Design And Fabrication Of Welding Jigs And Fixtures For FKP Lab.

Teks penuh

Gambar

Dokumen terkait

SMAW process is a precise task that requires the welders to maintain their postures to ensure the welding product in a good quality. The SMAW process may expose the welders

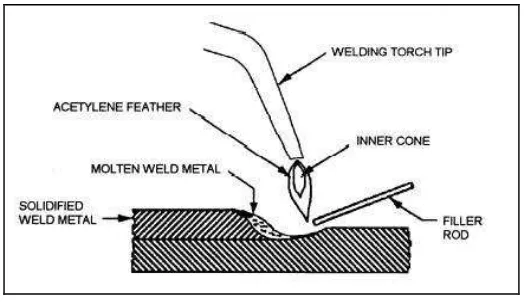

The main challenge for this project was to design and fabricate a Multiplex Electrode Holder (MEH) that can perform two fundamentally different welding process such as

This study aims to determine the hardness and strength of the welded joint of 6 inch schedule pipe 80 API 5L Grade B using a combination Gas Tungsten Arc Welding

128 Figure 6: Cooling Speed and Minimum Average and Maximum Temperature without Load Figure 7: Cooling Speed and Minimum Average and Maximum Temperature with Load Performance

Process models The responses from bead-on-plate welding experiments, i.e., the bead attributes penetration, bead width, bay area, reinforcement area, % Dilution, process measures

Therefore, by giving prime emphasis on microhotplates for gas sensing application, we attempted to answer the key questions such as: how factors such as heater design, materials