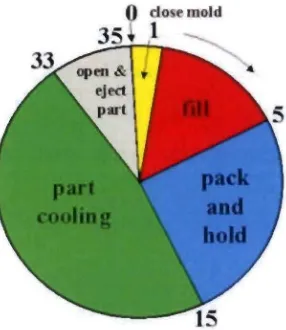

Design and simulation of cooling channel for plastic injection moulding.

Teks penuh

Gambar

Dokumen terkait

This report submitted in accordance with requirement of the Universiti Teknikal Malaysia Melaka (UTeM) for the Bachelor Degree of Manufacturing Engineering..

DEVELOPMENT OF FIBER OPTIC SENSOR FOR WATER LEVEL MEASUREMENT USING FIBER OPTIC APPLICATION.. This report is submitted in accordance with the requirement of the Universiti Teknikal

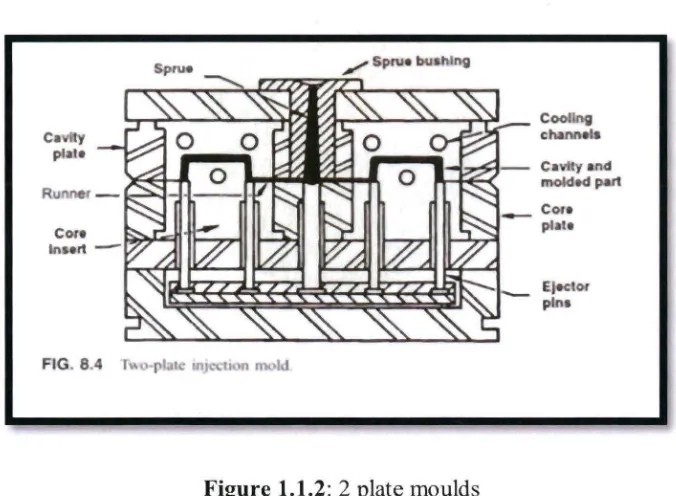

Therefore, to understand the reasons how the defects occur during injection moulding process, the image of flow pattern of molten polymer flow in mould cavity

TITLE: EFFECT OF ASSEMBLY LINE AND NORMAL WORKING ENVIRONMENT TO CYCLE TIME.. This report submitted in accordance with requirement of the

Fatigue Life Prediction Model for Fiber Reinforced Polymer Composites.. This report submitted in accordance with requirement of Universiti Teknikal Malaysia Melaka (UTeM) for

DEVELOPMENT OF PROTOTYPE SUGAR CANE JUICE EXTRACTION MACHINE (MECHANICAL).. This report is submitted in accordance with requirement of the Universiti Teknikal Malaysia Melaka

ANALYSIS OF QUALITY PRODUCT BY USING QFD METHOD AND SATISFACTION CRITERIA ON CONSUMER PRODUCT.. This report submitted in accordance with requirement of the Universiti

This report submitted in accordance with requirement of the Universiti Teknikal Malaysia Melaka (UTeM) for the Bachelor Degree of Manufacturing Engineering.. (Manufacturing