Proceedings of International Conference on Mechanical &

Manufacturing Engineering (ICME2008)

General Mechanical Engineering

Manufacturing

Automotive Technology

Heat and Fluid Technology

Industrial Engineering

International Conference on Mechanical & Manufacturing Engineering (ICME2008), 21

–

23

May 2008, Johor Bahru, Malaysia.

© Faculty of Mechanical & Manufacturing Engineering, Universiti Tun Hussein Onn

Malaysia (UTHM), Malaysia.

ISBN: 97

–

98

–

2963

–

59

–

2

Faculty of Mechanical and Manufacturing Engineering

Universiti Tun Hussein Onn Malaysia (UTHM)

Proceedings of International Conference on Mechanical &

Manufacturing Engineering (ICME2008)

MANUFACTURING ENGINEERING

Study of Surface Roughness on Induction Hardened Steel using CBN Cutting Tool

MFG_ID_0001.pdf

Control of Blank Holder Force to Eliminate Wrinkling and Fracture in Deep-Drawing Rectangular Components

MFG_ID_0004.pdf

Implementation of Toyota Production System (TPS) in the Production Line of A Local Automotive Parts Manufacturer

MFG_ID_0006.pdf

Analysis of Variance on the Metal Injection molding parameters using a bimodal particle size distribution feedstock

MFG_ID_0009.pdf

Effect of Cryogenic Cooling during Grinding of Mild Steel and Stainless Steel

MFG_ID_0011.pdf

Traveling Salesman Problem with Precedence Constraint for Manufacturing Application: A Review

MFG_ID_0013.pdf

Strain Rate and Temperature Dependence of Mechanical Pproperties and Microstructure of Biomedical Titanium Alloy

MFG_ID_0020.pdf

Temperature Distribution and Bending Characteristics in Plastics Laser Forming

MFG_ID_0027.pdf

EFFECT OF ELECTRODE COOLING ON THE ELECTRICAL DISCHARGE MACHINING OF TITANIUM ALLOY

MFG_ID_0028.pdf

Optimal Lot Size of EPQ Model Considering Imperfect and Defective Products

MFG_ID_0052.pdf

Simulation based Control System for a Flat Screen Monitor Remanufacturing System

MFG_ID_0054.pdf

Scaling Effects In Milling Operations Of Tungsten-Copper-Composites

MFG_ID_0067.pdf

MFG_ID_0071.pdf

A Study on Dimensional Accuracy of FDM Machine Fabrication Style via DOE Technique

MFG_ID_0078.pdf

Design and Manufacturing of a Spherical Rolling Robot

MFG_ID_0083.pdf

The effect of nodularisation parameters on the quality of ductile iron

MFG_ID_0087.pdf

Development of an Artificial Neural Network Algorithm for Predicting the Cutting Force in End Milling of Inconel 718 Alloy

MFG_ID_0089.pdf

Mathematical Model of chip Serration frequency in end milling of Inconel 718

MFG_ID_0094.pdf

Potential Application of Rapid Prototyping Techniques to Fabricate a Laminated Rapid Tooling of Polyurethane Foam Mould

MFG_ID_0098.pdf

Influence of Micro End Milling Process Parameters on Surface Roughness

MFG_ID_0125.pdf

Fabrication of Micromold Cavity for Microreplication: A Review

MFG_ID_0127.pdf

Design of an aluminum alloy side door impact beam for passenger cars

MFG_ID_0143.pdf

The Effect of Radial Clearance between Impeller-Diffuser on Design Point Operation in a Centrifugal Fan

MFG_ID_0152.pdf

Automotive Part Prototype Development Using Reverse Engineering Technology

MFG_ID_0155.pdf

Integrating STEP with a PC-based Open Architecture Controller (OAPC-NC) for a Milling Process

MFG_ID_0169.pdf

Design of a Reliable Stair Climbing Tracked Robot

MFG_ID_0176.pdf

Processing and properties of PA6/MMT clay nanocomposites produced using selective laser sintering

MFG_ID_0193.pdf

Shear Deformation of Non-Crimp Fabrics

MFG_ID_0207.pdf

A Web-based Real-time Mould Machining Process Tracking System

MFG_ID_0222.pdf

A Study of Machining Error Compensation for Tool Deflection in Micro End-Milling

MFG_ID_0228.pdf

Development of a Micro Tool Inspection and Verification System

Cutting Force Simulation of Nose Radius Oblique Tools

MFG_ID_0233.pdf

Optimum hydroforming preform design by shape sensitivity analysis

MFG_ID_0239.pdf

An investigation of process parameters on quality of X-shape hydroformed joint by design of experiment and finite element method

MFG_ID_0240.pdf

Semi-automated Robotic Sculpting of Freeform Surfaces for Direct Digital Manufacture

MFG_ID_0316.pdf

The EWR of graphite and copper electrodes in electrical discharge machining (EDM) of AISI H13 harden steel

MFG_ID_0332.pdf

Experimental Study of the Effective Parameters in Polymeric Coating of Metal Powder Used as Raw Material in Powder-based Rapid Prototyping

MFG_ID_0333.pdf

A Study of Wire Looping Formation to Improve Ball Neck Strength of Wire Bonding Process

MFG_ID_0341.pdf

Modeling of General Etching System in Wafer Fabrication

MFG_ID_0343.pdf

A study of oxidized leadframe for QFN package on the cyclic test variable temperature effect

MFG_ID_0376.pdf

The Effect of Drill Point Geometry and Drilling Technique on Tool Life when Drilling Titanium Alloy, Ti-6Al-4V

MFG_ID_0393.pdf

Mathematical Modeling of Cutting Force in End Milling Ti-6Al4V using TiAlN Coated Carbide Tools

MFG_ID_0394.pdf

MECHANICAL

ENGINEERING

MANUFACTURING

ENGINEERING

AUTOMOTIVE

TECHNOLOGY

HEAT & FLUID

TECHNOLOGY

INDUSTRIAL

ENGINEERING

International Conference on Mechanical & Manufacturing Engineering (ICME2008), 21

–

23

May 2008, Johor Bahru, Malaysia.

© Faculty of Mechanical & Manufacturing Engineering, Universiti Tun Hussein Onn

Malaysia (UTHM), Malaysia.

Faculty of Mechanical and Manufacturing Engineering

Universiti Tun Hussein Onn Malaysia (UTHM)

Proceedings of International Conference on Mechanical & Manufacturing Engineering (ICME2008), 21– 23 May 2008, Johor Bahru, Malaysia. © Faculty of Mechanical & Manufacturing Engineering, Universiti Tun Hussein Onn Malaysia (UTHM), Malaysia.

ISBN: 97–98 –2963–59–2

Mathematical Modeling of Cutting Force in End Milling Ti-6Al4V

using TiAlN Coated Carbide Tools

Mohruni, A.S.1,2*, Sharif, S.2, Noordin, M.Y.2

1

Department of Mechanical Engineering Sriwijaya University

Indralaya - 30662 – South Sumatera Indonesia

2

Faculty of Mechanical Engineering Universiti Teknologi Malaysia

UTM Skudai - 81310 - Johor Malaysia

*[email protected], [email protected]

Abstract:

This paper deals with the development of cutting force predicted models in end milling titanium alloy Ti-6Al4V using TiAlN coated solid carbide tools under flood conditions. The primary machining parameters such as cutting speed, feed and radial rake angle, were used as independent variables for factorial design of experiment coupled with response surface methodology (RSM). Results from the 3D-response surface contour showed that the linear model generate better results than the second order models obtained during machining this advanced material. An optimum cutting conditions was also recognized for a particular range of cutting force values. The models were verified by analysis of variances and were found to be adequate.

Keywords: Cutting Force, End Milling, TiAlN Coated Carbide, Titanium Alloy, RSM.

1. Introduction

Numerous studies have shown titanium and its alloys are difficult to machine, regardless of the various types of cutting tools used. This has been attributed to their low thermal conductivity, which concentrates heat in the cutting zone (typically less than 25% that of steel), retention of strength at elevated temperatures and high chemical affinity for all cutting tool materials.

Although the cutting forces generated are not excessively high (almost similar to those with steel), they are confined to a small area due to the short chip contact length which leads to high stresses. The combination of high stress and temperature resulted in plastic deformation of the tool edge. Depth of cut

notching and chipping at the flank can also be a problem with intermittent cutting operations [1].

Knowledge of the cutting forces owing to a predictive model is very interesting with respect to the choice of machine tool power, the cutting tools and the optimization of cutting conditions for a given machining operation. It could allow the number of long and expensive tests to be limited and the best tool geometry to obtain quasi-constant and low cutting forces, which lead to a reduced tool wear and consequently, a better tool-life, to be found [2].

Proceedings of International Conference on Mechanical & Manufacturing Engineering (ICME2008), 21– 23 May 2008, Johor Bahru, Malaysia. © Faculty of Mechanical & Manufacturing Engineering, Universiti Tun Hussein Onn Malaysia (UTHM), Malaysia.

ISBN: 97–98 –2963–59–2

independent cutting conditions such as feed rate, cutting speed and depth of cut etc. This has reflected on the increased total cost of the study as it involved a large number of cutting experiments. Furthermore, with this purely experimental approach, researchers have investigated the effect of cutting parameters on cutting forces using machining experiments based on a one-factor-at a-time design, without having any idea about the behavior of cutting forces when two or more cutting factors are varied at the same time. Furthermore, this approach cannot describe and identify, with a great accuracy, the effect of the interactions of different independent variables on the responses when they are varied simultaneously [3].

Recent study takes into account the effect of simultaneous variations of three cutting parameters such as cutting speed (V), feed per tooth (fz)and radial rake angle ( o) on

the behavior of cutting forces by utilizing response surface methodology (RSM). RSM is a group of mathematical and statistical techniques that are useful for modeling the relationship between the input parameters (cutting conditions) and the output variable or response (cutting force) [4].

This method was also used by previous researchers [5]-[9], which studied cutting force as the machining response.

2. Mathematical Models for Cutting Force

In this study, RSM was used and the mathematical models relating to the machining responses were developed according to Alauddin et. al.[5].

2.1 Postulation of the Mathematical Models

Assuming that the proposed model for cutting force is merely depend on cutting speed V, feed per tooth fz and radial rake o.

Other factors, which influence machining process, are kept constant. Thus, the cutting

By utilizing a natural logarithmic transformation Equation (1) can be written in first order polynomial as

ε

which can be transformed to

ε

and finally can be formed as

3

natural logarithmic value of predictive (estimated) tangential force or cutting force, x0

= 1 as a dummy variable, xi (i= 1 to 3) are the

coded variables of V, fzand o respectively, =

ln ’ and bj (j = 0 to 3) are the model

parameters to be estimated using experimental data [5].

If the observation region is extended, then the second order model is useful to represent the effect of second order and interaction components. The second order can be extended from the first order model in estimated using least squares method and 2 is

the predicted response on natural logarithmic scale.

Proceedings of International Conference on Mechanical & Manufacturing Engineering (ICME2008), 21– 23 May 2008, Johor Bahru, Malaysia. © Faculty of Mechanical & Manufacturing Engineering, Universiti Tun Hussein Onn Malaysia (UTHM), Malaysia.

ISBN: 97–98 –2963–59–2

2.2 Experimental Design.

In order to determine the Equation of the response surface, several experimental designs have been developed which attempt to approximate the Equation using the smallest number of possible experiments [4][10].

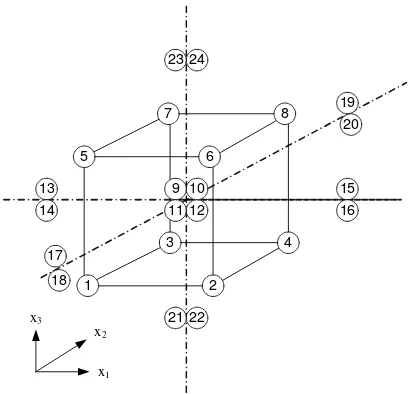

In this study the 2k-factorial design using the first 8 points from design of experiments as shown in Figure 1, was carried out for screening test. This design is necessary when interactions between variables are to be investigated. Furthermore, factorial design allow the effects of a factor to be estimated at several levels of other factors, giving conclusions that are valid over a range of experimental conditions [4][10].

1

Figure 1: Design of Experiment.

To investigate the effect of nonlinearity in the observation region and to construct an estimated errors with nc -1 (nc is

number of center points), it is useful to add center points in screening test with 2k-factorial design when the factorial points in the design are not replicated [10]. Four experiments represent added center points to the first 8 points and were repeated four times to estimate the pure error.

An extended design of 23-factorial design is a second order central composite design (CCD), which easily gained by augmentation of 23-factorial design with

replicated star points ( = 1.4142 [9]) as shown completely in Figure 1.

2.3 Coding of the Independent Variables

The independent variables were coded by taking into account the capacity and limiting cutting conditions of milling machine. The following transforming Equation was used.

natural value to the base or zero level [5][9]. The coded values of the independent variables shown in Table 1 for use in Equation (4) and (5) were obtained from the following corresponding to its natural value of o.

Table 1: Levels of Independent Variables for Ti-6Al4V

Proceedings of International Conference on Mechanical & Manufacturing Engineering (ICME2008), 21– 23 May 2008, Johor Bahru, Malaysia. © Faculty of Mechanical & Manufacturing Engineering, Universiti Tun Hussein Onn Malaysia (UTHM), Malaysia.

ISBN: 97–98 –2963–59–2

3. Experimental Set-Up

A CNC MAHO 700S machining centre was used for experimentation, while side-milling process was conducted with a constant axial depth of cut aa 5 mm and radial

depth of cut ae 2 mm under flood coolant with

a 6 % concentration.

The reference workpiece material of Ti-6Al4V, which was a rectangular block of 110 mm x 55 mm x 150 mm, was used for cutting force measurements.

The end mill was clamped to the tool holder with a constant 22 mm overhang. The TiAlN coated grade-K-30 solid carbide end mills with different radial rake angle according to design of experiment, were used in the experiments. To avoid the influence of tool wear, the forces data (Fx, Fy, Fz) were

recorded during the initial cut when the end mill was still new without wear. The recording of cutting force was carried out using multi component force measuring system consisting of the following elements:

• A 3-component dynamometer comprising of basic unit (Kistler, Type 9265B) and a screwed-on working adapter for milling (Kistler, Type 9443B).

• A multi channel charge amplifier (Kistler, Type 5019A).

• A data acquisition system consisting of a personal computer (PC) equipped with an A/D board as well as the DynoWare software (Kistler, Type 2825 D1-2, version 2.31).

The analysis for the developed models was carried out using a Design Expert 6.0 package.

4. Experimental Results and Discussion

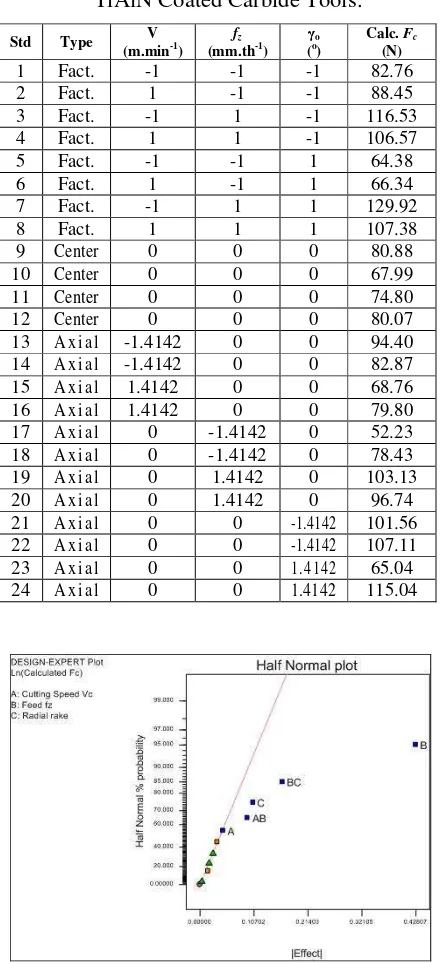

4.1 Development of the Cutting Force Model using 2k-Factorial Design.

The development of the cutting force model was based on the first 12 trials of the experiments shown in Table 2. From the main effect plot in Figure 2, it was observed that the most significant factor that affected the cutting

force was factor B (feed), followed by interaction BC (feed and radial rake angle), C (radial rake angle), interaction AB (cutting speed and feed) and lastly factor A (cutting speed.

Table 2: Cutting Force Fta or Fc when using

TiAlN Coated Carbide Tools.

Std Type V

Proceedings of International Conference on Mechanical & Manufacturing Engineering (ICME2008), 21– 23 May 2008, Johor Bahru, Malaysia. © Faculty of Mechanical & Manufacturing Engineering, Universiti Tun Hussein Onn Malaysia (UTHM), Malaysia.

ISBN: 97–98 –2963–59–2

The cutting force prediction model can be formulated as

3 force decreases with increasing cutting speed and radial rake angle. In contrary, it increases with increase in feed. From interaction terms, it was observed that the combination of speed and feed contributes to decrease in cutting force. However, the combination of feed and radial rake angle adversely increases the cutting force, whilst the feed alone tends to increase the cutting force. From the ANOVA results in Table 3, it is evident that the 3F1-model is valid for the observation region, because the lack of fit (LOF) is not significant.

Table 3: ANOVA for 3F1-Cutting Force Prediction Model using TiAlN Coated Tools

Figure 3: Response Surface of V and fz for

3F1-Cutting Force Model using TiAlN Coated Tools.

Figure 4: Response Surface of fzand o for

3F1-Cutting Force Model using TiAlN Coated Tools.

Figure 5: Response Surface of V and o for

3F1-Cutting Force Model using TiAlN Coated Tools.

Proceedings of International Conference on Mechanical & Manufacturing Engineering (ICME2008), 21– 23 May 2008, Johor Bahru, Malaysia. © Faculty of Mechanical & Manufacturing Engineering, Universiti Tun Hussein Onn Malaysia (UTHM), Malaysia.

ISBN: 97–98 –2963–59–2

from the highest slope of the feed curve. The last response surface for investigation of performance evaluation is shown in Figure 5. It indicates that radial rake angle has more significant effect than cutting speed on cutting force. The maximum cutting force was achieved with combination of the lowest radial rake angle and lowest cutting speed when end milling Ti-6Al4V using TiAlN coated tools.

In combination of all independent variables, the minimum cutting force can be achieved when using the lowest feed coupled with the highest cutting speed and highest radial rake angle.

4.2 Development of the First Order Cutting Force Model using CCD.

The same data from Table 2 for 3F1-model were used in developing the first order CCD model. According to fit and summary test for the first order cutting force model (Table 4), a linear model was suggested.

Table 4: Fit and Summary Test for the First Order Cutting Force CCD Model using TiAlN

Coated Tools

The first order CCD model for cutting force is

3 2

1 0.21403 0.0528

02293 . 0 4615 . 4

ˆ x x x

y= − + − (10)

which can be presented in the following form

17062 . 0 50521 . 0 22086 . 0

32819 .

1811 − −

= z o

c V f

F γ (11)

where Fc is the predicted cutting force in (N).

To validate the first order CCD cutting force model, ANOVA was conducted and the results are presented in Table 5. It is obvious

that the LOF of the cutting force linear CCD model was not significant. Thus the model is valid for end milling of Ti-6Al4V using TiAlN coated carbide tools under wet conditions with the following range of respective cutting speed V, feed per tooth fz

and radial rake angle o: 130 V 160 m.min

-1

; 0.03 fz 0.07 mm.tooth-1; 7 o 13 (o).

Table 5: ANOVA for 1st order CCD-Cutting Force Model using TiAlN Coated Tools

Figure 6: Response Surface of V and fz for 1 st

CCD-Cutting Force Model using TiAlN Coated Tools.

Figure 7: Response Surface of V and o for 1st

Proceedings of International Conference on Mechanical & Manufacturing Engineering (ICME2008), 21– 23 May 2008, Johor Bahru, Malaysia. © Faculty of Mechanical & Manufacturing Engineering, Universiti Tun Hussein Onn Malaysia (UTHM), Malaysia.

ISBN: 97–98 –2963–59–2

Figure 8: Response Surface of fz and o for 1st

CCD-Cutting Force Model using TiAlN Coated Tools.

More information resulted in the CCD linear cutting force model is shown by the response surface in Figure 6 to 8. From these graphical plots, it can be recognized that increasing the cutting speed decreases the cutting force slightly. Similar findings was reported by other researchers [11][12] for the observation region of cutting speed.

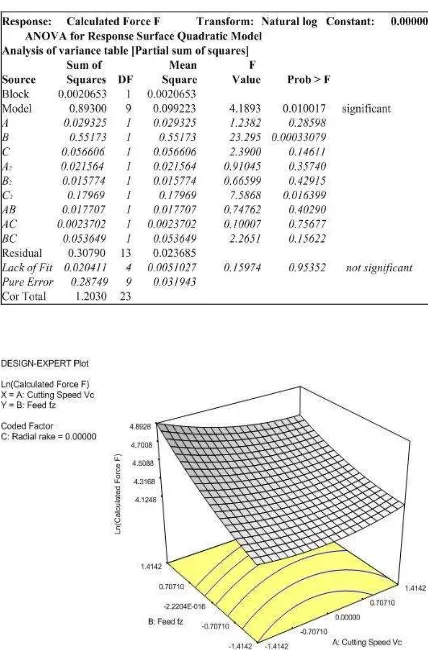

4.3 Development of the Second Order Cutting Force Model using CCD.

A second order model was postulated to extend the variables range in obtaining the relationship between the cutting force and machining variables. The model is based on the second order CCD model for k = 3 (Figure 1) and 24 set of experimental results as given in Table 2. The results is presented in the

From ANOVA results, it was also found that the second order CCD model can be used as the mathematical model in the region of observation, since the LOF is not significant as shown in Table 6.

It was interesting to observe that when the region was extended, the contour of cutting force in the cutting range changes from linear (Figure 6) to a slightly curve form (Figure 9). This was also confirmed by other

researchers [11][12] for low and high cutting speeds region.

Table 6: ANOVA for 2nd order CCD-Cutting Force Model using TiAlN Coated Tools

Figure 9: Response Surface of V and fz for 2nd

CCD-Cutting Force Model using TiAlN Coated Tools.

Figure 10: Response Surface of V and o for

Proceedings of International Conference on Mechanical & Manufacturing Engineering (ICME2008), 21– 23 May 2008, Johor Bahru, Malaysia. © Faculty of Mechanical & Manufacturing Engineering, Universiti Tun Hussein Onn Malaysia (UTHM), Malaysia.

ISBN: 97–98 –2963–59–2

Figure 11: Response Surface of fz and o for

2nd CCD-Cutting Force Model using TiAlN Coated Tools.

They found that the cutting force was very high at low cutting speed and reduced rapidly at medium cutting speed and finally increased slightly with further increase in cutting speed. It was also observed in Figure 9 that there was a significant increase in cutting force with increase in feed.

The significant findings from the experimental result in Figure 10 as compared to Figure 7 is that the effect of radial rake angle in the extended observation region (using second order model) increased significantly than in the linear region due to the value of the radial rake angle almost achieved the maximum value. Nevertheless, increasing trend when radial rake angle increased can still be seen.

It is obvious in Figure 11 that the effect of feed as a function of radial rake angle decreases with increasing radial rake angle. The maximum value was achieved when the highest feed combined with the highest radial rake angle.

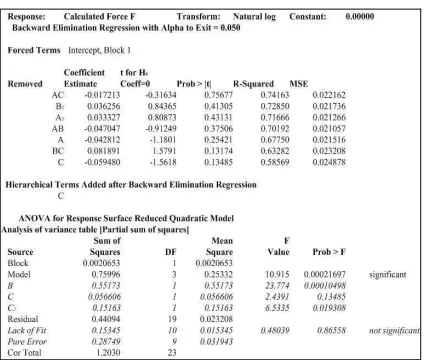

Further observation by means of ANOVA, was conducted to find the significant level of each factor of the model and to reduce the second order CCD model into a simpler form. This method known as backward elimination, can be used when some of the influencing factors have “Probe>F” larger than 0.05 confident level. Contribution of each factor can also be found from the value of coefficient of each factor (Equation (12)). The larger the coefficient of each factor,

the higher the contribution of each factor to the response (cutting force).

ANOVA was conducted once again using the backward elimination to find the reduced form of Equation (12). The results are presented in Table 7.

Table 7: ANOVA for 2nd order CCD-Cutting Force Model using TiAlN Coated Tools.

Comparing the ANOVA in reduced form (Table 7) with ANOVA in completed form (Table 6), the mean square error (MSE) of ANOVA in reduced form is higher than MSE of ANOVA in completed form.

The Equation in reduced form can be presented as

2 3 3

2 0.05948 0.10664

1857 . 0 3182 . 4

ˆ x x x

y= + − + (13)

Equation (13) is much simpler than the origin of Equation (12). However, the accuracy decreased with reduced parameters involved in the original Equation (12).

4.4 Optimum Cutting Conditions

Proceedings of International Conference on Mechanical & Manufacturing Engineering (ICME2008), 21– 23 May 2008, Johor Bahru, Malaysia. © Faculty of Mechanical & Manufacturing Engineering, Universiti Tun Hussein Onn Malaysia (UTHM), Malaysia.

ISBN: 97–98 –2963–59–2

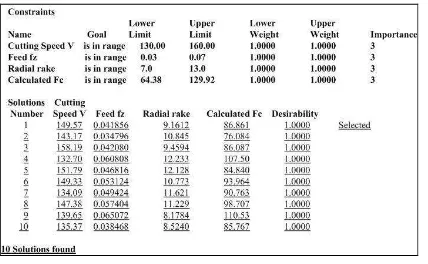

Table 8: Numerical Optimization of validated cutting force model for Fc minimum

Table 9: Numerical Optimization of validated cutting force model for Fc in range

5. Conclusions

• Response surface methodology (RSM) has proved to be a successful technique that can be used to predict the cutting force Fc

and to reveal the relationship between independent cutting conditions and cutting force with minimum set of trials.

• There are three appropriate prediction models namely 3F1, 1st and 2nd order CCD model to formulate the relationship amongst machining parameters such as cutting speed, feed and radial rake angle. • The models indicate that feed is the most

significant factor, which influenced cutting force. It increases significantly with increasing feed in the observation region. • The first optimum cutting condition to

achieve minimum cutting force is cutting speed V = 133.20 m.min-1, feed fz = 0.03

mm.tooth-1 and radial rake angle o =

12.98 (o).

• The second optimum cutting condition when cutting force is in range, is cutting speed V = 149.57 m.min-1, feed fz = 0.042

and radial rake angle o = 9.2 (o).

Acknowledgements

The authors wish to thank the Research Management Center, UTM and the Ministry of Science, Technology and Innovation Malaysia for their financial support to the above project through the IRPA funding 03-02-02-0068 PR0074/03-01- Vote no. 74545.

References

[1]. H. Niemann, Ng. Eu-gene, H. Loftus, A. Sharman, R. Dewes and D. Aspinwall,

Metal Cutting and High Speed

Machining, edited by D. Dudzinski, A. Molinari, H. Schulz, Kluwer Academic/Plenum Publisher.

[2]. S. Bissey-Breton, G. Poulachon and F. Lopujoulade, Proceeding of the Institution of Mechanical Engineers,

Part B: Journal of Engineering

Manufacture, 220, pp. 579-587, January, 2006.

[3]. K.A. Abou-El-Hossein, K. Kadirgama, M. Hamdi and K.Y. Benyounis, Journal of Materials Processing Technology,

182, pp. 241-247, July, 2007.

[4]. D.C. Montgomery, Design, Analysis of Experiments, 5th ed. John Wiley & Sons, 2001.

[5]. M. Alauddin, M.A. El-Baradie and M.S.J. Hashmi, Journal of Materials Processing Technology, 58, pp. 100-108, 1996.

[6]. H.F. Kuang and Y.C. Hung, Journal of Materials Processing Technology, 72, pp. 42-27, 1997.

[7]. M.Y. Noordin, V.C. Venkatesh, S. Sharif, S. Elting and A. Abdullah,

Journal of Materials Processing

Technology, 145, pp. 46-58, 2004. [8]. T. Radhakrishnan and U. Nandan,

Proceedings of International Conference on Mechanical & Manufacturing Engineering (ICME2008), 21– 23 May 2008, Johor Bahru, Malaysia. © Faculty of Mechanical & Manufacturing Engineering, Universiti Tun Hussein Onn Malaysia (UTHM), Malaysia.

ISBN: 97–98 –2963–59–2

[9]. A.S. Mohruni, S. Sharif and M.Y. Noordin, Proceeding of Regional

Postgraduate Conference on

Engineering and Science, Johore Bahru, Malaysia, July 2006, pp. 337-342. [10]. R.H. Meyers and D.C. Montgomery,

Response Surface Methodology: Process

and Product Optimization using

Designed Experiments, 2nd ed. John Wiley & Sons Inc., 2002.

[11]. E.M. Trent and P.K. Wright, Metal

Cutting, 4th ed. Butterworth and

Heinemann, 2000.

[12]. J.H. Xu, K.Q. Ren and G.S. Geng, In