unless the Code is amended by this document. The following amendments, additions, deletions and modifications apply to and form part of the Code. Ultimately, this document will contain additions, additions, deletions and changes to Part 1 'Planning and Design' of the Code so that it forms a complete supplement to the Code.

Currently, amendments, additions, deletions and changes to Part 1 'Planning and Design' of the Code are included in the Mackay Regional Council document 'Engineering Design Guideline - Water Supply Design - Planning Scheme Policy No.

Glossary of Terms, Abbreviations and References

Construction

Scope

Interpretation

HOLD POINT means a point beyond which work may not proceed (the blocking point is released) without authorization and sign-off by the Superintendent's Representative and/or the Mackay Regional Council representative. The release of a guard may also be subject to an inspection of the works by the Superintendent's representative and/or the representative of the Mackay Regional Council. MONITOR means intermittent monitoring of each phase of work in progress by the Superintendent and/or the Representative of the Superintendent and/or the Representative of the Director and/or the Representative of the Regional Council of Mackay.

WITNESS POINT means a point beyond which work shall not proceed without the Contractor notifying the Superintendent's representative and/or the Mackay Regional Council representative to enable the Superintendent's representative and/or the Mackay Regional Council representative to witness and sign off, inspect or test or aspect of work.

Quality Assurance

- General

- Inspection and test plans

- Quality tests

- Quality audits

Personnel Qualifications

General

Protection Of People, Property And Environment

- Protection of Other Services

- Disused / Redundant water mains

- Private and public properties

Affected Party Notifications

Authorised Products and Materials

- Pressure pipe-work and pipe fittings

- Valves

PE pipe and fittings must be; .. i) electrofusion, blow melting or compression joined ii) a minimum of class PN16 . iii) a minimum Standard Dimensional Ratio (SDR) of 17 iv) complying with Section SP6 of WS-SPEC. v) of either PE80B or PE100 polymer material. vi) comply with WS-SPEC Section SP6 'Polyethylene pipes and fittings'.. externally with PE in accordance with AS4129. Steel pipe and fittings must be; .. i) rubber ring welded, flanged or welded .. ii) Fusion bonded polyethylene (FBPE, eg Sintakote) or epoxy coated iii) SR type cement or epoxy lined. iv) Minimum wall thickness the greater of 6mm or diameter/120 v) Complies with Section SP1 of WS-SPEC .. i) to Figures B7, B8 & B9 of AS 4087, as applicable. ii) provided with Grade 316 SS bolts and Grade 304 SS nuts and washers Steel pipe to be provided with cathodic protection where specified. Pipe and fittings must be handled, transported and stored according to the manufacturer's guidelines. e) Glass reinforced plastic (GRP) pipe and fittings.

GRP pipes and fittings may only be used with Council approval on a project-by-project basis. If approved, they must be GRP pipes and fittings; .. i) joined with rubber ring (elastomeric) joint couplings ii) of the smallest tube rigidity class SN10. iii) minimum pressure class PN16. iv) in accordance with section SP5 WS-SPEC "GRP pipes and fittings". Pipes and fittings must be handled, transported and stored in accordance with the manufacturer's guidelines. f) ABS pipes and fittings.

Pipes and fittings must be handled, transported and stored in accordance with the manufacturer's guidelines. g) Copper pipes and fittings. Copper pipes and fittings must be; .. i) manufactured in accordance with AS 1432 . ii) in the range DN6 to DN200 for Type A or Type B iii) isolated from ferrous mesh. iv) comply with AS3500 'Plumbing and drainage Part 2: Sanitary plumbing and drainage' .. i) comply with AS 3688 'water supply - Metallic fittings and end connections'. ii) be resistant to dezincification. iii) , if capillary fittings, have silver-soldered joints or solder insert capillary connections 12.1.3 Valves. The internal surfaces of the valves must be free of sharp projections which can initiate secondary cavitation at high flow rates.

For the supplier's feed pump packages, the supplier's nominated check valve system will be acceptable. f) Ball valves must be; .. i) comply with WS-SPEC Section SP-22 'Ball valves', ii) with flange unless otherwise stated on the drawings.. i) only used with prior approval of the Board, . ii) if approved, comply with WS-SPEC Section SP-24 'Butterfly valves for waterworks purposes', . iii) if approved, with flange, unless otherwise stated on the drawings.. i) sluice valves, . ii) have assemblies as indicated on the drawings.. i) comply with WS-SPEC Section SP-28 'Spring Hydrant Valves', . ii) between 100mm and 200mm below finished surface level (from top of hydrant) - achieved by using hydrant risers of different heights where necessary, . iii) DN100 flange spring type (SWASH) hydrants without isolating valves. Maximum spacing between hydrants must be 80m. j) Pressure reducing valves must be; .. i) comply with AS4020 . scale factor of 0.1, . ii) with flange unless otherwise stated on the drawings. iii) installed with isolating valves upstream.

Transportation, Handling and Storage of Products and Materials

Rejected Products and Materials

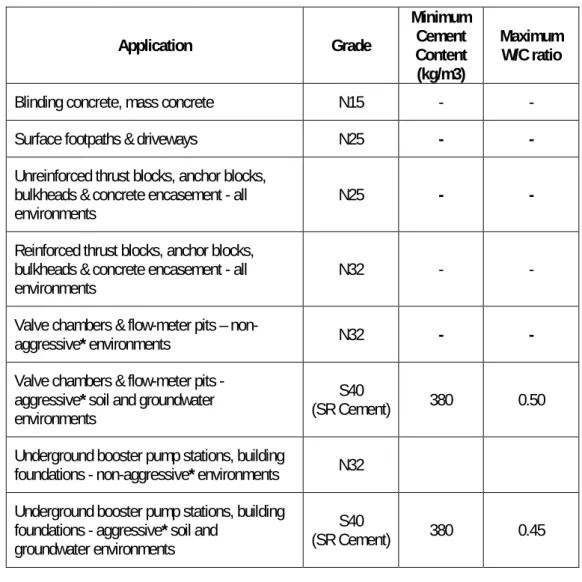

Concrete Works

Underground booster pump stations, built. foundations - non-aggressive* environments N32 Underground booster pump stations, building. foundations - aggressive* soil and groundwater environments. Slump shall be 90 mm ± 10 mm unless otherwise specified in the project specific WSA product specifications. Cover to reinforcement for structures other than waterproofing structures must meet the requirements of the relevant Exposure Classifications within AS3600 'Concrete Structures', but must not be less than that required for C1 in aggressive environments and B1 elsewhere.

Concrete surfaces exposed to aggressive environments must be provided with a protective coating in accordance with section WS-SPEC TR-20 "Protective Coatings". All concrete work will be supervised by a person (Supervisor) experienced in all aspects of concrete construction. The Supervisor shall inspect all formwork, reinforcement and pour location for any concrete structure (including thrust blocks etc.) prior to placing any concrete.

The contractor will be present when the supervisor inspects the work before the concrete is placed. All formwork, rebar, rebar supports, blocking, excavation and preparation, etc., shall be in place, and the supervisor notified, at least one full working day before concrete is scheduled to be placed on any part of the work. . Superintendent's sign holding point release after inspection is required prior to placing concrete in any concrete construction.

At the time of notification from the supervisor, the council must notify whether the possibility of inspection is to be used. If utilized, witness release is required, at signoff by council, prior to concrete placement at each concrete structure.

Precautions

Support of Excavations

Trench Excavation

- General

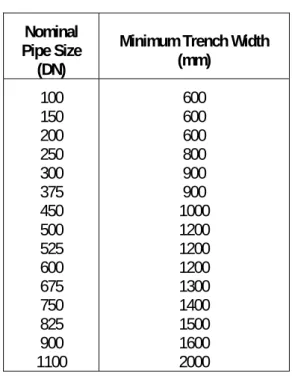

Where trench fortification is used, the clear trench width is measured between the inner faces of the trench fortification.

Foundations and Foundation Stabilisation

Surplus Excavated Material

Trench Floor Preparation

Bedding and Pipe Support

Placement of Bedding

Installation of Pipes

- General

- Cleaning, Inspection & Joint Preparation

- Laying

15 PIPES AND JOINTS 15.1 Installation of pipes 15.1.1 General. above bedding) form a WITNESS POINT. If exercised, the release of the Witness Point, by signature by the Board, is required before the supplement begins. Where PVC pipes are to be joined to ductile iron pipes, the joints should be made by inserting a PVC spigot into a ductile iron socket.

Horizontal and Vertical Deflections of Pipes

- Deflection at a Pipe Joint

Flotation Control

Thrusts & Anchor Blocks and Restrained Joints

Trench stops

Bulkheads

Corrosion Protection of Cast Iron

Marking Tapes

- Detectable Marking Tape

Valves, Hydrants and Surface Fittings

- Installation

- Valve Chambers for Large Mains

Valves and hydrants must be compatible with the piping system to ensure that a proper seal is achieved between pipe flanges and valve flanges. Valves shall be located to avoid conflict with property accesses, telecommunications service pits, electrical service wells and other street furniture.

Bored Pipes Under Roads, Driveways and Elsewhere

Concrete linings in pipelines must not be chipped or reduced to provide clearance from the working parts of the valves. The annular space between the pipeline and casing pipe shall not be filled or grouted except for sealing the ends of the casing arrangement as described in the standard drawings. The DICL conduit enclosed in the casing pipe need not be socketed in accordance with clause 15.9 (amended).

The Contractor must give written notice to the Authority of the intention to carry out the work and pay any applicable fees. The Contractor must then obtain written authorization to carry out the work from the Authority before work commences. Release of the Holding Point, by signature by the Superintendent, after submission of the written authorization is required before works commence.

Submission, by the Superintendent, of a copy of the authorities' written permission to the Council constitutes an POINT OF WITNESS. At the time of notification from the supervisor, the council must advise whether the possibility of revising the written authorization should be used. If utilized, the release of the witness statement is required to be signed by the Council before work commences.

Method of work statements for trenchless pipeline installations must be submitted to the Superintendent and must address the following matters;. a) General description of method and operation sequence. Release of the Holding Point, by sign-off by the Superintendent, following review of Work Method Statements and confirmation of their adequacy by the Superintendent is required before works commence.

Appurtenance Location Marking

Where a pipeline crosses a government-controlled road, watercourse or any landform, feature or structure under the control or jurisdiction of any Authority or Owner ("Authority"), the works must comply with the requirements of that Authority. Pavement designation of fire hydrants shall be in accordance with section 1.25 "Fire hydrant indication system" of the Queensland Department of Transport and Main Roads "Traffic Management and Road Use Manual".

Welding of steel water mains

- General

Embedment Materials

Compaction of Embedment

- Methods

Concrete Embedment and Encasement

Trench Fill

- Material Requirements

- Placement

- Compaction of Trench Fill

General

Compaction Testing

- Compaction testing requirements

- Frequency and location of tests

Hydrostatic Pressure Testing

- General

- Mains

- Property services

A test section is defined as a length of water pipe that can be effectively isolated for testing, e.g. Water pipes with different diameters should be tested separately and should not be tested in the same test event. During testing, all pipe joints that have not been filled must be clean, dry and accessible.

During testing, each valve shall be able to withstand the full test pressure on one side of the valve in the closed position at least once and for a minimum of 15 minutes, with no pressure on the other side.

Water Quality Testing

- General

Detectable Marking Tape

General

General

General

Pavements

Provision for and rectification of settlement

Maintenance of restored surfaces

Reference is made to Council Construction Specification C101 'General' and Council Engineering Design Guidelines D20 'Drawings and Documentation Guidelines'. Structures represented on design drawings and removed during the work (including, but not limited to, pipes, fittings, pavements, etc.) shall not be represented on the as-built drawings. Structures represented on design drawings and rendered redundant during the work (including, but not limited to, pipes, fittings, pavements, etc.) shall be noted as 'redundant' on the as-built drawings.

Areas of side fill that contribute to the structural integrity of pipelines greater than 225 mm in diameter should be shown on the construction drawings as areas that should not be disturbed without carrying out an appropriate risk assessment.