.. :?:.:

=l!'.t -:

!=-j

-=:

:::!: . - i:'rl:);':,:.

--'

)--,:

.=:::

-: i J:::: tl': :i::4..

a:

-:-ia .

i;:

l _),

.-t -,tr ,..

.-t:

-"

-I:

an

ii.,,

Thm

frm{;wr*ffiffi&4ffiff'tffiH ffimro$mtrffir*effiffi

ffiffi

Mw&wr*$m$m

ffi

r.mffiffiffifr

rnffi

T"mmhmm$mffiy

5-6

Januany,

e0l

O

Wesbin

Gnande

Sukhumv'i

Hotel,

Bangkok, Thailand

o.n.n,redby

@Hn

uNlvEFslTY "'t

I

fl

T.

I

tuE0n Eu[ulnu doa$trt ttt'l-n

Intemational Conference on Materials Proccssing Technology 2010 January 5-6, 2010, Bangkok, THAILAND

Preparation of Neodymium Substituted Bismuth Titanate by

a

Fuel-liee

Combustion

Process

[Jmor

Al-Amani Azlan*, Srimala

Sreekantan, AhrnqdFauzi M. N., Khairunisak

A.R.School of

Materials

andMineral

ResourcesEngineering, (Jniversiti

SainsMalaysia,

14300Nibong

Tebal, Penang, MalaYsia.E -mail

:

ibnuazlan2 0 0 5 @gmail. comFine powders of neodymium substituted-bismuth titanate, Bi4-,Nd,Ti3O12 @NT) with x ranging from 0 to

1.0 were prepared by the fue1-free combustion process at 1ow combustion temperature of about 200"C The influence

of Nd

addition on the bismuth titanate system (BIT) was sh:died and characterizedby

themethods of XRD, Rieweld method and SEM.

It

was found that the intermediate phase of Bi12TiO26 had reduced with addition of Nd. Crystallinity and orthorhombicity of the system was found to be decreased asthe Nd content increases. The size of platey grains is strongly influenced by the Nd added to the system.

Ke.t v,ords;fuel-free combustion; neodymium; bismuth titanate; crystallinity

Introduction

Bismuth titanate

or

generally calledBIT,

alsooften abbreviated as BiaTi3O12

to

clearly

defineits composition, is a ferroelectric material which

has a perovskite structure (ABO3 structure) that

possesses

high

dielectric constant-200

and lowdissipation

factor -0.017

[1].

Recently,BIT

isbelieved to be the most promising candidate for

dielectric material

for

wireless application [2].Previously,

this

system

has

been used

forferroelectric

random

accessmemory

(FRAM),optical display, high

temperature piezoelectricapplication, pyroelectric sensors

and

electrooptic devices

[3-5].

The

performanceof

thissystem

is

comparablewith

other

perovskitestlucfure systems

such

as

barium

titanate(BaTi03),

lead

titanate (PbTiO3),

strontium titanate (SrTiO3) and calcium titanate (CaTiO3). Therefore,it

is

reasonableto

say thatBIT is

analternative

material

in

ceramic rndustry andit

can be used to replace PbTiO3 due to its

toxicity

and very harmful to the human body [6].

From a material

view point, BIT is

composedof

mixed

oxides

of

Bi2O3

and TiOz

andlanthanide atoms are frequently introduced to the

A

site

in

perovskite

BIT

matrix

to

replacebismuth

(Bi)

atoms,thus

it

is

also known

aslanthanide

doped-BlT.

The

substitution of

lanthanides element

in

this svstem has been usedin

many

studies

in

order

to

enhance theferroelectric properties.

For

instance,Kan

:t

alU)

showed

that the

dissipation

factor

of

lanthanum doped-BlT was successfully reduced

by

about 8-10 times lower than

of

pure

BIT.Besides that, the polarization properties

of

BIT

material were greatly improved

with

the additionof

Nd

[8].

in

this work,

however, the trivalentcation

of

neodymium

(Nd'*)

is

used

as

asubstitution element in

BIT

system.BIT

can be preparedby

a varietyof

methods such as mixed oxide route which based on solidstate reaction,

soi-gel route,

and hydrothermal[9-11]. Each

of

these routes has their merits anddrawbacks. However,

in

present study, a newlyprocess

which

is known as fuel-free combustion synthesis has been usedfor

the

preparationof

BIT. It

has

been

developed

from

self-propagating high-temperature synthesis (SHS)

combined

with wet

chemical techniquesfor

thesynthesizing

of

metal

oxide

based

ceramicpowders [12]. Having

this

is

mind, there

are three factors to generateignition

and combustiouactiviti,s

and

these factors

are

oxidizer,temperature,

and

fuel [13]. A

fuel-free combustion process, which does not employ anyfuel

agents such ascitric

acid, urea,or

glycine, makes useof

low-cost precursors resultingin

abased on the fact that a

wet

chemical technique (onetype

of

fuel-free combustion process) canform a stabie solution

with

better ion distribution[14].

This Drocessis

capableof

producing finepowder

after

combustion, andthe

experimentalsetup is very simple [15, 16]' Hence, in this work,

pure and

neodymium substituted-BlT

ate slmthesizedby

a

fuel-free

combustion processusing

aqueoussolutions

of

nitrate salts

andtitanium

(IV)

isoproPoxide.MethodologY

Bi4,Nd*Ti3Or2

(BNT)

systems where x -- 0,0.2,0.6 and

I

were

synthesized

via

fuel-freecombustion

process.

Bismuth

nitratepenthahydrate, Bi(NO3)3.5HzO and neodymium

nitrate

hexahydrate, Nd(NO3)3.6H2O

wereinitially

dissolved

in

2-Methaoxyethanol, CH3OCH2CHzOHat

40"C

on hot

plate

andstired

for

about 30

min.

Separately, titanium(N)

isopropoxide,

Ti[OCH(CH:)z],

wasdissolved

in

a

homogeneoussolution

of

2-MEand acetylacetone, CsHeO2 at

room

temperature and stirredfor

30 min. TheTi

solution was thenpoured

into

the

Bi

solution

with

continuousstiring

at 40oCfor

another2 h. After

that, thetemperature

of

hot plate was then set to reach at-130"C

to

for:rna

sticky

gel.

Within

a

fewseconds,

the

temperaturewas then

increasedrapidly,

andwhen

it

reachedto

-200oC, large amountof

gases(NH,,

Hz, CO2 and H2O) were liberated and a darkfluffy

powder was producedafter

the

combustion process. The process wasconsistently repeated

for

other powder

ratios.Their phase formation was determined

by XRD

(Bruker

D8

Advanced)

with

Cu

ko

(hor

= 1.5405A

and l.t*z:

1.5443A,

20 range between10o

and

90o,step size

of

0.034" (20),

fixeddivergence

slit:

0.2o, receiving slit = 0.2mm).In

addition,

the crystallite

sizewas

calculated byRietveld

method.

A

Zeiss

Supra

55VPPGT,IIKL Field

Emission

Scanning ElectronMicroscope (FE-SEM) was used

to

observe themicrostructure

and

morphology

in

the

bulkceramics. The process

flow

for the preparationof

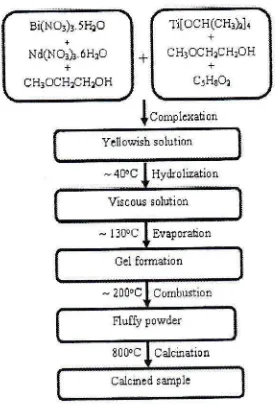

those powders is shown in Figure 1.

lnternational Conference on Materials Processing Technology 2010 January 5-6, 2010, Bangkok, THAILAND

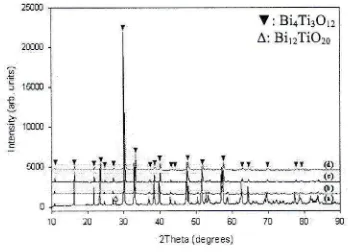

[image:3.595.352.491.428.631.2]Result and discussion

Figure

2

shows

the XRD

pattem

of

Bi+--Nd-Ti3O12 after calcination at 800oCfor

3h'

It

was found that

a

small amount

of

Bi12TiO2o intermediate phase was formedin

the pureBIT

sample, while no such an intemediate phase was observed

in

the sampleswith Nd

addition" Thisresult

indicatesthat the

peak corresponding tointermediate phase

had

reduced

as the

Ndcontent increases.

It

was similarly

reported inother work that the incorporation of

Nd

intoBIT

lattice

had

reduced

the

formation

of

theintermediate phase [8]. Other factor such as heat-treated at a higher temperature could reduce the

intermediate

phase

while

increase

thecrystallinity

of

BIT

phase.

Kan

et al.

ll7l

reported

that the

presence

of

BirzTiOzointermediate phase at 825oC was greatly reduced

after being heated

to

1000"C.

Tkough

thisanalysis,

the

intermediate

phase

in

BIT

compound can

be

reducedat a

temperature aslow

as 800"Cin

a

conditionof

introducing thelanthanide element.

Yellowish solutioq

-4loc I Hydrolsahon Viscous soiution - 1300C I Evaporahon

Ge1 fomation

- 2000C I Combustrot

Fluf$ powder

8!0oC I Calcinatiotr Calcucd smple

Figure 1 Process

flow

for the preparation of Bi+"Nd,Ti:Orz via fuel-free combustion process.

-zoo-2Theta (degrees)

Figure

2

XRD

patterns

of

Bi4Nd,Ti:Orz

powders calcined at 800"C

for

3h:

(a) pureBIT,

(b) 0.2BNT, (c) 0.6BNT and (d) i.OBNT.

It

was also found that

the

(117) peak

hadshifted

to high

angleof 20

(Figure3).

In

otherwords, the peak position at (117) had changed its characteristic as

a result of

Nd

addition. There were rwo things that could be observed from this characteristic.Firstly,

the peak intensityof

pureBIT

is relatively high as compared to other BNTsamples.

This

indicatesthat the crystallinity

of

pure

BIT is

the highest amongall.

However,it

was found

to

be decreased whenBi

atoms werethen

substitutedwith

Nd

atoms

in

bismuthtitanate system. Secondly, the peak

position

of

all

powders

varies

from the

Nd

(or

Bi)

concentration

in

accordanceto

Vegard's

Law,which

meansthat

the crystal lattice

parameter and the concentration of the constiruent elementshave

a

linear relation

that

exists

at

constant temperature [18].To

estimate qualitatively the lattice parameter aswell

as other structure, the Rietveld method was used from the TOPAZ software with yersion3.0

provided

by

Bruker

Advanced

X-RaySoiutions.

The

Nd

content dependenceof

thelattice parameter

'a', 'b',

'c'

andthe unit

cellvolume,'V'

of the powders is shown in Table 1.According

to

Table 1,BIT

and 0.2BNT had anorthorhombic strucrure by considering the lattice constant

of 'a'

is larger than thatof 'b'.

However,this

sttucture hashigher

tendencyto

form

intetragonal-type

with

additionalof Nd

content,It

was confirmed

by

the

lattice

of

'a'

and 'b'

Intemational Conference on Materials Processing Technology 2010 January 5-6, 2010, Bangkok, THAILAND

become closer" Besides

that, the shift

of

structural system

is

dueto

the

changein

ionicradius and atomic mass of Nd ions.

Having this is mind, the ionic radius of Nd3* is

about 0.1 11nm which is smaller than that of Bi3*

(0.117nm)

[19].

Thus, the

replacementof

Bi

atoms with Nd atoms would lead to the structural distortion from orthorhombic to tetragonal which

also resulted in reducing of cell unit volume, V.

In

Table 2, the crystallite size of those samplesprepared

in this

work was

significantlydecreased as increase the

Nd

contentin

bismuth titanate compound. The crystallite size measuredby

Scherrer's formula for pureBIT

is about 69.1nm

andit

is

also considered larger than otherBNT

samples"Upon

increasing theNd

content, the vacancy site that alreadyleft

byBi

atoms is then occupied byNd

atoms whichfinally

results the decreasein

degreeof crystallinity

aswell

ascrystallite

size.

This

is

parallel

with

thediffraction profile

obtainedby XRD

shown inFigure 3.

Table

I

Structure and parameter refinementusing Rietveld Method

Smple Pue BIT 0.281'{T 0 6BI'IT 1 0BNT

Space group Lattice prameter

Crystal sysleru

t rB ^6 v,.&

Densrty, g/rm' Refinemcnt index

R.-% D

B2cb

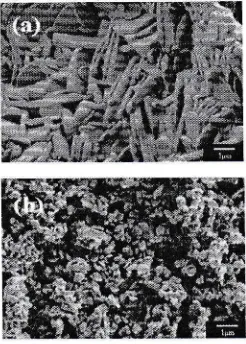

Figure

4

showsthe SEM

imagesof

pureBIT

and 1.0BNT which were calcined at 800"C

for

3h.

It

can be clearly seen that pureBIT

exhibits aplate-like

structure andits

sizeis

over

lpm

asshown

in

Figure

4(a).

On the

other hand,

a remarkable decreasein the grain

sizewith

less than 1pm was observedin

1.0BNT (Figure a(b)). From the size comparison between both samples,Orthorhombic Onhorhonibic Tetragorral Tetragonal

5.4432 5.4320 5.4052

5.40015,4015 5.4050 5.4175

5.403032.8127

328161

32.843'7 32.1928965.80 963.41 961.15

956.90'7.8354 7.4040

-7422']

'7.459610.65 12.15

4t2 t40

10.00

9 94I t5 000

-16t-it

is

reasonableto

say thatthe

substituted Nd3*ions act as a grain-growth

inhibitor in

BIT-typesystems. These results

are

consistentwith

theXRD

results where a decrease in peak sharpness and intensity was observed with Nd addition.Table 2: Crystallite size calculated

by

Scherrer's formulaPwe BIT 0 2BNI () 6BNT I,OBNI

lntemational Conltreec: oi,:. \ !a:ena-s P:oc es si:l-i

T:;:: :'.

:1'Ja:-'la;r j-,:. l'i - t-, Ba::-<;.'

li'.

-Conclusion

In

presentu'ork. pure

BIT

anil

B\-T

';':::

successfully prepared b1' a fue1-tree

conb.s:ii-synthesis.

The

influence

of \d

aioitr.-rl

o::bismuth

titanate-type system rvasclearlr'

see" through the eliminationof

intermediate phase.ri

BirzTiOzo in theXRD

pattern and the changedoi

peak characteristic at peak position (1 17). Uponincreasing of

Nd

content, the strucfural systemof

bismuth titanate

was also

changed

fromorthorhombic

to

fotm

in

tetragonal.

Suchinfluence

with this

addition was also shown inthe grain

morphologywhich

the grain

sizeof

pure

BIT

was recordedto

be over

lpm

but

it

tends

to

changeto

be

iessthan

ipm

with

Ndaddition.

Acknowledgement

The

authors

appreciatethe

technical support providedby

the School of Materials andMineral

ResourcesEngineering,

USM"

Thisresearch

was

supportedby

the

E-science Fund 305/Pbahan/6013357 and the USM Fellowship"References

lL)

Z.Lazarevi6,B. D.

Stojanovi6, J.A.

Varela,An

Approach

to

Analyzing

Synthesis,Structure

and

Properties

o.f

BismuthTitanate

Ceramics,

Sci.

Sintering,

3'7(200s) r99-216.

A.U.

A1-Amani,

S.

Sreekantan, M.N.Ahmad Fauzi, Ef.fect of

Bi

and Ti additionson

the phaseformation of

BiaTi3O12 usingfuel-free

combustion

method,

4'hIntemational

Conference

on

RecentAdvances

in

Materials,

Minerals,Environment and, 2"d

Asian

Symposium onmaterials

and

Processing

(RAMM

&

ASMP), Bayview Beach

Resort,

BatuFerringi, Penang, Malaysia, 1-3 Jun 2009.

A.M.

Umabala,

M.

Suresh),

A.V.

Prasadarao,

Bismuth titanate

.fro*

coprecipitated stoichiometric

hydroxideprecursors, Mater. Lett. 44 (2000) 175-1 80.

D.

Xie, Z,

Zhang, T. Ren,T. Liu, Y.

Dong,L.

Liu,

Properties

of

l,leodymium-DopedBiaTi jO

12 Thin

films

for

ferroelectric

Smple

Crysralilre ,lze, nfl 09. I 61.0

29 0 298 30 0 31.5

[image:5.595.77.280.227.415.2]2Theta (degrees)

Figure

3

XRD

patternsof

(a)

pure0.2BNT, (c) 0.6BNT

and(d)

1.OBNT powders at the (1 1 7) peak position. [image:5.595.126.249.484.656.2]41.9

Figure 4 Grains morphology

(a) pure

BIT

and (b) 1.0BNT.31 0

BIT,

(b)calcined

of caicined powder

12)

t3l

Random Access MemorY,

Integrated Fenoeiectric , 84 (2006) 6'7 ''73 .t5l

Q. Yang,

Y. Li,

Q.

Yin,

P. Wang, Y.B,

Cheng,

Bi[itOtz

nanoparticles ptepared by hydrothermal synthesis, J. Eur. Ceram' Soc',23 (2003)

l6l-166

t6l

H.L.W.

Chan, S.H. Choy, C.P. Chong, H.L.Li,

P.C.K. Lilu, Bismuth sodium

titanqtebased lead-free

ultrasonic

transducerfor

micro electronics wirebonding applications, Ceramics International, 34 (2008) 713-777.

11) Y. M.

Kan,

X.

H.

Jin, G. J. Zhang,P.

L.Wang,

Y.B.

Cheng,

and D.S.

Yan,Lanthanum

modified bismuth

titanateprepared by a hydrolysis method. J. Mater.

Chem. 2004, 14, 3566-357 0.

i8l

Y.M.

Kan,

G.J. Zhang,P.L. Wang,

Y.B.Cheng, Preparation

and

properties

of

neodymium-modified

bismuth

titanateceramics,

J. Eur.

Ceram.Soc.

28

(2008)164t-164',t.

t9l

L.B.

Kong,

J.

Ma,

W.

Zhu, O.K.

Tan,Preparation

of

BiaTijOl2

ceramicsvia

ahigh-energy

ball

milling process)

Mater.Lett. 51 (2001) 108-114.

t10l

X.Q.

Chen,

H.Y.

Qi,

Y.J.

Qi,

C.J.

Lu,Ferroelectric and dielectric properties

of

bismuth

neodymium

titanate

ceramicsprepared

using sol-gel

derived

-finepowders, Phys" Lett.

A

346 (2005) 204-208't11l

D.

Chen,X.

Jiao, Hydrothermal synthesisand characterization

of

Bi{i:Op

powdersfrorn dffirent

precursors, Mater. Res. Buil.36 (2001) 3ss-363.

[12]

S.Luo, Z.

Tang,W. Yao, Z.

Zhang,Low-temperature combustion synthesis

andcharacterization

of

nanosized tetragonalbarium

titanate powdets,

Microelectron.Eng. 66 (2003) 14'7-152.

[13]

K.C.

Patil,

M.S.

Hedge,

T.

Rattan,

S.T"Aruna, Chemistty of

Nanooystalline

OxideMaterials Combustion Synthesis, Properties

Intemational conference on Mnefi_f

:

i;iS:Hli:;Tli'trli$tj

and

Applications,

World

Scientif,rcPublishing Co. Pte.

Ltd.,

Singapore, 2008,pp-42.

t14l

A.

Ries,A.Z.

Simo'es,M.

Cilense,M.A'

Zaghete,

J.A.

Varela, Barium

strontiumtitonate

powder

obtained

by

polymericprecursor

method,

Mater

Charact'

50(2003)

2r1-22t.

[15]

P.Y.

Goh,

K.A.

Razak,

S.

Sreekantan,Structural

and

morphology studies

of

praseodymium-doped

bismuth

titanateprepared using

a

wet

chemicalroute,

J'Alloys

ComPd. 415 (2009)758-761,[16]

J.C. Baeet

al. Ferroelectricproperties

of

lanthanum-doped

bismuth titanate

thin.films grown

by

a

sol-gel

method,Thin

Solid Films 412 (200s) 90-95.

[17]Y.

Kan,X,

Jin, P. Wang,Y. Li, Y.B.

Cheng,D.

Yan,

Anisotropic

grain

growth

ClBiqTisOtz

in

molten salt Jluxes, Mater. Res.Bull.

38 (2003) s67-s76'[18]

P.Y.

Goh,

K.A.

Razak,

S"

Sreekantan,Structural

and

morphology studies

"J'praseodymium-doped

bismuth

titqnateprepared using

a

wet

chemicalroute,

I'

Alloys

Compd. 475 (2009)758-761,t19l

X.

Hu,

A.

Garg,Z. H.

Barber, Structutaland

electrical properties

of

samarium-substituted bismuth titanate

ferroelectricthin

films

on

Pt/TiOx/SiO2/Si substrates,