Jurnal

Teknologi ProsesMedia Publikasi Karya Ilmiah Teknik Kimia

6(1) Januari 2007: 82 – 84 ISSN 1412-7814

The Thermal Properties of Calcium Carbonate Filled Polypropylene (PP)/

Ethylene Propylene Diene Terpolymer (EPDM) Composites

Salmah

Department of Chemical Engineering, Faculty of Engineering University of Sumatera Utara, Medan 20155

Abstract

The thermal and crystallization behavior of PP/EPDM/CaCO3 composites was studied by thermogravimetry

analysis (TGA) and differential scanning calorimetric (DSC). The results showed that the increasing of filler loading increase the thermal stability and crystallinity of PP/EPDM/CaCO3 composites.

Keywords: paper sludge, calcium carbonate, polypropylene, ethylene propylene diene terpolymer, composites.

Introduction

Thermal analysis of polymers is an important subject as it covers a broad field, ranging from the development of thermoresistant polymers and ablation problem to the stabilization of thermolabile polymers. Thermal analysis is an important analytical method in understanding the structure-property relationship and mastering the technology for molecule design and industrial production of different polymeric materials. Moreover, it is a useful technique to determine the thermal stability of the materials. In addition, it is possible to quantify the amount of moisture and volatiles present which can cause detemoration in the composites.

Thermal analysis studies have been carried out and the effects of crystallinity, orientation and cross-linking haven reported (Daniel et al., 1994, George et al., 2000, Fangling et al., 2004, Joseph et al., 2003).

One of the accepted methods for studying the thermal properties of polymeric materials is

thermogravimetry (TG). Thermogravimetric data indicate a number of stages of thermal breakdown, weight loss of the material in each stage. Threshold temperature, etc. Both TG and derivative thermogravimetry (DTG) will provide information about the nature and extent of degradation of material. In differential scanning calorimetry (DSC), the heat flow rate associated with a thermal event can be measured as a function of time and temperature allowing us to obtain quantitative information about malting and phase transition of the composite system.

Experimental

Materials

Polypropylene homopolymer used in this study was of injection molding grade, from Titan PP polymers (M) Sdn Bhd, Johor, Malaysia (code 6331) with MFI value of 14.0

g/10 min at 2300C. Ethylene propylene diene

Salmah / Jurnal Teknologi Proses 6(1) Januari 2007: 82 – 84 83

Selangor, Malaysia. Calcium carbonate was obtained from Malaysia Calcium Corporation Sdn Bhd., Malaysia, with average size of 4.5µm

(density, 2.7 g/cm3). The formulation of

PP/EPDM/CaCO3 composites used in this study

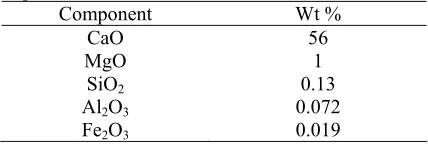

is shown in Table 1. Tables 2 show the results of semi-quantitative analysis of calcium carbonate used in this study.

Mixing Procedure

Composites were prepared in a Haake

Reomix PolyDrive. Mixing was done at 180 0C

and 50 rpm. EPDM was first charged to start the melt mixing. After 3 min. filler was added followed by PP at the fifth minutes. Mixing was continued for another 5 min. At the end of 10 min, the composites were taken out and sheeted through a laboratory mill at 2.0 mm nip setting. Sample of composites were compression molded in an electrically heated hydraulic press. Hot-press procedures involved preheating at

180 0C for 6 min followed by compressing for 4

min at the same temperature and subsequent cooling under pressure for 4 min.

Thermogravimetry Analysis

Thermogravimetry analysis of the composites was carried out with a Perkin Elmer Pyris 6 TGA analyzer. The samples weight of about 15 – 25 mg were scanned from 50 to 600

0

C using a nitrogen air flow of 50 ml/min and a

heating rate of 20 0C/min. The sample size was

kept nearly the same for all tests.

Differential Scanning Calorimetry

Thermal analysis measurements of selected systems were performed using a Perkin Elmer DSC-7 analyzer. Samples of about 10 – 25 mg

were heated from 20 to 220 0C using a nitrogen

air flow of 50 ml/min and the heating rate of 20

0C/min. The melting and crystallization

behavior of selected composites were also performed using a Perkin Elmer DSC-7. The

crystallinity (Xcom) of composites were

determined using the following relationship:

Xcom (%cryst) = UHf/UHof x 100 … (1)

Where UHf and UHof are enthalpy of fusion

of the system and enthalpy of fusion of

perfectly (100%) crystalline PP, respectively.

For UHof (PP) a value of 209 J/g was used for

100% crystalline PP homopolymer (Greco et

al., 1987). Xcom, which is calculated using this

equation, however, gives only the overall crystallinity of the composites based on the total weight of composites including non-crystalline fractions, and it is not the true crystallinity of the PP phase. The value of

crystallinity for PP phase (Xpp) of the PP

fraction was normalized using Eq. (2) as follow (Shoinake et al., 1998):

Xpp = (Xcom)/Wfpp … (2)

Where Wf pp is the weight fraction of PP in

the composites.

TABLE 1: Formulation of PP/EPDM/CaCO3

composites with different filler loading

Materials Composites Polypropylene (PP) (wt %) 50

EPDM (wt %) 50 Calcium carbonate (wt %) 0, 15, 30,

45, 60

Results and Discussion

Thermogravimetry analysis (TGA) curve of

PP/EPDM and PP/EPDM/CaCO3 at 0,30 and 60

wt % filler loading is show in Figure 1. Table 3

show that the end degradation temperature (Te

deg) and total weight loss of PP/EPDM/CaCO3

at different filler loading. The total weight loss

of PP/EPDM/CaCO3 composites at 60 wt% is

lower than PP/EPDM/CaCO3 at 30% and

PP/EPDM, which might be due to the presence

of large content of inorganic material in CaCO3

with increasing filler loading. This result

indicate that PP/EPDM/CaCO3 composite have

better thermal stability compared PP/EPDM.

TABLE 2: Semi quantitative analysis of Calcium

Carbonate using X- Ray Flourescene Spectrometer Rigaku RIX 3000.

Component Wt %

CaO 56 MgO 1

SiO2 0.13

Al2O3 0.072

Salmah / Jurnal Teknologi Proses 6(1) Januari 2007: 82 – 84

TABLE 3: Percentage weight loss of

PP/EPDM/CaCO3 composites with different filler

loading

Table 4 show the parameter differential scanning calorimetric (DSC) of

PP/EPDM/CaCO3 at different filler loading.

The value of melting temperature (Tm), heat of

fusion of composites (UHf (com)), crystallinity of

composites (Xcom) and crystallinity of PP (Xpp)

also show in Table 2. The results show that the percentage of crystallinity of composites changed with filler loading. It can be seen that

the value of UHf(com) and Xcom decrease with

increasing filler loading. This is due to the decreasing of PP content at higher filler loading. The addition of fillers results in an

increase in Xpp. This behavior is consistent with

the results by reported by Salmah et al., (2005).

-10

FIGURE 1: Thermogravimetric analysis (TGA)

curve of PP/EPDM/CaCO3 composites at 0, 30 and

60 wt % calcium carbonate.

TABLE 4: Parameter DSC of PP/EPDM/CaCO3

composites with different filler loading.

Composites 1994. Crystallinity in the polypropylene/cellulose system. II. rystalliation kinetics. Journal of Applied Polymer Science.52, 605-615.

George, S., Varughese, K. T., Thomas, S. 2000. Thermal and cryatallisation behavior of isotactic polypropylene/nitrile rubber blends.

Polymer, 41, 5485-5503.

Gong, F., Feng, M., Zhao, C., Zhang, S., Yang, M. 2004. Thermal properties of poly (vinyl chloride)/montmorillonite nano-composites.

Polymer degradation and stability. 84, 289-294.

Joseph, P. V., Joseph, K., Thomas, S., Pillai, C. K. S., Prasad, V. S., Greoninckx, G. 2003. The thermal and crystallization studies of short sisal fibre reinforced polypropylene composites. Composites Part A: applied science and manufacturing.34, 253-266. Greco R., Manacarella C., Martuscelli E., Ragosta

G. 1987. Polyolefin Blends: 2. Effect of EPR composition on Structure, Morphology and Mechanical Properties of iPP/EPR Alloys,

Polymer, 28: 1929- 1936.

Salmah., Ismail, H & Abu Bakar, A. 2005. A comparative study on the effects of paper sludge and kaolin on properties of polypropylene/ethylene propylene diene terpolymer composites. Iranian Polymer Journal.14 (8), 705-713.

…

Panduan Penulisan Naskah

Jurnal Teknologi Proses (TNR 14pt bold)

…

…

Penyunting Pelaksana Jurnal Teknologi Proses (TNR 11 bold) Jurusan Teknik Kimia, Fakultas Teknik Universitas Sumatera Utara, Medan 20155

[email protected] (TNR 10)

…

…

Abstract (TNR 10 italic bold)

Jurnal Teknologi Proses published by Dept. of Chemical Engineering, Faculty of Engineering University of North Sumatera is a media for publishing the research papers of chemical engineering and the related fields. The paper is peer reviewed by Dewan Redaksi before published. The paper manuscript is initiated by 150 words of abstract and followed by 5 words of keywords. Abstract consists of objective, method, result and conclusion of research. (TNR 10 pt italic)

…

Keywords: chemical engineering, related fields.

… …

Pendahuluan (TNR 11pt bold)

…(5mm)

Karya ilmiah yang akan diterbitkan dapat berupa kertas kerja ilmiah penelitian dan kertas kerja ilmiah bukan penelitian (laporan studi kasus atau kajian pustaka komprehensif). Kirimkan naskah kertas kerja kepada:

…

Penyunting Pelaksana

Jurnal Teknologi Proses Jalan Alumni Kampus USU Medan – 20155, Indonesia …

Naskah kertas kerja yang dikirimkan terdiri dari 2 (dua) eksemplar di mana untuk keperluan evaluasi redaksi, 1 (satu) eksemplar tidak ditulisi nama/institusi penulis. Naskah harus asli dan belum pernah diterbitkan di media tulis lain. Naskah yang telah diserahkan untuk evaluasi agar tidak dikirimkan lagi kepada media tulis lain. Naskah yang telah dievaluasi akan dikirimkan kepada penulis utama (sertakan amplop balasan berprangko).

…

Naskah yang telah diperbaiki diminta untuk dikirimkan kembali sebanyak 2 (dua) eksemplar berikut disket 3.5” berisi file yang disiapkan dengan pengolahkata MS Word.

…

Kertas kerja ilmiah penelitian dikehendaki terdiri dari abstrak, pendahuluan, metodologi penelitian, hasil penelitian, pembahasan, kesimpulan, ucapan terima kasih (jika ada), tata

nama dan daftar pustaka. Untuk kertas kerja ilmiah bukan penelitian sekurang-kurangnya terdiri dari abstrak, pendahuluan, pembahasan, kesimpulan, saran dan daftar pusataka.

… …

Naskah Kertas Kerja

…

Jumlah Halaman, Ukuran dan Bahasa

…

Naskah berjumlah 5-10 halaman kertas A4 termasuk gambar dan tabel dengan ukuran huruf TNR 11pt (kecuali jika disebutkan ukuran yang lain) dan diketik dengan spasi tunggal. Biaya cetak bagi naskah yang akan diterbitkan adalah Rp 75.000,- dan bagi naskah yang lebih dari 10 halaman akan dikenakan biaya tambahan Rp 10.000,- per halaman.

…

Ukuran naskah adalah batas atas 30 mm, bawah 30 mm, kiri 25 mm, kanan 25 mm, antar kolom 8 mm dan nomor halaman 20 mm dari tepi atas.

…

The manuscript can be written in bahasa Indonesia or English.

… …

Gambar, Tabel, dan Persamaan

…

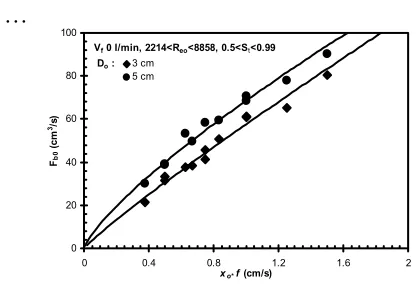

wmf alebih disukai. Untuk gambar berupa tampilan grafik, disarankan memilih ketebalan garis grafik yang patut sehingga gambar dapat direduksi hingga 50% dari ukuran semula untuk diletakkan pada teks.

…

Tabel yang lebih besar dari ukuran kertas A4 hendaknya dibuat bersambung. Lebih lanjut berkenaan dengan gambar dan tabel dapat merujuk pada contoh berikut:

…

…

…

GAMBAR 1: Pengaruh diameter bukaan pada

keadaan tanpa aliran kehadapan. (TNR 10 pt)

…

…

TABEL 1: Parameter Penyelidikan (TNR 10pt)

Cairan yang digunakan

: Air dan larutan Karboksi Metil Selulosa (CMC) Pengesan

(tracer)

: Larutan KCl 25% berat

…

…

Persamaan matematika ditandai dengan nomor yang berurutan sebagaimana contoh Persamaan 1.

Notasi yang digunakan pada persamaan

hendaklah dipaparkan pada bahagian TataNama

setelah bahagian Ucapan Terima Kasih atau

Kesimpulan seperti contoh berikut. …

…

Tata Nama

…

u0 kecepatan antar muka (cm/s)

v viskositas kinematik (m2/s)

x0 amplitudo osilasi (cm)

D diameter dalam kolom (cm)

Reo bilangan Reynolds osilasi

ω frekuensi sudut (rad/s)

ρ

densitas fluida (kg/m3)µ

viskositas fluida (kg/m.s)…

…

Rujukan

…

Setiap rujukan harus disertakan sumbernya seperti contoh berikut:

1. … model Peringkat Unggul dengan

Pencampuran Balik (Ideal Stage with

Backmixing Model, ISB) dikembangkan oleh Xu (1994) dan Mohd. Sobri Takriff (1996).

2. … dengan menggunakan ISB model (Xu

1994; Mohd. Sobri Takriff 1996).

3. … kajian fenomena pencampuran balik di

dalam kolom bersekat (Howes & Mackley 1990; Zuhrina Masyithah & Mohd Sobri Takriff 2000a, 2000b).

…

…

Daftar Pustaka

…

(contoh rujukan jurnal)

Howes, T. & Mackley, M.R. 1990. Experimental axial dispersion for oscillatory flow trough a baffled tube. Chem.Eng.Sci. 45: 1349-1358. (TNR 10pt)

(contoh rujukan prosiding & tahun terbit yang sama) Zuhrina Masyithah & Mohd Sobri Takriff. 2000a.

Interstage backmixing in oscillatory flow in a baffled column. Proc. 2nd International Conference on Advances in Strategic Technologies. 1: 493-498.

Zuhrina Masyithah & Mohd Sobri Takriff. 2000b. Interstage backmixing in oscillatory flow in a baffled column. Jurnal Teknik Mesin. 3(1): 55-60.

(contoh rujukan buku teks)

Fogler, H.S. 1992. Elements of chemical reaction engineering. Ed.2. New Jersey: Prentice-Hall. (contoh rujukan skripsi/tesis/disertasi)

Mohd Sobri Takriff. 1996. Column flooding, gas holdup and interstage backmixing in an aerated multistage, mechanically-agitated, compartmented column. Ph.D Dissertation. University of Arkansas.

(contoh rujukan internet)

Elsevier. 2002. Pedoman penulisan kertas kerja.

http://www.elsevier.com (26 Agustus 2002). (catatan: 26 Agustus 2002 adalah tanggal saat situs

tersebut dirujuk).