*Corresponding author. Tel.: 2859-7059; fax: 00852-2858-6535.

E-mail address:[email protected] (F.T.S. Chan)

The development of intelligent decision support tools to aid the

design of

#

exible manufacturing systems

Felix T.S. Chan

!

,

*

, Bing Jiang

!

, Nelson K.H. Tang

"

!Department of Industrial and Manufacturing Systems Engineering, The University of Hong Kong, Pokfulam Road, Hong Kong "Leicester University Management Centre (LUMC), University of Leicester, Leicester LE1 7RH, UK

Abstract

The design of#exible manufacturing systems (FMSs) is an essential but costly process. Although FMS design appears to be an excellent area for applying arti"cial intelligence (AI) and computer simulation techniques, to date there have been limited investigations on integrating AI with the modular simulation software available for FMS design. In this paper an integrated approach for the automatic design of FMS is reported, which uses simulation and multi-criteria decision-making techniques. The design process consists of the construction and testing of alternative designs using simulation methods. The selection of the most suitable design (based on the multi-criteria decision-making technique, the analytic hierarchy process (AHP)) is employed to analyze the output from the FMS simulation models. Intelligent tools (such as expert systems, fuzzy systems and neural networks), are developed for supporting the FMS design process. Active X technique is used for the actual integration of the FMS automatic design process and the intelligent decision support process. ( 2000 Elsevier Science B.V. All rights reserved.

Keywords: FMS design; Systems simulation; Multi-criteria decision support; AI; Integration

1. Introduction

Flexible manufacting system (FMS) design is a very complex task due to two important charac-teristics: (a) The wide variety of alternative system control strategies and con"gurations available to the designer [1]; (b) FMS design is a task in which a variety of selection criteria are involved, many of which are di$cult to quantify. Additionally, some criteria have to be balanced against each other

while taking into account the preferences of man-agers of the"rm [2,3].

Modeling techniques have been devised to model and evaluate FMSs prior to their installation. Modeling is advantageous since it is costly to evaluate the performance of an FMS after installa-tion. Today, physical models, analytical models, discrete simulation models, and, more recently, knowledge-based simulation systems, have been used for this purpose. However, a major problem exists as current modeling techniques are unable to capture all the FMS design dimensions, i.e. they are not able to solve the FMS design problem as a whole. This is a consequence of local, myopic, and isolated approaches to FMS design [4]. Therefore, a new approach combining operational research

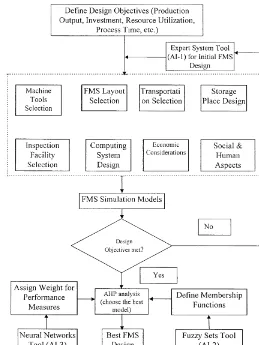

Fig. 1. Outline of the intelligent decision support system for the FMS design.

and intelligent decision-making process is needed and a user-friendly interface can be considered as being an essential requirement.

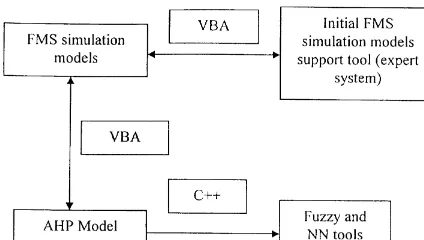

The approach introduced in this paper integrates initial FMS design, systems analysis, decision-mak-ing support and arti"cial intelligence (AI) tech-niques and methodologies into one system. Fig. 1 shows the outline of this integrative approach for FMS design. As Fig. 1 indicates, FMS design mod-els are built based on the objectives obtained from engineers. The multi-criteria decision support tech-nique, the analytic hierarchy process (AHP), is then used to choose the best design. AI techniques (ex-pert system, fuzzy sets and neural network) are used for the FMS design initialization, analysis, and evaluation. In other words, the ongoing research

project by the present authors tries to integrate the FMS simulation models, AI tools and the decision support system into a uni"ed system. Thus, devel-oping an integrative intelligent decision support system for the design of FMS is the core activity of this research.

Kong manufacturing company. Another source of expertise is from one of the research project direc-tors who has had over 20 years of experience in the use of simulation techniques in process design. The third source is from the literature.

In this research, the AHP technique has been employed to develop the decision-making support tool for FMS design. AHP applications in the FMS area have been proved to be e!ective by our col-leagues [5]. However, applications of AHP still need human judgement and this relies on experi-enced technical operators. Fuzzy sets and neural network intelligent techniques are also imple-mented for assisting the development work. Fig. 1 shows the fuzzy sets tool (AI-2) and the neural network tool (AI-3) which have been built to sup-port the evaluating of systems performance measures.

Integration of FMS design system is also a very important task. In this research, there are tools for FMS design, simulation and decision-making sup-port. All these tools are integrated in a unique environment. A user-friendly interface is needed for the whole system. The general programming lan-guages such as Visual Basic and C/C##are the preferred media among these tools. Active X tech-nique is employed for integration. The Active X technique is developed by Microsoft Company for application integration. This technique allows Windows applications to control each other and themselves via a programming interface.

This paper "rst reviews the current literature concerning FMS design. Secondly, the simulation of generic FMS models and the expert systems tool for initial FMS model building are presented. Thirdly, the AHP process and the intelligent tools (fuzzy sets and neural networks) for decision sup-port are described. Finally, the integration of the intelligent decision support tools and the design procedure using Active X technique is discussed.

2. Literature review

Many researchers have suggested various approaches for FMS design and analysis [6]. Engineering economics and operational research/ management science methodologies and techniques

have been applied with the object of obtaining performance data (e.g. lead time, productivity, cost, #exibility, product quality, etc.) from di!erent con-"gurations [7,8].

Simulation modeling has attracted much atten-tion recently [9]. The simulaatten-tion technique is main-ly a computerized procedure utilizing numerical techniques [10}12]. For FMS, simulation models represent the facilities, the layout, and the intercon-nections. Running simulation models shows basic operations and input and output of FMS. In FMS design, a simulation model is developed using com-puter software; the developed model is then ex-ecuted and the designer analyses the output to determine whether or not design objectives can be achieved [13]. For FMS simulation models, the performance measures are often the total produc-tion, the average waiting time in a queue, the max-imum time waiting in queue, the maxmax-imum number of parts that were at any time waiting in the queue, the average and maximum#ow-time of parts, and the utilization of machines, etc. A model described by Aly and Subramaniam [2] is one such example. In addition to the simulation modeling method, the FMS design problem also appears to be a very good application for expert system technique [14]. An expert system uses a number of heuristics in much the same way as a human designer would approach the problem. Mellichamp and Wahab [15] proposed an expert system to design FMSs, and they have demonstrated that development of expert systems for FMS design is within the realms of possibility. Recently, researchers have paid much attention to the integration of simulation with ex-pert systems. El Maraghy and Ravi [16] have re-viewed some applications of knowledge-based (expert system) simulation systems in the domain of FMSs. They have also discussed the potential of knowledge-based simulation systems towards the development of new, powerful and intelligent simu-lation environments for modeling and evaluating FMSs.

Basically, the problem in FMS design is a matter of selecting one of the preferred alternatives in the light of a variety of criteria, including tangible and intangible criteria. A company may often have sev-eral alternative plans when it prepares to imple-ment an FMS [5]. Therefore, analysis and evaluation of the FMS design becomes very impor-tant, with the ideal objective being that of selecting the most suitable plan for implementation.

Analysis and evaluation of the possible alterna-tives require su$cient knowledge to make com-parisons among them [17}19]. In fact, this process is called system performance measurement [20}23]. There are many approaches suggested by researchers [24}26]. Multi-criteria decision sup-port approaches, such as AHP, are appropriate and provide a useful method because FMS design is an evolutionary decision-making process [27,28]. The multi-criteria decision-making technique is a meth-odology that provides the ability to incorporate both qualitative and quantitative factors in the decision-making process. For example, the AHP uses a hierarchical model (not to be confused with a simulation model) comprising a goal, criteria, and perhaps several levels of sub-criteria and alterna-tives for each problem or decision [29]. The objec-tive of AHP is to choose the best alternaobjec-tive.

The use of AI, such as expert system, fuzzy logic and neural network, to support the decision-making in FMS design has attracted much atten-tion in recent years [14,30,31]. When analyzing the output of the FMS design model, AI techniques are implemented by many researchers. Fuzzy logic and neural network are two popular techniques [5,31]. When making decisions in comparative problems, the fuzzy logic technique is quite useful for the measurement of preferences [5,32]. Unsupervised and supervised neural networks combined with decision science are e!ective to handle complex multivariate relationships and nonlinear problems in manufacturing system planning and scheduling [30,33,34]. However, studies in this regard are just beginning and it is expected that more research will be conducted in this area in the next few years.

However, the main problem in FMS design (in-cluding analysis and evaluation) is the isolated use of design techniques and methods [9]. Develop-ment of fully integrated, automated intelligent tools

for the design of FMS is desired. As described by Spano et al. [6], the e!ective performance of these tools depends primarily on the proper design speci-"cation of the various components, and also on the operation of these components as an integrated system. Thus, an integration of design and analysis tools is useful and practical; this is the approach which is described in the present paper.

3. Expert system tool(AI-1)for initial FMSs design

The expert system tool (AI-1) is built to support the initial FMSs design, i.e. the simulation models in this research project. The aim of the AI-1 is to ensure that the design objectives can be met. The procedure (logic) of the initial design is shown in Fig. 2; this is a schematic of the initial design procedure. As the diagram indicates, the AI-1 re-quires design objectives such as production output, investment, and operating conditions. For initially building the simulation models, the equipment fea-tures of the FMS are speci"ed by selecting indi-vidual machines, robots, conveyors and automated guided vehicles.

In attempting to determine simulation models that are e$cient with respect to FMS design objec-tives, the AI-1 analyses the results of the simulation model, and uses a number of heuristics in much the same way a human designer would approach the problem. These are identi"ed as: operational heu-ristics, which are used to assess production level considerations; economic heuristics, which con-sider the"nancial options, and social and human heuristics, which are used to access the number of operators and maintenance technicians and work-load of workers, etc.

In case the operational objectives are not met, the AI-1 searches for ways of modifying the simula-tion models to make it more e$cient. This is ac-complished by identifying bottlenecks in the simulation models}these are usually indicated by very high or low utilization and excessive queue lengths. There are three causes of bottlenecks:

f inadequate loading/unloading or transporting

devices,

Fig. 2. Schematic of the initial design procedure.

f machines having one or more excessively long

processing times (with respect to that machine or other machines in the model).

The AI-1 "rst determines the speci"c machine which is on the operational routing and for which the part production objectives are not being met. Utilization and queue length statistics for that ma-chine are examined. If the statistics do not indicate a potential problem, the system will consider the machine on the next operational routing for which the objectives are not met; if the statistics do indi-cate a potential problem, the AI-1 takes a global view to track down the causes of the problem. This global view considers the machine itself, machines which precede the problem machine, and materials handling devices which serve the problem machine. When a bottleneck is identi"ed and the underlying cause is isolated, the AI-1 attempts to locate (from

a list of equipment alternatives) a more e$cient replacement for the problem machine or materials handling device.

The structure of the expert system tool is a basic scheme of a knowledge base and an inference en-gine. The knowledge base includes the machine knowledge, the material handling facilities know-ledge, the computing equipment knowknow-ledge, etc. Rules in the knowledge base are composed of de-sign objective rules and operational analysis rules. The inference engine is a standard match}act cycle, in which the action part of the rule is invoked when the premises of the rule are matched by the facts stored in the knowledge base. The match}act cycle is continued until a recommendation is made.

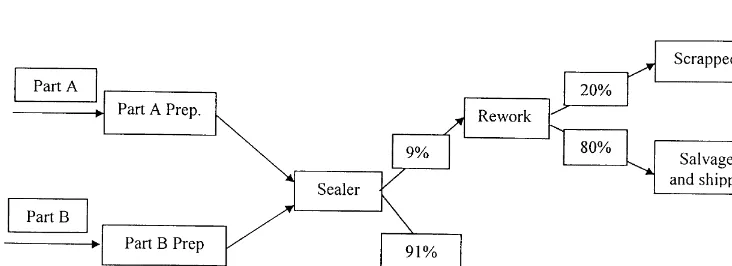

Fig. 3. An example model.

statistics, and queue lengths) are input to the AI-1. Once the AI-1 has made a recommendation, the simulation models are adjusted appropriately and re-run. This process continues until an acceptable design is obtained. The interface between the simu-lation models and the AI-1, especially for the alteration of a simulation model to re#ect changes, is a complex task. Our approach uses Active X technology.

As the system currently exists, simulation models are developed in ARENA program [35] and ex-ecuted on an IBM PC. The AI-1 is written in CAPPA [36], which is an expert system develop-ment tool, and run on an IBM PC machine. To illustrate the capability of the FMS design expert system tool, a case study is presented in this paper. A clock manufacturing company would like to do a feasibility study for FMS implementation. The system shown in Fig. 3 represents the FMS opera-tions for the production of two di!erent sealed electronic units. Part A and Part B arrive with pre-determined inter-arrival times to the Part A Preparation area and the Part B Preparation area, respectively. After being delayed by the corre-sponding processing time, the two parts are trans-ferred to the sealer. At the sealing operation, the electronic components are inserted, the case is as-sembled and sealed, and "nally the sealed unit is tested. According to the companys statistics, 91% of the parts pass the inspection and will be transfer-red directly to the shipping department. The re-maining parts are transferred to the rework area where the parts are disassembled, repaired, cleaned,

assembled, and re-tested. Eighty percent of the parts here are salvaged and transferred to the ship-ping department as reworked parts. The remaining parts are transferred to the scrap area. We assume all transfer times are 2 minutes and two automatic guided vehicles (AGVs) are used. We collect statis-tics in each area on resource utilization, number in queue, time in queue, and the cycle time (total process time) by shipped parts, salvaged parts, or scrapped parts.

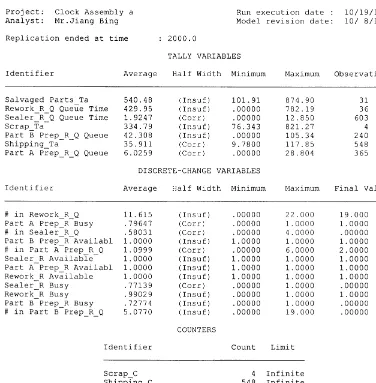

There are several objectives when building FMS models, such as studying the e!ect of various dis-patching rules at the workstation, di!erent machine selection rules for alternative operations, balancing the workload between the machines, and maximiz-ing the routmaximiz-ing#exibility. In this paper, 10 models are developed according to di!erent machine types and dispatching rules. The FMS models are de-veloped in the environment of a simulation pro-gram. During the simulation, animation of the FMS and the simulation time can be displayed on the screen. Thus, the simulation process can easily be observed and inspected by the user. After simu-lation, the report of the stations utility, the queues, the operations, etc. can be generated. An example of such a report is shown in Fig. 4.

Fig. 4. An example of simulation result.

are then shown to the operators. Then, the parameters of the simulation models are modi"ed manually. This iterative process continues until the design is accepted.

In this research, an automatic interface (although not fully automatic) between the simulation models and the expert system tool has been built. The

building tool. The integration computing environ-ment is Visual Basic using Active X technology.

4. Fuzzy and neural network decision support

tools(AI-2 and AI-3)

As described in Section 3, it is probable that more than one design is available when a company designs its FMS. The evaluation of the di!erent designs then becomes a problem for managers and engineers. Many researchers have considered this problem and several techniques are available, the multi-criteria decision support technique being one of them.

The AHP is a multi-criteria decision support technique, which has been employed e!ectively by our colleagues in the area of CIM and FMS [5]. AHP is a methodology that provides the ability to incorporate both qualitative and quantitative fac-tors in the decision-making process. The AHP uses a hierarchical model (not to be confused with a simulation model) comprised of a goal, criteria, perhaps several levels of sub-criteria and alterna-tives for each problem or decision [29]. In each level, pairwise comparisons between each criterion are used to make judgements on the relative im-portance of criteria. The alternatives are also com-pared pairwise according to their importance with respect to each criterion. Finally, a composite im-portance weight for each of the alternatives is cal-culated, resulting in a "nal ranking of the alternatives.

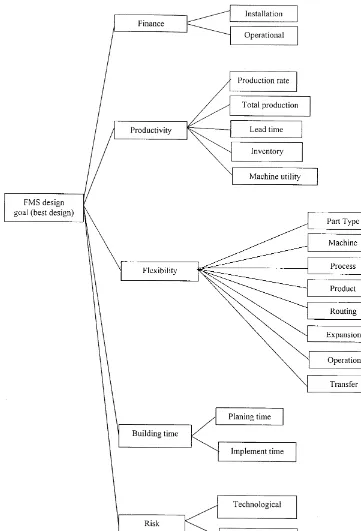

The evaluation of FMS simulation models is conducted by AHP methodology in this research project and Fig. 5 shows the hierarchical structure used. The goal (top of the hierarchical structure) of the AHP model is to choose the best (the most suitable) FMS for a company. First-level criteria are "nance, productivity, #exibility, building time and risk. The sub-criteria of"nance are the facilities and installation cost, and the operational cost. The sub-criteria of productivity are production rate, total production, lead time, inventory and machine utility. The sub-criteria of#exibility are#exibility of part type, machine, process, product, routing, ex-pansion, operation and transfer. The sub-criteria of building time are planning time and implementing

time. The sub-criteria of risk are technical risk and operational risk. Thus, the AHP approach decom-poses a problem into the elements. Then, the ele-ments (i.e. criteria) are assessed by pairwise comparisons. The lowest level is the alternatives.

Pairwise comparison means that one element is compared against another with respect to the level above. For example, when choosing the best FMS design, we may look at"nance against productivity with respect to the goal (upper level). The judge-ment comes from operators. In order to support the judgement (decision-making), a fuzzy set decision support tool (AI-2), and a neural network decision support tool (AI-3) are proposed in this research.

In AHP, pairwise comparisons use verbal com-parisons, and could be considered fuzzy, in the sense that decision makers (operators) need to ex-press their preference in an approximate way by verbal judgement or by stating a single number taken from the 1}9 comparison scale. A fuzzy set (logic) tool (AI-2) which supports the pairwise com-parison is proposed.

A fuzzy set is an excellent tool with which one can represent the satisfaction of alternatives to cri-teria. In fuzzy logic, the truth of any statement is a matter of degree. Assume we have a set of alterna-tives in a decision:

X"[X

1,X2,2,Xn]. (1)

If we have a particular criterionA, we can associ-ate, with each value inX, a numberA[X

i] in the

interval [0, 1], indicative of how well X

i satis"es

criterion A, which of course then speci"es A as a fuzzy set ofX.

In this paper, it was de"ned that alternatives (X) are 10 di!erent feasible FMS models, and criteria (A) are 19 criteria. To determine how an alternative satis"es a criterion, a membership function has to be de"ned.

For those criteria that are to be maximized (like total production), the following membership func-tion is used:

measured value!minimum value maximum value!minimum value.

used:

maximum value!measured value maximum value!minimum value.

A decision function, sayD, is needed to determine the desirablex. FunctionDis de"ned as follows:

D"Max(MinAai

i(x)), i"1, 2,2,p, (2)

wherepis the number of criteria, Aai

i(x)"(Ai(x))ai

anda

iis the power of importance of each criterion.

The power of importance of each criterion is de-rived by the AI-3.

In AHP, calculating the preference ratings estab-lishes the power of importance of each element in the reciprocal comparison matrix (the reciprocal comparison matrix comes from the pairwise com-parisons, see [28]). In AI-3, we use a feed-forward neural network proposed by Stam et al. [33] to approximate the mapping from the reciprocal com-parison matrix in the AHP to the associated prefer-ence ratings. The information that is provided by then]npairwise comparison matrix serves as in-put to the feed-forward neural network. Thus, the neural network will have n

i"n(n!1)/2 input

nodes. The desired output vector consists of the

n-dimensional true preference rating vector r, so that the number of output nodes is n

o"n. The

compound vector (aT,rT) represents one pattern in the training set.

The software NEUFrame [37] is used to train separate neural nets for each matrix size. For the FMS problem discussed in this paper, networks with two hidden layers provided good results. The network con"gurations yielded tolerable errors and converged within a reasonable time. A feed-forward neural network for the 3]3 pairwise comparison matrices has 10 nodes in the"rst hidden layer and 6 in the second. The result of AI-3 is the assigned weight for performance measures.

5. Automation and integration of design process and decision support tools

One of our objectives in this research was to automate the FMS design and evaluation pro-cesses; also we aimed to integrate the intelligent

tools into one system. The automation and integra-tion of the intelligent tools included the following tasks:

f A template panel object has been built. The

panel includes four templates, Arrive, Sealer}t, Rework}t, and Depart. The templates are special modules in simulation models and have their own logic and functions. Through the Active X technology, the templates is integrated with the utilities in AI-1. Thus, modules could be created from the recommendations made by AI-1.

f The results of running the FMS models are saved

as text only"les. The developed intelligent tools, AI-2 and AI-3, read the text "les as the input. The output data of the AI-2 and the AI-3 are also saved as the text "les.

f AHP models read the text"les generated by the

AI-2 and the AI-3 to produce the"nal ranking of each alternative. Wizards (i.e. guides to the oper-ators) are created in cooperation with AHP models for generating specialized graphs and re-ports, loading data, etc.

f A user-friendly environment has been built using

the Visual Basic Forms and the C##objects (for the programs that are associated with C## language). Active X technology has been used for the automation of di!erent functions.

Fig. 6 shows the integration methods used in FMS design and intelligent decision support tools.

6. Conclusion

Fig. 6. Integration of FMS design tools.

A certain degree of automation in FMS design is realized in this research by using the Active X technology. It is important that future research e!ort should be directed toward fully automating the interface between the simulation models and the intelligent tools, thus enhancing the intelligence of the design system and enlarging its knowledge base.

To summarise, the current research has demon-strated that the use of an integrated methodology of system modeling and AI tools for FMS design has enabled system designers to improve the e$ -ciency of the design task. The present research work will continue to test the system in practical situations. Enlarging the knowledge base is the main task so that the system would have the capa-bility to design a suitable FMS system for various industrial sectors.

References

[1] P. Floss, J. Talavage, A knowledge-based design assistant for intelligent manufacturing systems, Journal of Manu-facturing System 9 (1990) 87}102.

[2] A.A. Aly, M. Subramaniam, Design of an FMS decision support system, International Journal of Production Re-search 31 (1993) 2252}2273.

[3] D.E. Brown, G. AnadaLinggam, An expert system for design of#exible manufacturing systems, Proceedings of the 1986 IEEE International Conference on Systems, Man and Cybernetics, Atlanta, Georgia, 1986, pp. 852}857. [4] D. Borenstein, IDSSFLEX: An intelligent DSS for the

design and evaluation of#exible manufacturing systems, Journal of the Operational Research Society 49 (1998) 734}744.

[5] A. Kazerooni, F.T.S. Chan, K. Abhary, A fuzzy integrated decision-making support system for scheduling of FMS using simulation, Computer Integrated Manufacturing Systems 10 (1) (1997) 27}34.

[6] M.R. Spano, P.J. O'Grady Sr., R.E. Young, The design of

#exible manufacturing systems, Computer in Industry 21 (1993) 185}198.

[7] P. Ranky, The Design and Operation of FMS, FS (Publi-cations) Ltd., UK, 1983.

[8] H. Tempelmeier, H. Kuhn, Flexible Manufacturing Systems: Decision Support for Design and Operation, Wiley, New York, 1993.

[9] D. Borenstein, Intelligent decision support system for# ex-ible manufacturing system design, Annals of Operations Research 77 (1998) 129}156.

[10] C.J. Antonelli, R.A. Volz, T. Mudge, Hierarchical de-composition and simulation of manufacturing cells using Ada, Simulation 46 (1986) 141}152.

[11] T.C.E. Cheng, Simulation of #exible manufacturing systems, Simulation 45 (1985) 299}302.

[12] J.M. Mellichamp, A.F.A. Wahab, Process planning simu-lation: An FMS modeling tool for engineers, Simulation 48 (1987) 186}192.

[13] J. Haddock, A simulation generator for#exible manufac-turing systems design and control, IEE Transactions 20 (1988) 22}31.

[14] J.M. Mellichamp, O. Kwon, A.F.A. Wahab, FMS designer: An expert system for#exible manufacturing system design, International Journal of Production Research 28 (11) (1990) 2013}2024.

[15] J.M. Mellichamp, A.F.A. Wahab, An expert system for FMS design, Simulation 48 (1987) 201}208.

[16] H.A. El Maraghy, T. Ravi, Modern tools for the design, modeling and evaluation of #exible manufacturing sys-tems, International Journal of Robotics and Computer-Integrated Manufacturing 9 (4}5) (1992) 335}340. [17] L. Abdel-Malek, C. Wolf, Evaluating#exibility of

alterna-tive FMS designs}a comparative measure, International Journal of Production Economics 23 (1991) 3}10. [18] A. Arbel, A. Seidmann, Performance evaluation of#exible

manufacturing systems, IEEE Transactions on Systems, Man, and Cybernetics SMS-14 (4) (1984) 606}617. [19] M. Barad, K. Hoang, Cutting tools versus machine tools

investments in FMS design, International Journal of Production Economics 42 (1995) 29}40.

[20] I.J. Chen, C.H. Chung, An examination of #exibility measurements and performance of#exible manufacturing systems, International Journal of Production Research 34 (2) (1996) 379}394.

[21] M. Barad, Impact of some #exibility factors in FMSs } a performance evaluation approach, Interna-tional Journal of Production Research 30 (11) (1992) 2587}2602.

[22] P.L. Primrose, C.C. Brown, FMS evaluation: A case study, The FMS Magazine 5 (3) (1987) 131}132.

#exible manufacturing systems, Computers in Industry 25 (1994) 131}143.

[24] P. Afentakis, A model for layout design in FMS, in: A. Kusiak (Ed.), Flexible Manufacturing Systems: Methods and Studies, North-Holland, Amsterdam, 1992, pp. 133}150. [25] K.E. Stecke, Formulation and solution of nonlinear inte-ger production planning problems for#exible manufactur-ing systems, Management Science 29 (1991) 273}288. [26] C.M. Harmonosky, Preliminary system design for#exible

manufacturing systems (FMS): Essential elements, analysis tools, and techniques, Control and Dynamic Systems 46 (1991) 83}122.

[27] A. Stam, M. Kuula, Selection a #exible manufacturing system using multi-criteria analysis, International Journal Production Research 29 (4) (1991) 803}820.

[28] T.L. Saaty, The Analytic Hierarchy Process: Planning, Priority Setting, Resource Allocation, McGraw-Hill, New York, 1980.

[29] Expert Choice, Inc., Decision Support Software Expert Choice User Manual, McAllen, Virginia, 1995.

[30] D.-C. Li, C. Wu, K.-Y. Torng, Using an unsupervised neural network and decision tree as knowledge acquisition

tools for FMS scheduling, International Journal of Systems Science 28 (10) (1997) 977}985.

[31] K. Dunk, C. Lee, Optimizing the Design of Flexible Manu-facturing Systems Using a Neural Network, Conference publication, no. 360, 1992, pp. 281}286.

[32] A.W. Labib, G.B. Williams, R.F. O'Connor, An intelligent maintenance model (System): An application of the ana-lytic hierarchy process and a fuzzy logic rule-based Con-troller, Journal of the Operational Research Society 49 (1998) 745}757.

[33] A. Stam, M. Sun, M. Haines, Arti"cial neural network representations for hierarchical preference structures, Computers Operations Research 23 (12) (1996) 191}1201. [34] H.-S. Min, Y. Yih, C.-O. Kim, A competitive neural network approach to multi-objective FMS scheduling, In-ternational Journal Production Research 36 (7) (1998) 1749}1765.

[35] Systems Modeling Corporation, Arena User's Guide, 1996.

[36] IntelliCorp, Inc., Kappa-PC User's Guide, 1995. [37] NCS, Getting Started, NEUFrame User Manual, Neural