UNIVERSITI TEKNIKAL MALAYSIA MELAKA

SIX SIGMA (DMAIC) IMPLEMENTATION IN

INDUSTRY

Report submitted in accordance with the partial requirements of the

Universiti Teknikal Malaysia Melaka for the

Bachelor of Manufacturing Engineering (Manufacturing Management)

Asleeda Binti Ahmad

Faculty of Manufacturing Engineering

UTeM Library (Pind.112007)

b "814

(cz

UNlVERSlTl TEKNIKAL MALAYSIA MELAKA"

-=

JUDUL:

SIX SIGMA DMAlC IMPLEMENTATION IN INDUSTRY

SESl PENGAJIAN:

SEMESTER 2 2007 12008

Saya ASLEEDA BlNTl AHMAD

mengaku membenarkan laporan PSM I tesis (SarjanaIDoktor Falsafah) ini disimpan di Perpustakaan Universiti Teknikal Malaysia Melaka (UTeM) dengan syarat-syarat kegunaan seperti berikut:

I.

Laporan PSM 1 tesis adalah hak milik Universiti Teknikal Malaysia Melaka dan penulis.2. Perpustakaan Universiti Teknikal Malaysia Melaka dibenarkan membuat salinan

untuk tujuan pengajian sahaja dengan izin penulis.

3. Perpustakaan dibenarkan membuat salinan laporan PSM I tesis ini sebagai bahan

pertukaran antara institusi pengajian tinggi. 4. *Sila tandakan

( 4 )

(Mengandungi maklumat yang berdarjah keselamatan atau SULIT kepentingan Malaysia yang terrnaktub di dalam AKTA RAHSIA

RASMl 1972)

TERHAD (Mengandungi maklumat TERHAD yang telah ditentukan oleh organisasilbadan di mana penyelidikan dijalankan)

TI DAK TERHAD

A

(ASLEEDA BlNTl AHMAD) (EN.NOR AKRAMIN BIN MOHAMAD)*

BLOK AG-4-2

TAMAN TUN SARDON, Cop Rasmi:

11 700 GELUGOR, NOR AKMMlN BIN MOHAMAD PULAU PINANG Pensyarah

Fakultl Kejuruteraan Pembualan Un~vers~t~ Tekntkal Malays~a Melaka

Karung Benunc~ 1206 Ayer Keroh

Tarikh: 05.0 5'm** 73450 Melaka

Tarikh: S / S / a 8

DECLARATION

I hereby, declare this report entitled "Six Sigma (DMAIC) Implementation In Industry is the result of my own research except as cited in the references.

Signature

Author's Name : Asleeda Binti Ahrnad

APPROVAL

This report submitted to the senate of UTeM and has been accepted as partial

fulfillment of the requirements for the degree of Bachelor of Manufacturing Engineering (Manufacturing Management). The members of the supervisory committee are as follow:

Main .Supervisor

Mr. Nor Akrarnin Bin Mohamad NOR AKRAMIN BIN MWAMAD

Censyarah

Fakulti Kejurutenan Pembuatan Uilveniti Teknikal Malaysia Melaka

ABSTRACT

This project is providing to explain the Six-Sigma DMAIC (Define, Measure, Analyze, Improve, and Control) methodologies implementation in industry. The focused on

DMAIC method were use as a guideline to design the Six-Sigma. The DMAIC

methodologies were use to reduce scrap cost in one of the electronics company in

Penang. The project were analyze by using

Y=

F (x) factor problem statement. Thisproject covers the importance, benefits, limitations and any related issues that occurred

in Six-Sigma, example; problem statements, objectives, scope of work, project outline,

literature review of previous study and the methodologies and tools are using in this

project. There are five factors were identified contributed to high scrap. The five factors

are Xl(Lacquer splashes), X2 (Glue A & B not mix properly), X3 (Fluxing), X4 (Machine set up for solder paste printing), X5 (Lacquer at the press fit hole). All the data

was obtained fiom several techniques and methodologies. The Minitab 14 software use

to provides the result whether it's significant or not significant after the project run and

get the result in the analyze phase. In addition, based on result, several components of

product was redesign to improve the product to be a quality and reduce higher scrap and

wastage. This project was achieving the target to reduce scrap cost for 65% by using the

ABSTRAK

Projek ini disediakan bagi menerangkan perjalanan kajian terhadap projek yang

berkaitan dengan pelaksanaan "Six-Sigma" menggunakan kaedah "DMAIC (Define,

Meaure, Analyse, hprove,and Control)" dalam industri Tumpuan diberikan kepada

penggunaan kaedah DMAIC sebagai garis panduan kajian berkenaan dengan "Six-

Sigma". Kaedah DMAIC digunakan untuk mengurangkan kadar buangan yang

disebabkan oleh beberapa faktor yang terjadi pada salah satu syarikat elektronik di

Penang Projek ini dianalisa menggunakan formula Y=F(x). Kajian ini meliputi

kepentingan, kebaikan, pembatasan dan berbagai lagi isu-isu yang berkaitan dengan

kadar buangan seperti contoh adalah seperti; penyataan masalah, objektif, skop kerja,

rumusan projek, dm cara kerja serta peralatan yang digunakan bagi projek ini. Terdapat lima faktor yang dikenalpasti menjadi penyebab kepada kadar buangan yang tinggi.

Lima faktor tersebut adalah "Xl(Lacquer splashes), X2 (Glue A & B not mix properly), X3 (Fluxing), X4 (Machine set up for solder paste printing), X5 (Lacquer at the press fit

hole)". Data diperolehi daripada pelbagai teknik dan kaedah untuk projek ini.

Penggunaan perisian Minitab 14 adalah untuk mendapatkan keputusan yang berkaiatan

dengan data yang diperolehi sama ada penting atau tidak sesuatu faktor itu di kaji

dengan lebih mendalam dalam fasa analisis. Daripada data yang diperolehi, sesetengah

komponen yang digunakan juga akan dikaji untuk memperbaiki sesuatu produk tersebut

supaya berkualiti dan mengurangkan kadar buangan yang tinggi. Projek ini telah berjaya

mencapai objektif untuk mengurangkan kadar buangan sebanyak 65% dengan

DEDICATION

Specially dedicated to my beloved mother, Sahir Banun Binti Anor Kassim, my late

father, Ahmad Bin Othman, my fiance Muhamad Jamil Bin Mashdar and who are very concerns, understanding patient and supporting. Also thank you to my supervisors, Mr.

Nor Akramin Bin Moharnad, my brothers, sister and all of my friends. Thanks a lot for

all who was support me in this project and this project will never been achieved without

ACKNOWLEDGMENTS

Firstly of all I would like to thankful to Allah S.W.T that was give me permission to

complete and finish my Final Year Project. Allah have gives me life and chance to do

the job that was given to me. Next, I want to regard my thankful to beloved mother and

my late father and also my family for their support and give me spirit in doing these

jobs. With bless of them, I was complete my report and done the task.

I also would like to acknowledge the advice and guidance to the important person that

was guides me in the report preparation and the project preparation, Mr. Nor Akramin

Bin Mohamad, and Mr. Noor A m i from electronic company. Thanks also to my fellow

friends of BMFU 2004 - 2008 for their help.

The important person that was guides me in the report preparation and the project

preparation, Mr. Nor Akramin Bin Mohamad and my high appreciation to Mr. Noor

Azrni

,

assistant manager from electronic company. Not forget to all lecturers from Faculty of Manufacturing that was give me the knowledge about the engineering field.Lastly, I want send my thankful to all UTeM staff, my friend and all the people that

involved in my thesis and project. Thank you to all for the help and support.

Asleeda Binti Ahrnad

TABLE OF CONTENTS

..

Approval..

...

.ii*..

Declaration.....

iiiAbstract

...

ivAbstrak

...

.vDedication

...

.vi.

.

Acknowledgement...

.viiTable of Contents..

...

.xi. .

List of Figures...

xi1List of Tables

...

.xivList of Abbreviations, Symbols, Specialized Nomenclature..

...

.xv1 .INTRODUCTION..

...

11 .O. Introduction..

...

.11.1. Problem Statements.

...

.2.

.

1.2. Project Objectives.....

31.3. Scope of Project..

...

..41.4. Outline of Study..

...

42. LITERATURE REVIEW

...

62.1 Research Areas in Methods of Quality Improvement..

...

.6- 9 2.1.1 Taguchl s methods..

...

-62.1.2 Shainin System of Statistical Engineering..

...

..72.1.3 TQM and its implementation steps..

...

.82.2 Comparison of Quality Improvement Methodologies..

...

.9. . .

2.3 Research m Six.S~gma

...

12. .

2.4 SIX-Sigma Implementation...

142.5 Level of Six.Sigma

...

142.6 Six-Sigma Deployment Process

...

162.7 Research in Six-Sigma Methodologies Concept

...

182.7.1 DMAIC

...

192.7.2 DMADV

...

-192.8 Research in Six-Sigma's DMAIC Methodology

...

202.9 Summary of Research in Six-Sigma

...

233 METHODOLOGY

...

283.1 Introduction

...

-283.2 Design of Methodology

...

28. .

3.3 The SIX-Sigma programme...

313.4 The Analysis Tollgates of Six.Sigma

...

323.5 DMAIC Implementation in Six.Sigma

...

333.5.1 Phase 1 : Define Phase

...

343.5.2 Phase 2: Measure Phase

...

353.5.3 Phase 3: Analyze Phase

...

353.5.4 Phase 4: Improve Phase

...

36...

3.5.5 Phase 5: Control Phase 36 3.6 The Six-Sigma Tools...

-374 RESULT AND DISCUSSION

...

384.1 Introduction

...

384.2 Root Cause Analysis

...

384.3 DMAIC Methodology

...

39. .

4.3.1.1 Project Defimt~on

...

404.3.1.2 Project Drill Down Tree

...

404.3.1.3 Project Metric- BC Division Scrap Trend

...

414.3.1.4 Scrap Analysis Breakdown Details

...

424.3.1.5 Project Metric- Pareto Chart for Causes versus Count

...

434.3.2 Measure Phase

...

434.3.2.1 Process Mapping

...

444.3.2.2 Key Process Input and Key Process Output Variable

...

454.3.2.3 Cause and Effect Matrix

...

464.3.2.4 Selected Cause and Effect Matrix

...

474.3.3 Analyze Phase

...

474.3.3.1 The Five X-Factor of Problem

...

484.3.3.2 Data Test Using Minitab Software

...

-534.3.3.2.1 Xl- Lacquer Splashes at FCI Connector

...

544.3.3.2.2 X2- Housing Leakage (Glue A and B Not Mix Properly

...

574.3.3.2.3 X3- Flux at FCI Connector Pin

...

634.3.3.2.4 X4- Missprint at Solder Paste Printing

...

-654.3.3.2.4 X5- Lacquer at the Press Fit Pin Hole

...

68...

4.3.3.3 Summary of test Using Minitab 14 Software between X-factor 73...

4.3.4 Improve Phase 77 4.3.4.1 X1 and X3-

Lacquer Splashes at FCI Connector...

784.3.5 Control Phase..

. . .

.

. .

.

. . .

. . . .

.

. . . ... . .

.

. . .

.

. . .

. . .

.

.

.

.

. . .

...

874.3.5.1 SCDC Production Scrap Rate..

.

.

. . . .

.

. . .

. .

. . .

.

. .. . .

.

. .

. .. . .

. . .

. . .

.874.3.5.2 SCDC May Scrap by Model..

.

. .

.

.

.

. . . .

.

.

.

. . .

.

.

. .

.

.

...

.

.

.

.

.

. . . ....

884.4 S m

...

. . .

.

.

.

.

. .

.

.

...

. . .

.

. . .

. .

.

.

. . .

.895. CONCLUSION AND RErOs\/V%fli;X3 4 YEOX. . ; . . . . ; ,

.

;.

. , . ; , ..

, . . , : . ..

, . : ; ; . :. .

; ; ; : a .9fi 5.1. Introduction.,. . .

, , , , , , , . , , , , ,.

, ,.

, ,.

. . . . , . . ..

. . . . . . . . . . . . . . . . . sn 5.2. Conclusion.. . .

.

.

. .

. . .

.

.

. . .

.

.

. . .

. .

.

. . .

.

. .

. . .

.

.

. . .

.

. . .

.

. . .

,.

. . .

. .

,.

.

. . .

.

.

. . .

.9 1 5-3. Recommendation...

.

. . .

.

.

.

. . .

.

. .

.

.

. . .

. .

. .

. . .

.

. . .

,.

,. . .

, ,..

. . .

.

,. . . .. ...,.

93REFERENCES..

. . .

.

. . . .... . .

.

. .

. . .

.

. .

.

. . .

. .

.

.

.

. . .

....

.

. . .

. .

.

.

.

.

. . .

.

. . .

....

94A Key Process Input and Key Process Output Variable

R Cause and Effect Matrix C Failure Mode Effect Analysis

LIST OF FIGURES

Outline of The Project

Flow Chart of Research Methodology

Flow Chart for Six-Sigma Methodology

Project Drill Down Tree

Project Metric

-

BC Division Scrap Trend Pareto ChartPortion of the session window output fiom One-Way ANOVA

Summary for Splashes Factor

Boxplot of Splashes by Factor

Summary of Beforc and After Component A

Portion of the session window output from Test For Equal Variance

Test for equal variances for leakage Comp~nciit A

Portion of the sessi~n window output from Two Sample T

Boxplot of Before and After Component A

Summary of Before and After Component B

Portion of the session window output from Tesr For EquaI Vnriancc

Test for equal variances for leakage Component B

Portion of the session window output from Two Sample

T

B~xpfot cf Before and After Component B Individual value plot for Component A and B

,Dort.iorl ~f the session vVinbovY~ output hn;Test For Equal Variance

Tcst for e p a l variancss for flux staiii

Pertior; af :he se~siol'i -~dl;fido\v output h m One-Way ANOVA

Boxplot of Stain by Pr;rr;rneter

Ps~iorr of +F3e session window? otrtp~t from Test For Equal Variance

Test for equal variances for missprint

Portion of the session window output from One-Way ANOVA

Boxplot of misprint by factor

Scatter Diagram for misprint factor

Summary of Before and After Applied Sticker

Portion of the session window output fiom Test For Equal Variance

Test for equal variances lacquer sipped through

Portion of the session window output from Two Sample T

Boxplot of Before and After Applied Sticker

Individual value plot for Before and After Applied Sticker

Portion of the session window output fiom Two Sample T

Boxplot of After Applied Sticker and modified pallet

Improvement of Lacquer at FCI connector Pin & Fluxing Portion of the session window output from Two Sample T

Portion of the session window output fiom Two Sample T

Boxplot of Flux Before and After

Improvement of Dimension Mixer

Improvement of Mixer Body Hole

Improvement of Pump

Process Capability of Housing Leakage

Process Capability of Missprint at Solder Paste Printing

Improvement of Lacquer at press fit pin hole protection

Improvement of Modification Pallet

Portion of the session window output from Two Sample T

Boxplot of without sticker and applied stickcr

Ponion of the session window output fiom Two Sample T

Boxplot of After Applied Stickcr and modificd gallct

Histogram for production scrap cost

LIST OF TABLES

2.0 Quality Improvement Comparison 2.1 Six-Sigma Road Map

4.0 Scrap Analysis of Scrap and Wastage

4.1 Key Process Input and Output Variable 4.2 Data for Splashes and Factor

LIST OF ABBREVIATIONS, SYMBOLS, SPECIALIZED

NOMENCLATURE

FYP

PSM

DMAIC

DMADV

SE

COPQ

DPMO

DFSS

ANOVA

FMEA

DOE

Final Year Project.

Projek Sarjana Muda

Define, Measure, Analyze, Improve, Control.

Define, Measure, Analyze, Design, Verify.

Statistical Engineering.

Cost of Poor Quality.

Defect per Million Opportunities.

Design For ix-Sigma.

Analysis of Variance.

Failure Modes Effect Analysis.

CHAPTER

1

INTRODUCTION

1.0 Introduction

Six-Sigma is a philosophy, a measure and a metrology that provides business with

the perspective and tools to achieve new levels of performance both in services and

products. In Six-Sigma, the focus is on process improvement to increase capability

and reduce variation. The Six-Sigma methodology aims to reduce the number of

mistakesldefects in a manufacturing process and hence the manufacturing costs.

Sigma is a letter in the Greek alphabet used to denote the standard deviation of a

process. Standard deviation measures the variation or amount of spread about the

process aver-age. Six-Sigma is the ultimate measure of quality (Tom Pyzdek, 1999).

As f m s improve their processes, and move towards the exclusive Six-Sigma, they

often need to redesign the products, process and services to "design-out defects and

design-in quality". In its broadest sense six sigma is a methodology that firms can

use to improve the output quality of a process. Six-Sigma has its roots in the

repetitive processes of manufacturing; however, the same tools can be used in any

business process fiom hiring new people to effective product design and marketing

plans. The foundation of the Six-Sigma programs is statistics; Sigma stands for

standard deviations from the mean of a data set in other words a measure of

variation, while six sigma stands for six standard deviations from the mean. When a

process reaches the six sigma level that process will be running close to perfection,

firms can reduce the amount of variation in a process by removing the causes of

variation therefore increasing the output quality of the process.

Six-Sigma is a part of proactive business strategy that is planned, executive,

monitored, steered towards success, and nurtured by the executive management of

the deployment organization and also provides companies with a series of interventions and statistical tools that can lead to breakthrough profitability and

quantum gains in quality, whether the products of a company are durable goods or

services. There has been a tremendous amount of discussion around defining Six-

Sigma in terms people within your business or organization can understand.

Six-Sigma should not be viewed as a way to achieve one very successfUl project.

Six-Sigma should become a company wide mantra and be implemented as a core part of the companies culture and strategy with training from top to bottom in order to see

the fullness of its benefits. Some examples of companies that have successfully

implemented a six sigma program are (Adam and Gupta, 2002):-

i. GE boasts gains of $2 billion to the bottom line in 1999 and $2.4 billion in

200 1 because of Six-Sigma.

ii. Motorola saved $15 billion in the first 10 years of Six-Sigma implementation.

iii. DuPont realized more than $1.6 billion in cost savings the first four years of

Six-Sigma.

iv. Many other companies and even municipalities have had similar success by

implementing Six-Sigma.

1.1 Problem Statements

Six-Sigma process improvement methodologies have been accepted as the

pioneering process improvement framework. Industry leaders like Raytheon,

Motorola, GE and Honeywell (formerly, Allied Signal) have laid out specific blue

prints for process improvement using this framework. The original Define, Measure,

review by the practitioners and implementers. Every corporation looks at any

possible issue of cost cutting and wise deployment of scarcely available funds. So it

is worthwhile to deliberate on quality improvement example like Six-Sigma, TQM,

Statistical Engineering (SE) and the others. Miss-implementing Six-Sigma can be

extremely damaging to a business because the Six-Sigma often leads to an entire

overhaul of every single process and function within a business, its implementation

impacts all levels and employees. When done it properly, this means that every

employee and process will be used to its fullest potential, creating the highest level of

quality, and leading to the most successful bottom line.

One of the electronic company in Penang facing high scrap problem cost of an

average RM29, 670.22 per month. The focus of this research is on Manufacturing

Cost Effective is one of the main factors for one of the company in Malaysia. Base

on scrap data, overall Body Controller wastage and scrap was RM326, 372.47 from

the period of October '05 to August '06.

1.2 Project Objectives

The objectives of this project are follows:

i. To design a proper method of Six-Sigma (DMAIC) implementation in industry.

ii. To analyze the problem statements using Y=F(x) factor. iii. To solve the possible issue of higher cost because of waste.

1.3 Scope of Project

Six-Sigma are one of the quality improvement methodologies to reduce wastage or

cost. This project is to analyze the problem statement using DMAIC methodologies

to solve the problem. According to the DMAIC methodologies, it will only focus on

factors F (x) that had higher scrap wastage. The possible factor that cause the high

scrap will be identified in DMAIC methodologies and these projects only focus on

significant factors.

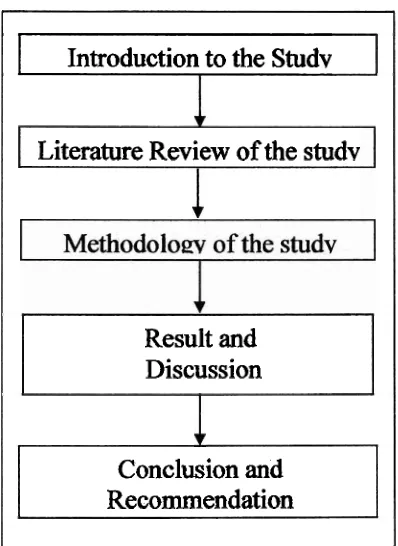

1.4 Outline of Project

The rest of the project's chapters are organized are as follows (summary in figure

1.0):

Chapter 2: Literature Review

Reviews the basic of Six-Sigma implementation in industry theory according to the

journal, books and other resources about the method, barriers, and implementation in

industry.

Chapter 3: Methodology

Review the method of Six-Sigma methodology of DMAIC (Define Phase, Measure

Phase, Analyze Phase, Improve phase and Control Phase).

Chapter 4: Result and Discussion

This chapter will done the data collection, result and discussion of Six Sigma project

to Reduce Scrap Cost for Body Controller Division implementation in electronic

industry in Penang using Y=F(x) factor.

Chapter 5: Conclusion and Recommendation

I

Introduction to the Studv

Literature Review of

the

studv

Result

and

Discussion

[image:21.522.175.374.53.326.2]Conclusion and

Recommendation

CHAPTER

2

LITERATURE

REVIEW

This chapter provides a review of the concept of Six-Sigma implementation in

industry. There are two methods that can apply in Six-Sigma are DMAIC (Define,

Measure, Analyze, Improve and Control) and DMADV (Define, Measure, Analyze,

Design and Verify). This method will also briefly explain in sub topic in this chapter.

Six-Sigma gives us a statistical scale to measure our progress and benchmark others

companies, processes or products. The defect per million opportunities measurement

scale ranges from 0 to 6. The research methodologies of quality improvement fiom

the previous study also will explain in this chapter.

2.1 Research Areas in Methods of Quality Improvement

For this project research there are three methods of quality improvement are done for

comparison.

2.1.1 Taguchi's methods

A Taguchi's method was introduced by the Japanese engineer name Genichi

Taguchi. He had been working on his quality improvement ideas since the 1950s;

his methods were virtually unknown outside of Japan until the 1980s. His techniques

some extent fiom the statistical techniques and vocabulary that are used in traditional quality improvement.

Taguchi discerns between online and offline quality control. Offline quality control

concerns the design (or re-design) of products and processes, and includes the stages

system design, parameter design and tolerance design (Taguchi, 1986, pp. 75-79; see

also Kackar, 1985). Restricted to operational production processes Taguchi's offline

quality control conforms to my definition of quality improvement.

Taguchi invented and promoted various new concepts, such as a quadratic loss

fbnction (Taguchi, 1986). These concepts represent a view on quality in which

variation plays a dominant role. This view on quality is generally accepted (Nair,

1992). Furthermore, Taguchi introduced an alternative experimentation methodology

(using orthogonal arrays; see Ross, 1988). The adequacy of this methodology has

been the subject of much debate among statisticians (Nair, 1992), though it is popular

in engineering (Jugulum and Dichter, 2001). As an operationalization of Taguchi's

methodologies and concepts consider a stepwise strategy described by Ross (1988).

This approach is built around Taguchi's quantitative experimentation methodology.

Taguchi emphasizes the importance of variation reduction in quality improvement.

Based on the results of an experiment, settings for the control variables are chosen

such that the process is made robust against variation in the nuisance variables. Next,

the process mean is brought on target by manipulation of control variables that affect

the mean but not the variation. Finally, tolerance design is exploited if needed to

accomplish a further reduction in variation.

2.1.2 Shainin System of Statistical Engineering

Dorian Shainin is the introducer for Shainin system. She was put several techniques

both known and newly invented in a coherent stepwise strategy for problem solving

statistical engineering. The system is described in various papers (Shainin, P., 1993;

Shainin, R., 1993). Part of the strategy is promoted by Bhote (1991). Starting from a

problem in the output of a process, the objective of the strategy is to select the one,

two or three dominant causes of variation (called the Red X, Pink X and Pale Pink X,

respectively) from all possible causes. This is achieved by a "homing in" method;

using statistical analysis tools, the classes of causes in which the important causes are

likely to be found are selected, thus zooming in on the Red X. Once the Red X is

identified, either an irreversible corrective action is taken, or the tolerances on the

Red X are tightened and controlled.

The Shainin system is built around a set of tools that are plainly understood and

easily applied, hereby refraining fiom more advanced techniques. The theory is

clarified using a clear vocabulary (featuring concepts as "Red X" and "homing in

strategy") because of its simplicity and the integration of tools the system appeals to

persons with a technical background and limited knowledge of statistics.

2.1.3 TQM and its implementation steps

According to Juran and Grayna (1993), emphasis on customer satisfaction, broad

application of quality concepts, and participation of all employees has given rise to a

new title TQM. TQM is an approach to improving the competitiveness, effectiveness

and flexibility of a whole organization. It is essentially a way of planning, organizing

and understanding each activity. The philosophy of TQM, in the words of Bates

(1993), recognizes that customer satisfaction; business objective, safety and

environmental considerations are mutually dependent and applicable in any

organization. According to Barclay (1993), the impact of TQM on any organization

is, first, to ensure that the management adopts a strategic view of quality.

Eight points that guide implementation of TQM are:

1. The organization needs long-term commitment to constant improvement