STUDY TECHNIQUE AT AEROSPACE MANUFACTURING COMPANY ( E-MOST)

TAUFIQ BIN ALIAS

This report is submitted in partial fulfilment of the requirements for the Bachelor of Computer Science (Media Interactive)

FACULTY OF INFORMATION AND COMMUNICATION TECHNOLOGY UNIVERSITI TEKNIKAL MALAYSIA MELAKA

ii

DEDICATION

DECLARATION

I hereby declare that this project report entitled

SIMULATION SYSTEM ON PRODUCTIVITY USING SMARTMOST WORK

STUDY TECHNIQUE AT AEROSPACE MANUFACTURING COMPANY

( E-MOST)

is written by me and is my own effort and no part has been plagiarized without citations.

STUDENT : TAUFIQ BIN ALIAS

iii

ACKNOWLEDGEMENT

First and foremost, I would like to thank my parents for their unconditional love, encouragement, and motivated me to complete this project.

I would like to thanks to my supervisor, Prof. Madya Dr. Sazilah Binti Salam who has always been there to guide me throughout the project. She had given me moral supports and also gives me ideas to incorporate to my project. Words could not describe how thankful I am to have a great supervisor who believes in me.

ABSTRACT

v

ABSTRAK

TABLE OF CONTENTS

CHAPTER SUBJECT PAGE

DECLARATION i

DEDICATION ii

ACKNOWLEDGEMENTS iii

ABSTRACT iv

ABSTRAK v

TABLE OF CONTENTS vi

LIST OF TABLES xi

LIST OF FIGURES xiii

LIST OF ABBREVIATIONS xvii

LIST OF APPENDIX xviii

CHAPTER I INTRODUCTION

1.1 Project Background 1

1.2 Problem Statements 2

1.3 Objectives 3

1.4 Research Question 4

1.5 Scope 4

1.6 Project Significant 5

1.7 Expected Output 5

1.8 Project Framework 6

vii

CHAPTER II LITERATURE REVIEW

2.1 Introduction 8

2.2 Domain 9

2.3 Existing System 9

2.3.1 Maynard Operation Sequence

Techniques (MOST) 10

2.3.2 Sequence Models of Basic MOST 12 2.3.3 Productivity Using SMARTMOST

Work Study Technique at Aerospace Manufacturing

Company 14

2.3.4 Data Collection 14

2.3.5 SmartMOST Template 15 2.3.6 Data Entry Interface 16 2.3.7 Data Store Interface 21

2.3.8 Summary Interface 24

2.3.9 Histogram Output Interface 25 2.3.10 Pareto Diagram Interface 26 2.3.11 User Manual Interface 27 2.4 Interactive Simulation Systems 27 2.4.1 Definition of Simulation 27 2.4.2 Definition of System 28 2.4.3 Interactive Language Learning

on the Web 29

2.5 Project Requirement 40

CHAPTER III METHODOLOGY

3.1 Introduction 43

3.2 Research Activities 43

3.2.1 Data Gathering/Collection 44 3.2.1 Analysis of the data 44 3.3 Product Development Methodology 45

3.4 Gantt Chart /Mile Stone 47

3.5 Conclusion 49

CHAPTER IV ANALYSIS

4.1 Introduction 50

4.2 Current Scenario Analysis 50

4.3 Requirement Analysis 51

4.3.1 Project Requirement 52 4.3.1.1 Need Analysis 53 4.3.1.2 User Analysis 62

4.3.2 Data Requirement 64

4.3.3 Functional Requirement 64 4.3.4 Functional Requirement 76

4.4 Software Requirement 77

4.5 Hardware Requirement 80

4.6 Network Requirement 81

4.7 Conclusion 81

CHAPTER V DESIGN AND IMPLEMENTATION

ix

5.2 High Level Design 83

5.2.1 System architecture 83

5.2.2 Sequence Diagram 85

5.2.3 Navigational Design 88 5.2.4 Input Design and Validation 89

5.2.5 Interface Design 92

5.2.6 Output Design 93

5.3 Implementation 95

5.3.1 Software Development

Environment Setup 95

5.3.2 Server Hardware Configuration 96 5.3.3 Client Hardware Configuration 97 5.3.4 System Interface of eMOST 97 5.3.5 Product Configuration Management 98 5.3.6 Configuration Environment Setup 99 5.3.7 Implementation Status 104

5.4 Conclusion 107

5.4 Conclusion 95

REFERENCES 96

APPENDICES

Appendix A: Gantt Chart 97

Appendix B: ERD Diagram 101

LIST OF TABLES

TABLE TITLE PAGE

2.1 General Move Sequence model (Zandin, 2004) 13

2.2 Types of Input in the Data Entry Interface 17

2.3 Data Entry Analysis. 19

2.4 Data Store Dictionary 23

2.5 Design Process and Evaluation 35

2.6 Optimizing the User Experience 35

2.7 Accessibility 36

2.8 Hardware and Software 36

2.9 Page Layout 37

2.10 Navigation 37

2.11 Scrolling and Paging 38

2.12 Headings, Titles, and Labels 38

2.13 Links 38

2.14 Text Appearance 39

2.14 Software requirement 40

2.15 Hardware requirement 41

2.16 Milestones 42

5.1 Input Design and Validation for login page 89

5.2 Input Design and Validation for activity record base

on MOST index table 90

5.3 Input Design and Validation new activity 90

xi

5.5 Input Design and Validation new activity task 91

5.5 Input Design and Validation new activity task 91

5.6 Interface Design of the eMOST System for

The main process 92

5.7 Hardware Configuration for Server

(Personal Computer/Laptop) 96

5.8 Hardware Configuration for Client

(Personal Computer / Laptop) 97

5.9 MySQL Server Configuration 104

FIGURE TITLE PAGE

1.1 The Project Framework using System

Development Life Cycle (SDLC) 6

2.1 Data Entry of SmartMOST Template 17

2.2 Data Entry of SmartMOST Template 19

2.3 Data Store of SmartMOST Template 23

2.4 Summary of SmartMOST Template 24

2.5 Histogram chart of SmartMOST Template 25

2.6 Pareto Diagram of SmartMOST Template 26

2.9 Homepage 36

3.1 System Diagram Life Cylce 45

5.1 3-Tier Architecture 83

5.2 Sequence Diagram for Admin Login 85

5.3 Sequence Diagram for Admin Search

Users Data 86

5.4 Sequence Diagram for Staff adding

the activity task by MOST 87

5.5 Navigation Design of the eMOST System 88

5.6 Interface Design of the eMOST System

for the main process 92

5.6 Description of the interface design

5.8 Interface Design of the eMOST System

xiii

5.9 Interface Design of the eMOST System

for the main processs 94

5.10 Interface Design of the eMOST System

for the main process 94

5.11 System Environment Setup 95

5.12 Main Menu Interface 98

5.13 XAMPP setup for Windows 99

5.14 Installation Progress 100

5.15 XAMPP Control Panel Application 101

5.16 Apache, MySQL, and Mercury is running 101

5.17 MySQL database icon in main menu of Cpanel 103

5.18 Create the database 103

CHAPTER 1

INTRODUCTION

1.1 Project Background

This is a system that is proposing a simulation system applying the concept of using Work Study Technique called Maynard Operation sequence Technique (MOST) for aerospace manufacturing company. This project is a sub project for RAGS project entitled Formulation of Mathematical Model for Man-Machine Configuration Work Study in Electronic Manufacturing headed by Puan Rohana bnti Abdullah,Faculty of Manufacturing Engineering (FKP) UteM.

The literature review will include the work study technique, web based user interface design, simulation system technique, the user friendly system and the interactivity of the system. At the end of this project, a web based prototype is expected to be able to be used for data entry, simulate the manufacturing process based on data, display related graph, and generate the statistic and conclusion for the optimization process.

The methodology on this system development process is using System Development Life Cycle Water fall Model. By using this methodology it will assist the system development process phase by phase. The expected outcomes are achieving the objective of the system need and use by company to change their manual system to the intelligent system.

1.2 Problem Statement

1. Spend a lot of time to collect the data.

The manual and data record is on manual process and need a long time to overcome the proces. For the current process situation the staff need to prepared all the data and from the problem process area. So that it take a time to entry the data manually on the Microsoft Excel.

2. No automated system

There is no automated system to identify the waste contribution in production line from the manual system into the automated system. The staff need to configured all the calculation in each of process. So that the staff need to make the formula for many time and it is hard to create a template because of the factor of the capability of the the software is not support to perform the task efficiently.

and need to use the human work energy to solve. In this part, the view of point it taking serously about the automated data to make a summary as result all of the time process need to perform manually. It need to find the solution how to generate the summary effiently and comprehensive to simulate the data automatically.

1.3 Objectives

The objectives go in this paragraph. This section discusses the objectives of the project. Can be in point form format (use bullets) together with a brief explanation.

1. To investigate the user friendly automated simulation system to perform Work Study Technique that is Maynard Operation sequence Technique (MOST) at aerospace manufacturing company.

2. To develop the web application that is will help company to identify the waste contribution in production line from the manual system into the automated system

3. To evaluate the usability of the web based simulation system.

1.4 Research Question

a) How to organize the data to ease the staff to study the system

b) What the easier method to create the calculation of time for each activity involve

c) How make the easiest way for staff to plan and simulate the process

1.5 Scopes

The scopes of the project are divided by two the system and user:

1. System

- Recieving index by user

- Generate the result

- Report and Chart comparison

2. User

- Human Resourse Staff Department

1.6 Project Significance

1. This project is a product that will be used in manufactring company in order to use the manual system to run the activity to overcome the process.

2. This project will simulatethe Work Study Technique that is Maynard Operation sequence Technique (MOST) at aerospace manufacturing company.

3. This project is develop by web application to help company to identify the waste contribution in production line from the manual system into the automated system and evaluate the usability of the web based simulation system.

1.7 Expected Output

The expected output of the project are:

1. Achieve the objective of the system need

2. Use by company to change their manual system to intelligent system.

3. Will recommend to other industry to use the intelligent system to reduce the time spend in manual operation

1.8 Project Framework

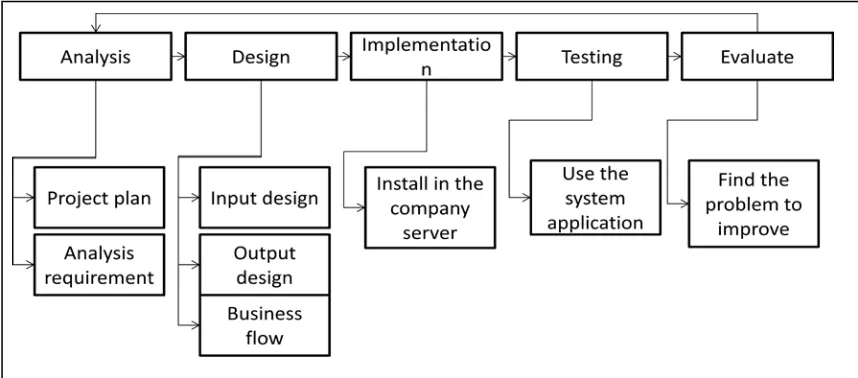

[image:21.595.127.556.238.427.2]System Development Life Cycle (SDLC)

Figure 1.1: The Project Framework using System Development Life Cycle (SDLC)

Based on the figure 1.1, the project framework is design to ensure all the system development phase is follow the aspect as show as the figure above. The figure tell us the diagram of System Development Life Cycle (SDLC) that show the flow of the project development

1.9 Conclusion

The conclusion is the current system is not apply the interactivve method that will help user to perform the tas effectively. It is hard to use and need to make an improvement in aspects that help to develop the efficient and dinamic system. The system that need to develop is need to fulfil the dinamic system to provide the dinamic vew to see the difference of activity rocess improvement.

CHAPTER 2

LITERATURE REVIEW

2.1 Introduction

In the first chapter of this study was described about the background that consists of objectives, problem statement and outline of the study. In this chapter mainly discussed about the references review. Generally, this chapter contains of literature review that based on the operation, principle and mechanism that related to the work study technique which consist of method study and work measurement. To ensure the system is in user friendly environment, some research about the simulation system and interactively of the system based on interface and programming. Some of the previous research and studies were include into to this chapter to support of the development of the ideas for Predetermined Time study. This chapter also explain about the Mynard Operation Sequences Technique (MOST).

2.2 Domain

The domain for this project is web application. Web application is web based system that runs on browser to perform the task. As the client requirements the system need to be used by more than one pc and it need to locate the system on server to make it perform through the network.

Web application not use the internet connection because of the architecture of the system only around of the intranet area. Only user in the same area network can use the system and it is applicable with the user requirement.

2.3 Existing System

To develop this project, the research is based on the existing system; Productivity Using SMARTMOST Work Study Technique at Aerospace Manufacturing Company that needs the improvement to enhance the ability of the system based on the objective of the system development. The next sub topic is discuss what the SMARTMOST Work Study Technique is, and how it is implement in manufacturing industry and how the current system is running.