k

UNIVERSITI TEKNIKAL MALAYSIA MELAKA

Effect of Process Parameters on the Mechanical Properties of RSSP/PP

Composites

This report submitted in accordance with requirements of the Universiti Teknikal Malaysia Melaka (UTeM) for the Degree of Bachelor of Manufacturing

Engineering (Engineering Materials) with Honours.

By

NUR ATIQAH BT AB GHANI

Tarikh: _______________________ Tarikh: _______________________

SULIT

TERHAD

TIDAK TERHAD

(Mengandungi maklumat yang berdarjah keselamatan atau kepentingan Malaysia yang termaktub di dalam AKTA RAHSIA RASMI 1972)

(Mengandungi maklumat TERHAD yang telah ditentukan oleh organisasi/badan di mana penyelidikan dijalankan)

Disahkan oleh:

** Jika Laporan PSM ini SULIT atau TERHAD, sila lampirkan surat daripada pihak berkuasa/organisasi berkenaan dengan menyatakan sekali sebab dan tempoh laporan PSM ini perlu dikelaskan sebagai SULIT atau TERHAD.

BORANG PENGESAHAN STATUS LAPORAN PROJEK SARJANA MUDA

TAJUK: EFFECT OF PROCESS PARAMETERS ON THE MECHANICAL PROPERTIES OF

RUBBER SEED SHELL POWDER (RSSP)/POLYPROPYLENE (PP) COMPOSITE

SESI PENGAJIAN: 2008/2009 Semester 2

Saya _____________________________________________________________________

mengaku membenarkan Laporan PSM ini disimpan di Perpustakaan Universiti Teknikal Malaysia Melaka (UTeM) dengan syarat-syarat kegunaan seperti berikut: 1. Laporan PSM adalah hak milik Universiti Teknikal Malaysia Melaka dan penulis. 2. Perpustakaan Universiti Teknikal Malaysia Melaka dibenarkan membuat salinan

untuk tujuan pengajian sahaja dengan izin penulis.

DECLARATION

I hereby, declared this report entitled “Effects of Process Parameters on The Mechanical Properties of Rubber Seed Shell Powder (RSSP)/ Polypropylene (PP) Composites” is the

APPROVAL

This report is submitted to the Faculty of Manufacturing Engineering of UTeM as a partial fulfillment of the requirements for the degree of Bachelor of Manufacturing Engineering (Materials Engineering) with Honours. The member of the supervisory

i

ABSTRACT

ii

ABSTRAK

iii

DEDICATION

“Special thanks to my parent,dedicated supervisor; Mr. Edeerozey Abd Manaf and

Professor Madya Dr T. Joseph Sahaya Anand, my family, my friends and all

iv

ACKNOWLEDGEMENT

v

2.2Polymer matrix composite (PMC) 6

2.2.1 Matrix 7

2.2.2 Reinforcement 7

2.3Thermoplastic 10

2.4Polypropylene 11

2.5Polypropylene composite 13

vi 3.0MATERIAL AND METHODOLOGY

3.1Introduction 15

3.2Process flow 16

3.3Preparation of polypropylene 17

3.4Preparation of RSSP 17

3.4.1 Shell preparation 17

3.4.2 Crushing and pulverization 18

3.5RSSP/PP composite fabrication 22

3.5.1 Process of extrusion 24

3.7Testing and analysis 33

3.7.1 Tensile test 33

4.3.2Data tensile analysis 42

4.4Flexural Testing 46

4.4Raw Data 46

4.4Data Analysis 48

vii

5.0DISCUSSION 55

5.1Introduction 55

5.2Product (Composite Plate) 55

5.3Material preparation 59

5.4Observation on the mechanical Testing 60

5.4.1Tensile testing 61

5.4.2Flexural testing 64

5.4.3Impact testing 66

6.0CONCLUSIONS AND SUGGESTIONS

6.1Conclusion 67

6.2Recommendation 68

7.0REFERENCES 69

8.0APPENDICES

8.1Appendix 1: Tensile 71

8.2Appendix 2: Flexural 75

8.3Appendix 3; Data Recorded (Print Screen) for Tensile test 79 8.4Appendix 4; Data Recorded (Print Screen) for Flexural test 80

8.5Appendix 5; Gantt chart PSM I 81

viii

LIST OF TABLES

NO TITLE PAGE

Table 2.1: Features, Fabrication and Applications of Polypropylene 12

Table 3.1 : Process Parameters for hot press process 27 Table 3.2 : Flexure Test Typical Configurations. [ASTM D790] 31

Table 4.1: Table of Number of sample for mechanical testing 41 Table 4.2 : Table of Tensile result/raw data for RSSP/PP composite 41 Table 4.3 : Table of Young Modulus, E (N/mm2) result 43

Table 4.4: Table of Data analysis for tensile test 44

Table 4.5 : Table of Flexural result/raw data for RSSP/PP composite 47 Table 4.6 : Table of value of m from the max force and max displacement. 49 Table 4.7 : Calculation of Flexural Modulus for RSSP/PP composite 50

Table 4.8: Table of Data Analysis of Flexural Test 51

Table 4.9 : Table of Energy Absorbed for Impact test 52 Table 4.10: Calculation of Impact Strength for RSSP/PP composite 53 Table 4.11: Table of Impact strength (J/m2) value 53

ix

LIST OF FIGURES

NO TITLE PAGE

Figure 2.1: Cloth of woven carbon fiber filaments; common element in composite materials

5

Figure 2.2: Continuous fiber (long fiber) reinforced composites 8 Figure 2.3: Random fiber (short fiber) reinforced composites 8 Figure 2.4: Whiskers as the reinforcement (Filler composites) 9 Figure 2.5: Particles as the reinforcement (Particulate composites) 9

Figure 2.6: Figure of Rubber seed shell 14

Figure 2.7: Figure of fruit of rubber tree 14

Figure 3.1: Polypropylene granule 17

Figure 3.2.: Rubber seed shell after separated. 18

Figure 3.3: Washing and cleaning process. 18

Figure 3.4 : Crusher machine 19

Figure 3.5: Variable of rotor mill machine 20

Figure 3.6: Sieves ring and rotor blade 20

Figure 3.7: Vibrotary Sieve Shaker machine at UTeM Laboratory. 21 Figure 3.8 : Figure shows + 400 grams RSSP (size under 250 micron) 22 Figure 3.9 : Manually mixer of PP (42 grams) and RSSP (18 grams) 22

x

Figure 3.11 : Size produce by the internal mixer. 23

Figure 3.12 : Extruder at UTeM laboratory 24

Figure 3.13: A common setup for an extrusion line 25

Figure 3.14: Flow chart of Extrusion process 25

Figure 3.15: Hot press machine in the UTeM laboratory 26

Figure 3.16: Hot press machine details 26

Figure 3.17 : Process Flow for Hot Pressing Process 27

Figure 3.18: Type of specimen for tensile test. [ASTM D638] 29 Figure 3.19 : Hardness Plastic Specimen Cutting Machine 29

Figure 3.20 : Specimen Gripping 30

Figure 3.21: Specimen for tensile test. [ASTM D638] 30

Figure 3.22: Specimen for flexural test. [ASTM D790] 31

Figure 3.23: Dimension of impact specimen 32

Figure 3.24: Specimen for impact test 32

Figure 3.25: Figure shows the Universal Testing Machine 33 Figure 3.26 : Anatomy of a universal hydraulic testing machine 34 Figure 3.27 : Engineering Stress-Strain Diagram depicting important

mechanical properties

35

Figure 3.28: Impact test machine with labeling 37

Figure 3.29 : Testing Running 38

Figure 3.30: Impact test machine with labeling 38

Figure 3.31 : Impact Test Machine at UTeM laboratory 39

xi

Figure 4.1: Percentage of Elongation comparison of each composite 45 Figure 4.2: Young‟s Modulus comparison of each composite 45 Figure 4.3: Tensile Strength comparison of each composite 46 Figure 4.4 : Comparison of Flexural Strength with different RSSP weight

fraction

51

Figure 4.5 : Flexural Modulus of varied parameters of RSSP/PP composite 51 Figure 4.6 : Comparison of Impact Strength with different parameters of

producing RSSP/PP compos

54

Figure 5.1 : Graph of elongation of break for each difference parameters 56 Figure 5.2 : Graph of tensile strength properties for each difference

parameters

57

Figure 5.3 : Graph of Young‟s Modulus properties for each difference parameters

58

Figure 5.4 : Graph of flexural strength properties for each difference parameters

59

Figure 5.5 : Graph of flexural modulus properties for each difference parameters

60

Figure 5.6 : Graph of impact strength properties for each difference parameters

61

xii

xiii

ASTM. American standard testing material b width of beam tested

C celcius

CaCO3 wollastonite

CMC ceramic-matrix composites Eb Flexural modulus

h thickness of beam tested

L specimen length between two support points. m initial slope of the load vs. deflection curve MAH-PP maleic anhydride polypropylen

MB methylene blue

MMC metal-matrix composites PBT Polybutylene terephthalate

PC Polycarbonate

PE polyethelene

PET Polyethylene terephthalate PMC polymer-matrix composites

PP polypropylene

PS polystyrene

RSS rubber seed shell

RSSP rubber seed shell powder

RSSP/PP composite of rubber seed shell with polypropylene Sdn Bhd sendirian berhad

SI units International Standard SiC silicon carbide

xiv Tg glass transition temperature Tm, melting temperature

UTeM Universiti Teknikal Malaysia Melaka UTM Universal Testing Machine

xv

LIST OF APPENDICES

APPENDIX TITLE PAGE

Appendix 1: Tensile graph result 72

Appendix 2: Flexural graph result 87

Appendix 3; Data Recorded (Print Screen) for Tensile test 101 Appendix 4; Data Recorded (Print Screen) for Flexural test 102

Appendix 5; Gantt chart PSM I 103

1

CHAPTER 1

INTRODUCTION

1.1 Background

During the past decade, increasing environmental awareness, new global agreements, and international governmental policy and regulations have been the driving attractiveness of a plant-based fiber as an alternative reinforcement material comes from its high specific strength and stiffness, natural availability, and environmental „friendliness‟.

Most of the composite materials used in different sectors are principally fabricated using thermosetting matrices. Disadvantages stemming from the use of thermosets include brittleness, lengthy cure cycles and inability to repair or recycle damaged or scrapped parts. These disadvantages have led to the development of the thermoplastic matrix composite system. Compared with thermosets, composites fabricated from thermoplastic materials typically have a longer shelf life, higher strain to failure, are faster to consolidate and retain the ability to be repaired, reshaped and reused as need arises.

2 1.2 Problem statement

Most of the composite materials used in different sectors are principally fabricated using thermosetting as a matrices. Disadvantages of thermosets include brittleness, lengthy cure cycle and inability to repair damaged parts. These disadvantages have led to the development of the thermoplastic matrix composite system. Composites fabricated from thermoplastic materials typically have a longer shelf life, higher strain to failure, are faster to consolidate and retain the ability to be repaired, reshaped and reused as need arises [S. Mukhopadhyay, R.Srikanta.2008]. Have a few studies that focused on fabricating lighter and tougher composite using bio-composite. In this project, a lighter and tougher bio-composite will be fabricated. Samples with different process parameters will be prepared and the effect of that will be studied by analyzing the mechanical properties of the composite. One of the significant points in this research is by applying the RSSP in the polymer composites; it could contribute towards the environmentally friendly. Furthermore there is almost none research done using rubber seed shell in composite, while many other natural plant-based fibers composites have been researched before. It is hoped that, this project will contribute for the knowledge in composite research.

1.3 Objectives of the study

(i) To fabricate the RSSP/ PP composite sample

(ii) To study the mechanical properties of RSSP/PP composite (iii) To study the effects of the process parameters to the composite

1.4 Scope of study

3

4

CHAPTER 2

LITERATURE REVIEW

2.1 Composite

Generally, a composite material is composed of reinforcement (fibers, particles, flakes, and/or fillers) embedded in a matrix (polymer, metals, or ceramics). The matrix holds the reinforcement to form the desired shape while the reinforcement improves the overall mechanical properties of the matrix. When designed properly, the new combined material exhibits better strength than would each individual material.

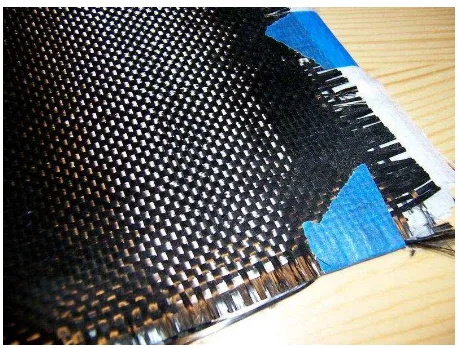

Composite material is a combination of two or more materials (reinforcing elements, fillers, and composite matrix binder; the example of the fiber used is woven carbon fiber filaments as Figure 2.1), differing in form or composition on a macro scale. The constituents retain their identities; that is, they do not dissolve or merge completely into one another although they act in concert. Normally, the components can be physically identified and exhibit an interface between one another.

5

Figure 2.1: Cloth of woven carbon fiber filaments; common element in composite materials

Composite can be classified into two types which is matrix and geometry of reinforcement. First, the classification based on geometry of reinforcement divide by four categories which is flake, whiskers, fiber composites and particulate composites. The second types is classification based on matrix, there are three kind of matrix which are metal-matrix composites (MMC), polymer-matrix composites (PMC) and ceramic-matrix composites (CMC). The ratio can be expressed either by the weight fraction (w), which is related to fabrication or by the volume fraction (v), which normally used in property calculations.

Rules of mixture:

Xc = Xf Vf + Xm ( 1- Vf)

There are two categories of constituent materials: matrix and reinforcement. At least one portion of each type is required. The matrix material surrounds and supports the reinforcement materials by maintaining their relative positions. The reinforcements impart their special mechanical and physical properties to enhance the matrix properties.