(Pengeluaran Sisa Kreosot dalam Tiang Listrik Bekas Pakai menggunakan Perlakuan Uap) 1)

By / Oleh

Han Roliadi 2) & Elvin T. Choong 3) ABSTRAK

Keberadaan sisa-sisa kreosot dalam produk kayu bekas pakai dan tak lagi

digunakan, diantaranya tiang listrik bekas, dapat mengakibatkan kesulitan/masalah dalam

pemanfaatannya menjadi produk berguna lain seperti: papan blok, papan partikel, papan

serat, dan pulp/kertas. Maka, sisa kandungan kreosot tersebut harus dihilangkan atau

diturunkan menggunakan perlakuan khusus yang efektif. Sebelum perlakuan uap, tiang

listrik tedsebut perlu dibuat menjadi partikel-partikel berukuran kecil, antara lain serbuk

gergaji sehingga memudahkan penguapan kreosot oleh uap.

Perlakuan uap terhadap tiang listrik bekas pakai telah dicoba keefektifannya dalam

menghilangkan/menurunkan sisa kandungan kreosotnya. Hasil menunjukkan bahwa

perlakuan uap dapat menurunkan kandungan kreosot hingga 1,31 persen, untuk kandungan

awal kreosotnya yang berbeda-beda. Tiang listrik dengan kandungan kreosot lebih tinggi

membutuhkan waktu perlakuan uap lebih lama. Pada kandungan awal kreosot tertentu

atau sama, penurunan/pengeluaran kreosot pada batang/tiang listrik bekas yang berumur

pakai lebih lama ternyata lebih sulit dari pada tiang listrik berumur lebih muda. Pada

berbagai umur Selanjutnya baik pada tiang listrik berumur lebih muda ataupun lebih tua,

penurunan/pengeluaran kresosote juga lebih sulit pada bagian dalam batang/tiang

dibandingkan dari bagian yang lebih dekat permukaan batang/tiang.

Perlakuan uap merupakan cara yang murah dan efisien menurunkan kandungan

cara lain, antara lain dengan pelarut organik yang memerlukan biaya mahal dan

penggunaan mikororganisme tertentu yang memerlukan waktu lebih lama.

Keywords: Perlakuan uap, sisa kreosot, tiang listrik bekas pakai, keausan, dan tiang listrik baru/segar diawetkan

______________________________________ 1)

Naskah ini merupakan bagian dari disertasi doktor pengarang pertama pada Lousiana State University, Baton Rouge, LA, USA, 1997

2)

Pusat Pengembangan dan Teknologi Hasil Hutan, Bogor, Indonesia 3)

School of Forestry, Wildlife, and Fisheries, Louisiana State University, Baton Rouge, LA, USA

ABSTRACT

The presence of residual creosote in out-of-service weathered creosote-treated wood

products, such as used utility poles, can bring about problems/troubles in their reutilization

into other useful products (e.g. block board, particleboard, fiberboard, and pulp/paper).

Therefore, their residual creosote content should be removed/reduced by particular effective

treatment. Prior to the steaming, the poles should be converted to smaller-size particles (i.e.

sawdust) to ensure more effective creosote volatilization by steam.

Steam treatment of weathered out-of-service utility poles has been experimented to

evaluate its effectiveness in removing their residual creosote content. The results revealed

that steaming reduced the creosote to a 1.31-percent level, regardless of different initial

creosote contents. Poles with higher initial creosote content required longer steaming

duration. At a given initial content, creosote removal from weathered poles and from

materials in the inner pole portion was more difficult than that from freshly treated poles

and the outer portion. Regardless of pole ages, creosote removal from the inner portion of

the poles was also more difficult than the outer portion. Steaming could prove an efficient

and cheap way for creosote removal. Further reduction in residual creosote content in the

poles below 1.31 percent can be done by other methods (e.g. more costly solvent extraction

Keywords: steaming, residual creosotes, out-of-service utility poles, weathering, and freshly treated poles

______________________________________ 1)

This article is a part of the first author’s doctoral dissertation at the Louisiana State University, Baton Rouge, LA, USA, 1997

2)

Research and Development Center for Forest Products Technology, Bogor, Indonesia 3)

School of Forestry, Wildlife, and Fisheries, Louisiana State University , Baton Rouge, LA, USA

I. INTRODUCTION

Attention has long been placed on removing or reducing creosote preservative in

weathered treated wood products which were no longer serviceable, among others utility

poles, before being utilized/processed into particular useful products, e.g. block board,

particleboard, fiberboard, and pulp/paper. This is because the residual creosote can bring

about troubles/problems in that processing. Two methods of creosote removal have been so

far experimentally tried, i.e. (1) bioremediation and (2) solvent extraction. Bioremediation

is a biological process using organisms that can “consume” the preservative. An

experiment done by Eslyn (1976) on creosote-treated marine piles showed that

approximately 80 percent of the creosote can be eliminated, but the processing is

exhaustively time-consuming. The microorganisms used for his work was Pseudomonas

creosotensis. Using water-nutrient broth, the incubation took about nine days.

The LSU (Louisiana State University) Institute for Environmental Studies has

conducted solvent (methanol) extraction on severely weathered creosote-treated wood. This

extraction could remove almost 100 percent of the creosote (Portier et. al., 1994).

However, the creosote-removal by this method in large-scale implementation can required

the use of expensive methanol solvent and costly extraction apparatus. Therefore, “cheaper

and not too lengthy” method to remove this creosote should be found out, such as steaming..

Steaming is often used in preservative treatment, especially by the vacuum-pressure

Steaming is also used to separate the volatile compounds in wood extractives (Browning

1967). Since creosote contains compounds that ranges from low-boiling fractions (i.e. more

volatile) to high-boiling fractions (less volatile), steaming can expectedly volatilize the

creosote thereby removing or reducing it in the creosote-treated wood.

II. MATERIALS AND METHODS A. Materials

Samples of sawdust from the sawing on the utility poles of southern yellow pine

species as previously used for creosote-content determination (Roliadi, et. al. 2000) were

collected from various vertical and horizontal locations in 5- and 25-year weathered

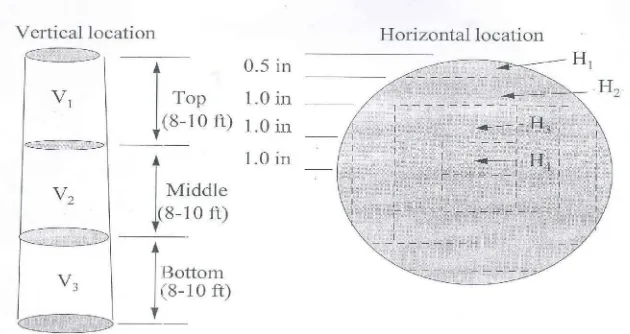

out-of-service poles and freshly treated poles (Figure 1). For replication, five poles were taken

from each group of pole ages.

[image:4.624.147.462.390.557.2]

Figure 1. Patterns of cutting/sawing procedures in treated poles

Gambar 1. Pola prosedur pemotongan/penggergajian tiang listrik yang diawetkan

Translation of English words in Figure 1 into Indonesian (Terjemahan kata-kata bahasa Inggris dalam Gambar 1 ke bahasa Indonesia): Vertical location = Lokasi vertikal; Top = Bagian atas; Middle = Bagian tengah; Bottom = Bagian dasar; and/dan Horizontal location = Lokasi horisontal.

B. Methods

Each of these samples weighing about 5 grams, with predetermined creosote content

using toluene extraction (AWPA Standard, 1984), was placed in fritted glass crucible and

minute interval, the samples in the glass crucibles were removed from the retort and washed

with boiling water to facilitate as much creosote removal as possible. The possible

remaining creosote contents in the samples were determined again in accordance with the

corresponding AWPA Standard (1984). Steam treatment was terminated, when the residual

creosote contents became stable and were further considered as the final contents. The

criteria used to evaluate the effectiveness of steam treatment were final creosote content and

steaming duration.

C. Data Analysis

In order to assist the data evaluation (i.e. final creosote content and steaming

duration), statistical analysis that employed repeated-measurement design was used,

whereby pole ages (i.e. freshly treated, and 5 and 25 years) acted as the main plot, various

vertical and horizontal locations in the poles as the sub plot, initial creosote contents as the

covariate, and five poles taken from each age group as replicate.

II. RESULTS AND DISCUSSION

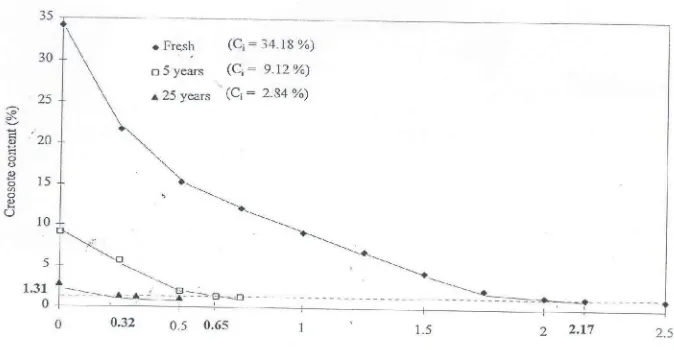

In general, steaming reduced creosote to a final content that ranged about 1.2 – 1.5

percent regardless of different initial contents (Figure 2). Heat from the steam caused the

volatilization of compounds in creosote and lowered their viscosity, thereby greatly

assisting the movement of creosote, which is not chemically held in wood. However, the

capability of steam treatment was limited to about 1.2 – 1.5 percent final creosote content,

which is less effective than solvent extraction and bioremediation. This is because creosote

is oil-soluble and therefore immiscible in a polar substance (steam). Also, creosote left at

that low percentage might contain greater fractions of high-boiling compounds which are

[image:6.624.126.463.71.246.2]

Steaming duration (hours)

Figure 2. Approximate steaming durations required in 3 kinds of creosote-treated

poles (i.e. 2.17 hours for freshly treated poles; 0.65 hours for 5-; and 0.32 hours for 25-year weathered poles, respectively) to reach 1.31 % final creosote

content (Ci = initial creosote content)

Gambar 2. Perkiraan waktu perlakuan uap yang diperlukan pada 3 macam tiang listrik yang diawetkan dengan kreosot (2,17 jam untuk tiang listrik baru/segar

diawetkan; 0,65 jam untuk tiang listrik berumur 5 tahun; dan 0,32 jam untuk tiang listrik berumur 25 tahun) guna mencapai kandungan kreosot akhir 1,31 % (Ci = kandungan kreosot awal)

Translation of English words in Figure 2 into Indonesian (Terjemahan kata-kata bahasa Inggris dalam Gambar 2 ke bahasa Indonesia): Steaming duration (hours) = Waktu perlakuan uap (jam); Fresh = Tiang listrik baru/segar diawetkan; 5 years = Tiang listrik diawetkan telah berumur 5 tahun; 25 years = Tiang listrik diawetkan telah berumur 25 tahun; dan/and Creosote content (%) = Kandungan kreosot (%).

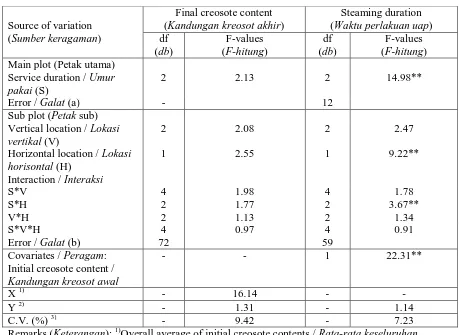

The analysis of variance (Table 1) reveals that that the final creosote contents were

not significantly different among all the variable tested (i.e. poles, ages and various vertical

and horizontal locations, and hence those final contents could be averaged, i.e. 1.31 percent.

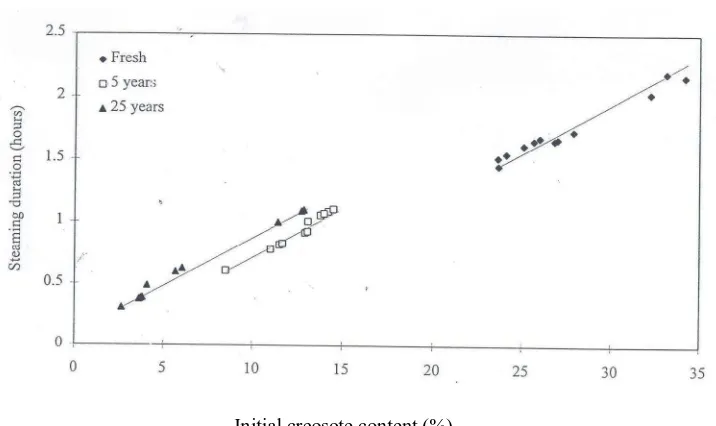

The approximate steaming duration for various initial creosote contents could be

determined, as shown in Figure 2, by interpolating it to the overall 1.31-percent average,

which was regarded as the effective final creosote content. As a result, when the

experimental data of initial creosote content were plotted against the steaming duration

[image:7.624.126.484.67.280.2]

Initial creosote content (%)

Figure 3. Relationship between initial creosote content and steaming duration to reach 1.31 % final creosote content

Gambar 3. Hubungan antara kandungan kreosot awal dan waktu perlakuan uap untuk mencapai kandungan akhir kreosot 1.31 %

Translation of English words in Figure 3 into Indonesian (Terjemahan kata-kata bahasa Inggris dalam Gambar 3 ke bahasa Indonesia): Initial creosote content (%) = Kandungan kreosot awal (%); Fresh = Tiang listrik baru/segar diawetkan; 5 years = Tiang listrik diawetkan telah berumur 5 tahun; 25 years = Tiang listrik diawetkan telah berumur 25 tahun; and/dan Steaming duration (hours) = Waktu perlakuan uap (jam).

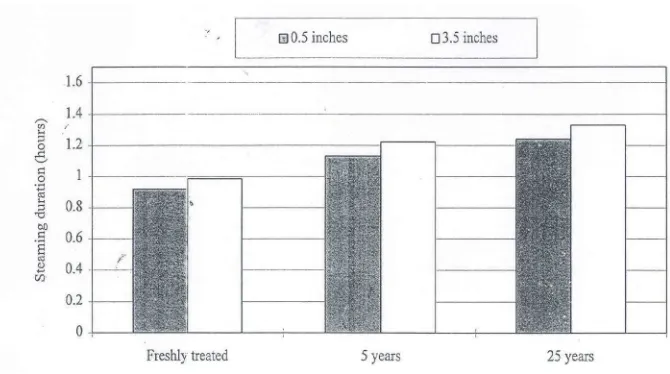

In addition, the analysis of variance on steaming duration (Table 1), which

incorporated the initial creosote contents, explained the effect of various locations in the

poles and different service durations (pole ages), whereby the overall initial contents were

statistically assumed as constant. At that constant initial creosote, i.e. 6.14 percent (Table

1), steaming duration of samples from pole of older ages and of the outer portions was

actually longer than that of freshly treated poles and of the inner portion, respectively

(Figure 4). More difficulty in steaming of older poles again confirmed that the residual

creosote in 5- and 25-year weathered poles contained greater high-boiling fractions, due to

more evaporation of low-boiling compounds, as compared to those in the freshly treated

poles. On the other hand, more difficult creosote removal from the inner pole portion could

analysis of variance further reveals that different vertical locations in poles did not

[image:8.624.82.541.174.509.2]significantly affect steaming duration.

Table 1. Analysis of variance on final creosote content and steaming duration

Tabel 1. Analisa keragaman terhadap kandungan kreosot akhir dan waktu perlakuan uap

Source of variation

Final creosote content (Kandungan kreosot akhir)

Steaming duration (Waktu perlakuan uap) (Sumber keragaman) df

(db) F-values (F-hitung) df (db) F-values (F-hitung) Main plot (Petak utama)

Service duration / Umur pakai (S)

2 2.13 2 14.98**

Error / Galat (a) - 12

Sub plot (Petak sub) Vertical location / Lokasi vertikal (V)

2 2.08 2 2.47

Horizontal location / Lokasi horisontal (H)

1 2.55 1 9.22**

Interaction / Interaksi

S*V 4 1.98 4 1.78

S*H 2 1.77 2 3.67**

V*H 2 1.13 2 1.34

S*V*H 4 0.97 4 0.91

Error / Galat (b) 72 59

Covariates / Peragam: Initial creosote content / Kandungan kreosot awal

- - 1 22.31**

X 1) - 16.14 - -

Y 2) - 1.31 - 1.14

C.V. (%) 3) - 9.42 - 7.23

[image:9.624.129.464.70.257.2]

Service duration

Figure 4. Steaming duration required in sawdust samples from three kinds of treated poles (freshly treated, and 5- and 25-year weathered poles) at 0.5-inch distance (outer portion) and 3.5-inch distance (inner portion) from pole surface, by assuming that their initial creosote contents were the same (i.e. 16.14 %) Gambar 4. Waktu perlakuan uap yang diperlukan pada contoh serbuk gergaji dari tiga macam tiang listrik yang diawetkan (baru/segar diawetkan, berumur pakai 5 tahun, dan berumur pakai 25 tahun) pada jarak 0,5 inci (bagian lebih luar) dan pada jarak 3,5 inci (bagian lebih dalam) dari permukaan tiang listrik, dengan asumsi bahwa kandungan kreosot awalnya sama (16,14 persen)

Translation of English words in Figure 4 into Indonesian (Terjemahan kata-kata bahasa Inggris dalam Gambar 4 ke bahasa Indonesia): Service duration = Masa pakai tiang listrik; Freshly treated = Tiang listrik baru/segar diawetkan; 5 years = Tiang listrik diawetkan telah berumur 5 tahun; 25 years = Tiang listrik diawetkan telah berumur 25 tahun; 0.5 inches implies the distance from pole surface (outer portion) toward the pole core = 0,5 inci menunjukkan jarak dari permukaan tiang listrik (bagian lebih luar tiang listrik) menuju ke bagian pusat tiang listrik; 3.5 inches implies the distance from pole surface (outer portion) toward the pole core = 3,5 inci menunjukkan jarak dari permukaan tiang listrik (bagian lebih luar tiang listrik) menuju ke bagian pusat tiang listrik; and/dan Steaming duration (hours) = Waktu perlakuan uap (jam).

IV. CONCLUSSIONS AND SUGGESTIONS

Trial on removal of out-of service using steam treatment was conducted by at first

converting the poles into smaller-size particles, i.e. sawdust. In this way, therefore, it will

inflict more effective creosote removal, because sawdust particles has substantially much

larger surface area than the corresponding poles. As a result, there would be more intimate

contact between creosote stuffs and hot steam, thereby incurring effective volatilization of

The initial creosote contents in sawdust samples from the creosote-treated poles

correlated positively with steaming duration. Regardless of different initial creosote

contents, steaming reduced the creosote to 1.31 percent level. Beyond this level, steaming

brought about no significant reduction in creosote content.

At a given initial creosote content, removal of creosote by steam was more difficult

for poles with longer service duration (i.e. older ages) than with shorter duration/younger

ages, and for pole materials from the inner portion than the portion near the surface.

Steaming, however, can be an efficient and cheap method of reducing the creosote

content in weathered poles. Further removal for effective treatment can be done by other

methods (e.g. more costly solvent extraction and time-consuming bioremediation).

LITERATURE CITED

AWPA (American Wood Preservers’ Association) Standard. 1984. Method for the determination of oil-type preservative in wood. AWPA A6-83, Stevensville, MD (USA), pg. 1-7.

Andrew, J.W. 1952. Volatility of some of the compounds in creosote produced from high- temperature tar. Proc. of Am. Wood Preserv. Assoc, 48: 85-98

Browning, B. L. 1967. Methods of Wood Chemistry. Interscience Publishers. A Division of John Wiley & Sons. New York – London – Sydney.

Eaton, R.A. and M.D.C. Hale. 1993. Wood: Decay, Pests, and Protection. Chapman and Hall. London – Glasgow – New York – Tokyo – Melbourne.

Esslyn, W.E. 1976. Wood preservative degradation by marine borers. Proceedings of the Third International Biodegradation. 679 – 686 pp. Applied Science J. Publ. Ltd. London (UK)

Hickin, N.E. 1971. Wood preservation: A Guide to the Meaning of Terms. Hutchinson and Co. Ltd. London