EFFECTS OF CPPU AND CoSO

4ON POSTHARVEST

QUALITY OF MANGOSTEEN FRUIT (G

arcinia mangostana

L.)

DURING STORAGE

CHEA SINATH

GRADUATE SCHOOL

BOGOR AGRICULTURAL UNIVERSITY

BOGOR

DECLARATION

I declare that this thesis titled “Effects of CPPU and CoSO4 on postharvest quality

of mangosteen fruit (Garcinia mangostana L.) during storage.” was entirely

completed by myself with resourceful help from the Department of Agronomy

and Horticulture, Bogor Agricultural University. Information and quotes which

were sourced from journals and books have been acknowledged and mentioned

where in the thesis they appear. All complete references are given at the end of the

paper.

Bogor, September 2010

Chea Sinath

ABSTRACT

CHEA SINATH. A252098171. Effects of CPPU and CoSO4 on Postharvest Quality

of Mangosteen Fruit (Garcinia mangostana L.) during Storage. (Under supervision of ROEDHY POERWANTO, DARDA EFENDI, and SUTRISNO)

Mangosteen (Garcinia mangostana L.) fruit is one of the most delicious

tropical fruits, known as “queen of tropical fruit” with short shelf life during

storage. The research objective was to study the effects of CPPU and CoSO4 on

postharvest quality and physiological changes of mangosteen fruit during storage.

The experimental design was arranged in a completely randomized block design

(CRBD) with two factors, i.e., cobalt sulphate and CPPU. Postharvest treatment

with CPPU was found to be effective to promote lightness of mangosteen fruit at

day 4 and day 6, while CoSO4 tended to accelerate the darkening in both fruit and

sepal. The resistance of mangosteen fruit pericarp was considered as low (less

than 2 kgf/cm2), representing that fruit were still easily to be opened during 30

days of storage. CPPU and CoSO4 were less effective in inhibiting fruit

hardening. Titratable acidity was significantly reduced in CPPU-treated fruit at the

end of storage, while total soluble solids were not clearly affected by the

treatment. TSS/TA ratio was significantly higher in fruit treated with CPPU at the

end of storage. Respiration rate of mangosteen fruit was low and remained

constant with prolonged storage period. CPPU and/or CoSO4 could considerably

decrease the respiration rate, but less effective in inhibiting ethylene production

during storage at 14oC-16oC (78%-96% RH).

ABSTRAK

CHEA SINATH. A252098171. Pengaruh CPPU dan CoSO4 terhadap Kualitas

Pascapanen Buah Manggis (Garcinia mangostana L.) selama Penyimpanan. (Dibimbing oleh ROEDHY POERWANTO, DARDA EFENDI, dan SUTRISNO)

Buah manggis (Garcinia mangostana L.) merupakan salah satu buah

tropis yang paling lezat, yang dikenal sebagai "queen of tropical fruit" dengan

masa simpan rendah selama penyimpanan. Tujuan penelitian ini adalah untuk

mempelajari pengaruh CPPU dan CoSO4 terhadap kualitas pascapanen dan

perubahan fisiologis buah manggis selama penyimpanan. Rancangan percobaan

menggunakan rancangan acak kelompok lengkap (RAKL) dengan dua faktor,

yaitu, kobalt sulfat dan CPPU. Perlakuan pascapanen dengan CPPU ditemukan

efektif untuk mempromosikan kecerahan buah manggis pada hari ke 4 dan 6,

sedangkan CoSO4 cenderung mempercepat gelap baik pada buah atau sepal.

Resistensi pericarp buah manggis dianggap rendah (kurang dari 2 kgf/cm2),

menunjukkan bahwa buah masih mudah untuk dibuka selama 30 hari

penyimpanan. CPPU dan CoSO4 kurang efektif menghambat pengerasan buah.

Asam tertitrasi berkurang secara signifikan dalam buah pada perlakuan degnan

CPPU di akhir penyimpanan, sedangkan total padatan terlarut tidak jelas

terpengaruh oleh pelakuan. Rasio PTT/AT secara signifikan lebih tinggi dalam

buah yang diberi perlakuan dengan CPPU di akhir penyimpanan. Laju respirasi

buah manggis masih rendah dan tetap konstan dengan periode penyimpanan yang

lama. CPPU dan / atau CoSO4 dapat menurunkan laju respirasi, tetapi kurang

efektif dalam menghambat produksi etilen selama penyimpanan pada 14 oC-16 oC

(78% -96% RH).

SUMMARY

CHEA SINATH. A252098171.

Effects of CPPU and CoSO4 on Postharvest Quality of Mangosteen Fruit (Garcinia mangostana L.) during Storage. (Under supervision of ROEDHY POERWANTO, DARDA EFENDI, and SUTRISNO)Physical, chemical and physiological changes during storage are

common phenomena occurring in all commodities. Postharvest quality is

strongly associated with those changes and depends heavily on commodity

characteristics, preharvest factor, postharvest treatment and storage

condition. Physiochemical changes of climacteric products during storage are

substantially triggered by its respiratory rate and ethylene production. Since mangosteen

fruit is climacteric fruit, postharvest attributes may be related to climacteric respiration

and ethylene production. Postharvest application of substances that can suppress

respiration and ethylene production may help prolong shelf-life of mangosteen fruit

during storage. The objective of the research was to study the effects of CPPU and CoSO4

on postharvest quality and physiological changes of mangosteen fruit during storage.

The research was done at Postharvest Laboratory, Faculty of Agriculture,

Laboratory of Food and Agricultural Product Process Engineering, Laboratory of

Environmental and Agricultural Building, Faculty of Agricultural Technology, Bogor

Agricultural University (IPB), starting from February to May 2010. The research was

divided into two stages. The first experiment covered physical and chemical changes of

mangosteen fruit treated with CPPU and CoSO4 during storage, while the second one

involved the study of physiological and its relation to color development of mangosteen

fruit treated with CPPU and CoSO4 during storage. The experimental design was

arranged in a completely randomized block design with 2 factors and 3 replications. The

first factor was cobalt sulphate (CoSO4) at four concentrations 0, 500, 1000, and 2000

ppm, while the second one was CPPU at four concentrations 0, 10, 20, and 30 ppm. The

combination of the above factors provided 16 treatments with 48 experimental units. Each

experimental unit comprised 40 mangosteen fruit. For the second experiment, the design

was as in the first experiment, but only cobalt sulphate at 0, 2000 ppm, and CPPU at 0, 30

ppm were used with 5 mangosteen fruit per experimental unit. The fruits used in the

on the same day and were of similar sizes. The harvested fruit were transported at night to

laboratory. In the following morning, the fruit were sorted, and washed with tap water to

remove the dust. After washing, the fruit were air dried, and then treated with solution of

fungicide TBZ 1 ppm for 30 seconds and air dried. Following fungicide application,

air-dried fruit were dipped in the solution of CoSO4 and CPPU for 30 seconds according to

its concentrations used in the treatments. To facilitate the absorption of the solution by

fruit, tween20 (1%) was added. After application, treated fruits were air dried, then stored

at 14-16oC (76-96% RH).

Fruit resistance (FR), pericarp water content (PWC), fruit and sepal color, weight

loss (WL), total soluble solids (TSS), and titratable acidity (TA) were measured every

two days in the experiment one. Respiration rate was measured every 3 hours on the first

day, followed by 6 hours in the second day, 12 hours, and 24 hours in the following days

up to day 27. Ethylene production was measured every day up to storage day 12.

Analysis of variance was done using SPSS statistics 17.0 and treatment means were compared using Duncan‟s Multiple Range Test (DMRT) at P<0.05.

The results showed that Postharvest treatment with CPPU was found to be effective

to promote lightness of mangosteen fruit at day 4 and day 6, while CoSO4 tended to

accelerate the darkening in both fruit and sepal. The resistance of mangosteen fruit was

considered as low (less than 2 kgf/cm2), representing that fruit were still easily to be

opened during 30 days of storage. CPPU and CoSO4 were less effective in inhibiting fruit

hardening. Titratable acidity was significantly reduced in CPPU-treated fruit at the end of

storage, while total soluble solids were not clearly affected by the treatment. TSS/TA

ratio was significantly higher in fruit treated with CPPU at the end of storage. Respiration

rate of mangosteen fruit was low and remained constant with prolonged storage period.

CPPU and/or CoSO4 could considerably decrease the respiration rate, but less effective in

inhibiting ethylene production during storage at 14-16oC (78%-96% RH).

In conclusion, Postharvest treatments of either CPPU or CoSO4 were found to have

low effectiveness on the component of postharvest quality of mangosteen fruit although

sporadic significances were observed among observed times. Mangosteen fruit is a

climacteric fruit with high ethylene production after harvest. However, no clear peak of

respiration was observed during cold storage. Fruit color changes were closely associated

with ethylene production.

Keywords: Climacteric fruit, shelf life, color development, ethylene production,

© Copyright of IPB, year 2010

Copyright reserved

1. Forbidden to quote part or all of these writings without including or

mentioning the source.

a. Be cited only for educational purposes, research, writing papers,

drafting reports, writing criticism or review an issue;

b. Quotation must not harm the affairs of IPB.

2. Prohibit publication and reproduction of part or all of the paper in any

EFFECTS OF CPPU AND CoSO

4ON POSTHARVEST

QUALITY OF MANGOSTEEN FRUIT (G

arcinia mangostana

L.)

DURING STORAGE

CHEA SINATH

A Thesis

As Partial fulfillment of the Requirement to obtain

Master of Science Degree in Agronomy and Horticulture

GRADUATE SCHOOL

BOGOR AGRICULTURAL UNIVERSITY BOGOR

Title : Effects of CPPU and CoSO4 on Postharvest Quality of

Mangosteen Fruit (Garcinia mangostana L.) during

Storage.

Name : Chea Sinath

Registration Number : A252098171

Major : Master of Science in Agronomy and Horticulture

Approved:

Advisory Committee

Prof. Dr. Ir. Roedhy Poerwanto, M.Sc

(Chairman)

Dr. Ir. Darda Efendi, M.Si Dr. Ir. Sutrisno. M.Agr

(Member) (Member)

Agreed:

Graduate Coordinator of Major Dean of Graduate School

Dr. Ir. Munif Ghulamahdi, MS Prof. Dr. Ir. Khairil Anwar Notodiputro, MS

ACKNOWLEDGEMENT

My study and thesis research would not have been accomplished without the

help of many people.

Special thanks to Prof. Dr. Ir. Roedhy Poerwanto, MSc, Dr. Ir. Darda

Efendi, MSi, and Dr. Ir. Sutrisno, M.Agr, as supervisory committee, for all of

guidance and encouragement as well as invaluable academic advices for the whole

period of my study and research at IPB.

Special thanks also are to be given to the Department of Agronomy and

Horticulture and Department of Agricultural Technology for the full support given

to enable the successful completion of this research. I am very grateful to all the

invaluable lecturing staff as well as lab and technical staff of Agronomy and

Horticulture Department who have imparted knowledge and help.

Extended thanks are expressed to all fellow students of Agronomy and

Horticulture Department and KNB Scholarship. Of these fellows, I would like to

express my deepest thanks to close friends Sanou Faye, Dahono and Herman who

always providing a helping hand and good advices. I wholeheartedly thank to

research team of mangosteen fruit postharvest such as Ismadi, Mesil, and Hatifah,

who made my master research a great experience of team working.

Further, I am highly indebted to my affectionate parents, brother (Na

Bunnan), sisters (Na Dany, Na Chantha, Na Chan Thu, Chea Veasna, Chea Ratana

and Chea Phalla) and other family members who always inspire and encourage

me for higher education, and finally to Miss Bao Lian who contributes immensely

in providing psychological supports and good constructed advice during busy time

of my study and research.

The research was financially supported by Hibah Tim Pasca Sarjana, and

additional funding was provided through my study sponsor-Dikti under

Developing Countries Partnership Program.

Bogor Agricultural University, September 2010

BIOGRAPHY

Chea Sinath was born on the 2nd of March, 1981 in Takeo province to Mr

Na Cheam and Mrs Sok Kimngy from Cambodia. Chea Sinath was born the fifth

of eight children.

In 2001, he finished Senior High School from Heng Somrin Prey Lovea

High School and continued with Bachelors Degree study in Agronomy and

graduated in August 2005, from the Royal University of Agriculture. After

Bachelors level, he had worked for Cambodian Agricultural Research and

Development Institute (CARDI) as research assistant in Agronomy and Farming

systems office for a year. In 2006, he continued with higher teacher training

(Bachelor +1) at National Institute of Education and started teaching at Prek Leap

High School located in Phnom Penh since 2007. In 2008, he was awarded by the

Indonesian Government to do Masters Degree in Bogor Agricultural University,

majoring in Agronomy and Horticulture under the Developing Countries

Partnership Program (KNB – Kemitraan Negara Berkembang) with official

permission from the Cambodian Ministry of Education, Youth and Sports for a

TABLE OF CONTENTS 2.1. Mangosteen Fruit Development and Maturity Indices ... 3

2.2. Mangosteen Fruit Quality and Color Development ... 5

2.3. Causes of Mangosteen Fruit Hardening ... 6

2.4. Fruit Ripening and Senescence ... 7

2.5. Ethylene Biosynthesis and its Physiological Effects ... 9

2.6. Ethylene Action and Methods for Inhibiting Ethylene Responses ... 11

2.7. Cytokinin and its Physiological Effects ... 12

2.8. Cobalt Sulphate (CoSO4) and its Effects ... 13

III. MATERIAL AND METHODS 3.1. Time and Place ... 14

3.2. Plant Material and Treatment... 14

3.3. Observed Variables ... 15

3.3.2. Chemical Attributes... 16

3.3.2.1.Total Soluble Solids ... 16

3.3.2.2.Titratable acidity ... 16

3.3.3. Physiological Variables ... 17

3.3.3.1.Respiration Rate ... 17

3.3.3.2.Ethylene Production ... 17

3.4.Statistical Analysis ... 18

IV. RESULTS AND DISCUSSION 4.1. Physical Changes of Mangosteen Fruit during Storage ... 19

4.1.1. Fruit Resistance ... 19

4.1.2. Pericarp Water Content ... 20

4.1.3. Weight Loss ... 21

4.1.4.1.Lightness ... 22

4.1.4.2.a/b ratio ... 24

4.1.4.3.Hue angle (ho) ... 25

4.1.5. Sepal Color ... 26

4.1.5.1.Lightness ... 26

4.1.5.2.a/b ratio and Hue angle ... 27

4.1.6. Visual Observation ... 30

4.2. Chemical Changes of Mangosteen Fruit during Storage ... 31

4.2.1. Total Soluble Solids (oBrix) ... 31

4.2.2. Titratable Acidity (%) ... 32

4.2.3. TSS/TA ratio ... 34

4.3. Physiological Changes and its Relation to Color Development ... 35

4.3.1. Respiration Rate of Mangosteen Fruit ... 35

4.3.2. Ethylene Production of Mangosteen Fruit ... 37

4.3.3. Lightness and Hue angle of Mangosteen Fruit ... 38

V. CONCLUSIONS AND SUGGESTION ... 40

REFERENCES ... 41

LIST OF TABLES

Page

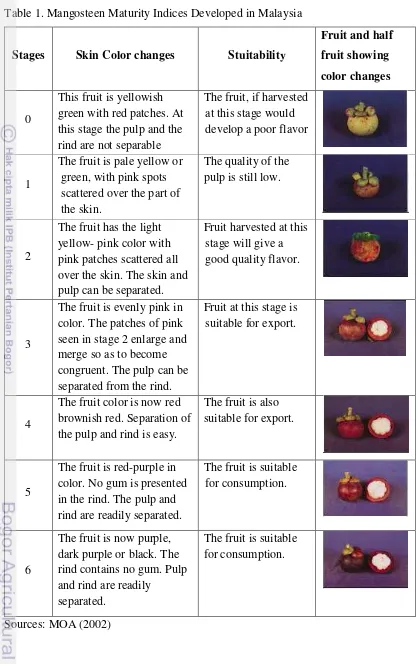

1 Harveste mangosteen maturity indices developed in Malaysia ... 4

2 Effects of CPPU and CoSO4 interaction on pericarp water content (%)

of mangosteen fruit during storage at day 18 ... 21

3 Effects of CPPU and CoSO4 interaction on a/b ratio of sepal of

mangosteen fruit during storage at day 22 and day 26 ... 29

4 Effects of CPPU and CoSO4 interaction on hue angle of sepal of

mangosteen fruit during storage at day 22 and day 26 ... 30

5 Effects of CPPU and CoSO4 interaction on TSS &TA ratio of

mangosteen fruit during storage at day 18 ... 35

6 Effects of CPPU and CoSO4 interaction on respiration rate of

mangosteen fruit during storage ... 37

LIST OF FIGURES

Page

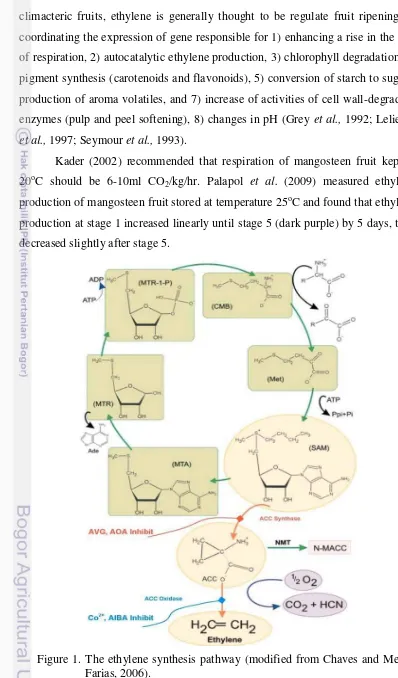

1 The ethylene synthesis pathway ... 10

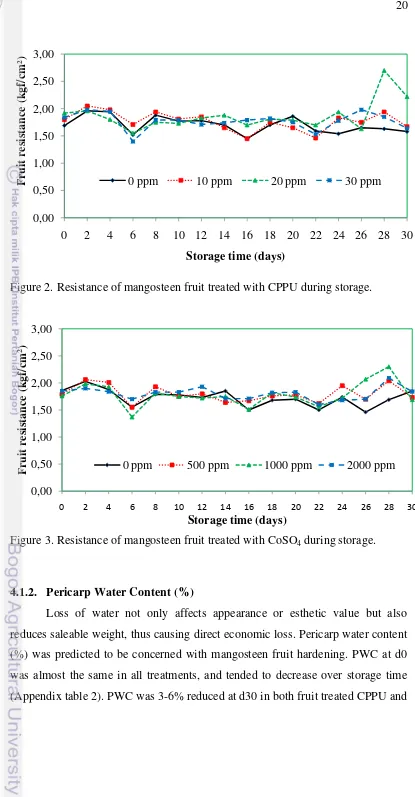

2 Resistance of mangosteen fruit treated with CPPU during storage ... 20

3 Resistance of mangosteen fruit treated with CoSO4 during storage ... 20

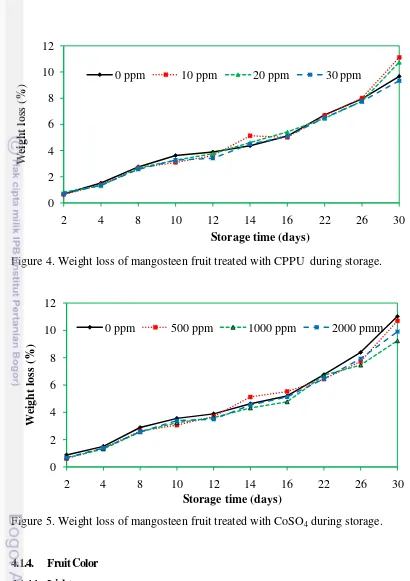

4 Weight loss of mangosteen fruit treated with CPPU during storage ... 22

5 Weight loss of mangosteen fruit treated with CoSO4 during storage ... 22

6 Changes in skin lightness of mangosteen fruit treated with CPPU during storage ... 23

7 Changes in skin lightness of mangosteen fruit treated with CoSO4 during storage ... 23

8 Changes in skin color (a/b) of mangosteen fruit treated with CPPU during storage ... 24

9 Changes in skin color (a/b) of mangosteen fruit treated with CoSO4 during storage ... 24

10 Changes in skin color (ho) of mangosteen fruit treated with CPPU during storage ... 25

11 Changes in skin color (ho) of mangosteen fruit treated with CoSO4 during storage ... 25

12 Changes in sepal color (L) of mangosteen fruit treated with CPPU during storage ... 26

13 Changes in sepal color (L) of mangosteen fruit treated with CoSO4 during storage ... 27

14 Changes in sepal color (a/b) of mangosteen fruit treated with CPPU during storage ... 27

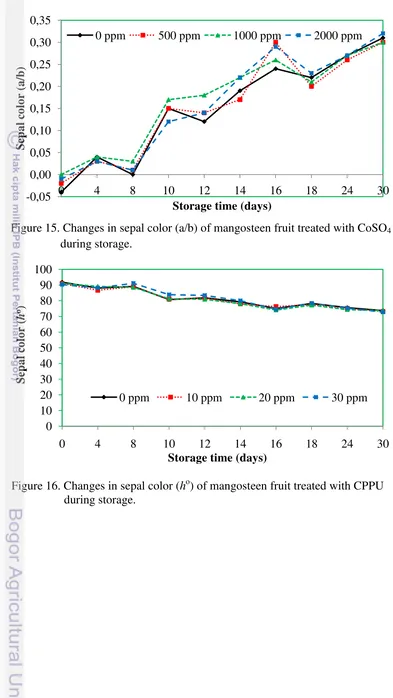

15 Changes in sepal color (a/b) of mangosteen fruit treated with CoSO4 during storage ... 28

16 Changes in sepal color (ho) of mangosteen fruit treated with CPPU during storage ... 28

17 Changes in sepal color (ho) of mangosteen fruit treated with CoSO4 during storage ... 29

18 Changes in total soluble solids of mangosteen fruit treated with CPPU

during storage ... 32

19 Changes in total soluble solids of mangosteen fruit treated with CoSO4

during storage ... 32

20 Changes in titratable acidity of mangosteen fruit treated with CPPU

during storage ... 33

21 Changes in titratable acidity of mangosteen fruit treated with CoSO4

during storage ... 33

22 Changes in TSS/TA of mangosteen fruit treated with CPPU

during storage ... 34

23 Changes in TSS/TA of mangosteen fruit treated with CoSO4

during storage ... 35

24 Respiration rate of mangosteen fruit treated with CPPU and CoSO4

during storage ... 36

25 Ethylene production of mangosteen fruit treated with CPPU and CoSO4

during storage ... 38

26 Changes in lightness of mangosteen fruit treated with CPPU and CoSO4

during storage ... 39

27 Changes in Hue angle (ho) of mangosteen fruit treated with CPPU

and CoSO4 during storage ... 39

LIST OF APPENDICES

Page

1 Effects of CPPU and CoSO4 on fruit resistance (kgf/cm2) of mangosteen

fruit during storage ... 47

2 Effects of CPPU and CoSO4 on pericarp water content (%) of

mangosteen fruit during storage ... 48

3 Effects of CPPU and CoSO4 on weight loss (%) of mangosteen fruit

during storage ... 49

4 Effects of CPPU and CoSO4 on lightness (L) of mangosteen fruit

during storage ... 50

5 Effects of CPPU and CoSO4 on a value (red-green) of mangosteen fruit

during storage ... 51

6 Effects of CPPU and CoSO4 on b value (yellow-blue) of mangosteen

fruit during storage ... 52

7 Effects of CPPU and CoSO4 on a/b value of mangosteen fruit during

storage ... 53

8 Effects of CPPU and CoSO4 on hue angle of mangosteen fruit during

storage ... 54

9 Effects of CPPU and CoSO4 on lightness (L) of sepal of

mangosteen fruit during storage ... 55

10 Effects of CPPU and CoSO4 on a value (red-green) of sepal

of mangosteen fruit during storage ... 56

11 Effects of CPPU and CoSO4 on b value (yellow-blue) of sepal

of mangosteen fruit during storage ... 57

12 Effects of CPPU and CoSO4 on a/b ratio of sepal of mangosteen fruit

during storage ... 58

13 Effects of CPPU and CoSO4 on hue angle of sepal of mangosteen fruit

during storage ... 59

14 Effects of CPPU and CoSO4 on total soluble solids (oBrix) of

mangosteen fruit during storage ... 60

15 Effects of CPPU and CoSO4 on titratable acidity (%) of mangosteen

fruit during storage ... 61

16 Effects of CPPU and CoSO4 on TSS &TA ratio of mangosteen fruit

during storage ... 62

17 Changes in respiration rate of mangosteen furit treated with CPPU

and CoSO4 during storage ... 63

18` Ethylene production of mangosteen fruit treated with CPPU and CoSO4

during storage ... 65

19 Images of mangosteen fruit treated with CPPU and CoSO4

during storage ... 66

I. INTRODUCTION

1.1 Background

Indonesia is one of the major mangosteen producers in Southeast Asia. The

production of mangosteen in 2007 was 112,722 ton with average yield of 9.42

ton/ha. Indonesia exports fresh mangosteen to China (including Hong Kong and

Taiwan), Japan, Singapore, the Netherlands, France and Saudi Arabia (Osman and

Milan, 2006). The volume of export was 9,093,245 kg in 2007 and increased to

9,465,665 kg in 2008, which valued at USD 4,951,442 and USD 5,832,534 in

2007 and 2008, respectively (Ditjen Hortikulura, 2009). Indonesian mangosteen

export is only 8.06% from the total production 112,722 ton in 2007. Many issues

are involved in low fruit quality and have resulted in a barrier for exports and low

export value, namely (i) gamboge, a physiological disorder evident by exudating

latex onto the fruit surface and aril rendering the fruit unsuitable for eating, (ii)

brown spot (burik) on the fruit skin, and (iii) short shelf life of mangosteen fruits

(pericarp hardening, color changes to dark blackish purple, and fruit calyx turns

brown within a few day).

Generally, the fruit will soften within a few days after harvested. On the

contrary, mangosteen fruit hardens and causes difficulty in opening after

prolonged storage. Mechanical injury of fruit during storage and handling of

mangosteen often causes fruit hardening (Kader, 2003). A drop of 10 cm can

cause slight pericarp damage, indicated as hardening at the point of impact within

24 h. Higher drops cause significantly greater damage and often lead to

downgrading of the fruit (Tongdee and Suwanagul, 1989; Ketsa and Atantee,

1998).

Azhar (2007) reported that optimal temperature for endurance of skin color

and calyx was 10 oC, and temperature storage less than 10 °C (50 oF) leads to

rapid hardening and darkening of pericarp when fruit are returned to ambient

temperature (Uthairatanakij and Ketsa, 1995). Storage at 4 °C (39.2 °F) or 8 °C

(46.4 °F) can lead to significant hardening of the pericarp (Augustin and Azudin,

1986), although the flesh may still be acceptable after 44 days. However, storage

of mangosteen fruit at temperature above 15 oC can also cause hardening and

treatment was more effective to inhibit pericarp hardening, and shelf-life of

mangosteen fruit could be kept as long as 20 days after treatment (Ekaputri,

2009). Changes of fruit color are one of maturity parameter. Inayati (2009) found

that fruits coated with wax, chitosan and coconut oil suspension could inhibit fruit

hardening from 14 days to 20 days.

In climacteric fruits, ethylene production at the onset of ripening controls

the changes of color, aroma, texture, flavour, and other biochemical and physical

attributes (Lelievre et al., 1997). Since mangosteen fruit is climacteric fruit

(Qanitah, 2004), postharvest quality changes may be related to climacteric

respiration and ethylene production. Co2+ is a potent inhibitor of ethylene

biosynthesis. Application of cobalt sulphate is expected to change the climacteric

respiration of mangosteen during storage. Williams and Golden (2002) found that

the enzyme ACC was inhibited by Cobalt sulphate (CoSO4). Forchlorfenuron

(CPPU) is a type of synthetic cytokinins, which is responsible for the maintenance

of chlorophyll, protein, and RNA levels. Although CPPU has been found to be

effective in improving postharvest quality of many fruits when applied at

preharvest, its direct postharvest application has not yet been reported. Therefore,

research on postharvest application of CPPU and CoSO4 needs to be conducted.

1.2 Research Objective

The objective of the research was to study the effects of CPPU and CoSO4

on postharvest quality and physiological changes of mangosteen fruit during

storage.

2. Application of CPPU can delay changes of sepal color because it can delay

chlorophyll degradation.

3. Combination of CPPU and CoSO4 can extend shelf-life of mangosteen fruit

II. LITERATURE REVIEW

2.1 Mangosteen Fruit Development and Maturity Indices

Mangosteen fruits are produced singly at the end of the branchlets, and

usually do not mature and ripen uniformly. The tree will bear coexisting

generations of fruit, resulting from successive generations of flowers. Therefore,

not all the fruits will reach maturity or ripen at the same time. Mangosteen fruits

take 5 to 6 months to mature from fruit set. Initially, fruit growth is dominated by

the pericarp, with aril dry matter not increasing until 20 days from anthesis and

then continuing throughout the fruit development. At 13 weeks the fruit shows

the highest percentages of pulp, rind, sugar and acid: 29.37%, 69.14%, 18% and

0.49%, respectively (Kanchanapom and Kanchanapom, 1998). During ripening, a

thick, clear green cortex changes to dark purple or red purple. Enclosed by the

rind are 4-8 edible white segments. The flavor is slightly acidic, but sweet

(Nakasone et al., 1998).

At present, there is no standard or uniform maturity index that is universally

used. Countries such as Malaysia, Thailand and Australia have developed their

own maturity indices for harvesting to meet various marketing purposes. For

harvesting maturity indices used by growers in Australia, fruit harvested at stage 1

with pale yellow-green color, pH 3.9, rind thickness 9.0 mm, Brix%<12, and

firmness index 7.9, and stage 2 with botchy pink color, pH 3.3, rind thickness

7.7mm, Brix%<14 and firmness index 6 are not acceptable. Fruit harvested at

stage 3 with pinkish red, pH 3.2, rind thickness 7.4mm, Brix%>16, and firmness

index =5; fruit harvested at stage 4 with maroon-red, pH 3.2, rind thickness

7.2mm, Brix%>16, firmness index 5; and stage 5 with maroon-violet, pH 3.2,

rind thickness 7.0mm, Brix%>16, firmness index=5 are acceptable. Fruit

harvested at stage 6 with violet-black, pH 3.6, rind thickness 6.8mm, Brix%<14,

and firmness index=5 is also unacceptable. However, Tongdee and Suwanagul

(1989) reported that fruits are at the edible, ripe stage when the skin has darkened

to a reddish purple, no latex remains in the skin, and the flesh segments separate

easily from the skin, and soluble solids content ranges from 17 to 20% and

Table 1. Mangosteen Maturity Indices Developed in Malaysia

Stages Skin Color changes Stuitability

Fruit and half this stage the pulp and the rind are not separable

The fruit, if harvested at this stage would develop a poor flavor

1

The fruit is pale yellow or green, with pink spots over the skin. The skin and pulp can be separated.

Fruit harvested at this stage will give a good quality flavor.

3

The fruit is evenly pink in color. The patches of pink seen in stage 2 enlarge and merge so as to become

2.2 Mangosteen Fruit Quality and Color Development

The quality of mangosteen (Garcinia mangostana L.) fruit is measured not

only by external factors such as color, shape, size, skin blemishes, latex staining

and insect damage, but also by internal factors such as translucent flesh, yellow

gummy latex and hardening pericarp which are also very important for consumer

acceptance (Teerachaichayut et al., 2006). Fruit color is a major criterion used to

judge maturity and for grading of mangosteen fruit. The fruit are usually harvested

at different stages according to colour, from light greenish yellow with scattered

pink spots to dark purple. After harvest, the purple color continues to develop very

quickly. For high fruit quality, the minimum harvest color stage is that of distinct

irregular, pink–red spots over the whole fruit. If fruit are harvested with a light

greenish yellow with scattered pink spots, the fruit do not ripen to full flavor

(Tongdee and Suwanagul, 1989; Paull and Ketsa, 2004). `

The color of mangosteen (Garcinia mangostana L.) fruit changes from

green to purple black after harvest as the fruit ripens, and is used as a quality

guide for growers and consumers. During the postharvest period, hue angle values

and pericarp firmness decreased significantly, while soluble solids contents

increased. Anthocyanin contents in the outer pericarp were higher than in the

inner pericarp and increased to a maximum at the final color stage (Palapol et al.,

2009). Commercial production has been limited by slow growth, long juvenile

periods of 10-15 years and short shelf-life of fruits when mature (Wiebel et al.,

1992). Keeping quality of mangosteen fruits is longer compared to other tropical

fruits. Long storage of fruits leads to hardening of pericarp and opening of fruit

become difficult (Radha et al., 2007). Palapol et al. (2009) indicated that fruit

harvested at stage 1 developed rapidly to the purple black stage (stage 6) within 9

days with color development from stage 5 to stage 6 being slower than other

stages. During color development, the a*/b* value increased slightly from stage 1

to stage 3, and then increase sharply to stage 6. The increase in the a*/b* values

correlated well with color development. When fruit at the six different stages of

maturity were harvested and kept at 25 oC, each stage fully developed to the

purple black stage 6. No matter at what stage the fruit were harvested, they all

including hue angle values, firmness, soluble solids content (SSC) and titratable

acid (TA), when the fruit were accessed at stage 6 (Palapol et al., 2009).

Calyx freshness of mangosteen fruit strongly affects quality value during

periods of storage. Fresh mangosteen fruit has green and fresh calyx, but the

freshness becomes brown after a few days. Research conducted by Suryanti et al.

(1999) showed that mangosteen fruit harvested at green and fresh peel with purple

spots and calyx freshness could maintain its freshness for 6 days of storage.

Optimum temperature for retention of peel and calyx color is 10 oC (Azhar, 2007).

Ekaputri (2009) found that treatment of chitosan 1.5% could retain color of

mangosteen peel and calyx. Beeswax 6% treatment and BAP 20 ppm could retain

calyx color for 21 days after treatment, but it started wrinkling after 15 days of

treatment (Pratiwi, 2008). Anggraeni (2008) reported that combination of 0.01

mm- thick plastic wrapping and chitosan coating 1.5%, and plastic wrapping with

wax Britex gave a better effect on inhibiting changes of peel and calyx color for

30 days of storage at room temperature, and 35 days at temperature 15oC.

2.3 Causes of Mangosteen Fruit Hardening

Generally the fruit will soften during a few days after harvested, but

mangosteen fruit become harden that causes difficulty in opening fruits for

consumption. Mechanical injury of fruit during storage and handling of

mangosteen often causes fruit hardening (Kader, 2003). A drop of 10 cm can

cause slight pericarp damage, indicated as hardening at the point of impact within

24 h. Higher drops cause significantly greater damage and often lead to

downgrading of the fruit (Tongdee and Suwanagul, 1989; Ketsa and Atantee,

1998).

Storage temperature less than 10°C (50 oF) leads to rapid hardening and

darkening of pericarp when fruit are returned to ambient temperature

(Uthairatanakij and Ketsa, 1995). Storage at 4 °C (39.2 °F) or 8 °C (46.4 °F), can

lead to significant hardening of the skin (Augustin and Azudin, 1986), although

the flesh may still be acceptable after 44 days. Ideal storage temperature for

mangosteen is 15oC. Temperature above 15oC mangosteen fruit hardens and

Anggraini (2008) reported that chitosan-coated treatment gave better effects

on inhibiting pericarp hardening change, while shelf-life of mangosteen fruit

could be kept as long as 20 days after treatment (Ekaputri, 2009). Dangcham et al.

(2008) found that when pericarp hardening occurred, pericarp firmness and lignin

contents increased while total phenolics decreased and fruit at the red-brown and

red-purple maturity stages stored at 6oC had higher lignin contents than of those

stored at 12 oC. Of the phenolic acids predominant in the hardened pericarp, p

-coumaric acid declined whereas sinapic acid increased throughout the storage

time. Application of low O2 (0.25%) to red-purple fruit during storage at 6 oC

(84% RH), or at room temperature (30 oC, 71.5% RH) following storage at 6 oC,

did not reduce pericarp hardening and there were no significant differences in

firmness, lignin and total free phenolics when compared with fruit in normal air

conditions. The results also suggested that increase in pericarp firmness of

mangosteen fruits results from induction of lignin synthesis, associated with an

increase in phenylalanine ammonia (PAL) and peroxydase (POD) activity and

gene expression. Recent research conducted by Palapol et al. (2009) showed that

pericarp firmness of mangosteen fruit decreased from stage 1 to stage 6, 779.3,

201.3, 136.0, 98.4, 66.5 and 46.5 N, respectively when stored at temperature

25oC. Increases in pericarp lignin contents are at least part of the reason for the

tissue hardening. Bunsiri (2003) found that 3 hours after impact, lignin contents

increased in the damaged pericarp.

2.4. Fruit Ripening and Senescence

Ripening and senescence are the ultimate phases in the developmental

events of fruits that result in the expression of the quality characteristics inherent

to the fruit (Paliyath et al., 2008) and this phenomenon involves structural,

biochemical, and molecular changes that in many cases bear the hallmarks of

programmed cell death (Arora, 2008). Degradation of structural elements such as

the cell wall and the plasma membrane results in a loss of compartmentalization

of ions and metabolites, leading to the loss of tissue structure and ultimately

Fruit ripening is accompanied by a number of biochemical events, including

changes in color, sugar, acidity, texture, and aroma volatiles that are crucial for

the sensory quality. At the late stages of ripening, some senescence-related

physiological changes occur that lead to membrane deterioration and cell death.

All biochemical and physiological changes that take place during fruit ripening

are driven by the coordinated expression of fruit ripening-related genes. These

genes encode enzymes that participate directly in biochemical and physiological

changes. They also encode regulatory proteins that participate in the signaling

pathways, and in the transcriptional machinery that regulate gene expression and

set in motion the ripening developmental program (Bouzayen et al., 2010).

For the consumers and distributors, the process of ripening corresponds to

those modifications that allow fruit to become edible and attractive for

consumption (Bouzaye et al., 2010). Fruits have classically been categorized

based upon their abilities to undergo a program of enhanced ethylene production

and an associated increase in respiration rate at the onset of ripening. Fruits that

undergo this transition are referred to as climacteric and include tomato, apple,

peach, and banana, whereas fruits that do not produce elevated levels of ethylene

are known as non-climacteric and include citrus, grape, and strawberry (Barry and

Giovannoni, 2007). The relationship existing between the climacteric respiration

and fruit ripening has been questioned following the discovery that ripening on

the vine of a number of fruit may occur in the absence of any increase in

respiration (Salveit 1993; Shellie and Salveit 1993). More recently, it has been

reported that the presence or absence of a respiratory climacteric on the vine

depends upon prevailing environmental conditions (Bower et al. 2002). These

observations indicate that the respiratory climacteric is probably not an absolute

trigger of the ripening process, but secondary and consequential to the process of

ripening. An ethylene burst that precedes respiratory climacteric has been shown

during the ripening of banana (Pathak et al. 2003).

Senescence of leaves, flowers and fruits can be regulated by an array of

external and internal factors. Many environmental stresses (such as extreme

temperatures, drought, nutrient deficiency, insufficient light/shade or total

senescence. Internal factors influencing senescence include age, levels of plant

hormones and other growth substances, and developmental processes such as

reproductive growth (Gan, 2004). Ethylene plays a key role in promoting

senescence of climacteric fruits and flowers although it is less effective in

stimulating non-climacteric fruits and flowers to senesce. Other promotions of

senescence process include sugar, jasmonic acid (JA), salicylic acid (SA),

brassinosteroids (BRs), and abscisic acid (ABA), while cytokinins (CK),

Polyamines (PAs), Auxin, Gibberellins are considered to delay senescence

process (Gan, 2004).

2.5. Ethylene Biosynthesis and its Physiological Effects

Ethylene is synthesized by most tissues in response to stress. In particular, it

is synthesized in tissues undergoing senescence or ripening (Davies, 2004).

Chaves and Mello-Farias (2006) provide a thorough review of the ethylene

synthesis pathway that the end of the ethylene synthesis pathway involves three

enzymes to convert methionine into ethylene (Figure 1). Two of these enzymes

are involved in the formation and oxidation of the immediate precursor of

ethylene, 1-aminocyclopropane-1-carboxylic acid (ACC). ACC-synthase converts

S-Adenosylmethionine (SAM) into ACC and is the rate-limiting step in the

pathway. ACC-oxidase catalyzes the conversion of ACC to ethylene. The final

conversion of ACC to ethylene is oxygen dependent (Kende, 1993).

Ethylene is a plant hormone influencing plant processes such as the so

called triple response, maintenance of the apical hook in seedlings, stimulation of

defense responses in response to injury or diseases, release from dormancy, shoot

and root growth and differentiation, adventitious root formation, leaf and fruit

abscission, flower induction in some plants, induction of femaleness of dioecious

flower, flower opening, flower and leaf senescence, fruit ripeing (Davies, 2004).

Of particular economic importance is the role of ethylene as an inducer of

fruit ripening (Bleecker and Kende, 2000). Through this action, it induces changes

in certain plant organs, such as textural changes, color changes, and tissue

degradation. Some of these changes may be desirable qualities associated with

climacteric fruits, ethylene is generally thought to be regulate fruit ripening by

coordinating the expression of gene responsible for 1) enhancing a rise in the rate

of respiration, 2) autocatalytic ethylene production, 3) chlorophyll degradation, 4)

pigment synthesis (carotenoids and flavonoids), 5) conversion of starch to sugars,

production of aroma volatiles, and 7) increase of activities of cell wall-degrading

enzymes (pulp and peel softening), 8) changes in pH (Grey et al., 1992; Lelievre

et al., 1997; Seymour et al., 1993).

Kader (2002) recommended that respiration of mangosteen fruit kept at

20oC should be 6-10ml CO2/kg/hr. Palapol et al. (2009) measured ethylene

production of mangosteen fruit stored at temperature 25oC and found that ethylene

production at stage 1 increased linearly until stage 5 (dark purple) by 5 days, then

decreased slightly after stage 5.

2.6. Ethylene Action and Methods for Inhibiting Ethylene Responses

Ethylene inhibitors reduce or eliminate the biological activity of

ethylene.These compounds can be divided into two groups: inhibitors of ethylene

biosynthesis and inhibitors of ethylene action. The first are substances that interact

with the ethylene biosynthesis pathway through inhibition of key enzymes, ACC

synthase, and ACC oxidase. The 1-aminoethoxyvinylglycine (AVG) and the

amino-oxyacetic acid (AOA) are inhibitors of ethylene biosynthesis, while silver

thiosulfate (STS), silver nitrate, and 1-methylcyclopropene (1-MCP) are inhibitors

of ethylene action (Ferrante and Francini, 2008). Yang and Hoffman (1984)

indicated that aminoethoxyvinylglycine (AVG) and aminoethoxycetic acid (AOA)

disrupt ACC synthase, while cobalt (Co2+) and α-aminois-butyric acid (AIBA) disrupt

ACC oxidase.

Blocking ethylene effects at the receptor level is more effective as it will

protect against both endogenous and exogenous ethylenes (Serek and Reid, 1993).

The silver ion (Ag+) has proved to be a potent inhibitor of ethylene action in

ornamentals. STS is generally applied as a pretreatment solution to cut flowers.

The persistence and mobility of STS allows very short pulse treatments. In potted

plants STS is applied as an aqueous spray. Beneficial effects of STS are reported

for a great variety of cut flowers and potted plants. STS treatment prevents petal

senescence induced by ethylene and prolongs the vase life (Arora, 2008).

1-Methylcyclopropene (1-MCP) has been reported to be a non-toxic antagonist of

ethylene action (Sisler and Serek, 1997) that blocks the physiological action of

ethylene (Sisler et al.,1996). Applications of 1-MCP to delay fruit ripening and

extend the storage life have been extensively reported in both climacteric and

non-climacteric fruit (Watkins, 2006). The use of 1-MCP for harvested fruits and

vegetables represents a revolutionary advance in postharvest science and

practices. The gas works by attaching to a site (receptor) in fruit tissues that

normally binds to ethylene. Binding of ethylene to these sites is how plant tissues

perceive that ethylene is present in the environment. If ethylene binding is

prevented, ethylene no longer promotes ripening and senescence (Huber et al.,

2.7. Cytokinin and its Physiological Effects

Cytokinins are derivatives characterized by an ability to induce cell division

in tissue culture, and the most common cytokinin base in plants is zeatin. It is

biosynthesized through the biochemical modification of adenine and transported

from roots to shoots. The effects of cytokinins include cell division,

morphogenesis, growth of lateral buds, leaf expansion, delay leaf senescence,

enhancement of stomatal opening in some species, chloroplast development

(accumulation of chlorophyll and conversion of ethioplasts into chloroplasts)

(Davies, 2004).

A synthetic cytokinin N1-(2-Chloro-4-pyridyl)- N3-phenylurea (CPPU) is

known to be effective for enhancing fruit enlargement by stimulating cell division

and/or cell expansion in many kinds of fruits including Actinidia deliciosa

kiwifruit (Iwahori et al., 1988; Lewis et al., 1996; Cruz-Castillo et al., 2002). Jo et

al. (2003) reported that a single application of CPPU at the concentration of 16

mg l-1 15 days after pollination was effective for increasing the fruit size of a local

selection. The effectiveness of CPPU application on fruit development of

Actinidia deliciosa kiwifruit was largely influenced by the time of application and

concentration (Cruz-Castillo et al., 1999). Antognozzi et al. (1996) found that

spraying application of CPPU 20 ppm on Actinidia deliciosa (A. Chev.) fruitlets

inside the canopy 2 weeks after full bloom influenced fruit growth soon after

treatment and yield per vine were about 25% higher than the control. The

chlorophyll content was higher in CPPU treated fruits. During storage, the

differences in carbohydrate content disappeared and treated fruits performed as

well as control ones, maintaining good quality for up to 6 months. Cruz-Castillo et

al. (2002) reported that the cytokinin-active compound, N1

-(2-chloro-4-pyridyl)-N3-phenylurea (CPPU), applied at different flowering dates, affected final

„Hayward‟ kiwifruit size.

Recent research conducted by Kim et al. (2006) showed that fruit size of

hardy Kiwifruit was increased and fruit weight was doubled when CPPU was

applied at concentration of 5-10 mg l-1 and at 10 days after petal fall (DAPF).

Although a significant reduction in the concentrations of total soluble solids

was recorded, the TSS/TA ratio and AsA content per fruit increased by the

treatment. CPPU application at petal fall induced abnormally protruding fruit tip.

2.8. Cobalt Sulphate (CoSO4) and its Effects

Cobalt sulfate is an inorganic salt of divalent cobalt. It is the usual source of

water-soluble cobalt, because it is more economical and has less tendency to

dehydrate than cobalt chloride or cobalt nitrate (Budavari et al., 1996). Co2+ is a

potent inhibitor of ethylene biosynthesis. Williams and Golden (2002) studied

purification and characterization of ACC oxidase from Artocarpus altilis and

found that the enzyme ACC was inhibited by cobalt sulfate (CoSO4). When

applied in concentration of 0.1 mM, activity of enzyme ACC was only (0.09 ±

0.01) ×10-18 kat ml extract, and its percentage inhibition reached 97.1%, compared

to control (1.11±0.03) ×10-18 kat ml extract. Singh and Agrez (2000) reported that

single exogenous spray applications of CoSO4 (200 mg/L) to fully-grown panicles

of 'Kensington Pride' mango before anthesis, was most effective for improving

fruit set, fruit retention and yield, compared to aminoethoxyvinylglycine (AVG),

aminooxyacetic acid (AOA), and ethylene action inhibitor silver thiosulphate

III. MATERIALS AND METHODS

3.1. Time and Place

The research was done at Postharvest Laboratory, Faculty of Agriculture,

Laboratory of Food and Agricultural Product Process Engineering, Laboratory of

Environmental and Agricultural Building, Faculty of Agricultural Technology,

Bogor Agricultural University (IPB), starting from February 2010 to May 2010.

3.2. Plant Material and Treatment

The research was divided into two stages. The first experiment covered

physical and chemical changes of mangosteen fruit treated with CPPU and CoSO4

during storage, while the second one involved the study of physiological and its

relation to color development of mangosteen fruit treated with CPPU and CoSO4

during storage. The experimental design was arranged in a completely randomized

block design with 2 factors and 3 replications. The first factor was cobalt sulphate

(CoSO4) at four concentrations (0, 500, 1000, and 2000 ppm), while the second

one was CPPU at four concentrations (0, 10, 20, and 30 ppm). The combination of

the above factors provided 16 treatments with 48 experimental units. Each

experimental unit comprised 40 mangosteen fruit. For the second experiment, the

design was as in the first experiment, but only cobalt sulphate at 0, 2000 ppm, and

CPPU at 0, 30 ppm were used with 5 mangosteen fruit per experimental unit.

The fruits used in the experiment were harvested from local orchard

(Purwakarta) at stage 1(light greenish yellow with 5-50% scattered spots) on the

same day and were of similar sizes. The harvested fruit were transported at night

to Postharvest Laboratory. In the following morning, fruit were sorted, and

washed with tap water to remove the dust. After washing, the fruit were air dried,

and then treated with solution of fungicide TBZ 1 ppm for 30 seconds and air

dried. Following fungicide application, air-dried fruit were dipped in the solution

of CoSO4 and CPPU for 30 seconds according to its concentrations used in the

treatments. To facilitate the absorption of the solution by fruit, Tween 20 (1%)

was added. After application, treated fruits were air dried, then immediately stored

at 14-16oC (76-96% RH) which is an ideal storage temperature for mangosteen

3.3. Observed Variables 3.3.1 Physical Attributes

3.3.1.1.Fruit Resistance(kgf/cm2)

Mangosteen fruit was pressed until breakdown to see the level of easiness

for fruit to be opened by using fruit resistance tool. The observation was done

every two days with 16 times of observation, each of which two fruits were used.

3.3.1.2. Pericarp Water Content (%)

Pericarp sample (g) were weighed, and placed in the paper envelope. The

sample was dried in oven at 105 oC for 96 hours, then cooled down in desiccators

and weighed. PWC was calculated using formula:

Pericarp water content (%) =a−b

a × 100, where a = Fresh weight (g)

b = dried constant weight (g)

3.3.1.3. Weight Loss

Loss of fruit weight is measured based on the percentage of the reduction in

the weight since the beginning up to the end of the storage period. The weight loss

was calculated using the following formula:

Weight loss (%) =W−Wi

W × 100, where W = Weight at initial storage (g)

Wi = Weight at ith observation (g)

3.3.1.4. Fruit and Sepal Color

The observation of fruit and sepal color was conducted every two days to

see colour development during storage. Fruit and sepal color was measured using

Color Reader CR-10 that was already calibrated. The tool consists of color

notation (color system L, a, and b). Color system L means the brightness with

value 0 (black) until 100 (white). The color system a and b is chromaticity

coordinate. It means that chromatic mixture of red and green with value +a from 0

to +60 for red and –a from 0 to -60 for green color. b value means that chromatic

yellow and blue mixture with the value of +b from 0 to +60 for yellow color and

the value –b from 0 to -60 for blue color. The colour reading was measured twice

at the equatorial region of each fruit and two sepals, and averaged to give a value

0=/black, 100= white color), a/b ratio and hue angle (ho) with red-purple at an

angle of 0o, 90o representing yellow color, and 180o bluish-green color (Palapol et

al., 2009). Hue angle was calculated using the following formula:

Hue angle (ho) = arctan (b/a)

3.3.2.Chemical Attributes

3.3.2.1. Total Soluble Solids (TSS)

To measure total soluble solids on fresh juice, the white fresh of the arils

with seeds, is wrapped in cheesecloth, and squeezed by hand to separate juice

from seeds. Pulp liquid is placed on the prism of digital refractometer. TSS was

reported as oBrix.

3.3.2.2. Titratable Acidity (Titration method AOAC 1984)

Analysis of titratable acidity of the mangosteen fruit was measured in

duplicate by using the titration method. Pulp was weighed as much as 10 g and

put in a glass baker. Distilled water was added to get a solution of 100 ml, and

then filtered with filter paper. Twenty five ml of the filtrate were titrated with 0.1

N NaOH using phenolphthalein (pp) as an indicator until the solution turns pink.

Titratable acidity was calculated with following formula:

��(%) = � � × � �× 64 × × 100 � �

Where, ml NaOH = NaOH Volume

N = NaOH normality (0.1 N)

df = dilution factor

3.3.3. Physiological Variables 3.3.3.1. Respiration Rate

Five fruits were weighed and placed in 3.3 L- glass jar and sealed with wax to

prevent the entry of gas O2 and CO2 and stored in 15oC. The carbon dioxide

concentration measurement was done by using Shimadzu Infrared Gas Analyzer

Model IRA-107, while O2 was measured using Oxygen Portable Tester Model

POT-101. The measurement was done every 3 hours on the first day (after

treatment), every 6 hours on the second day, every 12 hours, and followed by

every 24 hours. The rate of respiration was calculated with the following fomula:

R = � × , where R = Respiration rate (ml kg-1 h-1)

Chromatograph (GC) with the FID system (Flame Ionization Detector) which was

connected with a chroma-integrator D-2000 was used. The measurement was done

by using the column (2000 mm x 4 mm) and the column 80-100 activated mesh

alumina. The column temperature for the measurement was 60 oC and injector

temperature was 110 oC. N2 carrier gas flow rate was 30 ml/minute and gas

pressure 5 kg/cm2. Mangsosteen fruit was incubated in the air-locked stopples,

and sample was taken as much as 1 ml. Only 0.5 ml was injected into gas

chromatograph. The measurement was done every 24 hours up to d13 of storage.

Ethylene production rate was expressed as µl kg-1 h-1.

Sample (ppm) =

Sample peak areaStandard peak area

× standard ( ppm)

�

=

�×

Where, EP = Ethylene production rate (µl/kg/h)

E = Ethylene concentration (ppm)

t = time (hour)

V = Space volume (L)

W = Product weight (kg)

3.4. Statistical Analysis

All the recorded data was entered and stored in Microsoft Excel 2007.

Analysis was performed using SPSS statistics 17.0. Analysis of variance was done

and treatment means were compared using Duncan Multiple Range Test (DMRT)

IV. RESULTS AND DISCUSSION

Experiment one: Physical and Chemical Changes of Mangosteen Fruit Treated with CPPU and CoSO4 during Storage

4.1. Physical Changes of Mangosteen Fruit 4.1.1. Fruit Resistance (kgf/cm2)

Fruit softening is closely associated with ripening process. The resistances

of mangosteen fruit were similarly noticed during storage from d0 to day 30 at

14-16oC (76-96% RH) in both fruit treated with CPPU and CoSO4 (Figure 2, 3). The

results showed that mangosteen fruit could be stored at 15oC for 30 days without

affecting fruit hardness, and treatments applied had no effect on fruit hardening

during storage period, except at day 16 and day 30 (Appendix table 1). At d16,

CPPU 20 and 30 ppm had higher fruit resistance than CPPU 10 ppm and control

fruit, while fruit treated with CPPU 20 ppm was most resistant and significantly

different from CPPU 0, 10 and 30 ppm at day 30 (Appendix table 1). High

resistant fruit treated with CPPU 20 ppm (2.70 kgf/cm2, and 2.22 kgf/cm2 at day

28 and d30, respectively) was due to fungal infection at the end of storage. Our

results were consistent with Azhar (2007), who reported that mangosteen fruit

pericarp was not difficult to be opened after 30 days of storage at 15oC. The

results also confirmed the findings by Inayati (2009), who found that BAP, a type

of cytokinins, from 0 to 40 ppm could maintain the pericarp resistance at less than

2 kgf/cm2 during 26 days of storage at 15oC. Resistance values equally less than 2

0,00

0 ppm 500 ppm 1000 ppm 2000 ppm

Figure 2. Resistance of mangosteen fruit treated with CPPU during storage.

Figure 3. Resistance of mangosteen fruit treated with CoSO4 during storage.

4.1.2. Pericarp Water Content (%)

Loss of water not only affects appearance or esthetic value but also

reduces saleable weight, thus causing direct economic loss. Pericarp water content

(%) was predicted to be concerned with mangosteen fruit hardening. PWC at d0

was almost the same in all treatments, and tended to decrease over storage time

CoSO4, and no statistical differences were observed, except day 18 which showed

significant interaction between CPPU and CoSO4. Pericarp water contents in fruit

treated with CPPU 0 ppm + CoSO4 500 ppm , CPPU 10 ppm + CoSO4 2000 ppm,

CPPU 20 ppm + CoSO4 0 ppm, CPPU 10, 20, 30 ppm + CoSO4 1000 ppm were

lowest and significantly different from control fruit at day 18 (Table 2). According

to Kondo et al. (2003), skin hardening of mangosteen fruit during storage at low

temperature was not accompanied by moisture loss.

Table 2. Effects of CPPU and CoSO4 interaction on pericarp water content (%) of

mangosteen fruit during storage at day18

CPPU (ppm) CoSO₄ (ppm)

Note: Different letters indicate significant differences among treatment means

(P < 0.05) by Duncan‟s multiple range test (DMRT).

4.1.3. Weight Loss (%)

Mangoteen fruit increasingly lost weight with storage time from day 0 to

day 30 in either fruit treated with CPPU or CoSO4 (Figure 4, 5). The rate of

weight loss in CPPU-treated fruit was lower than control fruit although no

statistical significance was observed from day 2 to day 12 (Appendix table 3).

Weight loss of fruit during storage was the results of water loss through

transpiration (Yaman and Bayoindirli, 2002) and loss of carbon due to respiration

(Pan and Bhowmilk, 1992). In mangosteen fruit, pericarp water content was only

reduced 3-6% during storage time from d0 to d30 as seen in appendix table 2.

This was not proportional to weight loss which ranged from 9-12%. The results

suggested that water loss from aril and other parts of the fruit, and carbon loss by

Figure 4. Weight loss of mangosteen fruit treated with CPPU during storage.

Figure 5. Weight loss of mangosteen fruit treated with CoSO4 during storage.

4.1.4. Fruit Color 4.1.4.1. Lightness

Fruit color is one of the most important appearance quality always

employed by consumers when purchasing products. The darkening of mangosteen

fruit drastically increased from day 0 to day 4, and was constant from day 4 to day

16. The darkening was reaccelerated from day 18 in either fruit treated with CPPU 0

and CoSO4 (Figure 6, 7). Lightness of mangosteen fruit reduced (darkening

increased) from 42 to 33 (around 9%) during storage time from day 0 to day 30.

CPPU 20 ppm could most effectively delay darkening of the fruit and

significantly varied from other concentrations as shown in day 4 and day 6

(Appendix table 4).

Figure 6. Changes in skin lightness of mangosteen fruit treated with CPPU during storage.

Figure 7. Changes in skin lightness of mangosteen fruit treated with CoSO4 during

storage.

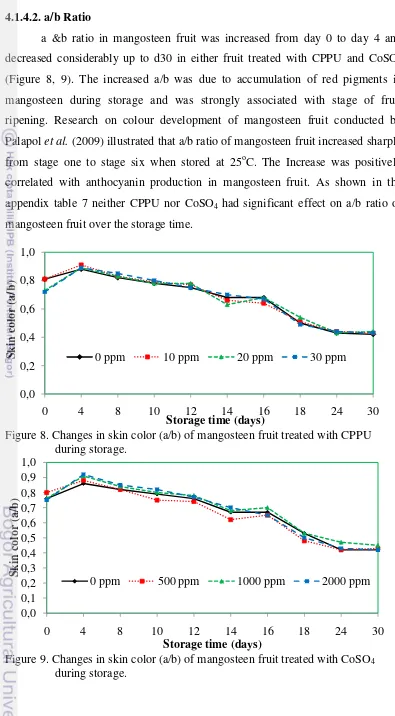

4.1.4.2. a/b Ratio

a &b ratio in mangosteen fruit was increased from day 0 to day 4 and

decreased considerably up to d30 in either fruit treated with CPPU and CoSO4

(Figure 8, 9). The increased a/b was due to accumulation of red pigments in

mangosteen during storage and was strongly associated with stage of fruit

ripening. Research on colour development of mangosteen fruit conducted by

Palapol et al. (2009) illustrated that a/b ratio of mangosteen fruit increased sharply

from stage one to stage six when stored at 25oC. The Increase was positively

correlated with anthocyanin production in mangosteen fruit. As shown in the

appendix table 7 neither CPPU nor CoSO4 had significant effect on a/b ratio of

mangosteen fruit over the storage time.

Figure 8. Changes in skin color (a/b) of mangosteen fruit treated with CPPU during storage.

Figure 9. Changes in skin color (a/b) of mangosteen fruit treated with CoSO4

during storage.

0 ppm 500 ppm 1000 ppm 2000 ppm

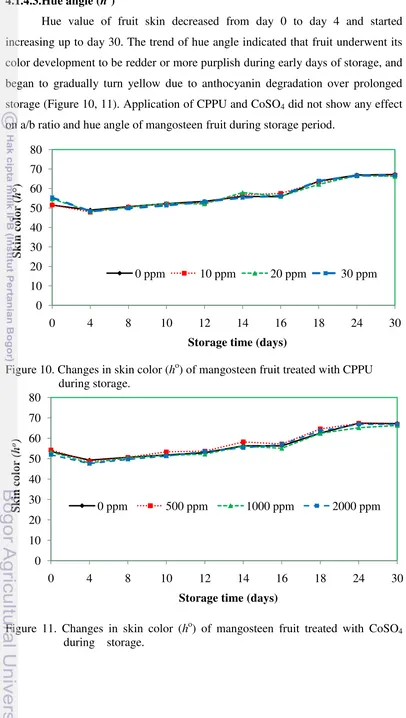

4.1.4.3.Hue angle (ho)

Hue value of fruit skin decreased from day 0 to day 4 and started

increasing up to day 30. The trend of hue angle indicated that fruit underwent its

color development to be redder or more purplish during early days of storage, and

began to gradually turn yellow due to anthocyanin degradation over prolonged

storage (Figure 10, 11). Application of CPPU and CoSO4 did not show any effect

on a/b ratio and hue angle of mangosteen fruit during storage period.

Figure 10. Changes in skin color (ho) of mangosteen fruit treated with CPPU

during storage.

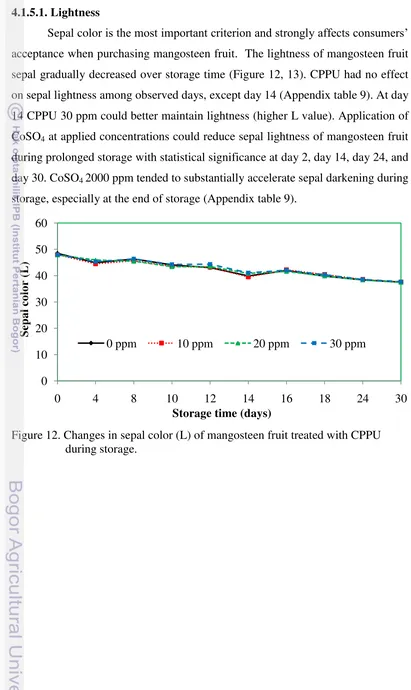

4.1.5. Sepal color 4.1.5.1. Lightness

Sepal color is the most important criterion and strongly affects consumers‟

acceptance when purchasing mangosteen fruit. The lightness of mangosteen fruit

sepal gradually decreased over storage time (Figure 12, 13). CPPU had no effect

on sepal lightness among observed days, except day 14 (Appendix table 9). At day

14 CPPU 30 ppm could better maintain lightness (higher L value). Application of

CoSO4 at applied concentrations could reduce sepal lightness of mangosteen fruit

during prolonged storage with statistical significance at day 2, day 14, day 24, and

day 30. CoSO4 2000 ppm tended to substantially accelerate sepal darkening during

storage, especially at the end of storage (Appendix table 9).

Figure 13. Changes in sepal color (L) of mangosteen fruit treated with CoSO4

during storage.

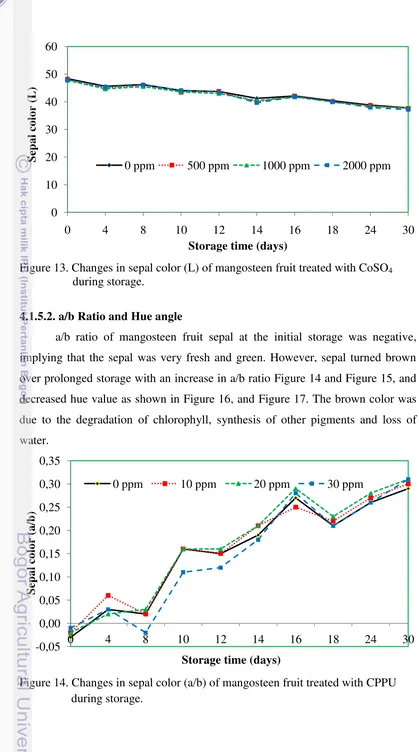

4.1.5.2. a/b Ratio and Hue angle

a/b ratio of mangosteen fruit sepal at the initial storage was negative,

implying that the sepal was very fresh and green. However, sepal turned brown

over prolonged storage with an increase in a/b ratio Figure 14 and Figure 15, and

decreased hue value as shown in Figure 16, and Figure 17. The brown color was

due to the degradation of chlorophyll, synthesis of other pigments and loss of

water.

Figure 14. Changes in sepal color (a/b) of mangosteen fruit treated with CPPU during storage.

0 ppm 500 ppm 1000 ppm 2000 ppm

Figure 15. Changes in sepal color (a/b) of mangosteen fruit treated with CoSO4

during storage.

Figure 16. Changes in sepal color (ho) of mangosteen fruit treated with CPPU

during storage.

0 ppm 500 ppm 1000 ppm 2000 ppm

Figure 17. Changes in sepal color (ho) of mangosteen fruit treated with CoSO4

during storage.

Table 3 showed that there were significant interactions between CPPU and

CoSO4 on a/b ratio of mangosteen fruit sepal at day 22 and day 26. The a/b was

significantly higher in fruit treated with CPPU 0 pmm + CoSO4 2000 ppm (0.37)

than control (0.27) at day 22. At day 26, CPPU 30 ppm and CoSO4 2000 ppm

gave higher a/b (0.41) and statistically significant compared to control fruit with a/b only 0.27. The result showed that application of Cobalt Sulphate was likely to accelerate redness of the sepal (increase a value) as seen in appendix table 10.

Table 3. Effects of CPPU and CoSO4 interaction on a/b ratio of sepal of

mangosteen fruit during storage at d22 and d26

Day CPPU (ppm) CoSO4 (ppm)

Note: Different letters indicate significant differences among treatment means

(P < 0.05) by Duncan‟s ultiple range test (DMRT)

0