EFFECT OF COMPATIBILIZER AND BAMBOO FIBER CONTENT ON

THE MECHANICAL PROPERTIES OF PP-G-MA COMPATIBILIZED

POLYPROPYLENE/BAMBOO FIBER COMPOSITES

B. C. Bonse1*, M. C. S. Mamede1, R. A. da Costa1 and S. H. P. Bettini2

1

Department of Metallurgical and Materials Engineering, Centro Universitário da FEI, São Bernardo do Campo, SP, Brazil – prebbonse@fei.edu.br; mauriciomamede@gmail.com; costara@uol.com.br

2 Department of Materials Engineering,Universidade Federal de São Carlos, São Carlos, SP, Brazil –

silvia.bettini@uol.com.br

An investigation was carried out regarding the effect of compatibilizer (maleic anhydride grafted PP) and bamboo fiber content on the mechanical properties of polypropylene/bamboo fiber composites according to a two-level factorial central composite design. Composites were prepared in a co-rotating twin-screw extruder and specimens were injection molded. Effect of the variables on mechanical properties has been assessed through flexural modulus and strength, tensile strength, elongation at break and impact strength. With the exception of impact strength, all properties assessed showed to be significantly affected by the variable bamboo fiber content: positively in the case of tensile strength, flexural strength and modulus; and negatively in the case of elongation and energy at break. Compatibilizer content showed significant positive effect on all properties, except impact strength and flexural modulus. The only variable that seemed to affect impact strength was the interaction between bamboo fiber and compatibilizer content. This interaction effect also seemed to be significant for the tensile, but not for the flexural properties. Scanning electron microscopy revealed the adhesion achieved between the nonpolar hydrophobic polymer matrix and the polar hydrophilic bamboo fibers when using the compatibilizer PPgMA.

Introduction

Currently, great efforts are being made to create sustainable eco-efficient practices and products. Within this context biofiber reinforced polymer composites are increasingly gaining attention as viable alternative to synthetic fiber reinforced composites, especially glass-based ones (Coutinho and Costa, 1999; Saheb and Jog, 1999; Bettini et al., 2008). In certain composite applications biofibers have shown to be competitive in relation to glass fiber (Mohanty et al., 2005). In addition to being renewable and biodegradable, advantages of biofibers over synthetic ones include low cost, light weight, low abrasiveness and excellent strength to weight ratio (Sanadi et al., 1994). However, there are some limitations in using biofibers

as reinforcement in polymers. These include

processing temperature, which should not exceed the degradation temperature of these fibers of around 200 °C, and high moisture absorption, which may impair mechanical properties as well as facilitate fungus growth (Kalia et al., 2009). One of the plastics that can be easily processed at temperatures below 200 °C is polypropylene (PP). Compared to the most commonly used biofibers (wood, jute, coir, sisal, banana etc) bamboo exhibits low density and high mechanical

strength. In this investigation moso bamboo

(Phyllostachys Eduli) was used as reinforcement in PP. However, polarity difference between hydrophobic PP and hydrophilic bamboo results in incompatible

composites, which are not useful in load-bearing

applications. To overcome this problem

compatibilizers are required, such as maleic anhydride grafted PP (PPgMA), which reduce interfacial stresses and improve adhesion between the polymer and fiber (Sanadi et al., 1994; Keener et al., 2003; Karmarkar et al., 2007).

In this investigation the effect of compatibilizer PPgMA and bamboo fiber content on the mechanical properties of polypropylene/bamboo fiber composites were assessed according to a two-level factorial central composite design.

Experimental

Materials

KM6100 polypropylene pellets were donated by Quattor (Mauá, Brazil) with MFI = 3.1 g/10min (230°C/2.16 kg). Compatibilizer used was Polybond 3200 maleic anhydride grafted PP (PPgMA) with MFI = 110 g/10 min (190 C/2.16 kg) purchased from Crompton-Uniroyal Chemical (São Paulo, Brazil).

Methods

The bamboo waste fibers were ground in a MAK-250 grinder from Kie Máquinas e Plásticos (Louveira/SP), using a 3-mm screen. Grinding required pre-drying the fibers for 4 hours at 105°C.

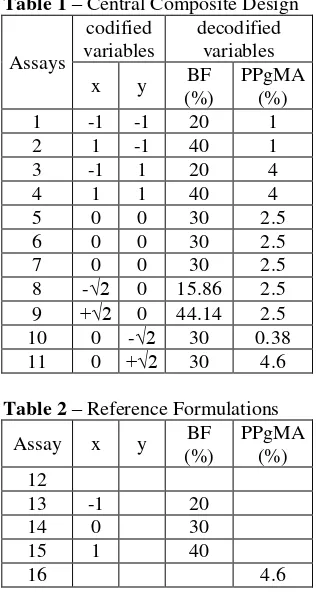

PP/bamboo fiber composites were prepared according to a central composite experimental design, shown in Table 1, based on previous investigation by Bettini et al. (2010) with coir fibers. Their findings indicated that the lowest PPgMA content used, i.e. 4wt%, was sufficient for composite compatibilization. Hence in the present investigation it was decided to use 4wt% as the highest level in the experimental design. Reference formulations were also prepared (Table 2). Ground fibers were dried for 12 hours at 105°C, as moisture content drying oven test results indicated that after this period moisture content remained stable (not shown). PP pellets, compatibilizer PPgMA and ground bamboo fibers were then pre-mixed in a Mecanoplast ML40 intensive mixer (Rio Claro/SP) for one minute and subsequently extruded in a Thermo Scientific HAAKE PolyLab OS RheoDrive co-rotating twin-screw extruder. Temperature profile used was: 170°C, 175°C, 180°C, 180°C, 190°C and 185°C. Rotor frequency was 250 rpm. Extruded strand was air-cooled by means of a fan, pelletized and stored for subsequent injection molding of tensile, bending and impact test specimens. Prior to injection molding pelletized composites were dried for 12 hours at 105°C. Injection molding was performed in an HM60/350 Battenfeld machine at the following conditions. Injection pressure 700 bar; holding pressure 560 bar; feed and compression section temperature 193°C; metering section and nozzle temperature 198°C; tool temperature 85°C; holding time 10 s; cooling time 20 s.

The injected specimens were submitted to tensile and flexure tests in an Instron 5565 Universal Testing Machine at test speeds of 5 mm/min and 1.3 mm/min, according to ASTM D638 and D790, respectively. Impact tests were carried out in an analogical VEB Werkstoff Prüfmaschinen Leipzig Charpy impact tester in accordance with ASTM D 6110.

Fractured surfaces of the tensile tests were gold-coated and analyzed in a JEOL JSM-T330A scanning electron microscope, SEM.

Table 1 –Central Composite Design

Assays

Table 2 –Reference Formulations

Assay x y BF

Analysis of PP/bamboo fiber composites

Results of the mechanical tests are listed in Table 3.

Table 3 –Results of the tensile, impact and flexural

tests: average of ten specimens, except for IS (five specimens)

TS: tensile strength; break: strain at break; Enbreak:

strength decreases as BF content increases (from 34.1 to 27.6 MPa, as %BF increases from 0 to 40%). A drastic decrease in strain at break is seen when 20wt% BF is introduced in PP, from higher than 500% to 9.61%. Increasing BF content reduces elongation further down to 2.55% at 40wt% BF. These results can be explained by the lack of adhesion at the interface between the polar hydrophilic fibers and the nonpolar hydrophobic PP. Thus, during tensile loading stress transfer is impaired and the fibers act as stress concentrators, resulting in composite embrittlement.

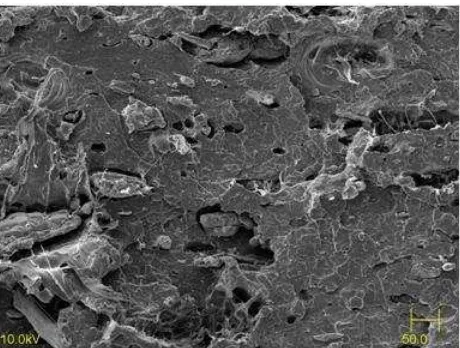

Lack of adhesion in composites without compatibilizer is evidenced in the SEM micrograph of Figure 1a, whereas in Figure 1b the fibers in the composite containing compatibilizer are seen to be well adhered to the matrix. Composite embrittlement with increasing fiber content without compatibilizer is also observed by the reduction in the values of energy at break (area under the stress-strain curve) and impact strength. The findings regarding impact strength are in conflict with those of Bettini et al. (2010) who observed an increase in this property at increasing coir contents above 20 wt%. However, it should be mentioned that depending on composite nature (different fibers with different stiffness) and type of impact test, apparent impact strength may either increase or decrease (Nielsen, 1994). With regard to flexural tests of the uncompatibilized composites, both flexural modulus and strength increase markedly with increasing BF content (assays 12 to 15, from 0 to 40wt% BF), due to the high stiffness of this fiber in relation to the PP matrix.

Figure 1a – SEM micrograph of tensile fractured

surface of 20wt %BF composite without PPgMA. Note the gap between fibers and PP matrix

Figure 1b – SEM micrograph of tensile fractured

surface of 20wt% BF composite with 4wt% PPgMA. No gaps between fibers and PP matrix

Preliminary analysis of the compatibilized composites containing lowest and highest levels of BF and PPgMA (assays 1 to 4) shows that increasing BF content (at the same level of PPgMA) increases tensile, impact and flexural strength, and reduces strain and energy at break. Moreover, increase in PPgMA content (at the same level of BF content) increases all assessed properties, but flexural strength, which decreases. It should be mentioned that comparing tensile strength of

40 wt% compatibilized with uncompatibilized

composite (assay 4 vs. 15) shows an increase in tensile strength of 66% and with pure PP (assay 4 vs. 12) an increase of 34%. These values are similar to those obtained by Bettini et al. (2010) with the same amounts of coir fiber and compatibilizer (63% and 35%), despite the higher reported tensile strength and modulus of bamboo fiber in relation to coir (Suddell and Evans et al., 2005). When the same analysis is applied to flexural modulus the compatibilized BF composite shows an increase of 114% in relation to pure PP, against 78% obtained by Bettini et al. Thus fiber stiffness seems to have a stronger effect on

composite flexural properties than on tensile

properties.

For more in-depth assessment of the effect of BF and PPgMA content - and possible interactions - on the mechanical properties of the composites, multiple regression analysis was performed by means of software Statistica® on all data used to generate Table 3. The mechanical properties could be fitted by a second order model, at significance level of 5%. Table 4 contains the coefficients of the fitted polynomial equations: a0+a1x+a2y+a3xy+a4x2+a5y2, where x and y

Table 4 – coefficients of the polynomial equations

obtained from the second order model fit

linear terms quadratic terms

a0 a1 a2 a3 a4 a5 well. The coefficients reveal whether an independent

variable (%BF, %PPgMA, %BF.%PPgMA, %BF2 and

%PPgMA2) has a positive or negative effect on the

dependent variable (mechanical property). The a1

values thus show that BF content has a positive effect on tensile strength, flexural modulus and strength and negative effect on elongation at break and energy to

break (area under the stress-strain curve). The a2 values

show that PPgMA content has a positive effect on all properties shown in Table 4, except for flexural modulus, which is not significantly affected by PPgMA

content. The a3 values show that, with the exception of

the flexural properties, all other properties are affected by the interaction between BF and PPgMA content.

Coefficients a4 and a5 refer to the quadratic effects of

BF and PPgMA content, respectively.

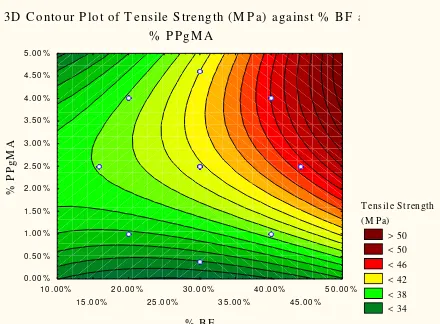

The above polynomial equations allow construction of 3D contour plots showing the response of the mechanical property as a function of BF and PPgMA content. As example are shown 3D contour plots of a tensile and flexural property in Figures 2 and 3. Raw data are also shown in these plots as dots.

3D C ontour P lot of T ensile S tr ength (M P a) against % B F a compatibilizer. At low BF content increasing PPgMA content does not lead to high increase in tensile

Figure 3 – 3D contour plot of flexural modulus against

BF and PPgMA content.

From Figure 3 increasing BF content is seen to always increase flexural modulus, regardless of PPgMA content. Thus, compatibilizer content has no effect on flexural modulus as already observed when analyzing the coefficients of the polynomial equation obtained from the second order model fit.

Conclusions

Investigation of the effect of bamboo fiber and compatibilizer content on mechanical properties of PP/bamboo fiber composites showed that bamboo fiber content has a positive effect on tensile strength, flexural modulus and strength, and negative effect on elongation at break and energy to break (area under the stress-strain curve). PPgMA content showed a positive effect on all assessed properties, except for flexural modulus and impact strength, which showed to be unaffected by this dependent variable. With the exception of the flexural properties, all other properties showed to be affected by the interaction between bamboo fiber and PPgMA content.

PPgMA concentrations between 2 and 4wt% seem to be sufficient for composite compatibilization.

Bamboo fibers can be successfully used as

reinforcement in polymer, with the aid of

References

Bettini S. H. P., Uliana A. T., Holzschuh D. J., “Effect

of Process Parameters and Composition on

Mechanical, Thermal and Morphological Properties of

Polypropylene/Sawdust Composites”, Appl.Polym.

Sci.,108, 2233-2241 (2008).

Bettini S. H. P., Antunes M. C., Bicudo A. B. L. C., Augusto I. S., Antunes L. A., Morassi P. L., Condotta, R., Bonse B. C., “Investigation on the Use of Coir Fiber as Alternative Reinforcement in Polypropylene”, Journal of Applied Polymer Science (2010)

Coutinho F. M. B., Costa T. H. S., “Performance of

polypropylene-wood fiber composites”, Polym.

.Test.,18,581-587 (1999)

Kalia S., Kaith B.S., Kaur I., “Preteatments of natural fibers and their application as reinforcing material in

polymer composites – A review”, Polymer Eng. and

Science, 49, 1253-1272 (2009)

Karmarmar A., Chauhan S. S., Modak J. M., Chanda

M., “Mechanical properties of wood-fiber reinforced

polypropylene composites: Effect of a novel

compatibilizer with isocyanate functional group”

Composites Parte A, 38, 227-233 (2007)

Keener T. J., Stuart R. K., Brown T. K., “Maleated coupling agents for natural fibre composites”,

Composites Part A, 35, 357-362 (2004)

Mohanty A. K., Natural Fibers, Biopolymers and Biocomposites, CRC Publishers, U.S. (2005)

Nielsen L. E, Landel R. F.: Mechanical Properties of Polymers and Composites, 2nd Edition, Marcel Dekker Inc, New York (1994)

Saheb D. N., Jog J. P., “Natural Fiber Polymer

Composites: A Review”, Adv. Polymer Technology,

18, 351-363 (1999)

Sanadi A. R., Caulfield D. F., Rowell R. M., “Reinforcing Polypropylene With Natural Fibers”,

Plastics Eng., 50, 27-28 (1994)

Suddell, B. C., Evans, W. J., “Chapter 7 Natural Fiber Composites in Automotive Applications”, in Natural Fibers, Biopolymers and Biocomposites, Mohanty et

al. (Ed.), Taylor &Francis Group, Florida p. 237–297