The project was carried out in partial fulfillment of the requirements for the degree Bachelor of Science (B.Sc.) in Mechanical Engineering of years of 2020 and was approved in terms of its style and content. We hereby declare that the work presented in this project is the outcome of the investigation and research work carried out by us under the guidance of Md. We also declare that no part of this project and thesis has been or is being submitted elsewhere for the award of any degree.

First of all, we would like to express my gratitude to Almighty Allah for giving me the strength to carry out my thesis responsibilities and complete the report within the stipulated time. Ahatashamul Haque Khan Shuvo” for his constant and close supervision, valuable suggestions and encouragement to carry out this work. Finally, we would like to thank everyone who supported us in any way in the preparation of this thesis.

In today's life, there is a wide variety of forklifts, from the big heavy-duty truck to the one that works between narrow aisles. Now a days advanced parking system is an important issue and day by day its necessity is increasing. In Bangladesh we still use the manual vehicle parking system and that's why we face problems like wasting time and fuel to get free space around the parking lot when we need to park our car which needs a good amount of lighting.

Another problem is the chaos that arises during parking because there is no specific system that allows someone to park somewhere which sometimes causes damage to the vehicles while leaving or in the parking lot.

Introduction

Research topic 02

Objectives 02

Develop an intelligent and user-friendly automated parking system to reduce the number of people and traffic congestion.

Literature Review

- Working principle of Forklift 03

- Types of forklifts 04

- Types of car parking system 05

- AVG Systems 05

- Crane Systems 05

- Puzzle Systems 06

- Tower Systems 06

- Application 07

- More places are car parking system by using forklift 07

There are different types of reach forklift that are best suited for a variety of scenarios:[7]. The two forks at the front of the truck slide under palletized loads to lift and transport safely. They offer straightforward operation and have twin forks at the front of the truck that lift and transport the load.

There are different types available, including three-wheeled models that offer better maneuverability, making them perfect for narrow hallways. The carefully calibrated counterbalance at the rear of the truck prevents overbalancing, making it easy to use in mud, ice or even snow. Guided Vehicle Automation known as AGV technology has been introduced to the automated parking system more recently, although AGVs have been used in automated warehousing for decades.

This system is used using a single mechanism that must simultaneously perform the horizontal and vertical movements of the vehicle to be parked or retrieved in the parking system. Jigsaw systems offer the densest form of automated parking as they utilize approximately 95% of the floor area and are often used in smaller systems. This system typically consists of a vehicle lift with a parking space on either side of the lift shaft.

The vehicle lift is simply raised to one of the parking levels of the tower and laterally deposits the vehicles into the parking space. In the decades that followed the development of our country, we came to a situation where the manual parking system in business premises had to be replaced. The manual car parking system creates obstacles and chaos in parking spaces, resulting in wasted time and economic losses.

This will help the staff to park their car without hindrance or waste of time. This will help customers park their car without obstructions, which will give them time to search for more products. If we install automated car parking systems in amusement parks and railway station or any other place, it will attract more people to come to these places.

Methodology

- Stepper motor 09

- How This Process Work 10

- Final Assembly 11

- Mass Calculation of The Components 12

- Torque Calculation of The Motors 12

- Torque to Lift Up and Down 12

- Torque to Move Right and Left 12

- Torque to Move Forward and Backward 13

- Rpm Calculation of The Motors 14

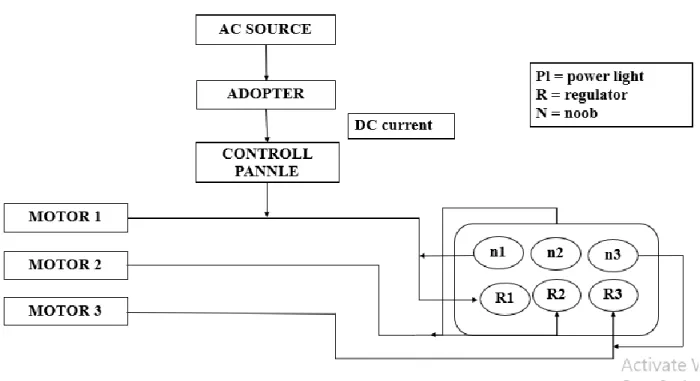

The two types of ladder control circuits commonly used are the three-wire control regulator and the three-wire motor control circuit. The three-regulator wire control circuit uses retained contact devices to control the up-down and left-right or front-rear. The three-motor control circuit uses momentary contact devices that control the magnetic motor starter.

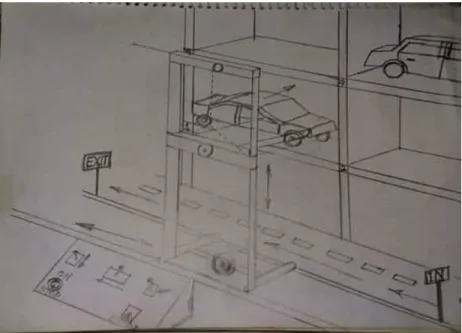

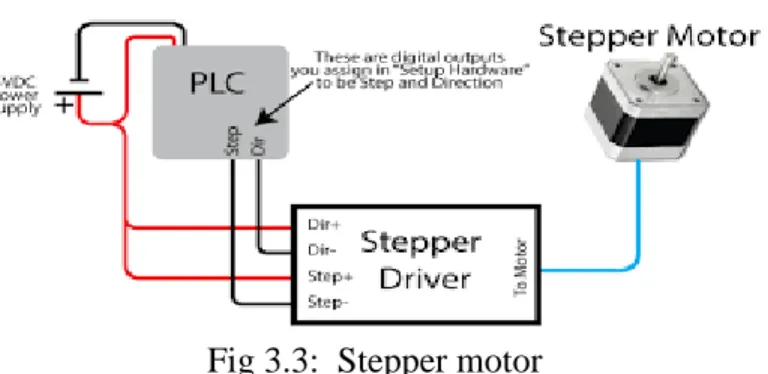

The stepper motor is an electromagnetic device that converts digital pulses into mechanical shaft rotation. Control unit is the unit from which we operate all the systems in this process. Car works to put the car to the parking area or take the car from parking area with forward and backward direction.

The CAD design of the final assembly was done based on the part drawing of the components of the project. Using the tool measurement command of SolidWorks software based on the final assembled CAD design of the forklift parts, which is done according to the assumed dimensions we get.

Experimental Setup and Performance Test

- Block Diagram 16

- Circuit Diagram 17

- Final Setup 18

- Performance Test 18

- Discussion 23

- Economical Benefits of Automated Car Parking System 24

- Disadvantages 24

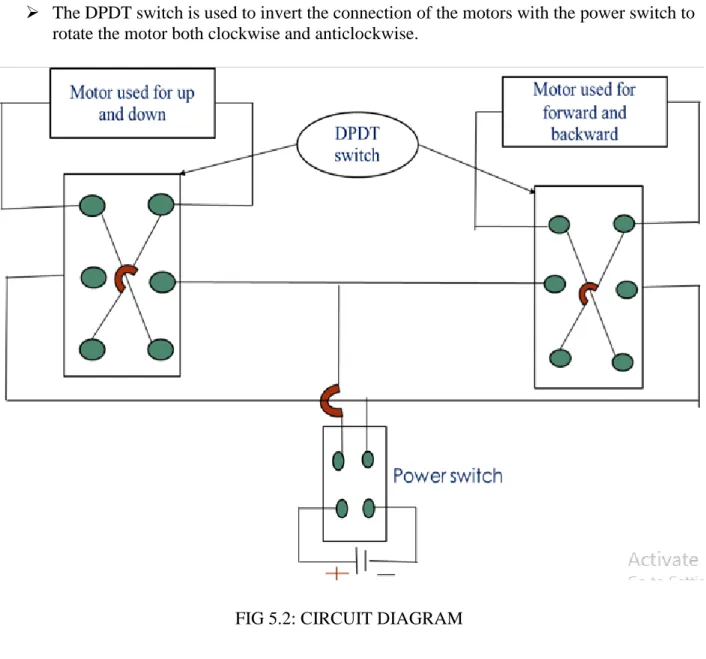

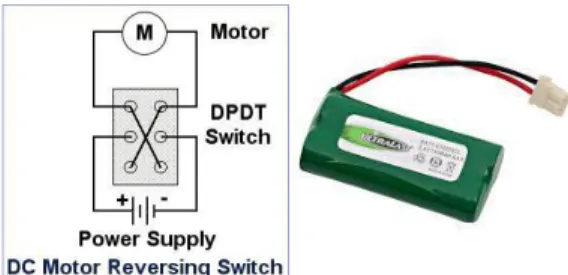

This section consists of the overall description of the hardware of the automatic parking system and details of the circuits used in the project. The DPDT switch is used to invert the connection between the motors with the power switch to rotate the motor both clockwise and counterclockwise. Finally, all components and parts of the project have been mounted on a wooden surface shown in.

Performance testing of the forklift consists of- The estimation of the maximum load it carries. The maximum mass of the car, fork and forklift stand that can be easily lifted by the forklift has been measured using a mass balancing scale. To calculate the average speed of the forklift, the time has been calculated using a stopwatch for a certain distance.

The distance is then divided by the time for which the average speed of the forklift has been calculated. The time required to store and retrieve is shown in Table: time required to store and retrieve operation-. Lift up-down and move forward-backward have worked correctly at the average speed shown in Table 5.2 and Table 5.3.

These changes in timing are due to the distortion of the wheel connected to the engine, which increases the tendency to increase friction, as well as reduce the grip properties of the rubber used in the steering wheel. In addition, a tilting effect at the base of the fork is caused due to gravity affecting the movement of the fork. Additionally, regular cleaning is mandatory to keep the car park system in good working order, especially with weather-induced problems (road salt can spread to the lift platforms and cause serious damage if not removed).

It is much more efficient to wash clothes using parking garage design and manufacture than manual parking. This keeps traffic free in the urban area and keeps them out of the harmful effects of the car. The townspeople are already using the parking lot and they will be able to understand the whole parking system and share the parking lot with the entire community.

Since manual parking systems are not planned properly, it takes a lot of time to find a parking space, park in and pick up the vehicles. The insurance premium, which is often heavily influenced by the likelihood of accidents or other incidents occurring, using a manual parking system can maximize the potential for property damage, theft, personal injury or death.