EFFECT OF PRE-TREATMENT AND DRYING

TEMPERATURE ON THE PROPERTIES OF GAC POWDER

ALDILA SETIAWATI

DEPARTMENT OF FOOD SCIENCE AND TECHNOLOGY

FACULTY OF AGRICULTURAL ENGINEERING AND TECHNOLOGY BOGOR AGRICULTURAL UNIVERSITY

STATEMENT LETTER OF THESIS AND SOURCES OF

INFORMATION

Hereby I genuinely stated that bachelor thesis entitled Effect of Pre-Treatment and Drying Temperature on the Properties of Gac Powder is an authentic work of mine under supervision of academic counselor and never being presented in any forms and universities. All the information taken and quoted from published or unpublished works of the writers has been mentioned in texts and attached in the bibliography at the end of this manuscript.

Hereby I bestow the copyright of my manuscript to the Bogor Agricultural University and Mae Fah Luang University.

Bogor, March 2016

Aldila Setiawati

ABSTRACT

ALDILA SETIAWATI. Effect of Pre-Treatment and Drying Temperature on the Properties of Gac Powder. Supervised by ADIL BASUKI AHZA and CHUTAMAT NIWAT.

Gac fruit has a high content of antioxidant, especially carotenoids. These carotenoids are currently in special demand as they are natural antioxidants with potential to prevent cancers. The objectives of this research were to study the optimum drying condition to produce gac powder, study the waste utilization from gac skin as a powder, and investigate the physical and chemical properties of dried gac powder. Annova completely randomized factorial design was used to study the effect of different pre-treatment (blanching and adding of ascorbic acid) and dried using tray dryer at different temperature (50 and 60ºC) until moisture content in range of 5.8-6.4%. The results showed that the best dried gac powder was from the ascorbic acid pre-treated, using aril pulp and dried at 50°C due to the less amount of antioxidant loses. Physical properties showed bulk density value 0.65±0.02 g/mL and water solubility index (WSI) 36.42±3.11 %. Color properties showed lightness (23.55±2.43), with redness (a*) (23.48±1.27) and yellowness (b*) (39.72±2.97) (p<0.05). Aril and pulp mixture using ascorbic acid as pre-treatment at 50ºC has the highest value in total carotenoid content (TCC) (93.49±11.35 mg β-carotene/100 mL samples),total phenolic compound (TPC) (467.44±7.64 µg GAE/g), DPPH (43.57±1.61 mmol Trolox/100g) and FRAP assay (598.22±18.59 µmol AAE/100g) (p<0.05) compared to other sample (p<0.05). Gac peel sample with blanching and dried at 60°C showed the lowest

value of TCC (32.40±2.23 mg β-carotene/100 mL samples), TPC (0.62±0.03 mg GAE/g), DPPH (15.67±1.02 mmolTrolox/100g), and FRAP assay (194.00±7.84 µmol AAE/100g). The aril-pulp mixture showed the highest TCC, TPC, DPPH and FRAP value compared to peel significantly (p<0.05). Peel with ascorbic acid pre-treatment and dried at 50°C had the greatest antioxidant activities among the peel samples.

Bachelor Thesis

In the partial fulfillment of the requirement for degree of Sarjana Teknologi Pertanian

at

the Department of Food Science and Technology

EFFECT OF PRE-TREATMENT AND DRYING

TEMPERATURE ON THE PROPERTIES OF GAC POWDER

DEPARTMENT OF FOOD SCIENCE AND TECHNOLOGY

FACULTY OF AGRICULTURAL ENGINEERING AND TECHNOLOGY BOGOR AGRICULTURAL UNIVERSITY

BOGOR 2016

PREFACE

First and foremost, author would like to give thanks to the Lord Jesus Christ for His guidance, protection, strength, bless to accomplish the research and manuscript for fulfilling the bachelor degree. The research was done in Mae Fah Luang University and many people have given their help for finishing it.

By completion of this research and manuscript, the author would like to give a lot of thanks and appreciation to:

1. My beloved parents, Mr. Edhy Putranto and Mrs. Sri Puji Yuliati, my brothers Yudhiy Ariawan and Yanuar Adita, my sisters in law Veranica and Andrea, and all of uncles and aunties for love, pray, and support 2. Dr. Adil Basuki Ahza as academic advisor, for his guidance, love and

care for completing manuscript and all advices in life

3. Dr. Chutamat Niwat for guidance, time and supports through exchange program and research in Mae Fah Luang University

4. Ditjen DIKTI for full financial support during exchange program and research and all of Bogor Agricultural University committees (Mr. Eko, Mr. Pungki, Mrs. Dias, Mrs. Antung, Mbak Tika) also for MFU committees (Ajarn of Food Technology Department, Ms. Warunee Kaewnbunruang and all of staff in International Division Affair) also Rufnia Ayu Afifah for all of helps to complete the document for doing research in MFU Thailand.

5. Phi Naan as the local farmer who has given the gac fruit for this research 6. All of laboratory staff in MFU (Phii Tik, Phii Phin, Phii Kwan, Phii Sud,

Phii M, Phi Nen) also all laboratory staff in S2, S3 and S4 laboratory and Department of Cosmetic Science

7. All of staff in Food Science and Technology Department Bogor Agricultural University for their time to help

8. Ruth Theresia, Nuriska Rahma, Razanah Aulia Marhan, Angithya Kesuma, Bobok and Ditia Andini for all of helps that you have given

through my university‟s life. IAAS members especially for Dinda Saraswati and Andrie Priandiri

9. AIMS Student Thailand 2014 (Gilang, Rasadi, Cynthia, Mujahid, Adimas, Nia, Ayendha, Samsul, Anggun) for their care and help for this research and Kak Rufnia Afifah for being as if you are the third advisor for this research and MFU friends (Poppy, Boon, Nat, Ben, FoodTech Student, Christian Club Student, Baan Athitan Church friends, Josh and Jessie) also UITM Student (Shana, Miezah, Belle, Amier) for the ride and all of the memories we made

10. All of ITP‟48 students and ITP‟49 students for being solid and have a good cooperativeness

Bogor, March 2015

TABLE OF CONTENT

LIST OF TABLE viii

LIST OF FIGURE viii

LIST OF APENDIX viii

INTRODUCTION 13

Background 13

Objectives 3

METHOD 3

Material 3

Equipments 3

Procedure 4

RESULT AND DISCUSSION 9

CONCLUSION AND RECOMENDATION 20

Conclusion 20

Recomendation 20

REFFERENCE 20

APPENDICES 13

AUTHOR BIOGRAPHY 15

LIST OF TABLE

1 Weight distribution of fresh Gac fruit (10 fruits) 2 2 Gac samples from different fruit fraction, pre-treatment methods and

drying temperature. 5

3 Chemical characteristics of gac powder 9

LIST OF FIGURE

1 Gac fruit on vines 13

2 Gac fruit and its components 2

3 Bulk density value of gac fruit powder 11

4 Water Solubility Index of gac fruit powder 12

5 Lightness value of gac powder 13

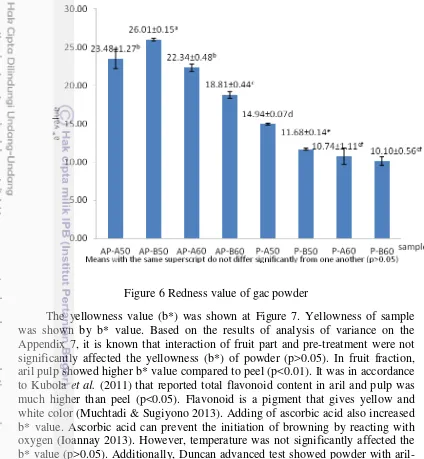

6 Redness value of gac powder 14

7 Yellowness value of gac powder 15

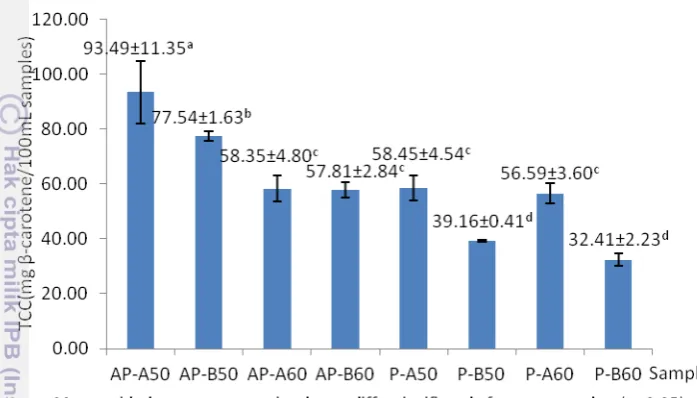

8 TPC value of gac powder 16

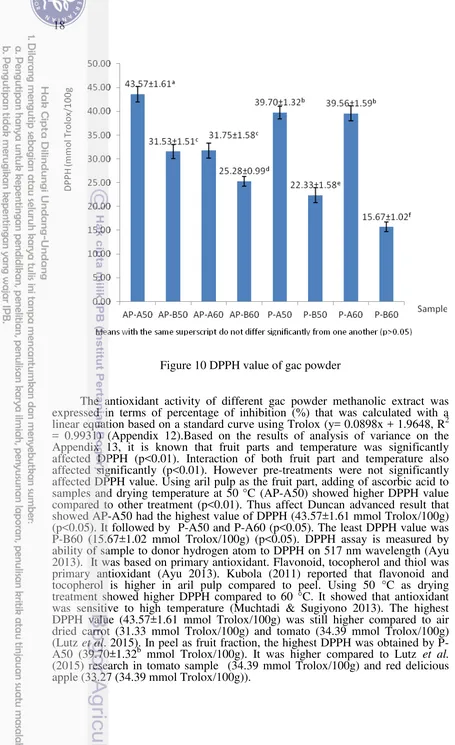

10 DPPH value of gac powder 18

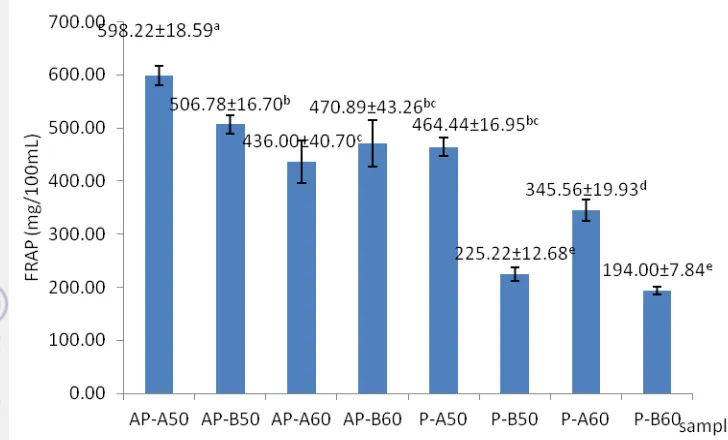

11 FRAP value of gac powder 19

LIST OF APENDICES

1 Stastical analysis of moisture content of dried gac powder 25 2 Stastical analysis of water activity of dried gac powder 27 3 Stastical analysis of bulk density of dried gac powder 29 4 Stastical analysis of WSI (Water Solubility Index) of Gac fruit powder 31 5 Stastical analysis of L* (lightness) of Gac fruit powder 33 6 Stastical analysis of a* (redness) of Gac fruit powder 35 7 Stastical analysis of b* (yellowness) of Gac fruit powder 37 8 Standard Curve of Galic Acid and statistical analysis of Total Phenolic

Compound (TPC) assay 39

9 Standard Curve of β-carotene and statistical analysis of Total Carotenoid

Content (TCC) assay 42

10 Standard Curve of Trolox and statistical analysis of DPPH assay 45 11 Standard Curve of L-ascorbic acid and Statistical Analysis of Ferric

INTRODUCTION

Background

Momordica cochinchinensis (Lour.) Spreng, is belong to Family Cucurbitaceae, Genus Momordica and Species Cochinchinensis (Kha 2010). It is

known as baby jackfruit, sweet gourd or cochinchin gourd in English (Kuhnlein 2004). It is usually known as Gac (in Vietnam), Fakkao (in Thailand), Bhatkerala (in India), Moc Niet Tu (in China) and Makkao (in Laos) (Kubola et al. 2011). It

is known that gac grows in many countries on Southeast Asia. Vietnam is its

origin country and usually used gac as colorant for “xoigac” or red rice (Aoki et al. 2002). In Thailand, gac fruit is usually cooked as vegetable in unripe stage

(Kubola et al. 2011). Gac fruits show green in unripe stage, while the ripe stage

show orange or red color (Tinrat 2014). Recently, gac fruit has entered commercial production as a functional food such as functional drink and supplement.

Gac is not well known in Indonesia, but in its country of origin, gac is familiar and grown easily from seed or root tubers separately between male and female plant. Figure 1 showed that the plant growing vines on lattices in homes or in gardens (Vuong et al. 2002). In one season, each vine produces up to 60 fruits with weight various from 1-3 kg (Vuong et al. 2005). There are some reasons which make gac fruit not well known worldwide such as, its seasonality, fruit susceptible to physical damage, regional lack of availability, and lack of awareness of its potential health value. The harvesting season only happen during September to December (Tran 2008). From the family and genus, it is similar with

Momordica charantia, bitter melon or bitter gourd, usually called „pare’ in

Indonesia (Nagarani et al. 2014). In Indonesia, bitter gourd is prepared in many local dishes, it usually steamed, stir fried or cooked in coconut milk. Bitter gourd antioxidant activity is also high (4.0 mg/mL) (Hou et al. 2011) and similar with

aril of gac fruit‟s (4.29 mg/mL) (Kubola et al. 2011). However, Nagarani (2014) reported that carotenoid of gac fruit (424.6 µg/g) is much higher than bitter gourd (261 µg/g).

2

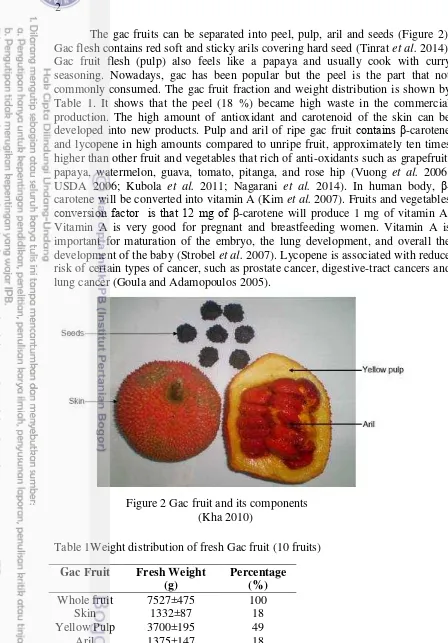

The gac fruits can be separated into peel, pulp, aril and seeds (Figure 2). Gac flesh contains red soft and sticky arils covering hard seed (Tinrat et al. 2014). Gac fruit flesh (pulp) also feels like a papaya and usually cook with curry seasoning. Nowadays, gac has been popular but the peel is the part that not commonly consumed. The gac fruit fraction and weight distribution is shown by Table 1. It shows that the peel (18 %) became high waste in the commercial production. The high amount of antioxidant and carotenoid of the skin can be developed into new products. Pulp and aril of ripe gac fruit contains β-carotene and lycopene in high amounts compared to unripe fruit, approximately ten times higher than other fruit and vegetables that rich of anti-oxidants such as grapefruit, papaya, watermelon, guava, tomato, pitanga, and rose hip (Vuong et al. 2006; USDA 2006; Kubola et al. 2011; Nagarani et al. 2014). In human body, β -carotene will be converted into vitamin A (Kim et al. 2007). Fruits and vegetables

conversion factor is that 12 mg of β-carotene will produce 1 mg of vitamin A. Vitamin A is very good for pregnant and breastfeeding women. Vitamin A is important for maturation of the embryo, the lung development, and overall the development of the baby (Strobel et al. 2007). Lycopene is associated with reduce

risk of certain types of cancer, such as prostate cancer, digestive-tract cancers and lung cancer (Goula and Adamopoulos 2005).

Figure 2 Gac fruit and its components (Kha 2010)

Table 1Weight distribution of fresh Gac fruit (10 fruits) Gac Fruit Fresh Weight

(g)

Percentage (%)

Whole fruit 7527±475 100

Skin 1332±87 18

Yellow Pulp 3700±195 49

Aril 1375±147 18

Seeds 1084±52 14

3 The powder forms are very convenient for lengthen the shelf life of gac fruits. The main benefits of powder forms compared to fresh fruits and vegetables are the potential for long storage at ambient temperature and a significant reduction in the cost for transportation and storage (Fellows 2000). Gac aril powder was expected to be more convenient to use as food colorants, nutrition supplementation and pharmaceutical ingredients than fresh Gac and the existing Gac products such as gac oil and gac juice (Tran 2008). Nowadays, large varieties of drying techniques are used for producing powder in the food industry. Many factors, such as the characteristics of the food material to be dried, the quality of the desired final product and processing costs, energy and space requirement must be considered (Tang and Yang 2004). However, many local gac farmers could not develop their products because the limitation of equipment. Tray dryer is the most simple and cheapest drying machine that can support domestic industry. However, technique selection and preservation of gac powder is essential in order to maintain the good quality and high yield of a potential natural source of lycopene,

β-carotene and colour for the powder. In addition, temperature and time of the drying process must be considered to give the minimal reduction of polyphenolic compound.

Objectives

The objectives of this research were to study the optimum drying condition to produce gac powder, study the waste utilization from gac skin as a powder, and investigate the physical and chemical properties of dried gac powder.

METHOD

Material

The ripe gac fruit (orange or red color) was purchased from local farmer in Chiang rai. Chemical reagent that used in this research were Folin- Ciocalteu‟s phenol reagent Loba ChemieTM India, Sodium carbonate Na2CO3 QRëC® New Zealand, Gallic acid Sigma-Aldrich® China, DPPH (1,1-diphenyl-2-picrylhydrazyl), methanol, trolox, potassium dihydrogen phosphate (NaH2PO4) QRëC® New Zealand, disodium hydrogen phosphate (Na2HPO4) QRëC® New Zealand, potassium ferricyanide K3[FeCN6] Fisher Scientific Qualigens® chemicals, trichloroacetic acid (TCA) Loba ChemieTM India, ferric chloride FeCl3 Fisher chemical® United Kingdom, L-ascorbic acid Ajax Finechempty® New Zealand, carotenoid, Petroleum Ether (PE), acetone, Na2SO4, NaOH, phthalate potassium acid, phenoftalein indicator, HCl, methyl red indicator, boric acid, NH3, NaOH, CuSO4, K2SO4, H2SO4. All other chemicals and solvents in this study were of analytical grade.

Equipments

4

Thai Company), desiccators (Normax 49 061 341), hammer mill (CMC-20 Thailand), sieving machine (AS 200 Digit 2001 Retsch Germany), sealer, vacuum bag, moisture can, oven, desiccators (Normax 49 061 341), water activity meter (Aqua Lab Pawkit, Decagon Devices, USA), colorimeter (Color Quest XE Hunter Lab), centrifuge tube, water bath (Memmert WB-22 Germany), centrifuge, beaker glass, cylinder tube, vortex, magnetic stirrer, separating funnel, spectrophotometer (ThermoFischer Scientific Model 4001/4 Genesis 20 USA).

Procedure Sample Preparation

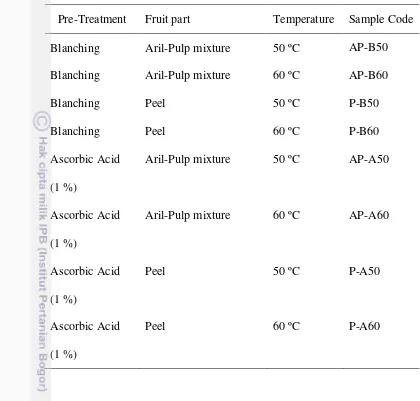

5 Table 2 Gac samples from different fruit fraction, pre-treatment methods and

drying temperature.

Pre-Treatment Fruit part Temperature Sample Code

Blanching Aril-Pulp mixture 50 ºC AP-B50

Blanching Aril-Pulp mixture 60 ºC AP-B60

Blanching Peel 50 ºC P-B50

Blanching Peel 60 ºC P-B60

Ascorbic Acid (1 %)

Aril-Pulp mixture 50 ºC AP-A50

Ascorbic Acid (1 %)

Aril-Pulp mixture 60 ºC AP-A60

Ascorbic Acid (1 %)

Peel 50 ºC P-A50

Ascorbic Acid (1 %)

Peel 60 ºC P-A60

Moisture Content (AOAC 2002)

Gac powder samples (2.000 g) were placed in a moisture can and it was put in pan and heated in an oven at 103±2˚C for overnight to constant weight. The moisture content were then calculated from the weight differences. All tests were performed in triplicate.

Moisture content (wb,%) =

w = original sample weight (g)

w1 = weight of sample + can after drying (g) w2 = weight of empty can (g)

6

Water Solubility Index (WSI) (da Silva et al. 2009)

Gac fruit powder (0.1 g) and distilled water (10 mL) were vigorously mix in a 50 mL centrifuge tube, mixed vigorously used vortex for 10 seconds, incubate in 37°C water bath for 30 minutes and then centrifuge for 15 minutes at 3000 rpm. The supernatant is carefully collect in a pre-weighed beaker and oven dry at temperature of 103±2˚C. The WSI (%) was calculated as the percentage of dried supernatant with respect to the amount of the original 0.1 g gac fruit powder. Water Solubility Index (WSI,%) =

w = original sample weight (g)

The water activity was measured by using water activity meter (AquaLab Pawkit, Decagon Devices, USA). First, verified and calibrated the water activity meter. Chamber lever was moved to the open position and lift the chamber lid. Powder was filled into cup. Prepared sample cup was put in the chamber. Chamber lid was closed and moved the lever to the read position. The chamber will be sealed and started reading. Water activity value will be displayed on the LCD.

Color Characteristics of Gac Powder (Andarwulan et al. 2011)

7 value was shown in LCD. Hunter values of the samples for each treatment method were measured in triplicate.

Preparation of Gac Powder Extractfor TPC, DPPHand FRAP Determination(Abu Bakar et al. 2009)

Gac powder (1 g) was extracted for 2 hour with 10 mL of 80 % methanol at room temperature on an orbital shaker set at 180 rpm. The mixture was centrifuged at 1400 g for 20 minute and the supernatant was decanted into a 15 ml vial. The supernatant was used for the total phenolic compound (TPC), DPPH radical scavenging activity and ferric reducing antioxidant power (FRAP) assay. The experiment and measurements were done in triplicate.

Determination of Total Polyphenol Content (TPC assay) (ISO 14502-1:2005) Gac powder extracts from aril-pulp and peel were diluted (5 fold) with distilled water. The diluted extracts was pour into tubes containing 5.0 mL

Folin-Ciocalteu‟s reagent diluted (1:10) in distilled water and stored in the dark place at room temperature for 5 minutes. Then, 4 mL of 7.5 % w/v sodium carbonate (Na2CO3) solution was added. The mixture was kept at room temperature for an hour and then measured the absorbance at 765 nm by using spectrophotometer ThermoFischer Scientific Model 4001/4 Genesis 20 US and using water as blank. The concentration of polyphenols in samples is derived from a standard curve of gallic acid ranging from 0 to 100 µg/mL gallic acid. Total polyphenol content is expressed as gallic acid equivalents (GAE) in g/100 g extract. The calculation were :

C = concentration of sample based on standard curve (µg/mL) V = sample extraction volume (mL)

D = dilution factor w = weight of sample (g)

DPPH Radical Scavenging Activity (DPPH assay) (Anesini et al. 2008)

The DPPH assay was determined according to the method by Anesini et al.

8

C = concentration of sample based on standard curve (µM) V = sample extraction volume (mL)

D = dilution factor w = weight of sample (g)

Ferric Reducing Antioxidant Power activity (FRAP assay) Tinrat et al. (2014)

A 1 mL aliquot of each extract was mixed with 2.5 mL of phosphate buffer (0.2 M, pH 6.6) and 2.5 mL of a 1 % potassium ferric cyanide [K3Fe(CN)6] solution. Sample was incubated for 30 minutes at 50°C. After incubation, sample was added by 2.5 mL of 10 % trichloroaceticacid. The feculences and supernatant was separated by centrifuged it at 6000 rpm for 10 minutes. A 2.5 mL aliquot of supernatant was mixed with 2.5 mL of water and 0.5 mL of 0.1 % aqueous ferric chloride. The absorbance was recorded at 700 nm by using spectrophotometer ThermoFischer Scientific Model 4001/4 Genesis 20 USA). The standard curve showed the concentration of polyphenols in samples which is used L-ascorbic acid. The standard curve range was from 0-1000 µmol/100mL.

C = concentration of sample based on standard curve (µM) V = sample extraction volume (mL)

D = dilution factor w = weight of sample (g)

Determination of Total Carotenoid Content (TCC assay) (Tran et al. 2008)

Gac powders (0.1 g) were extracted with 10 mL of solvent, which is a mixture of n-hexane and acetone (v/v 3:2). The residue was extracted with 5 mL of solvent four times using a magnetic stirrer until colorless. The extracts were combined and washed with 25 mL of distilled water twice to remove acetone, each time in a separating funnel. A drop of saturated NaCl solution was added to separate the acetone. The extract was combined and used for the total carotenoid content assay. The experiment and measurements were done in triplicate. The extracts were diluted (10 fold) and measured the absorbance by using spectrophotometer (ThermoFischer Scientific Model 4001/4 Genesis 20 USA) in

473 nm wavelength. A 0.0010 gram of β-carotene standard mixed with n-hexane in 100 mL volumetric flask was needed as standard solution (1000 µg/100 mL). Standard curve was performed in a range 0-75 µg/100 mL.

9 D = dilution factor

w = weight of sample (g) Statistical Analysis

Data were analyzed using completely randomized factorial design using IBM SPSS 20.0 software for Windows. Further analysis were Duncan Multiple range Test (DMRT) to figure out the level of significance difference within degree of confidence (95 % and 99 %)

RESULT AND DISCUSSION

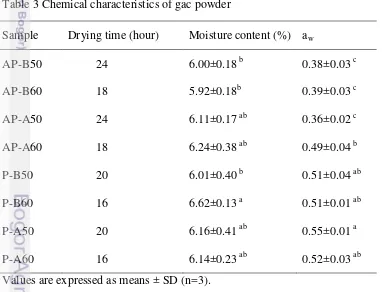

Chemical Properties

Moisture content is essential to follow up drying course and to decide whether drying treatment is achieved or not (FAO 2006). On the other hand, the storage process must be considered. Another important analysis is water activity (aw). Water activity describes the energy status or escaping tendency of the water in a sample (Decagon 2006). Furthermore, water activity is more closely related to the physical, chemical and biological properties of foods and other natural products than is total moisture content. The chemical analysis consists of moisture content and water activity analysis. The effects of gac fraction, pre-treatment and different air drying temperatures on the chemical properties of gac fruit powders are shown in Table 3.

Table 3 Chemical characteristics of gac powder

Sample Drying time (hour) Moisture content (%) aw

AP-B50 24 6.00±0.18 b 0.38±0.03 c

AP-B60 18 5.92±0.18b 0.39±0.03 c

AP-A50 24 6.11±0.17 ab 0.36±0.02 c

AP-A60 18 6.24±0.38 ab 0.49±0.04 b

P-B50 20 6.01±0.40 b 0.51±0.04 ab

P-B60 16 6.62±0.13 a 0.51±0.01 ab

P-A50 20 6.16±0.41 ab 0.55±0.01 a

P-A60 16 6.14±0.23 ab 0.52±0.03 ab

10

Means with the same superscript do not differ significantly from one another p>0.05

The presence of moisture in food is often linked to the quality of foodstuffs, as a measure of dry matter or solid part, determinant index of stability during storage, as well as the determinant of organoleptic quality, especially in terms of taste and tenderness (Andarwulan 2011). All of samples should reach moisture content of 5.92-6.62 % which was in accordance to Tran (2007) study about gac fruit powder. Low moisture content could minimize the deterioration of dried foods (fruit and vegetables) (Kha 2010). Moisture content showed total water in product that can result spoilage in food (Sandulachi 2012). Furthermore, spoilage in foods can be affected by two factors, being intrinsic and extrinsic factors (Robertson 2006). The intrinsic factors are pH, aw, and nutrient content, while storage temperature, relative humidity of the environment, and the concentration of gases in the environment are the extrinsic factors. Therefore, these causes of deterioration must be considered, and the appropriate storage conditions for food products were necessary (Kha 2010). In this study, all of variables such as fruit part, pre-treatment and temperature were not significantly difference (p>0.05) (Appendix 1). It is because the moisture content has to reach 5.80-6.40%. Different drying treatment showed in each treatment. Drying temperature at 60ºC reached moisture content 5.80-6.40 % faster than the drying temperature at 50 ºC. Drying in 50ºC with both pre-treatment for aril-pulp need the longest time, 24 hour and in 60ºC need 18 hour. Drying time for peel in 50 ºC and 60 ºC showed 20 hour and 16 hour respectively. Generally in air dryer, increasing drying temperature resulted in greater loss of water in the powder. It is because of higher rate of heat transfer into particles, causing faster water removal (Fellows 2000).

Water activity (aw) is useful to predict the growth of bacteria, yeasts and moulds. High water activity in the product may participate in chemical/biochemical reactions, which might deteriorate texture, flavor, color, taste, nutritional value of a product, and its shelf life time (Sandulachi 2012). For a food that have a long shelf life without relying on refrigerated storage, acidity level (pH) or the level of aw needed to be controlled (Sandulachi 2012). In a low aw, the availability of water for microorganism biological reaction was also low. Based on the results of analysis of variance on the Appendix 2, it is known that aw of products were significantly affected by interaction of fruit parts and temperature (p<0.05). In the fruit parts, aw of aril-pulp was lower than peel (p<0.01). It might happen because the presence of salt and sugar in peel is lower than aril and pulp. Water activity is reduced by the presence of salt and sugar (Koop et al., 2000). However, no scholar wrote any report on the proximate and

total soluble solid of peel. Water activity increases with temperature due to changes in the properties of water such as, the solubility of solute (salt and sugar) or the state of food (FDA 2015). Blanching as pre-treatment showed lower aw than adding of ascorbic acid (p<0.05). It is in accordance to Alakali et al. (2009) that

11 According to UNPA (2013), the deterioration of dried food powder caused by microorganisms and biochemical reactions can be prevented at aw lower than 0.6.

Physical Properties

The analysis was conducted to determine the physical properties of gac fruit powder. The physical properties that analyzed in this research were bulk density (BD), water solubility index (WSI) and color measurement. Color measurement analyzed the lightness (L*), redness (a*) and yellowness (b*).

The data of bulk density is shown at Figure 3. Bulk density is a property in

powders, granules, and other “divided” solids product. High bulk density is

desirable for reducing shipping and packaging cost. It is very useful for transporting gac powder to worldwide, thus everyone can feel the nutrition health (CalPoly DPTC 2001). Based on the results of analysis of variance on the Appendix 3, it is known that the bulk density of gac powder was highly significant affected by the interaction of drying temperature and fruit fraction and also their interaction (p<0.05). The bulk density of aril pulp was higher compare

to peel (p<0.01). Increasing of drying temperature decrease the bulk density (p<0.01). This was in accordance with the study by Kha (2010), that increasing inlet air drying temperature results in reducing bulk density of gac powder. Size reduction of powder can be prevented because in high temperature, the outer parts dry quickly, become rigid and their fixed, final tissue volume cannot contract as strongly (Wang & Brennan, 1995). Blanching as pre-treatment showed higher bulk density compare to adding of ascorbic acid (p<0.01). Furthermore, advanced test by Duncan showed that AP-B50 was not significantly different with AP-A50 and AP-B60 (p>0.05). AP-A50 and AP-B60 also showed that is not significantly different with AP-AA 60 (p>0.05). Peel powder with adding of ascorbic acid in 60 ºC has the lowest bulk density, 0.37 g/mL. Minimum value of bulk density on desirable powder is 0.30 g/mL (CalPoly DPTC 2001). It showed that all of samples in this study have desirable bulk density.

12

The data of water solubility index (WSI) of gac fruit powder is shown at Figure 4. Based on the results of analysis of variance on the Appendix 4, it is known that the WSI of gac powder was significantly affected by the interaction of drying temperature and fruit fraction (p<0.05). However, it was highly affected by the three factors (p<0.01). In fruit fraction, aril pulp solubility index was higher

compared to peel (p<0.01). Drying temperature at 50ºC also showed higher WSI compared to 60ºC (p<0.01). Blanching as pre-treatment showed higher WSI compared to adding of ascorbic acid (p<0.01). It might happen because blanching causes softening of structure (Verma & Joshi 2000). Pectin which is insoluble in water was partly hydrolyzed (Isnaini & Khamidah 2012). Powder using aril pulp with blanching and drying at 50ºC (AP-B50) showed the highest WSI among all of samples (p<0.05). Overall, in this study, the WSI of samples ranged from 11.55 to 43.70 %. Solubility of the gac powders using vacuum drying ranged from 35.94 to 39.07 % (Kha et al., 2010). The water solubility index of powder was low. It could be due to a high content of liposoluble substances, such as carotenoids and tocopherol, a significant level of fatty acids, and high level of insoluble pulp in the original aril (Kha et al. 2010). It might be better to use aril-pulp powder compared to peel as it showed higher WSI significantly (p<0.01). The higher WSI is preferable because the powder is easy to be soluble in water. The lower WSI in peel compared to aril-pulp might be due to a high content of fiber in peel (Lopez

et al. 2011).

Figure 4 Water Solubility Index of gac fruit powder

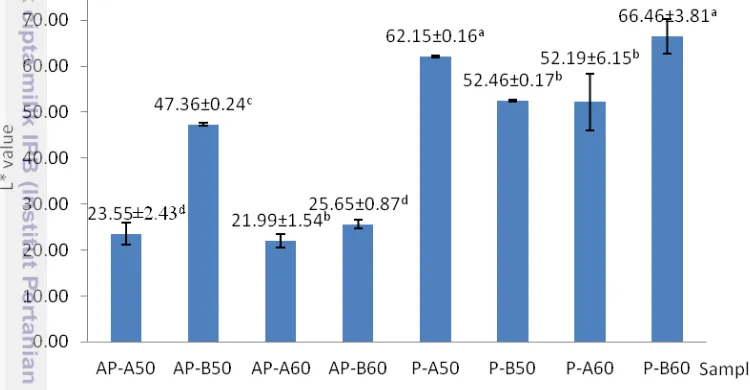

The lightness value (L*) was shown at Figure 5. Based on the results of analysis of variance on the Appendix 5, it is known that interaction of fruit fraction and drying temperature highly significant affected the lightness of samples (p<0.01). Lightness of peel part is higher than aril-pulp (p<0.01). Drying temperature at 50 ºC showed highly significantly brighter as shown from higher lightness value compared to 60 ºC (p<0.01). This is in accordance with Shi et al.

13 value. The interaction between fruit part and pre-treatment and between fruit part and temperature significantly affected the lightness (p<0.05). Lightness of products increased was significantly obtained by blanching treatment (p<0.05). It was in accordance with results of Piga et al. (2004) which reported that blanching of figs fruit had higher lightness value than that of untreated fruits. Blanching inactivates the enzymatic systems responsible for sensory and vitamin alteration and thus limit the better presentation(what is this mean exactly)???????. In

addition, the colors of plants are heightened, for better presentation (Ioannau & Ghoul 2013). Thus resulted in advanced test with Duncan that showed P-B60 had highest lightness value among all of samples (p<0.05). However, it was not significantly difference with P-A50 (p>0.05).

Figure 5 Lightness value of gac powder

14

compared to untreated. Generally, Duncan advanced test showed highest lightness was obtained by AP-B50 (Figure 6).

Figure 6 Redness value of gac powder

The yellowness value (b*) was shown at Figure 7. Yellowness of sample was shown by b* value. Based on the results of analysis of variance on the Appendix 7, it is known that interaction of fruit part and pre-treatment were not significantly affected the yellowness (b*) of powder (p>0.05). In fruit fraction, aril pulp showed higher b* value compared to peel (p<0.01). It was in accordance to Kubola et al. (2011) that reported total flavonoid content in aril and pulp was

much higher than peel (p<0.05). Flavonoid is a pigment that gives yellow and white color (Muchtadi & Sugiyono 2013). Adding of ascorbic acid also increased b* value. Ascorbic acid can prevent the initiation of browning by reacting with oxygen (Ioannay 2013). However, temperature was not significantly affected the b* value (p>0.05). Additionally, Duncan advanced test showed powder with aril-pulp mixture with ascorbic acid as pre-treatment and drying at 50 °C (AP-50) showed the highest value of yellowness (b*) (p<0.05). It was not significantly different with AP-A60 (p<0.05) (Figure 7). In aril-pulp powder, used 50 °C as drying temperature and using ascorbic acid as pre-treatment will increase the b* value. However, using 60 °C as drying temperature and ascorbic acid as pre-treatment will increase the b* value in peel powder.

15

Figure 7 Yellowness value of gac powder Bioactive Compound

Phenolic compounds are major plant secondary metabolite which has several biological functions including antioxidant and antibacterial activities (Tinrat et al.

2014). Gac fruits are extraordinary sources of carotenoids (β-carotene and lycopene). Vuong (2006) reported that Gac fruits also contain high concentration

of Vitamin E. Several carotenoids (α-carotene, β-carotene and lycopene) and tocopherols (vitamin E) are two important groups of a natural source of antioxidants (Kim et al. 2007). Bioactive compound of gac powder was determined by Total Phenolic Compound (TPC) and Total Carotenoid Content (TCC).

Phenolic compounds are widely distributed in plants. The total phenolic compounds of the tested medicinal plant extracts were demonstrated by using the Folin-Ciocalteau colorimetric method. The TPC of the all samples were calculated with a linear equation based on a standard curve using gallic acid (y= 0.01x + 0.005, R2 = 0.9991) (Appendix 8). Based on the results of analysis of variance on the Appendix 9, it is known that fruit part and drying temperature were very significantly affected the TPC (p <0.01). The interaction of fruit part and drying temperature were also affected TPC (p<0.01). TPC of samples is shown in Figure 8. Aril-pulp powder showed higher TPC compared to peel (p<0.01). It was in accordance to Kubola et al. (2011) that reported TPC of fresh aril was higher than

16

by P-A50. P-A50 (144.56 mg/100mL) was higher compared to air dried tomato TPC (44 mg/100 g) (Chang et al. 2006) and dried apple (77.83 mg/100g) which is reported high antioxidant (Aghilinategh et al. 2015). It showed that peel can be

utilized to be antioxidant powder.

Figure 8 TPC value of gac powder

The total carotenoid content (TCC) of the all samples were calculated with a linear equation based on a standard β-carotene (y= 0.0037x + 0.0014, R2 = 0.9986) (Appendix 10). TCC value was shown in Figure 9. Based on the results of analysis of variance on the Appendix 11, fruit parts, pre-treatment and temperature is highly significant affected TCC (p<0.01). Aril pulp showed higher TCC compared to peel (p<0.01). It was in accordance to Kubola (2011) that reported higher carotenoid in aril compared to peel using HPLC. In addition, carotenoid is easily oxidized in high temperature during drying (Muchtadi & Sugiyono 2013). Interaction between fruit part and temperature was significantly affected TCC (p<0.01). Pre-treatment are effective in maximize the retention of bioactive compound. Ascorbic acid can effectively prevent the loss of bioactive compound because its beneficial role of antioxidant activity. Blanching can prevent the loss of bioactive compound because blanching process removed the soluble solids from the tissue matrix (Kha et al. 2010). In this study, ascorbic acid

17 mg/100g of powder) (Muratone et al., 2008). The highest carotenoids of peel powder was shown by pre-treatment using ascorbic acid before drying at 50 °C (58.44 mg/100g of powder). It was much higher than other dried fruits such as cherry tomatoes (36 mg/100g of powder), pumpkin (14 mg/100g of powder) (Muratone et al., 2008). Therefore, it can be used for dried powder which is high of carotenoid.

Figure 9 TCC value of gac powder

Antioxidant Activity

Antioxidants are substances that neutralize free radicals or their actions (Sies, 1996). Carotenoids, flavonoids and related polyphenols, α-lipoic acid, glutathione include non-enzymatic antioxidant. Antioxidant is able to neutralize free radicals act at prevention, interception and repair stages (Devasagayam 2004). The antioxidant activity is influenced by many factors. Therefore, at least two assays is recommended for the evaluation of antioxidant activity (Schlesier et al. 2002). In this study, the antioxidant activity was determined by DPPH and

FRAP radical scavenging activity methods. DPPH assay is widely used to determine the free radical scavenging ability in plant extract. DPPH is a free radical compound and stable in room temperature. Antioxidant compound scavenges free radical by hydrogen donation and reduction of DPPH (violet color to DPPH-H (yellowish color) (Tinrat et al. 2014). Whilst FRAP assay determined the reducing potential of the methanolic extracts (Tinrat et al. 2014). FRAP

18

Figure 10 DPPH value of gac powder

The antioxidant activity of different gac powder methanolic extract was expressed in terms of percentage of inhibition (%) that was calculated with a linear equation based on a standard curve using Trolox (y= 0.0898x + 1.9648, R2 = 0.9931) (Appendix 12).Based on the results of analysis of variance on the Appendix 13, it is known that fruit parts and temperature was significantly affected DPPH (p<0.01). Interaction of both fruit part and temperature also affected significantly (p<0.01). However pre-treatments were not significantly affected DPPH value. Using aril pulp as the fruit part, adding of ascorbic acid to samples and drying temperature at 50 °C (AP-A50) showed higher DPPH value compared to other treatment (p<0.01). Thus affect Duncan advanced result that showed AP-A50 had the highest value of DPPH (43.57±1.61 mmol Trolox/100g) (p<0.05). It followed by P-A50 and P-A60 (p<0.05). The least DPPH value was P-B60 (15.67±1.02 mmol Trolox/100g) (p<0.05). DPPH assay is measured by ability of sample to donor hydrogen atom to DPPH on 517 nm wavelength (Ayu 2013). It was based on primary antioxidant. Flavonoid, tocopherol and thiol was primary antioxidant (Ayu 2013). Kubola (2011) reported that flavonoid and tocopherol is higher in aril pulp compared to peel. Using 50 °C as drying treatment showed higher DPPH compared to 60 °C. It showed that antioxidant was sensitive to high temperature (Muchtadi & Sugiyono 2013). The highest DPPH value (43.57±1.61 mmol Trolox/100g) was still higher compared to air dried carrot (31.33 mmol Trolox/100g) and tomato (34.39 mmol Trolox/100g) (Lutz et al. 2015). In peel as fruit fraction, the highest DPPH was obtained by

P-A50 (39.70±1.32b mmol Trolox/100g). It was higher compared to Lutz et al.

19

Figure 11 FRAP value of gac powder

The reducing potential of samples was calculated with a linear equation based on a standard curve using L-Ascorbic acid (y= 0.0018x + 0.1237, R2 = 0.9986) (Appendix 14).FRAP results in samples are shown in Figure 10. Based on analysis of variance on Appendix 15, fruit parts, pre-treatment and temperature was significantly affected FRAP value. In fruit part, aril pulp showed higher FRAP value compared to peel (p<0.01). FRAP value was also higher in the samples that treated using ascorbic acid and dried at 50 °C (p<0.01). However, interaction between fruit parts and temperature was not significantly affected FRAP value (p>0.05). Duncan advanced test showed the highest FRAP value was shown by AP-A50 (598.22±18.59 mg/100g) (p<0.05). It followed by AP-B50, AP-B60 and P-A50 (p<0.05). Moreover, AP-B60 and P-A50 was not significantly different with AP-A60. The least FRAP value was shown by P-B60 (194.00±7.84 mg /100g). P-A50 showed the highest value of DPPH and FRAP in powder from peel (39.70±1.32 mg/100g of powder) and (464.44±16.95 mg /100g).

Base on the result of analysis of variance, it is known that , DPPH and FRAP of samples was higher in aril-pulp as fruit part, ascorbic acid as pre-treatment and air dried at 50 °C. It was in accordance to TPC of gac powder. Aril pulp has higher antioxidant activity. Antioxidant activity of a combination of hydrophobic carotenoids and tocopherol is more effective than that of individual compounds (Kha 2010). Aril pulp contains tocopherol (7.6mg/100g), whilst in peel was not available (Kubola 2011). In this study indicate that prevention of antioxidant loss was affected by the drying temperature. Reduction of antioxidant activity was caused by thermal treatment (Kha et al. 2010). It was in accordance

to Miranda et al. (2009) observation that higher of antioxidant activity of Aloe vera gel was air dried at lower temperatures. Aril pulp is high in FRAP, which also showed high content of rutin and luteolin (Parashar et al. 2014). According to

20

CONCLUSION AND RECOMENDATION

Conclusion

Best dried gac powder was characterized with high antioxidant compound. The research found that using mixture of aril-pulp as fruit part and drying at 50 °C could prevent the loss of antioxidant in the process of making gac powder using air dryer. Utilizing Gac peel is advantageous to produce dried peel powder because high of carotenoid and antioxidant. Further study need to be conducted to increase the quality of peel powder and antioxidant stability during process.

Recomendation

Further research is needed to determine the utilization of powders in food. It can improve the utilization of powder, not only good for shipping but also can be consumed by consumers easily.

REFFERENCES

Abu Bakar MF, Mohamed M, Rahmat, A, Fry J. 2009. Phytochemicals and antioxidant activity of different parts of bambangan (Mangiferapajang) and tarap (Artocarpusodorastissimus). J. Food Chemistry. 113:479-483.

Aghilinategh N, Rafiee S, Gholikhani A, Hosseinpur S, Imia M, Mohtasebi SS, Maleki N. 2015. A comparative study of dried apple using hot air, intermittent and continuous microwave: evaluation of kinetic parameters and physicochemical quality attributes. Food Science and Nutrition. 3(6):519-526.

Alakali J, Irtwange SV, Satimehin A. 2009. Moisture adsorption characteristics of ginger slices. Cienc. Tecnol. Aliment. 29(1):155-164.

Andarwulan N, Kusnandar F, Herawati D. 2011. Analisis Pangan. Jakarta (ID):Dian Rakyat.

Anesini C, Ferarro GE, Filip R. 2008. Total polyphenol content and antioxidant aapasity of commercially available tea (Camellia sinensis) in Argentina. J.Agric Food Chem,56: 9225-9229.

AOAC. 2002. Properties of Water in Foods. Washington DC : AOAC.

21 Ayu RA.2013. Polyphenol Extraction from Mangosteen Pericarp (Garcinia mangostana L.) and Its Application in Tea Product [Thesis]. Bogor (ID) : Bogor Agricultural University.

Benzie IF and Szeto YT. 1999. Total antioxidant capacity of teas by the ferric reducing/antioxidant power assay. Journal of Agricultural and Food Chemistry. 47:633-636.

CalPoly DPTC. Bulk Density. 2001. Dairy Ingredients Fax. 3 (1)

Carvajal M, Martínez MR, Martínez-Sánchez F, Alcaraz CF. 1997. Effect of ascorbic acid addition to peppers on paprika quality. Journal of the Science of Food and Agriculture. 75(4): 442-446.

Chang HC, Lin HY, Chang CY, Liu YC. 2006. Comparisons on the antioxidant properties of fresh, freeze dried and hot dried tomates. Journal of Food Engineering. 77:478-485.

Chen JP, Tai CY, Chen BH. 2007. Effects of different drying treatments on the stability of carotenoids in Taiwanese mango (Mangifera indica L.). Food Chemistry. 100(3):1005-1010.

Da Silva C, Carvalho P, Andrade C. 2009. The effects of water and sucrose contents on the physicochemical properties of non-directly expanded rice fluor extrudates. Ciencia e Tecnologia de Alimentos. 29: 661-666.

Decagon. 2006. Fundamentals of Water Activity. Washington (US) : Nelson

Court.

Devasagayam TPA, Tilak JC, Boloor KK., Sane, KS, Ghaskadbi SS, Lele RD. 2004. Free radicals and antioxidants in human health : current status and future prospects. J Assoc Physicians India. 52: 794-804.

FDA. 2015. Water activity (aw) in Foods. Accessed from http://www.fda.gov/ICECI/Inspections/InspectionGuides/InspectionTechni calGuides/ucm072916.htm

FAO. 2006. Good Hygiene Practices along the coffee chain. Fiat (FR) : Food and Agriculture Organization Report of the United Nations.

Fellows PJ. 2000. Food Processing Technology : Principles and Practice 3rdedition. Cambridge : Woodhead Publishing.

Goula MA, Adamopoulos KG, Kazakis NA. 2004. Influence of spray drying conditions on tomato powder properties. J. Drying Technology. 22(5):1129-1151.

Goula MA, Adamopolos KG. 2005. Stability of lycopene during spray drying of tomato pulp. LWT-Food Science and Technology. 38: 479-487.

Hou WC, Lu YL, Chyuan JH, Cheng KT, Liang WL. 2012. Antioxidant activities of different and wild bitter gourd (Momordica charantia L. var. abbreviate

Seringe) cultivars. Botanical Studies. 53: 207-214.

Ioannou I. and Ghoul M. 2013. Prevention of enzymatic browning in fruit and vegetables. European Scientific Journal. 30(9): 311-341.

Isnaini L and Khamidah A. 2012. Kajian lama blanching dan konsentrasi CaCl2 terhadap sifat fisik pembuatan french fries ubi jalar (Ipomoea batatas L.).

22

[ISO] International Organization for Standardization. 2005. ISO 14502-1: Determination of Subtances Characteristic of Green and Black Tea Part 1 Content of Total Polyphenols in Tea-Colorimetric Method Using Folin-Ciocalteu Reagent. Hongkong: Hongkong Polytechnique University.

Kha TC. 2010. Effects of different drying processes on the physicochemichal and antioxidant properties of Gac fruit powder [thesis]. Newcastle (AU) : The

University of Newcastle.

Kim MY, Giraud WD, Driskell AJ. 2007. Tocopherol and carotenoid contents of selected Korean fruits and vegetables. Journal of Food Composition and Analysis. 20: 458-465.

Koop T, Luo B, Tsias A, Peter T. 2000 .Water activity as the determinant for

homogeneous ice nucleation in aqueous solution. Journal of Nature. 406: 611 – 614.

Kubola J, Sirithon S. 2011. Phytochemicals and antioxidant activity of different fruit fractions (peel, pulp, aril and seed) of Thai gac (Momordica cochinchinensis Spreng). J. Food Chem. 127: 1138-1145.

Kuhnlein HV. 2004. Karat, Pulque and Gac: Three shining starts in the traditional food galaxy. Nutrition Reviews. 62:439-442.

Lopez MRR, Diaz PO, Perez LAB, Tovar J, Nicanor AB. 2011. Fiber concentrate from orange (Citrus sinensis L.) bagase : characterization and application as

bakery product ingredients. Int. J. Mol. Sci. 12 : 2174-2186.

Lutz M, Hernandez J, Henriquez C. 2015. Phenolic content and antioxidant activity in fresh and dry fruits and cegetables grown in Chile. Journal of Food. 13(4):541-547.

Miranda M, Maureira H, Rodríguez K, Vega-Gálvez A. 2009. Influence of temperature on the drying kinetics, physicochemical properties, and antioxidant capacity of Aloe Vera (Aloe Barbadensis Miller) gel. Journal of Food Engineering. 91(2):297-304.

Muchtadi TR, Sugiyono. 2013. Prinsip Proses dan Teknologi Pangan. Bandung (ID) : Alfabeta 2013.

Muratore G, Rizzo V, Licciardello F, Maccarone E. 2008. Partial dehydration of cherry tomato at different temperature, and nutritional quality of the products. Food Chemistry. 111 (4) : 887-891.

Nagarani G, Abirami A, Siddhuraju P. 2014. Food prospects and nutraceutical attributes of Momordica species : A potential tropical bioresources – A

review. Food Science and Human Wellness. 3 : 117-116.

Orphanides A, Goulas V, Gekas V. 2013. Effect of drying method on the phenolic content and antioxidant capacity of spearmint. Czech J. Food Sci. 5(31): 509-513.

23 Piga A, Pinna I, Özer KB, Agabbio M, Aksoy U. 2004. Hot air dehydration of fig (Ficus carica L.): Drying kinetics and quality loss. International Journal of Food Science and Technology. 39(7):793-799.

Rao AV and Rao LG. 2007. Carotenoids and human health. Pharmacological Research. 55(3):207-216.

Robertson GL. 2006. Food Packaging: Principles and Practice (2nd ed). Boca

Raton (FLA) : Taylor & Francis.

Shi J, Le Maguer M, Kakuda Y, Liptay A, Niekamp F. 1999. Lycopene degradation and isomerization in tomato dehydration. Food Research International. 31 (1): 15-21.

Sandulachi E. 2012. Water activity concept and its role in food preservative. FAO Agricultural Services Buletin. 3(1):39-41.

Schlesier K, Harwat M, Bohm V, Bitsch R. 2002. Assessment of antioxidant activity by using different in vitro methods. Free Radical Research.

36:177-178.

Sies H. 1996. Antioxidants in Disease, Mechanisms and Therapy. New York:

Academic Press

Strobel M, Tinz J, Blesalski HK. 2007. The importance of β-carotene as a source of vitamin A with special regard to pregnant and breastfeeding women.

European Journal of Nutrition. 40(1):1-20.

Tang J, Yang T. 2004. Dehydrated vegetables: Principles and systems. Hul YH,

Chazala S, Graham DM, Murell KD, Nip WK, editors. Handbook of vegetable preservation and processing. New York (US) : Marcel Dekker. Tinrat S. 2014. Comparison of antioxidant and antimicrobial activities of unripe

and ripe fruit extracts of Momordica cohinchinensis Spreng (Gac fruit). Int. J. Pharm. Sci. Rev.Res. 28 (1):75-82.

Tinrat S, Akkarachaneeyakorn S, Singhapol C. 2014. Evaluation of antioxidant and antimicrobial activities of MomordicacochinchinensisSpreng (gac fruit) ethanolic extract. J.International of Pharmaceutical Sciences and Research.

5(8):3163-3169.

Tran TH. 2007. Producing Carotenoid-rich Powder from Gac Fruit [thesis]. Sydney (AU) : University of Western Sydney.

Tran TH, Nguyen MH, Zabaras D, Vu LTT. 2008. Process development of Gac powder by using different enzymes and dying techniques. Journal of Food Engineering. 85:359-365.

Tuyen CK. 2010. Effects of Different Drying Processes on the Physicochemical and Antioxidant Properties of Gac Fruit Powder [thesis]. Newcastle (AU): The University of Newcastle Australia

[UNPA] United Natural Products Alliance. 2013. Shelf life recommendation for

supplements guidelines for manufacturers.

https://unpa.com/assets/news_resource/asset/5/Shelf_life_recommendations

24

Verma LR and Joshi VK. 2000. Postharvest Technology of Fruits and Vegetables : Handling, Processing, Fermentation and Waste Management. New Delhi : Indus Publishing Company.

Vuong LT, Ducker SR and Murphy SP. 2002. Plasma beta-carotene and retinol concentration of children increase after a 30-d supplementation with the fruit Momordica cochinchinensis (gac). American Journal of Clinical Nutrition. 75:872-879.

Vuong LT and King JC. 2003. A method of preserving and testing the acceptability of Gac fruit oil, a good source of beta-carotene and essential fatty acids. Food and Nutrition Bulletin. 24

Vuong LT, Burke DS and Schmidt CR. 2005. Momordica cochinchinensis, Rosa Roxburghii, wolfberry, and sea buckthorn-highly nutritional fruits supported by tradition and science. 2005. Current Topics in Nutraceutical Research.

3(4):259-266.

Wang N and Brennan JC. 1995. Changes in structure, density and porosity of potato during dehydration. Journal of Food Engineering. 24(1):61-76.

Widyastuti N. 2009. Pengukuran Aktivitas Antioksidan dengan Metode CUPRAC, DPPH, dan FRAP serta Korelasinya dengan Fenol dan Flavonoid pada Enam Tanaman [Thesis]. Bogor (ID): Institut Pertanian Bogor

25

APPENDICES

Appendix 1 Stastical analysis of moisture content of dried gac powder

Descriptive Statistics

Dependent Variable: Mc

pre_treatment fruit_parts temperature Mean Std. Deviation N

26

Appendix 1a Annova of moisture content of dried gac powder Tests of Between-Subjects Effects

Appendix 1b Duncan‟s Multiple Ranged Test of moisture content of dried gac powder

Means for groups in homogeneous subsets are

displayed.

Based on observed means.

The error term is Mean Square(Error) = .081.

a. Uses Harmonic Mean Sample Size = 3.000.

27 Appendix 2 Stastical analysis of water activity of dried gac powder

Descriptive Statistics

Dependent Variable: aw

pre_treatment fruit_parts temperature Mean Std. Deviation N

28

Appendix 2a Annova of water activity of dried gac powder Tests of Between-Subjects Effects

Appendix 2b Duncan‟s Multiple Ranged Test of water activity of dried gac powder

Means for groups in homogeneous subsets are displayed.

Based on observed means.

The error term is Mean Square(Error) = .001.

a. Uses Harmonic Mean Sample Size = 3.000.

29

Appendix 3 Stastical analysis of bulk density of dried gac powder

Descriptive Statistics

Dependent Variable: BD

pre_treatment fruit_parts temperature Mean Std. Deviation N

30

Appendix 3a Annova of bulk density of dried gac powder

Tests of Between-Subjects Effects

Appendix 3b Duncan‟s Multiple Ranged Test of bulk density of dried gac powder

Duncan

Means for groups in homogeneous subsets are displayed.

Based on observed means.

The error term is Mean Square(Error) = .001.

a. Uses Harmonic Mean Sample Size = 3.000.

31 Appendix 4 Stastical analysis of WSI (Water Solubility Index) of Gac fruit

powder

Descriptive Statistics

Dependent Variable: WSI

pre_treatment fruit_parts temperature Mean Std. Deviation N

32

Appendix 4a Annova of water solubility index of dried gac powder Tests of Between-Subjects Effects

Intercept 14076.465 1 14076.465 3720.381 .000

pre_treatment 80.975 1 80.975 21.402 .000

fruit_parts 2541.076 1 2541.076 671.601 .000

temperature 157.998 1 157.998 41.759 .000

pre_treatment * fruit_parts 67.718 1 67.718 17.898 .001

pre_treatment * temperature 22.157 1 22.157 5.856 .028

fruit_parts * temperature 213.932 1 213.932 56.542 .000

pre_treatment * fruit_parts *

temperature 16.858 1 16.858 4.456 .051

Error 60.538 16 3.784

Total 17237.719 24

Corrected Total 3161.253 23

a. R Squared = .981 (Adjusted R Squared = .972)

Appendix 4b Duncan‟s Multiple Ranged Test of water solubility index of dried gac powder

Means for groups in homogeneous subsets are displayed.

Based on observed means.

The error term is Mean Square(Error) = 3.784.

a. Uses Harmonic Mean Sample Size = 3.000.

33

Appendix 5 Stastical analysis of L* (lightness) of Gac fruit powder

Descriptive Statistics

Dependent Variable: L

pre_treatment fruit_parts temperature Mean Std. Deviation N

34

Appendix 5a Annova of lightness of dried gac powder Tests of Between-Subjects Effects

Intercept 46412.095 1 46412.095 6036.659 .000

pre_treatment 385.361 1 385.361 50.123 .000

fruit_parts 4933.821 1 4933.821 641.725 .000

temperature 138.672 1 138.672 18.037 .001

pre_treatment * fruit_parts 196.368 1 196.368 25.541 .000

pre_treatment * temperature 5.444 1 5.444 .708 .413

fruit_parts * temperature 279.962 1 279.962 36.414 .000

pre_treatment * fruit_parts *

temperature 730.076 1 730.076 94.958 .000

Error 123.014 16 7.688

Total 53204.811 24

Corrected Total 6792.717 23

a. R Squared = .982 (Adjusted R Squared = .974)

Appendix 5b Duncan‟s Multiple Ranged Test of lightness of dried gac powder L

Means for groups in homogeneous subsets are displayed.

Based on observed means.

The error term is Mean Square(Error) = 7.688.

a. Uses Harmonic Mean Sample Size = 3.000.

35 Appendix 6 Stastical analysis of a* (redness) of Gac fruit powder

Descriptive Statistics

Dependent Variable: a

pre_treatment fruit_parts temperature Mean Std. Deviation N

36

Appendix 6a Annova of redness of dried gac powder Tests of Between-Subjects Effects

Corrected Total 828.321 23

a. R Squared = .991 (Adjusted R Squared = .987)

Appendix 6b Duncan‟s Multiple Ranged Test of redness of dried gac powder

a

Means for groups in homogeneous subsets are displayed.

Based on observed means.

The error term is Mean Square(Error) = .453.

a. Uses Harmonic Mean Sample Size = 3.000.

37 Appendix 7 Stastical analysis of b* (yellowness) of Gac fruit powder

Descriptive Statistics

Dependent Variable: b

pre_treatment fruit_parts temperature Mean Std. Deviation N

38

Appendix 7a Annova of yellowness of dried gac powder Tests of Between-Subjects Effects

Intercept 24234.793 1 24234.793 4840.819 .000

pre_treatment 43.336 1 43.336 8.656 .010

fruit_parts 516.803 1 516.803 103.230 .000

temperature 3.046 1 3.046 .608 .447

pre_treatment * fruit_parts 24.584 1 24.584 4.910 .042

pre_treatment * temperature 14.711 1 14.711 2.938 .106

fruit_parts * temperature .015 1 .015 .003 .958

pre_treatment * fruit_parts *

temperature 1.097 1 1.097 .219 .646

Error 80.101 16 5.006

Total 24918.485 24

Corrected Total 683.692 23

a. R Squared = .883 (Adjusted R Squared = .832)

Appendix 7b Duncan‟s Multiple Ranged Test of yellowness of dried gac powder b

Means for groups in homogeneous subsets are displayed.

Based on observed means.

The error term is Mean Square(Error) = 3.600.

a. Uses Harmonic Mean Sample Size = 3.000.

39

40

Appendix 8a Stastical analysis of TPC of Gac fruit powder

Descriptive Statistics

Dependent Variable: TPC

pre_treatment fruit_parts temperature Mean Std. Deviation N

41

Appendix 8b Annova of TPC of dried gac powder

Tests of Between-Subjects Effects

Dependent Variable: TPC

Source Type III Sum of

Squares

df Mean Square F Sig.

Corrected Model 537132.015a 7 76733.145 387.154 .000

Intercept 1357243.501 1 1357243.501 6847.924 .000

pre_treatment 11955.038 1 11955.038 60.319 .000

fruit_parts 424538.660 1 424538.660 2141.995 .000

temperature 60333.462 1 60333.462 304.410 .000

pre_treatment * fruit_parts 1683.543 1 1683.543 8.494 .010

pre_treatment * temperature 436.310 1 436.310 2.201 .157

fruit_parts * temperature 37974.784 1 37974.784 191.600 .000

pre_treatment * fruit_parts *

temperature 210.219 1 210.219 1.061 .318

Error 3171.165 16 198.198

Total 1897546.681 24

Corrected Total 540303.180 23

a. R Squared = .994 (Adjusted R Squared = .992)

Appendix 8c Duncan‟s Multiple Ranged Test of TPC of dried gac powder TPC

Means for groups in homogeneous subsets are displayed.

Based on observed means.

The error term is Mean Square(Error) = 198.198.

42

b. Alpha = .05.

43

Appendix 9a Stastical analysis of TCC of Gac fruit powder Descriptive Statistics

Dependent Variable: TCC

pre_treatment fruit_parts temperature Mean Std. Deviation N

44

Appendix 9b Annova of total carotenoid content of dried gac powder Tests of Between-Subjects Effects

Intercept 84181.455 1 84181.455 3344.244 .000

pre_treatment 1348.176 1 1348.176 53.558 .000

fruit_parts 3793.708 1 3793.708 150.711 .000

temperature 1510.807 1 1510.807 60.019 .000

pre_treatment * fruit_parts 273.101 1 273.101 10.849 .005

pre_treatment * temperature 41.344 1 41.344 1.642 .218

fruit_parts * temperature 802.383 1 802.383 31.876 .000

pre_treatment * fruit_parts *

temperature 154.698 1 154.698 6.146 .025

Error 402.753 16 25.172

Total 92508.425 24

Corrected Total 8326.970 23

a. R Squared = .952 (Adjusted R Squared = .930)

Appendix 9c Duncan‟s Multiple Ranged Test of total carotenoid content of dried

gac powder

Means for groups in homogeneous subsets are displayed.

Based on observed means.

The error term is Mean Square(Error) = 25.172.

a. Uses Harmonic Mean Sample Size = 3.000.

45

46

Appendix 10a Stastical analysis of DPPH of Gac fruit powder

Descriptive Statistics

Dependent Variable: DPPH

pre_treatment fruit_parts temperature Mean Std. Deviation N

47

Appendix 10b Annova of DPPH of dried gac powder Tests of Between-Subjects Effects

Intercept 23324.512 1 23324.512 11581.763 .000

pre_treatment 1339.371 1 1339.371 665.063 .000

fruit_parts 82.919 1 82.919 41.173 .000

temperature 232.068 1 232.068 115.233 .000

pre_treatment * fruit_parts 193.859 1 193.859 96.260 .000

pre_treatment * temperature .343 1 .343 .170 .685

Corrected Total 1983.104 23

a. R Squared = .984 (Adjusted R Squared = .977)

Appendix 10c Duncan‟s Multiple Ranged Test of DPPH of dried gac powder

DPPH

Means for groups in homogeneous subsets are displayed.

Based on observed means.

The error term is Mean Square(Error) = 2.014.

48

b. Alpha = .05.

49 Appendix 11a Stastical analysis of FRAP of Gac fruit powder

Descriptive Statistics

Dependent Variable: FRAP

pre_treatment fruit_parts temperature Mean Std. Deviation N

50

Appendix 11b Annova of FRAP of dried gac powder Tests of Between-Subjects Effects

Intercept 23324.512 1 23324.512 11581.763 .000

pre_treatment 1339.371 1 1339.371 665.063 .000

fruit_parts 82.919 1 82.919 41.173 .000

temperature 232.068 1 232.068 115.233 .000

pre_treatment * fruit_parts 193.859 1 193.859 96.260 .000

pre_treatment * temperature .343 1 .343 .170 .685

Corrected Total 1983.104 23

a. R Squared = .984 (Adjusted R Squared = .977)

Appendix 11c Duncan‟s Multiple Ranged Test of FRAP of dried gac powder

FRAP

Means for groups in homogeneous subsets are displayed.

The error term is Mean Square(Error) = 632.360.

a. Uses Harmonic Mean Sample Size = 3.000.

51

AUTHOR BIOGRAPHY

The author‟s full name is Aldila Setiawati. She was born on 2nd October 1993 in Cirebon, West Java, Indonesia. She is the third daughter with two elders brothers from Mr. Edhy Putranto Sirjoso and Mrs. Sri Puji Yuliati. She was graduated from Saint Mary Catholic School Cirebon elementary school in 2005, SMPN 2 Cirebon junior high school in 2008 and SMAN 1 Cirebon senior high school in 2011. In 2011, the author continued her further study in Bogor Agricultural University as a Food Science and Technology student in the Faculty of Agricultural and Technology through Seleksi Nasional Masuk Perguruan TInggi Negeri (SNMPTN) Undangan.

The author involved in student activities while going through the study. She was the member of IAAS LC IPB (International Student in Agricultural and Related Sciences Local Committee IPB) as HRD (Human Resource Department) staff. She was secretary of Keluarga Mahasiswa Katholik IPB (KeMaKI) for two years. She also involved in some of the activities presented by HIMITEPA and Badan Eksekutif Mahasiswa (BEM) of Faculty of Agricultural Engineering and Technology. She also involved as actress of Teater Merah, theater club of FATETA. She also taught Senior High School Students as private teacher. The author also involved in anti-bullying program called We Are Siblings as a founder.

At last, the author was selected to be one of the Indonesian Delegates for the ASEAN International Mobility for Student (AIMS) program to Mae Fah Luang University (MFU) for one term. During this program, she did an undergraduate

research project entitled “Effect of Pre-Treatment and Drying Temperature on

Properties of Gac Powder”, supervised by Dr. Adil Basuki Ahza and Dr.