UNIVERSITI TEKNIKAL MALAYSIA MELAKA

EVALUATION OF PRODUCT ASSEMBLABILITY USING

LUCAS HULL METHOD

Thesis submitted in accordance with the requirements of Universiti Teknikal

Malaysia Melaka for the Bachelor Degree of Manufacturing Engineering in

Manufacturing Management

By

NURAZHANI BIN ABAS

Faculty of Manufacturing Engineering

UTeM Library (Pind.1/2007)

UNIVERSITI TEKNIKAL MALAYSIA MELAKA

BORANG PENGESAHAN STATUS TESIS*

JUDUL: EVALUATION OF PRODUCT ASSEMBLABILITY USING LUCAS HULL METHOD

SESI PENGAJIAN : 2007/2008

Saya NURAZHANI BIN ABAS

mengaku membenarkan tesis (PSM/Sarjana/Doktor Falsafah) ini disimpan di Perpustakaan Universiti Teknikal Malaysia Melaka (UTeM) dengan syarat-syarat kegunaan seperti berikut:

1. Tesis adalah hak milik Universiti Teknikal Malaysia Melaka .

2. Perpustakaan Universiti Teknikal Malaysia Melaka dibenarkan membuat salinan untuk tujuan pengajian sahaja.

3. Perpustakaan dibenarkan membuat salinan tesis ini sebagai bahan pertukaran antara institusi pengajian tinggi.

4. **Sila tandakan (√)

SULIT

TERHAD

√ TIDAK TERHAD

(Mengandungi maklumat yang berdarjah keselamatan atau kepentingan Malaysia yang termaktub di dalam AKTA RAHSIA RASMI 1972)

(Mengandungi maklumat TERHAD yang telah ditentukan oleh organisasi/badan di mana penyelidikan dijalankan)

Disahkan oleh:

(TANDATANGAN PENULIS)

Alamat Tetap:

LOT 1635 LRG. JUARA 1D TAMAN SUKMA, PETRA JAYA 93050 KUCHING SARAWAK.

Tarikh: 02 MEI 2008

(TANDATANGAN PENYELIA)

Cop Rasmi:

DECLARATION

I hereby, declared this thesis entitled “Evaluation of product assemblability using Lucas Hull method” is the results of my own research except as cited in the references.

Signature

Author‟s Name

Date

:

:

:

………..

APPROVAL

This report is submitted to the Faculty of Manufacturing Engineering of UTeM as a

partial fulfillment of the requirements for the degree of Bachelor of Manufacturing

Engineering (Management). The members of the supervisory committee are as follow:

………

Mr. Nik Mohd Farid Che Zainal Abidin

(PSM Supervisor)

Official stamp: ………..

ABSTRACT

This report was provided to explain the result of study on the evaluation of product

assemblability using Lucas Hull method. The focused on Lucas Hull Design for

Assembly (DFA) method that used as a guideline for design assembly product. This study

covers the importance, benefits, limitations and any related issues that occurred in Lucas

Hull DFA method. The data was obtained from several techniques and methodologies

such as further study on DFA tool, analysis product and implemented evaluation using

TeamSet software. The TeamSet software provides result of product assemblability. In

addition, based on result, several components of product was redesign to improve the

ABSTRAK

Laporan ini disediakan bagi menerangkan keputusan berkenaan kajian penilaian

keupayaan cantuman produk berdasarkan teknik Lucas Hull. Tumpuan terhadap teknik

rekabentuk untuk cantuman Lucas Hull yang digunakan sebagai tatacara untuk

rekabentuk produk cantuman. Kajian ini meliputi kepentingan, kelebihan, had dan

berkenaan isu yang terdapat pada teknik rekabentuk untuk cantuman Lucas Hull. Data

diperolehi dari teknik dan tatacara seperti belajar dengan lebih lanjut mengenai

rekabentuk untuk camtuman, produk analisis dan mengaplikasikan penilaian

menggunakan perisian ‟TeamSet‟. Keputusan penilaian keupayaan cantuman produk

diperolehi dari perisian ini. Tambahan pula, berdasarkan keputusan, beberapa komponen

dari produk akan direka semula untuk menaiktarafkan keupayaan cantuman produk

DEDICATION

Firstly, thank to Allah S.W.T for the opportunity to finish this project. I owe this project

and my true happiness to my beloved parent. Since the day I started joining this

University until today, they are very caring and supporting for me.

For my adored parents:

Abas bin Tomik

Temah binti Abang

And for my respected sisters:

Nurazah Aishah binti Abas

ACKNOWLEDGEMENT

Assalamualaikum warahmatullahi wabarakatuh.

First and foremost, Alhamdulillah, thank God for giving me a chance to complete my

Final Year Project. I would also like to thank my beloved parents Abas bin Tomik and

Temah binti Abang, my siblings and my friends especially Nurul Anis Nadia bt Zahar for

giving me their support and motivation during my good and hard times.

Thank you to all UTeM lecturers and staffs involved in this project especially my

supervisor, En. Nik Mohd Farid Che Zainal Abidin. Not forgetting all technicians at

UTeM that had been helpful in providing information needed to make this project a

success. Without all of you, I could not have achieved what I have today.

Last but not least, my special thanks to all of my colleagues that always giving assist for

me to finish this research. Without all of you, I would not be where I‟m today. Thank you

again.

Thank you. Wassalam.

TABLE OF CONTENTS

Abstract ... i

Abstrak ... ii

Dedication ... iii

Acknowledgement ... iv

Table of Contents ... v

List of Figure... ix

List of Table ... xi

List of Abbreviations ... xii

1. INTRODUCTION... 1

1.1. Background Introduction ... 1

1.2. Problem Statement ... 2

1.3. Objectives ... 3

1.4. Scope of Study ... 3

1.5. Benefit of Study ... 3

1.6. Report Outline ... 4

2. LITERATURE REVIEW ... 5

2.1. Introduction... 5

2.2. History ... 6

2.3. Assembly ... 7

2.3.1. Assembly Method ... 8

2.3.2. Manual Assembly ... 8

2.3.4. Robotic Assembly ... 11

2.4. Design for Manufacture and Assembly (DFMA ... 12

2.5. Guideline of DMFA ... 13

2.5.1. Simplify and Reduce Number of Parts ... 13

2.5.2. Standardize and Use Common Parts and Material ... 14

2.5.3. Design for Fabrication ... 14

2.5.4. Process Capability... 15

2.5.5. Mistake-proof product design assembly ... 16

2.5.6. Orientation and Handling ... 16

2.5.7. Interconnections and Flexible Parts ... 17

2.5.8. Design for Ease Assembly ... 18

2.5.9. Joining and Fastening ... 18

2.5.10. Modular Product ... 18

2.5.11. Automated Production ... 19

2.6. Design for Assembly (DFA ... 19

2.6.1. Methodology of DFA ... 20

2.7. Design for Manufacture ... 20

2.7.1..Methodology of DFM………21

2.8. Boothroyd Method ... 21

2.9. Hitachi Method ... 21

2.10. Lucas Hull Method ... 22

2.10.1. Theory of Lucas Hull Method... 22

2.10.2. Evaluation Procedure ... 22

2.11. Assemblability Analysis ... 25

2.11.1. Assemblability Factor ... 26

2.12. TeamSet Software ... 26

2.12.1. Design for Assembly... 27

2.12.1.1. DFA Methodology ... 28

2.12.1.2. Functional Analysis ... 28

2.12.2. Assembly Sequence Flowchart (ASF) ... 30

2.12.3. Manufacturing Analysis ... 31

2.12.4. Design to Target Cost (DTC ... 32

2.12.5. Failure Mode Effect Analysis (FMEA) ... 33

2.12.6. Quality Function Deployment (QFD) ... 33

2.12.7. Concept Convergence ... 34

3. METHODOLOGY ... 35

3.1. Introduction... 35

3.2. Methodology Flowchart of Project ... 36

3.3. Analysis Product ... 38

3.4. Evaluation Assemblability ... 39

3.4.1. Procedure of DFA ... 39

3.5. Design Improvement ... 40

3.6. Evaluation of Design Improvement ... 40

4. RESULT AND DISCUSSION ... 41

4.1 Introduction ... 41

4.2 Analysis of product ... 42

4.3 Assembling feature ... 47

4.4 Result ... 49

4.4.1 4.4.2 Assembly Sequence Flowchart ... 49

Evaluation Result ... 51

4.4.2.1 Result Analysis ... 51

4.4.3 Analysis Summary ... 55

4.5 Design Improvement ... 56

4.5.1 Redesign ... 56

4.5.1.1 Snap fit ... 56

4.5.1.2 Eliminate Parts ... 57

4.5.2 4.5.3 Evaluation ... 58

4.5.4 DFA Analysis Summary ... 61

4.6 Result Comparison ... 61

4.7 Discussion ... 63

4.7.1 4.7.2 4.7.3 4.7.4 4.7.5 Initial Design ... 63

Analysis on Assembly... 64

Product Design ... 64

Efficiency Factor ... 66

Manual Insertion and Fastening ... 69

4.7.5.1 Fastening Choice ... 69

5. CONCLUSION ... 72

5.1 Introduction ... 72

5.2 Result ... 72

5.3 Recommendation ... 73

5.3.1 5.3.2 Product Design ... 68

Teamset Software... 74

5.4 Further Study ... 74

REFERENCES ... 75

APPENDICES

A

B

Gantt Chart for PSM I

LIST OF FIGURE

Main schema of OPM

Entities in CPM

Geometrical features in part handling

Other features affecting parts handling

Incorrect geometry can allow part to jam during insertion

Relative costs of different assembly method

Production ranges for each type of assembly method

Examples of design features affecting assembly

DFA flowchart

Example of PBS

Part Assembly Window

Functional analysis window

Handling analysis window

Primary process in manufacturing analysis

Materials selection for manufacturing analysis

6

Methodology flowchart for PSM I

Methodology flowchart for PSM II

Example of product assembly

Liaison diagram

TeamSet window; DFA icon choose

36

Screw fastening area

46

4.3

Self locating area

Design for assembly flowchart for initial iron dry design

Design for assembly flowchart for initial iron dry design

Analysis result for initial design of iron dry

Potential improve area

Potential improve area

Potential eliminate part

Design for assembly flowchart for new design of iron dry

Design for assembly flowchart for new design of iron dry

Analysis result for new design of iron dry

Effect of part thickness on handling time

Effect of part size on handling time

Rearrangement of connected items to improve assembly efficiency and reduce costs

Holding down and combination factor

Parts that thickness and small in size

LIST OF TABLE

2.1

2.2

2.3

2.4

Lucas DFA method- Manual Handling Analysis

Lucas DFA method- Manual Fitting Analysis

Toolkits in TeamSet software

Symbol in ASF

Components of iron dry

Group of components and fastening process

Assembly problem

Group of components and fastening process for new iron dry design

Result comparison

Design change

LIST OF ABBREVIATIONS

Assembly Evaluation Method

Assembly Sequence Flowchart

Controlled Concept Convergence

Core Product Model

Component Supplier Management

Design for Assembly

Design for Manufacture

Design for Manufacture Assembly

Design to Target Cost

Failure Mode Effect Analysis

Manufacturing Analysis

Open Assembly Model

Product Breakdown Structure

Product Data Management

Projek Sarjana Muda

CHAPTER 1

INTRODUCTION

1.1 Background Introduction

Manufacturing industry is one of the fields that play an important role in gaining a profit

for country. It is also important in evolution of technology for human kind.

Manufacturing is being studied hundred of years ago. Many achievements have been

done regarding manufacturing field. In manufacturing, there were many processes that

involved. One of the process was assembling. Assembly was an old process that does

manually by human at ancient time. Time by time, assembly process evolved so more

efficient and reducing time of production. Nowadays, assembly is done manually by

human and automatically by robot.

Assembling part is one of important process in manufacturing. Final assembly is the

moment of truth (Charles H. Fine, MIT) (Whitney, 2004). Although this process is

infamous but it is process that human always do. Assembling part play a major role in

manufacturing field. Assembly is to bring or come together or to fit or put together. In

manufacturing, assemble means putting two or more parts together to make one product.

The product must be functioning to use by human. Assembling parts also involved

efficiency and time. The part that easily to assembled can reduce time and may lead to

A method that known as Design for Assembly (DFA) was proposed to help designers

considered assembly problem. Design for assembly is a process by which products are

designed with ease of assembly in mind. Most products are assembled manually and the

DFA method for manual assembly is the most widely used. Each product has their own

assembleability than to determine weather the product good in assembly or not.

The development of DFA has lead to development of Design for Manufacture (DFM).

DFM is design that considered for manufacture. The DFA and DFM have strong

relationship that gives benefit to manufacturing field. The manufacturing field has faced

many challenges and the survival in this field is by used effectives tools and

infrastructure. The uses of DFA and DFA have been made widely and these tools have

lead to increasing in new design development.

1.2 Problem Statement

Nowadays, one of the major processes in manufacturing field was assembling parts.

Many companies that involved manufacturing want to reduce cost of their product make

mass production and increase quality and reliability of the product. In assembling the

product, there is opportunity for defective component and an assembly challenge. Delay

in components assembly and miscommunication with manufacturers can lead to delays

and cost overruns. Many ways to reduce the cost have taken such as reduce time

assembling and simplified assembling process. Tolerance accumulation becomes more

significant and may require additional design and manufacturing to produce an

1.3 Objectives

1. To identify improvements on product assemblability using Lucas-Hull method

2. To evaluate product assemblability using Lucas-Hull DFMA software.

3. To redesign the product and re-evaluate its assemblability using Lucas-Hull

method.

4. To identify process in assembling parts of the product.

5. To compared product assemblability before and after improvement.

1.4 Scope

In this project, parts of the product will be identified and analyzed. Assemblability of the

product will be evaluated. Evaluation of the product is using Lucas-Hull DFMA software.

This evaluation is used to redesign and improved product structure. Redesign is on part of

product and this will lead to redesign the product itself. It is also to compare product

assemblability before and after improvement. All the process of assembling parts that

regarding for this project is discuss in this project.

1.5 Benefit of study

In this project, there are many benefit and advantages can get from this study. The

knowledge that gains from this project is useful in manufacturing industry field. The

benefits that get from this study are:

a. Gain more and further knowledge about manufacturing process especially

assembling process.

b. Can enhance in using software that regarding assembling process.

c. Able to generate idea and can solve problem that occur in the project.

d. Enable to analyze product and may able to outcome new design of product.

e. The result or finding from this study can be implementing by industry to improve

manufacturing activities.

1.6 Report outline

This report are consist five chapters. Chapter 1 generally about introduction of project

which covers the assembly process and tools that used in this project. This chapter also

includes problem statement, objectives, scope of study, benefits of study, report outline

and report structure. Chapter 2 is discussing about literature review where theory and

further knowledge are included in this chapter. Further about assembly process and tools

that used is discuss in this chapter. Software used for this project will also be described in

this chapter. Chapter 3 is about methodology in doing this project. The method that use is

analysis, evaluating using software, improvement and outcome solution.

In chapter 4, the data that collected are analyzed. The data will be evaluated and

recorded. In this chapter also mentioned the result from analysis and evaluation result.

This chapter also includes the proposing in improvement of product. The discussion

about whole project is discussed in this chapter. Lastly in chapter 5, it is conclusion about

project. This chapter will summarize all about this project and benefit that gain from the

Chapter 2

LITERATURE REVIEW

2.1 Introduction

This chapter will discuss about assembly process, tools of assembly and TeamSet

software that use in this project. Study and research has been done to gain better

knowledge regarding to this project. Further knowledge that gets from study and research

is used as guidance to enable proceeds with the project. The project is based on product

assembly and features in the assembly to make the assembly process easy to handle. In

assembly, the method of assembly and type of assembly are mention and analysis of

assembly doing during early stages. This to ensure potential problem can identify that

may affect product performance. Designer must know the difficulty of assemblability and

know weather the part can be assembled or not.

The assemblability and analysis can be made by evaluating assembly. Assembly

evaluation is to recognize design quality for assemblability or feasibility. Assembly

evaluation is very important to gather information regarding assemble and feature of

assemble. The information is very important because it is can used as a key to improving

design quality for better assemblability. The information also can use as a guide for

further research in assembly process. There are many way for assembly evaluation. There

are many model and tools that are used in making the evaluation. The model and tools are

developing to make the application assembly process used to make manufacture product

design for a better quality. One of the tools that used was Lucas Hull method. Teamset

2.2 History

The first guideline that widely used for assembly in manufacturing is Design for

Assembly (DFA). Design for Assembly is develop by Boothroyd and Dewhurst in 1989.

This guideline has resulted in several automated assembly evaluation and advisory

system. The DFA is earlier tools that used regarding assemble product. Then this pioneer

tool has encouraged to development of other tools and model. The other tools of DFA are

Lucas Hull method. Nowadays many other tools and model had been develop as a feature

to face nowadays challenge in manufacturing field especially assemble product. The

developing of model is to unify and integrate product or assembly information. The new

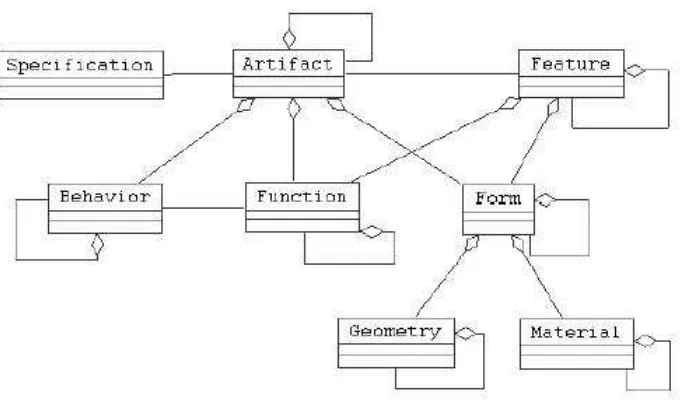

model that develops to support tools of assembly such as Core Product Model (CPM) and

Open Assembly Model (OAM). The model overview all aspect in assembling from parts

to process of assembled. This overview can help to analyzed product assemble more

easy. To make the tools easy to used, software regarding tools are develop.

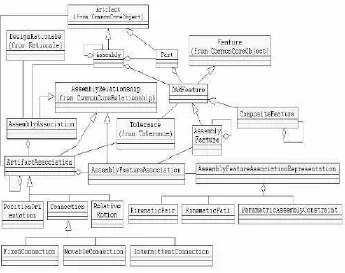

Figure 2.2: Entities in CPM

Source: Zha, Foufou, Sudarsan and Sriram, (2004)

The software will help the designer to applied tools of assembly easier and more

effective. In this project, the software that used is TeamSet software that based on Lucas

Hull method. The software is used to evaluate product assemblability and measure the

performance regarding assembling of product. TeamSet is a software package which

helps designers produce better products at minimum cost and in shorter time. This

software has been used widely to applied DFA tool. Toolkits that include in this software

are Quality Function Deployment (QFD), Manufacturing Analysis (MA), Failure Mode

Effects Analysis (FMEA), Design to Target Cost (DTC) and Controlled Concept

Convergence (Con-Con).

2.3 Assembly

Assembly is process that combine one or more parts to other parts to make product.

Process of assembly is old process that used by manufacturer to make product. Assembly

is an important process because it is last process to make functional product. Beside that,

assembly can influence cost to manufacture of product. Many guideline about assemble

manufacture the product. Process of assembly involved many method and process

capability. At ancient time, human used this process manually and supported by using

tools. Nowadays, assembly can be doing using robot and it is do automatically.

2.3.1 Assembly method

There are three major methods in the process of assembly. This method was widely

applied in the industrial field. These three methods were effectively used and

manufacturer usually used only one or two method at the same time. Each of the method

has its own advantages and disadvantages. The major method was manual assembly, hard

automation assembly and robotic assembly.

2.3.2 Manual assembly

This is the old and ancient process of assembly. Although it was an old method, but it

still widely used by certain manufacturer or company to assemble component. This

manual assembly is handled manually by human. This kind of method based on human

skill and human support by tool to manual assembly. Good assembly of product is

because of skillful handling by human. Unskillful of this process can lead to low quality

product. This method also usually takes more time. This manual assembly still chooses

by manufacturer as a method to assembly because it is low cost.

In manual assembly, there are many processes that involved making assemble to possible

to maintain and good of assembling product can be made. The design product that to be

assembled must be analyzed of it parts to detect the criteria of assembling. To joining two

parts, there is many ways that can be made but the best ways must be choose to ensure

the parts can be join easily and problem of joining can be avoid. The manual assembly

can be dividing to two major processes which are handling the assembly and insertion