UNIVERSITI TEKNIKAL MALAYSIA MELAKA

Design and Development of

Smart Storage System

for Clothes Drying

Thesis submitted in accordance with the requirements of the Universiti Teknikal Malaysia Melaka for the Bachelor Degree of

Manufacturing Engineering (Engineering Material)

By

Zamri Bin Ahmad

APPROVAL

This thesis submitted to the senate of UTeM and has been accepted as fulfillment of the requirement for the Bachelor of Manufacturing Engineering (Engineering Material) with

Honours. The members of the supervisory committee are as follows:

……….

Mr. Syahrul Azwan Bin Sundi @ Suandi (PSM Supervisor)

DECLARATION

I hereby, declare this thesis entitled “DESIGN AND DEVELOPMENT OF SMART STORAGE SYSTEM FOR CLOTHES DRYING” is the result of my

own research except as cited in the references.

Signature : ……….

Author’s Name : Zamri Bin Ahmad

ABSTRACT

ABSTRAK

ACKNOWLEDGMENTS

First at all, Alhamdulillah and praise to Allah,

I manage to complete my Final Year Project – Projek Sarjana Muda.

I also would like to offer thanks and deepest gratitude from the bottom of my heart for all the support, encouragement and inspirations I obtained through out the duration of this

project. The help rendered to me priceless, be it from the smallest of its kind to the largest. They include;

My supervising lecturer, Mr Syahrul Azwan Suandi of which we had a good working relationship, and who offered tremendous help and encouragement,

My family, who inspired me whether through the storm and carry on,

My friends and peers who are good companions in times of need.

Wassalam….

TABLE OF CONTENTS

List of Abbreviations, Symbols, Specialized Nomenclature xi

2.3.1.2 Disadvantages 11

3.3.3 Detailed Function and Design Requirements 23

3.3.3.1 External Search 23

3.3.7.5 Electrical and Electronic Component 28

3.3.8 Prototype Testing 30

3.3.9 Actual Condition 30

3.3.10 Patent and Manufacture for Marketing 31

CHAPTER 4: DEVELOPMENT OF PROJECT

4.1Introduction 32

4.2 Simulation 33

4.2.1 Programmable Logic Controller (PLC) 33

4.3 Conceptual Design 37 4.4 Design and Development 42 4.4.1 Designing Phase 42

5.2.3 The SSS Prototype Views 52

5.2.3.1 Front View 52

5.2.3.2 Back View 52

5.2.4.2 Control Panel 53 6.5 Suggestion for Further Improvement 71

6.6 Conclusions 72

CHAPTER 7 CONCLUSIONS

73REFERENCES

74LIST OF FIGURES

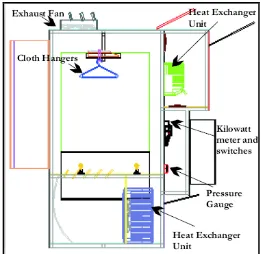

Figure 1: Schematic Diagram of Heat Pump Assisted Clothes Dryer Main Components (Ameen, A , 2004)

9 Figure 2: Schematic Diagram of Heat Pump Assisted Clothes

(Ameen, A , 2004).

10 Figure

3(a), 3(b)

Opened System ; Closed System (Ameen, A , 2004) 10

Figure: 4(a), 4(b)

3D representation of the Cloth Dryer ; Prototype Cloth Dryer (Ameen, A,2004)

11

Figure 5: The different position of air conditioner outdoor units between Heat Pump

12 Figure 6: Clothes dryer utilizing air conditioning waste heat schematic drawing

(United States Patent 5437106, 1995).

13 Figure 7: Illustration showing the air from the outdoor unit is not totally used. 15 Figure 8: Clothes Dryer Model: SDM-901 15 Figure 9: Illustration drawing to show the principle drying mechanism of

SDM-901 clothes dryer using “Solid Work 2005” software.

16

Figure 10: Air Ducting 28

Figure 11: Suzuki Power Window Drive motor 29 Figure 12: Lead-acid battery 30 Figure 13: PLC Control System 34 Figure 14: Smart Storage sensory system using “Ladder Builder for KV”

Figure 22: Front Cover using AutoCAD 2002 software 48

Figure 23: Back Cover using AutoCAD 2002 software 48

Figure 24: a) Simulation show how the door functioning b) SSS in static mode 50

Figure 25: Improvement of simulation design using AutoCAD 2002 software. 51

Figure 26: SSS Circuit diagram 52

Figure 27: a) The front view of SSS; b) The control panel and battery where situated; c) the front door which can be opened and closed for inserting clothes. 52

Figure 28: a) The back view of SSS; b) the motor; c) door for ducting 52

Figure 29: a) window for switching on the control panel; b) windows for inserting small size clothes; c) main door for clothes inserting; d) hinges and magnet 53

Figure 30: a) control panel connected with battery; b) inside the control panel; c) 2 sensors at the corner top of SSS. 54

Figure 31: a) ducting attached to out door unit by using rubbery rope while b) showing the ducting attached to SSS by using magnets 55

LIST OF TABLES

Table 1: PSM I Gantt Chart 19 Table 2: PSM II Gantt Chart 20 Table 3: The screening matrix for the design concept of Smart Storage

System

57

LIST OF ABBREVIATIONS, SYMBOLS, SPECIALIZED

NOMENCLATURE

SSS - Smart Storage System

PLC - Programmable Logic Controller 3D - Three Dimensional

CHAPTER 1

INTRODUCTION

1.1 Introduction

The characteristic features of the climate of Malaysia are uniform temperature; high humidity and copious rainfall and they arise mainly from the maritime exposure of the country. Winds are generally light. Situated at the equatorial doldrums area, it is extremely rare to have a full day with completely clear sky even in periods of severe drought. On the other hand, it is also rare to have a stretch of a few days with completely no sunshine except during the northeast monsoon seasons.

Malaysia has a tropical climate with high temperatures and rainfall all year round. Rainfall is heavy and usually occurs in the form of thunderstorms. The main differences of climate within the country are due to differences of altitude and the exposure of the coastal lowlands to the alternating northeast and southwest monsoon winds. Southwest monsoon winds blow from April to September while the northeast monsoon occurs from November-February. March and October are the transition months between the monsoons, characterized by light and variable winds (Reza Azmi, 2003).

Conditions are cooler in the hills but this is balanced by higher humidity and rainfall, and less sunshine. Although Malaysia has a warm and humid climate, severe heat stress is rare. The transition months (March and October) can be uncomfortable because winds are light and humidity may be higher. In the afternoons, conditions on the coast are often relieved by sea breezes. Over the east coast districts (Kelantan, Terengganu, Johor, Pahang), November, December and January are the months with maximum rainfall, while June and July are, generally, the driest months (Reza Azmi, 2003).

1.2 Problem Statements

Clothing is one of the basic needs for human. Clothing protects the vulnerable nude human body from the extremes of weather, other features of our environment, and for safety reasons. The practical function of clothing is to protect the human body from dangers in the environment: weather like strong sunlight, extreme heat or cold, and precipitation, for example like insects, noxious chemicals, weapons, and contact with abrasive substances, and other hazards (Wikipedia, 2007). Each time the clothes are used, it needs to be cleaned before it can be used again. This to make sure the clothes to be hygienic and free from dangerous bacteria.

1.3 Objectives

To make sure that this project meets the goals and requirement, the objectives of this project are defines below according to the points:

To design a smart storage for drying purposes focus on residential used.

To fabricate the replication of smart storage mechanism.

To simulate a smart storage functions and investigates the effectiveness of the overall idea.

1.4 Scope of study

Scope:

Study on mechanisms that help into smart storage automation. Detail design of a smart storage residential used.

Design criteria will focus on application, economical aspect and flexibility.

1.5 Conclusion

CHAPTER 2

LITERATURE REVIEW

2.1 Introduction

In this chapter, it wills mainly discussing about the general operation, principles and mechanisms that related to the Smart Storage studies. Some of previous research and studies were included into this chapter to support the development of ideas for Smart Storage System (SSS) concept and design.

2.2 Evaporation Process

energy to be considered past the boiling point of the liquid. If this happens near the surface of the liquid it may actually fly off into the gas and thus "evaporate".

Liquids that do not appear to evaporate visibly at a given temperature in a given gas (e.g. cooking oil at room temperature) have molecules that do not tend to transfer energy to each other in a pattern sufficient to frequently give a molecule the "escape velocity" the heat energy necessary to turn into vapor. However, these liquids are evaporating, it's just that the process is much slower and thus significantly less visible (Silberberg, Martin A., 2006).

2.2 Types of dryer

2.2.3 Traditional dryers

Traditional dryers continuously draw in the cool, dry, ambient air around them and heat it before passing it through the tumbler. Afterwards, the resulting hot, humid air is simply vented outside to make room for more dry air to continue the drying process. The traditional design makes no effort to recycle the heat put into the load, and so is quite inefficient. Nevertheless, the basic design is simple, reliable, and cheap.

2.2.2 Spin dryers

saves a worthwhile amount of time and energy for large laundry operations such as those of hospitals or hotels.

2.2.3 Condensation dryers

Just as in a normal dryer, condensation dryers pass heated air through the load. However, instead of exhausting this air, the dryer uses a heat exchanger to cool the air and condense the water vapor into either a drain pipe or a collection tank. Afterwards, this air is run through the loop again. The heat exchanger uses ambient air as its coolant, therefore the heat produced by the dryer will go into the immediate surroundings instead of the outside.

Because the heat exchange process simply cools the Internal air using ambient air, it will not dry the air in the internal loop to as low a level of humidity as the fresh, ambient air. As a consequence of the increased humidity of the air used to dry the load as well as the increased complexity of the design, this type of dryer requires more time and energy than a traditional dryer. However, it is a valid option where long, intricate ducting would be required to vent a traditional dryer.

2.2.4 Heat pump dryers

As with condensation dryers, the heat exchanger will not dry the internal air to as low a level of humidity as the ambient air. With respect to ambient air, the higher humidity of the air used to dry the clothes has the effect of increasing drying times; however, because heat pump dryers conserve much of the heat of the air they use, the already-hot air can be cycled more quickly, possibly leading to shorter drying times than traditional dryers, depending on the model.

2.2.5 Mechanical steam compression dryers

New types of dryer in development, these machines are a more advanced version of heat pump dryers. Instead of using hot air to dry the clothing, mechanical steam compression dryers use water recovered from the clothing in the form of steam. First, the tumbler and its contents are heated to 100 °C. The wet steam that results purges the system of air and is the only remaining atmosphere in the tumbler.

As wet steam exits the tumbler, it is mechanically compressed (hence the name) to extract water vapor and transfer the heat of vaporization to the remaining gaseous steam. This pressurized, gaseous steam is then allowed to expand and is superheated before being injected back into the tumbler where its heat causes more water to vaporize from the clothing, creating more wet steam and restarting the cycle.

2.3 Recently/Past studies

Followings are some of previous research and studies that had been develops to encounter problems, which are state in chapter 1. There are 3 innovations where each one build with different concept and operating mechanism but sharing same objective of working principle, to drying clothes.

2.3.1 Heat Pump Assisted Clothes Dryer

In densely built urban high-rise flats, natural drying of clothes is a problematic household chore that is aesthetically unacceptable as well. Natural drying of clothes in Malaysia is a very time consuming process because of year round humid climate, limited sun rays and restricted air flows. The use of conventional electrical dryer is a practical but expensive solution for drying clothes, as it is inherently an energy intensive process. Hence, a search for a low cost solution for drying clothes is quite relevant and more so in the context of the growing use of air conditioners and progressive compactness of apartments (Ameen, A , 2004).

2.3.1.1 Design

In closed system mode (Fig. 3b) air returning from the drying chamber is dehumidified by the evaporator and then heated by the condenser resulting in faster cooling. Drying of a batch of spin-dried clothes takes about 45 minutes for close system mode and 60 minutes for the open system mode compared to 150 minutes in a commercial dryer and more than 282 minutes for natural drying indoors. Wrinkle-free drying and subsequent storing of clothes in this dryer has another advantage of eliminating mould and fungi so common in humid climates. Developing an integrated air conditioner cum dryer is thus a practical proposition because the cost of the drying cabinet is marginal and the benefits are tangible (Ameen, A , 2004).