Optimization of cutting parameters to reduce cutting tool temperature in a dry turning process using genetic algorithm.

Teks penuh

Gambar

Dokumen terkait

To identify the optimized setting of cutting parameter of feed rate, spindle speed and depth of cut on surface roughness during face milling process of Mild Steel

To study the surface roughness of AISI D2 tool steel in dry drilling condition by using various type of cutting tools. To investigate the optimum parameter in dry drilling of AISI

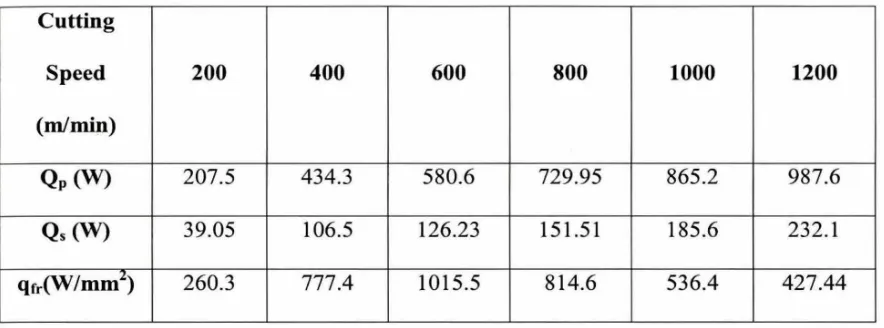

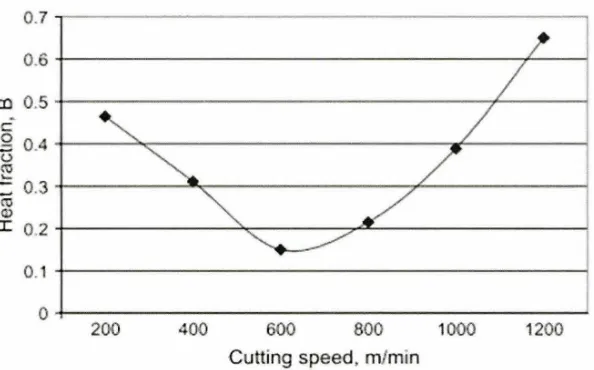

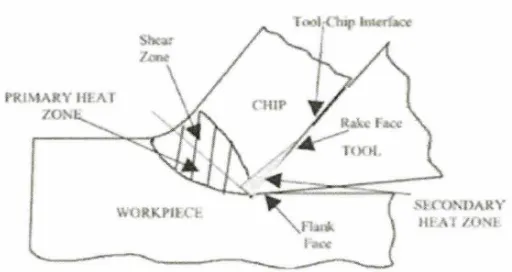

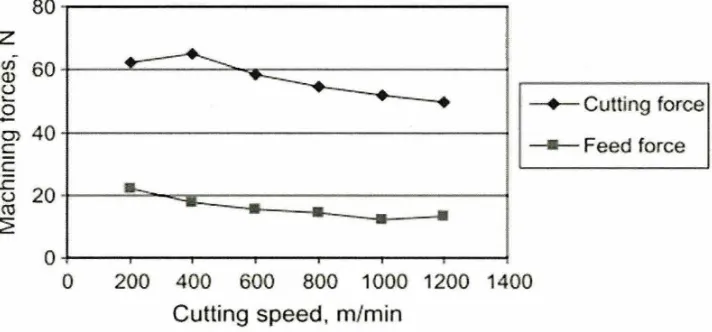

significant effect parameters on chip-tool temperature interface in turning of steel with cemented carbide inserts using a tool-work thermocouple technique were studied [5]

So, optimization on parameters in the laser beam cutting operation of stainless steel having various thicknesses is considered as a significant work and the same is taken as a

PERTORMANCE OF DIAMOND CUTTING TOOL IN THE TURNING PROSES OF STAINLESS STEEL,COPPf,R AND

The objectives of this experiment are to determine the effect of different cutting parameters, such as cutting speed and depth of cut onto the cutting tool tip temperature, to determine

Torque, Nm S1F1P4 0.047 0.051 0.035 V CONCLUSIONS This study presents the optimization of process parameters such as cutting speed, feed and point angle in drilling of BFRP