FABRICATION AND CHARACTERIZATION OF RUBBER

SEED SHELL POWDER (RSSP) FILLED

POLYPROPYLENE (PP) COMPOSITE

MOHAMED ASYRAF BIN RAFEEK AHMAD

UNIVERSITI TEKNIKAL MALAYSIA MELAKA

FABRICATION AND CHARACTERIZATION

OF RUBBER SEED SHELL POWDER (RSSP)

FILLED POLYPROPYLENE (PP) COMPOSITE

Project submitted in accordance with the partial requirements of the Universiti Teknikal Malaysia Melaka for the Degree of Bachelor of Engineering (Honours) Manufacturing (Engineering Material)

By

Mohamed Asyraf Bin Rafeek Ahmad

UTeM Library (Pind.1/2005)

UNIVERSITI TEKNIKAL MALAYSIA MELAKA

BORANG PENGESAHAN STATUS TESIS*

Disahkan ol eh:

(TANDATANGAN PENULIS)

Alamat Tet ap: (Mengandungi maklumat TERHAD yang t elah dit ent ukan oleh organisasi/ badan di mana penyelidikan dij alankan)

TIDAK TERHAD

√

TERHAD

SULIT (Mengandungi maklumat yang berdarj ah keselamat an at au kepent ingan Mal aysia yang t ermakt ub di dalam

AKTA RAHSIA RASMI 1972)

JUDUL: FABRICATION AND CHARACTERIZATION OF RUBBER SEED SHELL POWDER

(RSSP) FILLED POLYPROPYLENE (PP) COMPOSITE

SESI PENGAJIAN: 2/ 2006-2007

Saya _____________________________________________________________________ mengaku membenarkan t esis (PSM/ Sarj ana/ Dokt or Falsaf ah) ini disimpan di

Perpust akaan Universit i Teknikal Malaysia Melaka (UTeM) dengan syarat -syarat kegunaan sepert i berikut :

1. Tesis adalah hak milik Universit i Teknikal Malaysia Melaka.

2. Perpust akaan Universit i Teknikal Malaysia Melaka dibenarkan membuat salinan unt uk t uj uan pengaj ian sahaj a.

3. Perpust akaan dibenarkan membuat salinan t esis ini sebagai bahan pert ukaran ant ara inst it usi pengaj ian t inggi.

4. **Sila t andakan (√)

APPROVAL

This thesis submitted to the senate of UTeM and has been accepted as partial fulfillment of the requirements for the degree of Bachelor of Manufacturing Engineering (Engineering Material). The members of the supervisory committee are as follow:

……… Main Supervisor

(Official Stamp and Date)

……….. Co – Supervisor

DECLARATION

I hereby, declared this thesis entitled “Fabrication and Characterization of Rubber Seed Shell Powder (RSSP) Filled Polypropylene (PP) Composite.” is

the results of my own research except as cited in references

Signature : ………

Author’s Name : Mohamed Asyraf Bin Rafeek Ahmad

ABSTRACT

ABSTRAK

DEDICATION

ACKNOWLEDGEMENT

TABLE OF CONTENTS

List of Abbreviations, Symbols, Specialized Nomenclature………....…...……xii

1.

INTRODUCTION

……….11.1 Background………...….……1

1.2 Problem statement……..………...………....2

1.3 Research scope ……….………...……….2

1.4 Research objectives……….………..2

2.

LITERATURE REVIEW

………..….…...32.1 Introduction……….……….….3

2.2 Polymer Matrix Composite (PMC)………..……..…….….7

2.3 Matrix………..……….………...7

2.4 Reinforcement………….……….………...………...9

2.5 Thermoplastic…………...……….………10

2.5.1 Polypropylene………..………….12

3.

METHODOLOGY

………..………..…..163.4 Composite Formulation..………..………22

3.5 Fabrication process ……….………..………...…………....23

3.5.1 Extrusion Process……….………..23

3.5.2 Process Flow for Extrusion………24

3.5.3 Crushing Process………25

3.5.4 Process Flow for Crushing……….25

3.5.5 Hot press process………26

3.5.6 Cutting sample for testing………..27

3.5.6.1 Procedure of Sample Cutting………...27

4. RESULT

...384.1 Number of Specimen………...38

4.2 Tensile Test………....39

4.2.1 Raw Data………..…………..………..39

4.2.2 Data Analysis………...………….………40

4.3 Flexural Test………..42

4.3.1 Raw Data ……….42

4.3.2 Data Analysis………....43

4.4 Impact Test ………45

4.5 SEM for Tensile Fracture ………..…47

5. DISCUSSION

5.2.4 Microstructure Observation (of Fracture Surface)……….…….58

6. CONCLUSION AND RECOMMENDATION

…...62REFERENCES

………..…...64APPENDICES

LIST OF FIGURE

2.1 Random fiber (short fiber) reinforced composites..……… ...………..…….4

2.2 Continuous fiber (long fiber) reinforced composites....………..……...4

2.3 Particles as the reinforcement (Particulate composites)……….……….……..4

2.4 Flat flakes as the reinforcement (Flake composites)……….…… ...………….…...5

2.5 Fillers as the reinforcement (Filler composites)……… ...……….……...5

2.6 Stress and strain graph of thermoplastic material……… ...………...….….12

2.7 Molecular Structure of Polypropylene………...………..…….12

3.1 Flow chart of the methodology approach...……….……… ...………..…..…….17

3.2 Rubber seed sheel after saperated……….18

3.3 Washing and cleaning process………..…18

3.4 Variable Speed Rotor Mill……….………...19

3.5 The Sieve in the Rotor Mill………...20

3.6 Polypropylene granule ...21

3.7 Thermo HAAKE PolyLab Extruder OS………....23

3.8 Sectional view of a plastic extruder showing the components………..24

3.9 Hot Press Machine………..26

3.10 Hardness Plastic Specimen Cutting Machine………...27

3.11 Specimen Gripping………...28

3.13 Engineering Stress-Strain Curve………...30

3.14 Universal Testing Machine………...30

3.15 Standard Tensile Test Specimen………..….32

3.16 Flexural test...33

3.17 Impact Test Machine……….…33

3.18 Sample position for Izod and Charpy Impact Test………...….34

3.19 SEM component………35

3.20 SEM operating………..37

4.1 Figure shows some example of specimens that had been cut for mechanical testing following to the ASTM standard dimension as mentioned earlier………...…39

4.2 Comparison of Tensile Strength with different RSSP weight fraction………...41

4.3 Comparison of Young’s Modulus with different RSSP weight fraction………42

4.4 Comparison of Flexural Strength with different RSSP weight fraction……….…44

4.5 Comparison of Flexural Modulus with different RSSP weight fraction………....45

4.6 Comparison of Impact Strength with different RSSP weight fraction………...46

4.7 SEM micrographs tensile fracture surface of PP………..…….47

4.8 SEM micrographs tensile fracture surface of 5% RSSP (500x)……….47

4.9 SEM micrographs tensile fracture surface of 5% RSSP (2000x)………...48

4.10 SEM micrographs tensile fracture surface of 10% RSSP (500x)……….48

4.11 SEM micrographs tensile fracture surface of 10% RSSP (2000x)………...49

4.12 SEM micrographs tensile fracture surface of 15% RSSP (500x)……….49

4.13 SEM micrographs tensile fracture surface of 15% RSSP (2000x)………...50

5.1 Nonsimilar size of powder (355µm-125µm)……….51

5.2 Poor homogeneity of RSSP distribution in the composite……….52

5.3 Elongation at Tensile fracture with different RSSP weight fraction………..52

5.4 Tensile Strength of different RSSP weight fraction………53

5.5 Young’s Modulus of different RSSP weight fraction……….54

5.8 Impact strength of different RSSP weight fraction……….57

5.9 Microstructure of pure PP tensile fracture………..58

5.10 SEM micrographs tensile fracture surface of 5% RSSP (500x)………...59

5.11 SEM micrographs tensile fracture surface of 5% RSSP (2000x)……….59

5.12 SEM micrographs tensile fracture surface of 10% RSSP (500x)……….60

5.13 SEM micrographs tensile fracture surface of 10% RSSP (2000x)……….……..60

5.14 SEM micrographs tensile fracture surface of 15% RSSP (500x)……….61

LIST OF

TABLE

2.1 Types of matrix and its attributes………..……..………….….…8

2.2 Features, Fabrication and Applications of Polypropylene...13

3.1 Typical properties for Polypropylene Homopolymer 600G…..……….………...…….21

3.2 Number of sample for mechanical testing……….……….……….………..…….22

4.1 Number of sample for mechanical testing………..38

4.2 Result of tensile test of PP specimen………..39

4.3 Result of tensile test of 5% RSSP weight fraction………..40

4.5 Result of tensile test of 15% RSSP weight fraction………40

4.4 Result of tensile test of 10% RSSP weight fraction………40

4.6 Data analysis for tensile test………41

4.7 Result of flexural test of PP specimen………...…….42

4.8 Result of flexural test of 5% RSSP weight fraction……….………..….43

4.9 Result of flexural test of 10% RSSP weight fraction……….……….43

4.10 Result of flexural test of 15% RSSP weight fraction………43

4.11 Data Analysis of Flexural Test………..44

4.12 Impact Values (Joules)………..46

4.13 Impact strength (J/m2)………...46

LIST OF ABBREVIATIONS, SYMBOLS, SPECIALIZED

ASTM - American Standard Testing Method in - inches

kg - kilograms

m - Meter

PMCs - Polymer–Matrix Composites PP - Polypropylene

PSM - Projek Sarjana Muda RSSP - Rubber Seed Shell Powder s - Second

SEM - Scanning Electron Microscope UTeM - Universiti Teknikal Malaysia Melaka UTHM - Universiti Tun Hussein Onn

CHAPTER 1

INTRODUCTION

1.1 Background

Nowadays, many scientist and engineers are giving their great attention to the

natural bio-resources and at the same time study the properties and characteristics of

the natural bio-resources material in many application. The government also

encourages the scientist and engineers to make many researches in natural

bio-resources. Natural bio-resources have many benefits, beside of low cost they offer

low density, environmental harmless, good mechanical properties and also can

reduce waste product.

The materials used in this research to produce a composite material are rubber

seed shell powder (RSSP) and polypropylene (PP) granule. A mild steel is used as a

mold in this project. The mixture of RSSP and PP then poured into the mold and

then presses using hot press machine. Boards with different weight fraction of RSSP

at constant density are achieved by changing the weight ratio of the PP and RSSP

1.2 Problem Statement

Despite having potential to improve fuel consumption in automobile, there are

few studies that have focused on fabricating lighter and tougher composite using

bio-composite. In this project, a lighter and tougher bio-composite using RSSP particles as

reinforcement in PP will be fabricated. Samples with different percentage of RSSP

powder will be prepared and the effect of the RSSP weight fraction will be studied by

analyzing the mechanical properties of the composite.

1.3 Research Scopes

In this project, the composites are fabricated using hot press molding technique.

Tensile, flexural and impact test are carried out to determine the mechanical properties

of the composites. Their microstructures are observed using Scanning Electron

Microscope (SEM).

1.4Research Objectives

The purpose of this project is:

i. To fabricate rubber seed shell powder filled polypropylene composite.

ii. To study the mechanical properties of rubber seed shell powder and

polypropylene composite.

iii. To study the effect of rubber seed shell powder weight fraction on rubber seed

shell powder filled polypropylene composite.

iv. To study the bonding property between rubber seed shell and polypropylene in

CHAPTER 2

LITERATURE REVIEW

2.1 Introduction

A typical composite material is a system of materials composing of two or more

materials (mixed and bonded) on a macroscopic scale. For example, concrete is made up

of cement, sand, stones, and water. If the composition occurs on a microscopic scale

(molecular level), the new material is then called an alloy for metals or a polymer for

plastics.

Generally, a composite material is composed of reinforcement (fibers, particles,

flakes, and/or fillers) embedded in a matrix (polymers, metals, or ceramics). The matrix

holds the reinforcement to form the desired shape while the reinforcement improves the

overall mechanical properties of the matrix. When designed properly, the new combined

Based on the form of reinforcement, common composite materials can be classified as

follows:

1. Fibers as the reinforcement (Fibrous Composites):

Figure 2.1: Random fiber (short fiber) reinforced composites

Figure 2.4: Flat flakes as the reinforcement (Flake composites)

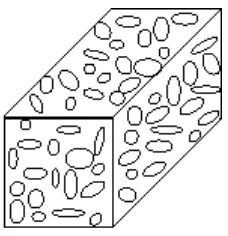

Figure 2.5 Fillers as the reinforcement (Filler composites)

The benefits of using composite are due to the types of material used. Different

materials are suitable for different applications. When composites are selected over

traditional materials such as metal alloys or woods, it is usually because of one or more

of the following advantages:

¾ Cost:

o Maintenance

o Long term durability

o Production time

o Maturity of technology

• Weight:

o Light weight

o Weight distribution

• Strength and Stiffness:

o High strength-to-weight ratio

o Directional strength and/or stiffness

• Dimension:

o Large parts

o Special geometry

• Surface Properties:

o Corrosion resistance

o Weather resistance

o Tailored surface finish

• Thermal Properties:

o Low thermal conductivity

o Low coefficient of thermal expansion

• Electric Property:

o High dielectric strength

o Non-magnetic

2.2 Polymer Matrix Composite (PMC)

In this project, the type of composite used is PMC because the matrix that

used are in polymer category. PMC consist of polymer resin as a matrix with fibers as

the reinforcement medium. These materials are in the greatest diversity of composite

application, as well as in the largest quantities, in light of their room temperature

properties, ease to fabrication and cost. In general the mechanical properties of polymers

are inadequate for many structural purposes. In particular their strength and stiffness are

low compared with metals and ceramics. This meant that there was a considerable

benefit to be gained by reinforcing polymers and that the reinforcement, initially at least,

did not have to exceptional properties. Processing of PMC need not involve high

pressures and does not require high temperature. It follows that problems associated with

the degradation of the reinforcement during manufacture are less significant for PMC

than for composites with other matrices. Also the equipment required for PMC may be

simpler. For these reasons polymer matrix composites developed rapidly and soon

became accepted for structural applications. Today glass-reinforced polymers are still by

the far most used composite material in term of volume with the exception of concrete.

The main disadvantages of PMC are their low maximum working temperatures,

high coefficients of thermal expansion and hence dimensional instability, and

sensitivity to radiation and moisture. The absorption of water from the environment

may have many harmful effects which degrade mechanical performance, including

swelling, formation of internal stresses and lowering of the glass-transition temperature.

2.3 Matrix

The matrix is the continuous phase of the composite that holds the reinforcement