The

11

th

International

Conference on

Membrane Science

&

Technology

"SUSTAINABLE TECHNOLOGY FOR

ENERGY, WATER

&

ENVIRONMENT"

27th - 29th Aug 2013

Seri Pacific Hotel

©

Advanced Membrane Technology Research Centre (AMTEC), Faculty of Petroluem & Renewable Energy Engineering (FPREE), Universiti Teknologi Malaysia (UTM) 2013All right reserved. No part ot trus publication may be produced, copied, stored in any retrieval system or transmitted in any form or any means - electronic, mechanical, photocopying, recording or otherwise; without prior permission in writing from the Advanced Membrane Technology Research Centre (AMTEC), Faculty of Petroleum & Renewable Energy Engineering (FPREE), Universiti Teknologi Malaysia (UTM), 8 I J

to

Skudai, Johor Darul Takzim, Malaysia.

The

11th

International Conference on Membrane Science & Technology (MST2013),

Sustainable Technology for Energy, Water & Environment, Seri Pacific Hotel, Kuala Lumpur, Malaysia,27

1h -29th

Aug

2013,

Organized by UniversitiTeknoloqi

Malaysia (UTM) Published and printed by:Advanced Membrane Technology Research Centre (AMTEC), Faculty of Petroleum & Renewable Energy Engineering (FPREE), Universiti Teknologi Malaysia (UTM),

81310

Skudai, Johor Darul Takzim, Malaysia.Tel:

+607-5535925/5581463

Fax:

+607-5535925/5535807

CONTENTS

Foreword by the Deputy Minister of Ministry of

Science, Technology and Innovation of Malaysia

(MOSTI)

i

Foreword by the Deputy Vice-Chancellor of

Universiti Teknologi Malaysia

iii

Foreword by the Chairman of MST 2013

vi

Organizing Committee

vii

Conference Program

ix

List of Poster Presentations

xxii

List of Industrial Participants

xxv

Invited Speakers

xxvi

Abstract of invited Speakers

1

Contribution papers

25

Abstract of contribution papers

27

ADVISORY COMMITTEES

Zaini Ujang Universiti Teknologi Malaysia. Malaysia

Mohd Azraai Kassim Universiti Teknologi Malaysia. Malaysia Anthony Gordon Fane Nanyang Technological University, Singapore Wirote Youravong Prince of Songkla University, Thailand

I.G. Wenten lnstitut Teknologi Bandung, Indonesia

Tutuk Djoko Kusworo Universitas Diponegoro (UNDIP), Indonesia

Takeshi Matsura University of Ottawa, Canada

H.G.L. Coster University of Sydney, Australia, Dean of College of Engineering, University of Tehran,Iran

Madzlan Aziz Universiti Teknologi Malaysia. Malaysia

Ariffin Samsuri Universiti Teknologi Malaysia. Malaysia

SCIENTIFIC COMMITTEES

Heru Susanto Universitas Diponegoro (UNDIP), Indonesia

Wang Rong Nanyang Technological University, Singapore

Neal Chung Tai-Shung National University of Singapore, Singapore Tutuk Djoko Kusworo Universitas Diponegoro (UNDIP), Indonesia Arun M lsloor National Institute of Technology Kamataka,India Mohammad M. Montazer-Rahmati University of Tehran, Iran

Mohamed Mahmoud El-Sayed

Nasef Universiti Teknologi Malaysia. Malaysia

Devaraj Veerasamy Malaysian Rubber Board (LGM), Malaysia Zularisam Bin Abd Wahid Universiti Malaysia Pahang, Malaysia Azmi Mohd Syariff Universiti Teknologi Petronas, Malaysia

Zakaria B Man Universiti Teknologi Petronas, Malaysia

Azeman Mustafa Universiti Teknologi Malaysia. Malaysia

Azman Shafawi Petronas Research Sdn. Bhd., Malaysia

Nur Awanis bt. Hashim Universiti Malaya, Malaysia Mohd lrfan Hatem bin Mohamed Dzahir Universiti Malaysia Perlis, Malaysia Rosli b. Md. lllias Universiti Teknologi Malaysia. Malaysia Wan Ramli b. Wan Daud Universiti Kebangsaan Malaysia

Kang Li Imperial College, London

Nurmin Bolong Universiti Sabah Malaysia, Malaysia

Rosalam Sarbatly Universiti Sabah Malaysia, Malaysia

SharifahAishah Syed A. Kadir UniversitiTeknologi Mara Mohamed Kheireddine b. Taieb Aroua Universiti Malaya, Malaysia

Azmi Rahmat Universiti Malaysia Perlis, Malaysia

Mohammad Reza Mehrnia University of Tehran, Iran Mojtaba Shariaty-niassa University of Tehran, Iran

Mohd. Ghazali Mohd. Nawawi Universiti Teknologi Malaysia. Malaysia

Meisam Tabatabaei Agricultural Biotechnology Research Institute of Iran Anil K. Pabby Bhabha Atomic Research Centre, Maharashtra, India

27th-29th August 2013

UNIVERSITI TEKNOLOGI MALAYSIA KUALA LUMPUR, MALAYSIA Pre-Conference

26th Aug 2013 (Monday)

1600-1800 Pre-registration

Conference Day 1 27th Aug 2013 (Tuesday)

0815-0930 Registration

0930-0945 Welcoming speech by MST2013 Conference Chairman

Prof. Dr. Ahmad Fauzi Ismail

0945-1045 MAIN HALL

Prof. Michael D. Guiver

Materials design for fuel cell ion exchange membranes

Chairperson: Prof. Abdul Latif Ahmad

1045-1130 Tea break/Poster preparation 1130 Parallel Session I

Membrane for water & wastewater application

Parallel Session II

Membrane for gas &vapor application

Parallel Session III

Membrane for fuel cell & energy, environment application 1130-1200 Dr. I. GedeWenten

Electrodeionization (EDI): State of the art

Prof. Kazukiyo Nagai

Polyimide Membranes Modified for Carbon Dioxide Separation

Prof. T. S. Chung

Molecular Design of Membranes for Clean Water and Clean Energy

Chairperson: Dr. I. GedeWenten Co-chairperson:Dr.NurAwanisHashim

Oral Session

(Pacific Ballroom A/B)

Chairperson: Prof. Kazukiyo Nagai Co-chairperson:Dr.HasrinahHasbullah

Oral Session

(Pacific Ballroom C)

Chairperson: Prof. T. S. Chung Co-chairperson:Farhana Aziz

Oral Session

(Bunga Room)

1200-1215 A022 Y. LukkaThuyavan

Clarification of sufarcane fruit juice using alginate/polyethersulfone blend ultrafiltration membranes

A005 Amir Mansorizadeh

Preparation of porous polyamide-imide Torlon membranes for CO2 absorption: Effect of glycerol in

polymer dope

A015 Evangeline Christina

Performance of polyethersulfone-cellulose acetate membrane blend on fluoride adsorption from aqueous phase

1215-1230 A024 ReshmaLakra

Novel ultrafiltration membrane technology for separation of organic acids and reducing sugars

A006 AzmanShafawi

Challenges of producing membranes from lab/R&D scale to commercial for CO2 separation from natural

A063 NadiahKhairulZaman

Novel glucamine containing adsorbent based on blended chitosan/poly(glycidyl methacrylate)

from rice husk gas electrospunnanofibrous sheet

1230-1245 A026 T. Gajendran

Concentration of orange juice using ultrafiltration employing biopolymer blend polyethersulfone membrane

A002 A. Y. Zahrim

Treatment ofdye solution via low pressure nanofiltration system

A225 R. A. Azmi

Membrane processing of crude palm oil by using crosslinkedpolyvynilidene fluoride hollow fibre membrane

1245-1300 A030 KhairulMuis B. Mohamed Yusof

Recovery of rubber from skim latex using membrane technology

A052 Kamal S. N. M.

Fabrication of PDMS/PES membrane incorporated with SAPO-44 Zeolite membrane for gas separation

A224 E. Yuliwati

Polyvinylidene fluoride hollow fiber membranes for refinery wastewater treatment: Effect of air gap length on membrane morphology and performance

1300-1400 LUNCH

1400-1430

Prof. Takeshi Matsuura

Effect of surface pattern formation on membrane fouling and its control in phase

inversion process

Prof. Mohamed Mahmoud El-SayedNasef

Radiation grafted microfibrous sheets containing functionalized

poly(glycidylmethacrylate) for environmental applications

Prof. M. JavaidZaidi

Polyelectrolyte multilayer films prepared by layer by layer assembly for reverse osmosis

desalination Chairperson: Prof. Takeshi Matsuura

Co-chairperson:Dr.NurminBolong

Oral Session

(Pacific Ballroom A/B)

Chairperson: Prof. Mohamed Mahmoud El-SayedNasef

Co-chairperson: Dr.Mahesh Padaki

Oral Session

(Pacific Ballroom C)

Chairperson: Prof. M. JayaidZaidi Co-chairperson:Dr.Erna Yuliwati

Oral Session

(Bunga Room)

1430-1445 A049 N. H. Othman

The effect of membrane pre-treatment towards the stability of refined palm oil

A070 Zee Ying Yeo

Effect of synthesis duration for the formation of zeolite T membrane by secondary seeded growth and its performance in CO2/CH4 gas separation

A019 R. Balamurali

Influence of unsteady state dynamics on the rejection of cadmium (II) by ultrafiltration

1430-1500 A054 A. W. Zularisam

Effect of piper betle extract as anti-biofouling

A092 Atsushi Morisato

Development of a large membrane module for CO2

removal from hydrocarbon gas and recovery of hydrocarbon liquids

A020 R. Saranya

Development of adsorbents based mixed matrix membranes for removal of heavy metals and dissolved salts from textile industry effluent

1500-1515 A159 A. Moslehyani

Polyethersulfone ultrafiltration membrane for oil-in-water emulsion separation

A074 Mohamed Mahmoud Nasef

New CO2 adsorbent with aminated poly(glycidyl

methacrylate) radiochemically grafted onto polyethylene nonwoven sheets

A044 NorulFatiha Mohamed Noah

Selective emulsion liquid membrane extraction of palladium from simulated liquid waste solution using D2EHPA as a mobile carrier

1515-1530 A069 Feras M. Kafiaha

Preparation of

polysulfoneelectrospunnanofibers: effect of electrospinning and solution parameters.

A099 H. N. Mohammed

CO2 absorption in membrane contactor usingpiperazine, monoethaolamine and diethanolamine in membrane contactor: A mass transfer and performance study

A059 S. C. Low

Studying the role of magnetite (Fe3O4) colloids

functionality on PES membrane in removing of humic acid foulant using QCM-D

1530-1545 A076 MantakaTauntong

Acetic acid removal of fish skin collagen by ultrafiltration

A102 SinaGilassi

An experimental investigation on permeability and selectivity of PTFE membrane: A mixture of Methane and Carbon Dioxide

A061 T. M. Ting

New radiation grafted boron selective adsorbent sheets containing poly(vinyl benzyl chloride) functionalized with N-methyl-D-glucamine

1545-1600 A081 H. R. Rashidi

The application of hybrid physical pre-treatment system for treatment of simulated batik wastewater

A109 BiruhShimekit

Effect of polyphenylene oxide (PPO) concentration on the morphological, thermal, crystalline and CO2

permeation properties of flat sheet dense PPO polymeric membranes

A086 Avin J. Kajekar

Synthesis and characterization of novel PVDF/PANI nanofiber membrane and its possible applications for heavy metal rejection

1600-1615 A091 B. S. Ooi

Poly(N-isopropylacrylamide-co-acrylic acid) hydrogel and its thermo-responsive properties for polymer enhanced ultrafiltration

A111 N. Dolmat

The effect of piperazine with

N-methyldiethanolamine in emulsion liquid membrane for carbon dioxide removal

A107 AdhiKusmastuti

Emulsion liquid membrane for cadmium removal: experimental results and model prediction

1615-1630 A094 R. Saranya

A comparative study on synthesized polymer nanocomposite membranes for the treatment of paper mill effluent

A120 F. A. Ismail

Synthesis and characterization of titania-13x membrane for CO2 separation

A117 EzaliaMohd. Fauzi

Performance of ionic liquid on the extraction of mercury using hollow fiber supported liquid membrane (HFSLM)

1630-1645 A096 Rajesha Kumar

Synthesis and characterization of novel water soluble derivative of chitosan as an additive for polysulfone ultrafiltration membrane

A216 NayefGhasem

Absorption of CO2 from natural gas utilized gas-liquid

PVDF hollow fiber membrane contactors via potassium gylcinate solvent

A118 AzadehGhaee

Chitosan/polyethersulfone composite

nanofiltration membrane for removal heavy metal from wastewater

1645-1700 A097 A. Mataram

Performance of electrospunnanofibers for water filter application

A127 N. Jusoh

Removal of bulk CO2 from methane with the

presence of heavy hydrocarbon using polyimide membrane

A229Noor Hidayu Othman

Application of membrane technology for degumming and deacidification of vegetable oils refining

1700-1715 A098 N. A. Samsure

Incorporation of silicon dioxide in the preparation of PVDF hydrophilic membrane

A134 Mohammad WashimUddin

Optimization of membrane preparation conditions and effect of methanol on performance of a facilitated transport membrane for natural gas sweetening

A189 MyzairahHamdzah

Effect of sulfonation of polyethylene sheets on the adsorption of Zinc (II)

1715-1730 A213 MuhamadZainiYunos

Influence of inorganic additives on the performance of polysulfone ultrafiltration membrane

A068 W. Wongthep

Semi-interpenetrating polymer network (Semi-IPN) membranes prepared from epoxidized natural rubber (ENR-50) and crosslinkedpolydimethylsiloxane (PDMS) (ENR50-inter-cross PDMS)

A119 AzadehGhaee

Synthesis and application of chitosan/cellulose acetate composite membranes for Copper ions removal from wastewater

1730-1745 A212 MuhamadZainiYunos

Investigation on the performance of

polysulfone/zinc oxide membrane: Effect of pore forming agent

A105 AdilHatem Rashid

Separation of biobutanol from acetone-butanol-ethanol (ABE) fermentation mixtures by polymeric membrane

A214 Maisarah Mohamed Bazin

Effect of starch addition on microstructure and strength of ball clay membrane

1730-1800 Tea break/Poster session

Conference Day 2

28th Aug 2013 (Wednesday)

0830 Parallel Session I

Membrane for gas and vapor application

Parallel Session II

Membrane for fuel cell & energy, environment application

Parallel Session III

Membrane for water & wastewater application

0830-0900

Prof. Matsuyama Hideto

Cutting-edge research at the membrane center in Kobe University in Japan

Prof. WiroteYouravong

An enzymatic membrane reactor in production of bioactive peptides used as nutraceutical and

functional foods

Prof. Wang Rong

Development of high performance PRO hollow fiber membranes for salinity gradient

energy harvesting Chairperson: Prof. Matsuyama Hideto

Co-chairperson:Dr.Surya Racha

Oral Session

(Pacific Ballroom A/B)

Chairperson: Prof. WiroteYouravong Co-chairperson: Noor Maizura Ismail

Oral Session

(Pacific Ballroom C)

Chairperson: Prof. Wang Rong Co-chairperson:Dr.Mukhlis A. Rahman

Oral Session

(Bunga Room)

0900-0915 A142 HazlinaJunoh

Effect of heat treatment parameters on the performance of asymmetric polyetherimide (PEI) hollow fiber membrane for CO2/CH4 gas

separation

A051 Akhondi E.

Optimization of operating conditions and energy consumption of submerged hollow fiber membrane systems with periodic backwash

A055 A. W. Zularisam

Perspective of biofouling from batik effluent

0915-0930 A149 Suhaina M. Ibrahim

Tailoring the pore size and gas separation properties of organic/inorganic membranes using 2,4,6-tris[3(triethoxysilyl)-1-propoxyl]-1,3,5-triazine (Triazine) as a triple-silicon alkoxide and comparison with mono and di-silicon alkoxides

A028 RaisHanizamMadona

Desalination of seawater using polyamide reverse osmosis (RO) membranes

A104 A. A. Abdulkarim

Preparation and characterization of

polyethersulfone membrane containing zinc oxide nanoparticles and polyvinylpyrollidone

0930-0945 A153 Haikal Mustafa

Powder preparation effect on oxygen permeation flux of hollow fibre LSCF6428 ceramic perovskite membrane

A045 Saren Qi

Fabrication of forward osmosis membranes based on layer-by-layer assembly

A110 DzetiFarhahMohshim

Effect of operating conditions on different

membrane types for removal of monoethanilamine from wastewater

1945-1000 A154 SajidHussain Shah

Development of and highly hydrophobic composite silica membrane system for high temperature gas separation and applications under steam environment

A048 Ang Wei Lun

Integrated/hybrid membrane system as alternative process in drinking water treatment plant and pretreatment for reverse osmosis desalination plant

A112 SyazwanLiyanaSulaiman

Synthesis of PVA/Chitosan/TiO2 beads

1000-1015 A161 M. Rezaei-Darzhandi

Preparation of porous PVDF/Montmorillonite hollow fiber mixed matrix membrane contactor via a phase inversion method to capture CO2

A057 Hosam A. Shawky

Conceptual design and simulation of a small mobile PV driven RO water desalination plant to be deployed at the North West Coast of Egypt

A115 RomchatRattanaoudom

Potential removal for high TDS wastewater from petroleum-based industry

D

A

1015-1030 A169 N.H. Nordin

Preparation of asymmetric polysulfone/ZIF-8 mixed matrix membrane for CO2/CH4 separation

A058 Dalia E.

Economic analysis of a stand-alone reverse osmosis desalination unit powered by photovoltaics for possible application in the North West Coast of Egypt

A116 Nora’aini Ali

Flux decline in low-pressure ultrafiltration membrane by surimi wash water: effect of operating parameters

1030-1045 A175 N. M. Ismail

Characterization of polyethersulfone/Cloisite 15A mixed matrix membrane for CO2/CH4

separation

A072 AsifMatin

Surface modification of RO membranes used for seawater desalination

A221 Mahesh Padaki

PSF/TiO2 composite membrane for chromium

removal and effect of acidic pH

1045-1100 A164 A. K. Zulhairun

Asymmetric Polysulfone-Cloisite 15A® nanocomposite membrane for gas separation

A078 Lei Shi

Development of novel composite dual-layer nanofiltration hollow fiber membranes for water softening at low operation pressure

A129 Atiye Sadat Abednejad

Wet ability improvement of polypropylene membranes by PEG grafting

1100-1200 Tea break/Poster session (Judging session)

1200-1300 MAIN HALL

Prof. Young Moo Lee

Thermally rearranged polymer membranes for gas separation

Chairperson: Prof. HamdaniSaidi

1300-1400 LUNCH

1400-1430 Prof. XiansheFeng

Pressure-vacuum swing permeation: a novel process mode for membrane separation of

gases

Prof. MojtabaShariaty-Niassa

A comparative survey on

Cu ion membrane adsorption from aqueous solution

Ir. B. P. Chow

Greening of the palm oil milling industry

Chairperson: Prof. XiansheFeng Co-chairperson:Dr.MohdIrfanHatim

Oral Session

(Pacific Ballroom A/B)

Chairperson: Prof. MojtabaShariaty-niassa Co-chairperson:Dr.MasoudRahbariSisakht

Oral Session

(Pacific Ballroom C)

Chairperson: Dr. JuhanaJaafar Co-chairperson:MyzairahHamzah

Oral Session

(Bunga Room)

1430-1445 A190 EbrahimAbouzari-Lotf

Preparation and gas separation properties of novel polyoxadiazole containing noncoplanar

1,1’-thiobis(2-naphthoxy) groups

A082 Song Xiaoxiao

Energy recovery from the brines of seawater and wastewater using thin-film nanofiber composite pressure retarded osmosis membranes

A198 Bolong N.

Numerical estimation of hollow fiber membrane for mobile water treatment

1445-1500 A192 S. A. Hashemifard

The reliability of the conventional gas permeation testing method for characterizing the porous asymmetric membranes

A084 Chang Liu

Fabrication of high performance hollow fiber membrane using layer-by-layer deposition and crosslinking on the lumen surface for niche applications

A137 Y. H. D. Alanezi

Crossflow microfiltration of synthetic oily wastewater using multi channel ceramic membrane

1500-1515 A196 R. Naim

Effects of additives on the structure and performance of polyetherimide hollow

A095 SeemaShenvi

Study of PPEES/Chitosan composite membrane crosslinked with tripolyphosphate

A140 C. S. Ong

Preparation and characterization of PVDF-TiO2

composite membranes blended with different

D

A

fibermembrane contactor for CO2 absorption

and stripping

molecular weights of PVP for oily wastewater treatment using submerged membrane system

1515-1530 A205 Ali Kargari

Experimental study of hydrogen and methane permeation through asymmetric PEI membranes

A151 T. D. Kusworo

Effect of PEG on cellulose acetate membrane morphology and nanofiltration performance for water softening

A141 NurulNabilahAminudin

Comparison study of effect of PEG and PVP as additives on polysulfone (PSf) membrane structure and performance

1530-1545 A206 Ali Kargari

Critical concentration of PEI in NMP as a criterion for the preparation of asymmetric membranes for gas separation

A155 M. M. Zerafat

Mathematical modelling of nanofiltration-based deionization processes in aqueous media

A143 D. Novin

Effect of operating parameters on performance of ultrafiltration (UF) to fractionate catfish protein hydrolysate

1545-1600 A108 N. A. Ahmad

Synthesis and characterization of

superhydrophobic alumina membrane with different silanes chain

A160 D. Emadzadeh

Study of thin film nanocomposite (TFN) membrane morphology by microscopic image analysis

A144 MohdRiduanJamalludin

The effect of polyethylene glycol (PEG) on the performance of blend polysulfone (PSf) membrane with rice husk silica (RHS)

1600-1615 A027 A. KazemiJoujili

Separation of olefins from paraffins by membrane contactor – A review

A179 N. Misdan

Study on the properties of polysulfone support membrane and its relation to the TFC nanofiltration membrane performance

A145 MuhamadFikriShohur

Performance of Psf ultrafiltration membrane: Effect of different nonsolvent in coagulation medium

1615-1630 A170 HazlinaJunoh

The development of exfoliated

SPEEK/Cloisitenanocomposite electrolyte membrane by electrospinning

A021 T. Chidambaram

Sodium sulphate recovery using novel membranes in the presence and absence of dye molecules

A147 SitiHawaMohamad

Membrane performance: TiO2 nanoparticles coated

on polysulfone (PSf) ultrafiltration membrane surface

1630-1645 A071 SantiKhoonsap

Nanocomposite membranes from PVA filled with silica nanoparticles grafted with

Poly(2-hydroxyethyl methacrylate) (SiO2-g-PHEMA)

A166 N. A. A. Sani

Performance of polyphenylsulfone solvent resistant nanofiltration membrane: Effects of polymer concentration, membrane pre-treatment and operating pressure

A148 NazatulShimabintiAzmi

Effect of sandwich configuration of ultrafiltration membranes on POME treatment

1645-1700 A122 SiripornLarpkiattaworn

PES membrane performance for TEG removal of wastewater from natural gas separation process

A100 Ng Law Yong

Stability and performance study of polyethersulfone membranes modified using polyelectrolytes

A157 Muhammad Said

Optimization of NaOH as the cleaning agent of polyethersufone (PES) membrane fouled by palm oil mill effluent (POME)

1700-1715 A150 Serene Lock Sow Mun

Modeling of concurrent and countercurrent flow hollow fiber membrane module for multi-component system

A060 FatemehRoozbahani

Poly(ε-caprolactone) electrospunnanofibrous scaffold with protein encapsulated for tissue engineering applications

A158 SirichaiKoonaphapdalert

Effect of hydraulic retention time and bisphenol A concentration on performance of membrane bioreactor

1715-1730 A172 M. Ghanbari

CFD modelling of membrane channel: application to gas separation

A202 Lim MimMim

Electrospun biodegradable membranes for drug delivery and tissue engineering applications

A056 A. W. Zularisam

Causes and biological mitigation of biofouling in MBR

1745-1800 Tea break

2000-2300 MST2013 GRAND DINNER/VVIP LAUNCHING

Conference Day 3 29th Aug 2013 (Thursday)

0830-0930 MAIN HALL

Prof. Wang Rong

Development of high performance PRO hollow fiber membranes for salinity gradient energy harvesting

Chairperson: Prof. Ir. Abdul WahabMohamad

0930-1000 Tea break

1000 Parallel Session I

Membrane for fuel cell & energy, environment application

Parallel Session II

Membrane for gas &vapor application

Parallel Session III

Membrane for water & wastewater application

1000-1030 Prof. ArunIsloor

Chitosan and its derivatives as potential materials for membrane technology

Dr. Anil K. Pabby

Hollow fiber membrane contactor technology in chemical and nuclear industry: current status, challenges, and future perspectives

Prof. ArthanareeswaranGangasalam

Polymer modification for performance enhanced membrane separations Chairperson: Prof. ArunIsloor

Co-chairperson:Dr.SeyedAbdollatifHashemifard

Oral Session

(Pacific Ballroom A/B)

Chairperson: Dr. Anil K. Pabby Co-chairperson:Dr.GholamrezaBakeri

Oral Session

(Pacific Ballroom C)

Chairperson: Prof. ArthanareeswaranGangasalam Co-chairperson:RosmawatiNaim

Oral Session

(Bunga Room)

1030-1045 A001 Helen Morabi

Industrial wastewater treatment in textile industry-Nylon 6

A032 Abdul Hakim M. Salem

Development and characterization of sago/PVA blend membrane for recover of ethyl acetate from water

A162 N. A. MohdNazri

Improved performance of PAN-based UF

membrane with PAN-g-PVA amphiphilic copolymer

1045-1100 A050 ThiamLeng Chew

Development of Ba-SAPO-34 zeolite membrane for separation of CO2 in the binary gas mixtures

A220 R. Surya Murali

Preparation and characterization of Pebax/zeolite 13X mixed matrix membranes for propane-propylene

A174 M. A. Mohamed

The potential of cellulose-based photocatalytic membrane for wastewater treatment application: A review

1100-1115 A126 Zing-Yi Ooi

Recovery of kraft lignin from pulping wastewater by an emulsion liquid membrane process

A128 Bolong N.

Zeta potential measurement of hollow fiber membranes modified by negatively charged-modifying macromolecule

A176 Norafiqah Ismail

Preparation and characterization of blends polysulfone/polyphenylsulfone ultrafiltration membranes for palm oil mill effluent treatment

1115-1130 A139 NorherdawatiKasim

Potential of nanofiltration membrane in groundwater treatment for drinking water resources

A199 Fouzia T. Minhas

Developing solvent resistant nanofiltration (SRNF) membranes for treatment of dye solutions

A180 R. Jamshidi

Adsorptive removal of arsenite from contaminated water solutions by PES/Fe-Mn binary oxide UF flat sheet mixed matrix membrane

1130-1145 A156 N. A. Jalanni

Investigation of new polyester nanofiltration(NF)

A203 RohaidaChe Man

Immobilization of recombinant Escherichia coli using

A171 N. A. M. Nor

A review study of nanofibers in

D

A

membrane fouling with humic acid solution hollow fiber membrane for improvement of extracellular enzyme expression and cell viability

photocatalyticprocess

1145-1200 A079 NurulIzzati

Separation of biobutanol using polymeric membrane: A review

A204 AlirezaKhademi

Classical design of experiments application on submerged membrane ultrafiltration system for refinery produced wastewater treatment

A183 YasamanSanayei

Modeling for biological treatment of reactive dye (Cibacron yellow FN_2R) wastewater in SBR systems

1200-1215 A167 E. Halakoo

The effect of SPEEK additive on

polyethersulfonenanofiltration membrane for dye removal

A208 D. Veerasamy

Latices concentration via utralfiltration as a cleaner processing technique

A187 S. Ismail

Fouling characteristics and cleaning of

ultrafiltration membranes in palm oil mill effluent (POME) treatment

1215-1230 A184 Zahra ShariatiNiasar

Removal of malathion from groundwater using nanoadsorbents

A209 N. Shamsinar

Lysozyme recovery from chicken egg white proteins using batch adsorption of cation exchange mixed matrix membrane chromatography

A195 Chin Boon Ong

Performance investigation of pilot study for wastewater reclamation using ferric chloride as coagulant

1230-1245 A123 Raja Norimie Raja Sulaiman

Recovery of ionized nanosilver from wash water using emulsion liquid membrane process

A210 TzeChingOng

Drying Simulation for hygroscopic membrane

A197 HeruSusanto

Membrane hydrophilization: towards low fouling polymeric membranes

1245-1300 A211 MuhamadZainiYunos

Effect of Zinc oxide on performance of ultrafiltration membrane for humic acid separation

A103 Ng Ching Yin

Fractionating the value-added product from skimmed coconut milk using membrane separation technique

1300-1400 LUNCH

1400-1430 Prof. Kang Li

Structural-controlled micro-tubular solid oxide fuel cell via phase inversion technique

Dr. Simon J. Shilton

Mass transfer and skin formation in hollow fibre membranes for gas separation Chairperson: Prof. Kang Li

Co-chairperson:Dr.Mohd Hafiz Dzarfan

Oral Session

(Pacific Ballroom A/B)

Chairperson: Dr. Simon J. Shilton Co-chairperson:Dr.HatijahBasri

Oral Session

(Pacific Ballroom C)

Chairperson: Dr. Lau WoeiJye Co-chairperson:Dr.Mukhlis A. Rahman

Oral Session

(Bunga Room)

1430-1445 A016 K. Sriram

Effects of nano particles on

sulfonatedpolyethersulfone membrane for fuel cell application

A047 Z. Khan

Effect of process parameters on electro spun polyacrylonitrile (PAN) fibers and fiber mats

A080 Zhang Jinsong

Feasibility of anaerobic membrane distillation bioreactor (AnMDBR) for wastewater treatment

1445-1500 A017 Elakkiya E

Comparison of various membrane performance in microbial fuel cell for power generation

A053 NorlisaHarruddin

Behaviour study of microporous polypropylene membrane development via thermally induced phase separation

A093 A. O. Imdakem

Simulation of heat and mass transfer in membrane distillation (MD) processes: the effect of membrane pore space description

D

A

1500-1515 A023 Arjun Ramesh

Utilizing optimize imidazolium functionalized polysulfone in a completely noble metal free alkaline membrane fuel cell

A066 S. Shahaidah

Study of binding interaction in BPA-MIP flat sheet membrane

A113 Mohammad Mahdi A. Shirazi

Characterization of PTFE membranes for membrane distillation using atomic force microscopy

1515-1530 A029 MostafaGhasemi

Preparation of sulfonated polyether ether ketone (SPEEK) and optimization of degree of sulfonation for using at microbial fuel cell (MFC)

A121 A. S. Noor Adila

A review on spinning parameters in fabricating the hollow fiber membrane

A163 N. M. Mokhtar

Effect of different additives on the performance of PVDF hollow fiber membranes for textile

wastewater treatment using DCMD

1530-1545 A152 S.E. Rosli

Study of the variation of catalyst loading in cathode for SPEEK/CSMM membrane in direct methanol fuel cell (DMFC)

A136 AlaminIdris

The grafting of γ ray pre-irradiated polytetrafluoroethylene film membrane

A185 M. N. A. Hawlader

Experimental study on a multi-stage air gap membrane distillation (AGMD) unit

1545-1600 A178 H. ilbeygi

Prediction and optimization of proton

conductivity for nanocomposite membrane using response surface methodology

A087 F. Nufaiei

(PAN)/CNT electrospunnanofiber mats: effect of concentration on the mechanical and surface properties

A186 S. O. Lai

Characteristic and performance of polyvinylidine fluoride membranes blended with lithium chloride in direct contact membrane distillation

1600-1615 A018 N. Samsudeen

Influence of operating parameter on electricity generation in microbial fuel cell during distillery wastewater treatment

A215 Chung Ying Tao

Membrane surface modification through UV-grafting

A114 Mohammad Mahdi A. Shirazi

Separation of water-glycerol mixture using sweeping gas membrane distillation

1615-1630 A025 Arjun Ramesh

Optimization of Imidazolium functionalized polysulfone for use as anion exchange membranes in fuel cell

1630-1700 CLOSING CEREMONY (ORAL AND POSTER PRESENTATION AWARDS)

LIST OF POSTER PRESENTATION

A031 RosiahRohani

Synthesis and characterization of conducting nanofiltration membranes from polyaniline coated PVDF with tuneable permeation properties

A034 A. Yoshida

Characterization and water 10ehavi sorption property of ABA-type triblock copolymer membranes derived from fluorine-containing polyimide and polymethylmethacrylate

A035 D. Tanaka

Effect of substituent groups on alcohol 10ehavi sorption property of POSS-containing polymer membranes

A036 M. Kishida

Characterization and gas separation properties of polyimide/zeolite composite membranes containing sulfolane

A037 M. Ichikawa

Preparation of ABA-type triblock copolymer membrane designed using fluorine-containing polyimide with high transparency and gas barrier properties

A038 M. Yamada

Effect of volatile organic compound on dissolved gas transport properties through poly(1-trimethylsilyl-1-propyne) membranes

A039 M. Kobayashi

Synthesis and Gas barrier properties of the crosslinked membrane with diacetylene group-containing polymer derived from ferulic acid

A040 R. Shindo

Characterization and CO2separation property of polyimide composite membranes containing ionic liquid

A041 S. Amanuma

Synthesis of UV-cured telechelic polyimide membranes with crosslinker

A042 S. Ando

Synthesis and characterization of ABA-type triblockcopolymer membranes derived from polyimide macroinitiator with 10ehaviour10-containing methacrylate

A043 Y. Hayashi

Effect of vacuum ultraviolet irradiation on dissolved gas transport properties through poly(lactic acid) membranes

A062 Farah Syuhada Abdul Halim

Preparation and characterization of 10ehaviou membrane electrode assembly

A067 ThanitpornNarkkun

Water permeability and diffusivity in natural rubber grafted with polyvinyl alcohol (NR-g-PVA)

A073 MuhammadameenHajihama

Concentration and desalination of protein derived from tuna cooking juice by nanofiltration

A075 PenpornSriniworn

Separation of oligosaccharides from UF-pretreated tofu whey by nanofiltration

A083 Nor Emma ErwinaWahab

A088 Amir-Al-Ahmeda

Study the properties of polyethersulfone(PES) /polyetherimide(PEI) composite membranes

A090 AbdellahAmmi Said

The effect of complexing agent through the exchange membranes

A106 B. Darunee

The use of ceramic membranes for micro-filtration of Thai beverage made from Indian gooseberry fermentation broth

A124 Oh Pei Ching

Effects of aluminosilicate mineral nano-clay fillers on polysulfone mixed matrix membrane for carbon dioxide removal

A125 BanderBawareth

Membranes separation of 2-Ethyl Hexyl Amine/1-Decene

A130 M. A. IndokNurulHasyimah

Ultrafiltration 11ehaviour of organic mixtures simulating sweetwater solutions: Influence of membrane surface and feed chemistry

A131 N. Yousefimehr

Investigation on influence of volatile solvent ratio, shear stress, forced convection residence time on gas separation performance of asymmetric polysulfone membrane

A165 SitiMuniraJamil

A single step co-extrusion/co-sintering technique: A review

A168 D. Emadzadeh

Neural networks simulation of thin-film nanocomposite membrane for brackish water desalination

A173 H. Dzinun

The potential of photocatalytic membrane process in treating wastewater – A review

A181 M. Rezaei-Darzhandi

Mixed matrix membranes (MMMs) comprising PVDF polymer with dispersed montmorillonite clay particles for CO2absorption

A188 KanungnuchKeawsupsak

Poly(lactic acid)/biodegradable polymer blends for the preparation of flat-sheet membrane

A191 Muhammad Irfan

Carbon nanostructured ultra-filtration membrane

A193 ArisaJaiyu

The effect of spinning parameters on pla hollow fiber membrane formation

A194 WeerapongBootluck

Innovation of polymer coating machine for producing various pore sizes of composite polymer/ceramic membranes

A207 W. N. W. Salleh

The effect of stabilization environment on the structure and gas permeation properties of carbon membrane

A217 N. Bolong

Tongkat Ali extraction using hollow fiber membranes modified by negatively charged-modifying macromolecule

A223 H. Hasbullah

Effect of co-solvent on Mindel S-1000 gas separation asymmetric membrane

Enhancement of ceramic water filtration using synthesized rice husk particles

A227 MohdRiduanJamalludin

The effect of synthetic silica to the ultrafiltration PSF membrane

A228 NurafiqahRosman

A224-1

POLYVINYLIDENE FLUORIDE HOLLOW FIBER MEMBRANES FOR

REFINERY WASTEWATER TREATMENT: EFFECT OF AIR GAP

LENGTH ON MEMBRANE MORPHOLOGY AND PERFORMANCE

E. Yuliwatia,*, A.F. Ismailb,c , A.S. Mohrunid ,T. Matsuurac,e

a

Department of Industrial Engineering, Faculty of Engineering, University of Bina Darma, Sumatera Selatan, Indonesia

Tel. +62 (711) 515-679

bAdvanced Membrane Technology Research Centre (AMTEC),

c

Faculty of Petroleum and Renewable Energy Engineering, Universiti Teknologi Malaysia, 81310 UTM, Skudai Johor, Malaysia

Tel. +60 (7) 553-5592; Fax: +60 (7) 558-1463

dDepartment of Mechanical Engineering, Faculty of Engineering,

Sriwijaya University, South Sumatera, Indonesia Tel. +62 (711) 580-272

eDepartment of Chemical Engineering, Industrial Membrane Research Laboratory,

University of Ottawa, Ont., Canada KIN 6N5

*Corresponding author: [email protected]

Abstract

Effects of air gap length on outer surface morphology and filtration performance of hydrophilic polyvinylidene fluoride (PVDF) hollow fiber membrane have been studied. Porous asymmetric hydrophilic PVDF membranes were prepared via a phase inversion method, using N,N-dimethylacetamide (DMAc) as solvent, lithium chloride monohydrate

(LiCl.H2O) and titanium dioxide (TiO2) as inorganic additives. Submerged membrane

ultrafiltration was conducted using non-ionic solutes of different molecular weight and refinery wastewater with constant suspended solid concentration. The comparison of the performance and morphology was conducted between PVDF membranes of different air gap length at 1, 4, 11, and 15 cm. The prepared membranes were characterizedthrough observations of field emission scanning electron microscope (FESEM) and atomic force microscopy (AFM), permeate flux measurement, and tensile propertytest.Average pore size and surface porosity were calculated by the permeate flux in submerged membrane system. It is resulted that the permeate flux is mainly determined by effective porosity.Moreover, the average pore size and nodules size were increased, while outer surface membrane was being smoother with increasing of air gap length. AFM analysis reveals that the air gap introduces an elongation stress due to the gravity on the membrane surface. Under the air gap length of

11 cm, high permeate flux of 148.53 L/m2h and suspended solids removal of 99.82 % and

also relatively high mechanical strength of membrane can be simultaneously achieved. It is concluded that there exists the best range of the air gap length for relatively high performance of membrane.

A224-2

1. Introduction

Synthetic membrane technology has grown up very fast and has received significant

attention from both academia and industry, since the first mention of hollow fiber membranes

in a series of patents by Mahon in 1966 and 1966b [1,2]. Nowadays, the hollow fiber

membrane configuration via phase inversion process is the most favored membrane geometry

in the most membrane applications. Hollow fibers have much larger surface area per unit

volume of the membrane module and hence offer higher productivity per unit volume. They

have also good flexibility in operation [3,4].

However, during membrane formation, the preparation of the hollow fibers often

requires more controlling parameters than those of flat sheet membranes (i.e. structure and

dimensions of the spinneret, viscosity and possibility of the spinning dope, nature of the

internal and external coagulants, flow rate of the bore fluid, dope extrusion rate, air gap

length, take-up speed, etc) [5]. Among the studies of membrane formation by the dry-jet wet

spinning process, the effects of air gap length on final hollow fiber membrane have been

investigated by many researchers [6-9]. However, the fabrication of a hollow fiber with

desirable performance is not trivial process and the effect on hollow fiber membrane

morphology and permeation process reported in the literatures often provide conflicting

observations. For instance, in spinning polysulfone hollow fibers, Aptel et al., (1985)

reported that the permeability decreased as the air gap length increased [10]. On the other

hand, it was reported by Kim et al., (1995) that air gap length had no impact on the

permselection properties of polysulfone hollow fibers [11]. Khayet (2003) was also

investigatedthat the separation factors of polyvinylidene fluoride hollow fibers increases with

increasing the air gap distance; however, the air gap distance did not significantly affect the

permeation rate [12]. He attributed this fact to the increase of the skin layer thickness with

increasing the air gap length. In addition, air gap length also proved to be an easy and

powerful tool to tune the prem-selective properties of hollow fiber membranes during

spinning process.It has been also reported that the membrane spun from air gap length of

20-30 cm exhibited very poor permeability, higher value of permeability were obtained from air

gap length of 10-15 cm and for lower air gap length the permeability was reduced drastically

[13]. Tsai et al. (2002) observed that the both inner and outer diameters decreased with

A224-3

anneals the fiber caused the change of inner and outer diameter [14]. Khulbe et al. (2004) and

Khayet et al. (2009) have similar results when using polyetherimide (PEI) polymer and

polyvinylchloride (PVC) polymer respectively [15,16]. It was explained that stress inside the

spinneret perpendicular to the fiber axis released when dope solution comes out from

spinneret. This will expand the fiber diameter, whereas the stress parallel to the fibers will

elongate the fiber and diminishing its diameter.

In this study, air gap length plays an essential role in the PVDF ultrafiltration

membrane preparation,meanwhile, all parameters were kept constant.The objective of this

study is to investigate the effects of air gap length on the morphological structure and

filtration efficiency of hydrophilic polyvinylidene fluoride (PVDF) membrane. Four varied

air gap lengthsof 1,4,7,and 15 cm wereused in order to produce different structure and

morphology of membrane. Based on this results obtained, it is expected to find out the

suitable PVDF membrane for preparation of hydrophilic ultrafiltration membrane for refinery

produced wastewater treatment.

2. Experimental

2.1.Materials

Ultrafiltration membranes have been prepared using Kynar®740 PVDF polymer

pellets were purchased from Arkema Inc. Philadelphia, USA. The solvent

N,N-dimethylacetamide (DMAc, Aldrich Chemical) (Synthesis Grade, Merck, >99%) was used as

polymer solvent without further purification. Lithium chloride monohydrate (LiCl.H2O) and

nanoparticles titanium dioxide (TiO2) were used as inorganic additives. Both chemical

additives were purchased from Sigma-Aldrich and used as received. Glycerol was purchased

from MERCK (Germany) and used as non-solvent for post treatment of membrane. In all

cases, tap water was used as the external coagulation bath medium in the spinning process.

A224-4

An amount of pre-dried (24 h oven dried at 50oC) PVDF pellets in ranging of 16 to

22 wt.%were weighed and poured into pre-weighed DMAc solvent. The mixtures were

stirred to ensure thorough wetting of polymer pellets, prior to the addition of appropriate

amounts of LiCl.H2O at 50 oC. TiO2 was then carefully added to the polymer dope mixtures,

which were continuously stirred for 48 h (IKA-20-W) at 500 rpm until a homogenous

solution was formed. The polymer solution was kept in a glass bottle and air bubbles formed

in the dope were removed using water aspirator for several hours.The fully dissolved polymer

solution was transferred to a glass reservoir, allowed to stand and degassed for 24 h at room

temperature prior to spinning process. Solution viscosity was measured using rheometer

(Bohlin Instrument Ltd.) at various temperatures between 25 and 50 oC.

2.3.Fabrication of hollow fiber membranes

2.3.1 Spinning parameters

In this study, hollow fiber membrane is produced through a dry-jet wet spinning

process. The membrane can be formed only in the appropriate conditions of all the spinning

parameters (i.e. dope extrusion rate, extrusion velocity from spinneret, take up speed, bore

fluid rate, and air gap length). The air gap length variable in the spinning system effects the

fiber geometry in terms of the inner diameter, outer diameter, wall thickness, and structure of

membrane sublayer. This may be attributed to the die swell of polymer macromolecules

when exiting from the spinneret due to the viscoelastic properties of the PVDF spinnning

dope. Furthermore, the gravity will influence the achievable in the spin line and introduces an

elongation stress on membrane and generally tends to decrease the membranes wall

thickness.

2.3.2 Dry-jet wet spinnning process

PVDF hollow fiber UF membranes were spun at room temperature by a dry-jet wet

spinning method. The spinning solutions were consisted of maintained PVDF concentration

of 19 wt.%, which were prepared at different air gap lengthof 1, 4, 11, and 15 cm. LiCl.H2O

and TiO2 were maintained at 5.2 wt % and 10 wt.% of the weight of PVDF, as shown in

Table 1 respectively. The hollow fiber spinning process by dry-jet wet phase inversion was

explained by Qinet al.,(2001); Ismail and Hassan (2006) [17,18]. The detailed spinning

A224-5

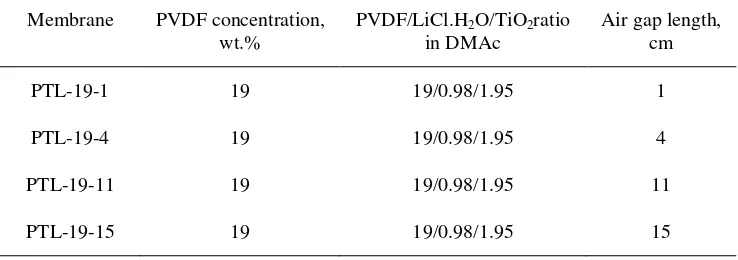

Table 1 Spinning conditions of the hollow fiber membranes

Spinning condition Value

Dope extrusion rate (ml/min) 4.20

Bore fluid Distilled water

Bore fluid flow rate (ml/min) 1.40

External coagulant Tap water

Air gap distance (cm) 1, 4, 11, 15

Spinneret od/id (mm) 1.10/0.55

Coagulation temperature ˚C 25

Room relative humidity (%) 70 − 75

The hollow fiber membranes were produced using the dope formulation solution

composed of PVDF/LiCl.H2O/TiO2 at different polymer concentration, as shown in Table 2.

Table 2.The air gap length condition for holow fiber membrane preparation

Membrane PVDF concentration, wt.%

PVDF/LiCl.H2O/TiO2ratio in DMAc

Air gap length, cm

PTL-19-1 19 19/0.98/1.95 1

PTL-19-4 19 19/0.98/1.95 4

PTL-19-11 19 19/0.98/1.95 11

PTL-19-15 19 19/0.98/1.95 15

2.3.3 Post-treatment

The spun fibers were cut in pieces of approximately 50 cm in length and then stored

in water bath at room temperature for at 1 day to remove the residual solvent. The fibers were

then soaked in the 20 wt.% glycerol aqueous solution bath for another 1 day in order to

prevent pore collapse or change of transport properties during drying at room temperature for

4 days, they were ready for making hollow fiber test bundles as mentioned in our previous

study by Yuliwati and Ismail (2011) and Yuliwati et al., (2011) [16,17}.

A224-6 The permeation flux and rejection of PVDF hollow fiber membranes for synthetized

refinery wastewater were measured by submerged ultrafiltration experimental equipment as

shown in Fig.1 [16]. An in-house produced U-shape hollow fiber module, with a filtration

area of 11.23 dm2, was submerged in prepared suspension in membrane reservoir with

volume of 14 L. A cross-flow stream was produced by air bubbling generated by a diffuser

situated underneath the submerged membrane module for mechanical cleaning of the

membrane module. The air bubbling flow rates per unit projection membrane area was set

constantly at 2.4mL/min in order to maintain proper turbulence. The filtration pressure was

supplied by a vacuum pump and controlled by a needle valve. Permeate flow rates were

continually recorded using flow meter respectively.

In order to conduct the studies at steady state, the hollow fiber membranes have to

compacted at a transmembrane pressure (TMP) of vacuum. The desired TMP was controlled

using the pressure regulator installed at the outlet of the membrane reservoir. TMP is the

driving force for the pressure-driven membrane process and is defined as the pressure

difference across the membrane,

TMP = ���+��

2 �‒ �� (1)

where Pf is the feed pressure (bar), Pr is the retentate pressure (bar), and PP is the permeate

pressure (bar).

Membrane performance was tested with anin-house U-shape membrane bundle

having about 11.23dm2 of membrane surface area. Pure water flux was measured after the

flux was steady. The collected permeate can be recorded in terms of flux and rejection by the

expression as follows,

Jw =

At V

(2)

whereJw is the pure water flux (L/m2 h), V is the permeate volume (m3), A is the membrane

A224-7

The values of Jw obtained from the experiments were converted to corresponding unit of m.s-1

during data analysis for better understanding. The pure water permeability coefficient, Lp was

then determined from the values of Jw versus the applied pressure for all the studied

membranes with the assumption of null value of the osmotic pressure, π.

Jw = Lp. ΔP (3)

The second property of feed contained neutral solute-PEG with different MWs at a

concentration of 200 ppm. This feed solution was used for the characterization of MWCO of

a membrane. The solute rejection was determined based on the total organic carbon (TOC)

rejection determined by total organic carbon analyzer, TOC-VCSH/CSN (Shimadzu

Corporation). The third property of feed contained synthetic refinery wastewater at constant

concentration that based on mixed liquor suspended solids (MLSS) concentration of 3 g/L.

The conductivity of refinery wastewater for the feed and permeate was measured using

conductivity meter (EC300, YSI Inc.). In order to determine the rejection, the effective solute

filtration efficiency, R (%) can be calculated using the following equation:

R = (1-f p C C

) x 100 (4)

WhereR is the rejection ultrafiltration process (%), Cpis the concentration of the permeate

(mg/L) and Cfis the concentration of the feed (mg/L).

2.6. Characterizations

The morphological structures of the hollow fiber membranes were studied using field

emission scanning electron microscope (JEOL JSM-6701F). The FESEM micrographs of the

cross section membranes were taken at certain magnifications. It produced photographs at the

analytical working distance of 10 nm.

Atomic force microscopy (AFM) was used to study the external and internal surfaces

A224-8 different areas of each hollow fiber membrane using a tapping mode Nanoscope III equipped

with 1553D scanner (SPA-300 HV,USA). In this study, scans were made on areas of 5 μm ×

5 μm. The AFM analysis software program allowed computation of various statistic related to

the surface roughness on predetermined scanned membrane area. To determine the pore sizes

and nodule sizes, cross-sectional line profiles were selected to traverse the obtained AFM

images and the diameter of nodules (i.e. high peaks) or pores (i.e. low valleys) were

measured by means of a pair of cursors. The sizes of the nodule aggregate are based on the

average of 15 measurements.In terms of surface roughness, the outer surface of the PVDF

hollow fiber membranes were compared using various roughness parameters such as the

mean roughness (Ra), the root mean-square roughness (Rq) and the average difference in

height between the five highest peaks anf the five lowest valleys (Rz) [16,19]. The average

pore sizes and average nodule sizes of outer surfaces were also determined. Those were

measured, as stated previously, by inspecting line profiles on the AFM images at different

locations of a membrane surface. The measured pore sizes from the line profiles on the AFM

micrographs were arranged in ascending order and the median rank (50%), χ, was calculated

using the followed equation,

100 4 . 0

3 . 0

+ − =

n i

χ (5)

wherei is the order number of the measured pore size arranged in ascending order and n is the

total number of the measured pores.

Differences in the membrane surface morphology can be expressed in terms of various

roughness parameters, such as (1) the differences between the highest and the lowest points

within the given area, Z; (2) the root mean-square of the Z data within the given area (RRMS);

(3) the mean roughness (Ra). This parameter represents the mean value of the surface relative

to the centre plane, the plane for which the volume enclosed by the image above and below

this plane is equal. It is calculated as follows

∫ ∫

= x

y L L

y x

a f x y dxdy

L L R

0 0

) , ( 1

A224-9

where f(x,y) is the surface relative to the centre plane, LxandLy are the dimensions of the

surface in the x and y directions, respectively; (4) the average difference in height, Rz,

between five highest peaks and five lowest valleys is calculated relative to the mean plane,

which a plane has a data variance. Roughness parameters obtained from AFM micrographs

should not be considered as absolute values because it depends on the treatment of the

captured surface data such as plane fitting, flattering, filtering, etc. In the present study, the

same tip was used for all experiments and all captured surfaces were treated in the same

method. The evaluation of the roughness parameters of each sample was based on micron

scan areas. Porosity was calculated also by the method described by Singh et al. (2008) [19].

Asymmetric porous membranes were characterized by determination of porosity and

average pore radius. The membrane porosity, ε,was defined as the volume of the pores

divided by the total volume of the porous membrane. The membrane porosity was calculated

using the following equation,

ε =

P W

W w w w

w w

ρ ρ

ρ 2 2 1

2 1

) (

) (

+ −

−

x 100 (7)

whereε is the porosity of the membrane (%), w1the weight of wet membrane (g), w2 the

weight of dry membrane (g), ρp the density of the polymer (g/cm3) and ρw is the density of

water (g/cm3).

To prepare the wet and dry membranes, five spun hollow fibers with the length of 25

cm were selected after solvent was exchanged in tap water for 3 days. The fibers were

immersed into the isopropanol for 3 days and distilled water for 3 days. The remained water

in the inner surface was removed using air flow, before weighing the membranes. The wet

membranes were dried in vacuum oven for 12 h at 40 oC and weighted.

Average pore radius, rm, was investigated by filtration velocity method, which a

measurement of the ultrafiltration flux of the wet membrane applied on pure water in limited

time (20 h) under 0.1 MPa pressure. It represents the average pore size along the membrane

thickness (), which was measured by the difference value between external radius and

internal radius of the hollow fiber membrane. The test module containing 60 fibers with the

length of 35 cm was used to determine water permeability. According to

A224-10

rm =

P xAx

Q x ∆ −

ε

η ε) 8 75 . 1 9 . 2 (

(8)

whereη is water viscosity (8.9 x 10-4 Pa s), is the membrane thickness (m), ∆P is the

operation pressure (0.1MPa), ε is the porosity of the membrane (%), Q is volume of permeate

water per unit time (m3 s-1), A is an effective area of membrane (m2).

3 Result and discussion

3.1 Effect of PVDF concentration on the membrane structure and filtration performance

3.1.1 Morphology studies by FESEM and AFM

The morphology of the membraneswas studied by FESEM to represent the

cross-sectional and surface at certain magnification.Heterogenous structure with top skin supported

by finger-like macrovoids substructure was often observed in many types of hollow fiber

fabricated via the phase inversion method due to the fast solvent and non-solvent exchange

rate [20]. Figure 1 shows FESEM micrographs of the cross-sectional morphology of the

prepared PVDF UF membranes. Increasing PVDF concentration in the range of 16 to 22

wt.% demonstrated an obvious change of morphology and suppressed both of inner and outer

finger-like macrovoids. The finger-like structure under the top layer, as this structure was

prepared from 22 wt.% PVDF in Figure 1(c), was much less than membrane structure

prepared from 19 wt.% PVDF in Figure 1(b). Furthermore, there was also a transition from

macroporous structure to asymmetric structure in membrane cross-section. A more

sponge-like substructure and thicker top layer of membranes were formed across the membrane wall.

This can be explained by the fact that higher dope viscosity decreases the solvent (DMAc)

and non-solvent (water from coagulation medium) exchange rate, thus resulted in higher

resistance of diffusion from polymer aggregation. From FESEM images, pores had not been

observed under FESEM at a magnification of 40.000. The results confirmed that the pores on

the membrane surface were in range of nanometer. Based on the previous studies, it is

reported that pore size decreases with increasing polymer concentration due to the increase in

the solution viscosity, leading to a stronger molecular orientation and tighter structure

[21,22]. Therefore, it is expected that membrane pores tend to be decreased with polymer

A224-11 means of pure water measurement and solute tranport method were carried out in the

following sections.

(a) (b) (c)

Fig.1. Partial cross-section of hollow fiber membranes (a) 16 (b) 19 (c)

PVDF-22

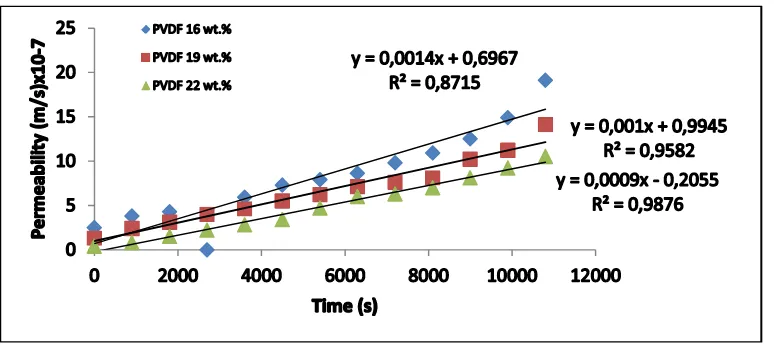

3.1.2 Flux characteristic

Experiment were performed with distilled water to determine the pure water flux

(PWF) and PWF coefficient of PVDF membranes prepared from different polymer

concentration. The experiments were tested using submerged membrane system at vacuum

and room temperature. Figure 2 shows the evaluation of permeate flux obtained in these

experiments. A straight line correlation was obtained with reasonably high coefficient (R2 =

0.8715-0.9876) while plotting the membrane permeability on ordinate vs. trans-membrane

pressure. The example of membrane permeation data and its PWP determination is shown in

A224-12

Fig.2. The pure water flux of the hollow fiber membranes prepared from 16 to 22 wt.%

PVDF as a function of filtration time

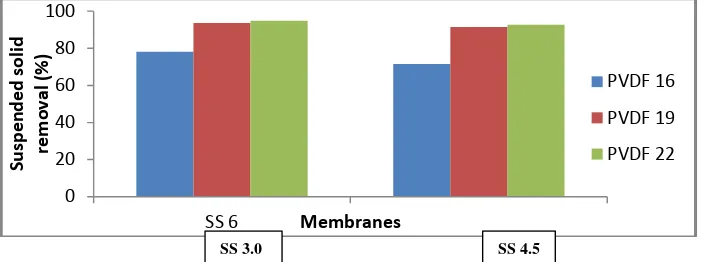

3.1.2 Solute rejection characteristics

The filtration efficiencies of PVDF membranes were further demonstrated using two

different feed solutions that based on suspended solids concentration (3000 mg/L and 4500

mg/L concentration) as shown in Figure 2. Basically, the electrostatic interactions between

ions and membrane surface charge are responsible for ion filtration. Therefore, the

steric-hindrance effect is also responsible for ion retentions. As can be seen in Figure 1, an increase

in polymer concentration led to increase suspended solids removal efficiency. The results

presented that increasing suspended solids removal is due to the corresponding decrease in

average pore size of membranes as tabulated in Table 3.

Table 3 The PEG rejection and MWCO of various membranes as a function of PVDF

concentration

a

Membrane Neutral solutes, R (%) MWCO (kDa)

PVP k-30 PVP k-60 PVP k-90 PVP k-360

PVDF 16 19.20 36.70 48.45 60.30 77

(±0.23) (±0.07) (±0.35) (±0.03)

PVDF 19 35.50 78.86 91.23 98.83 155

(±0.57) (±0.21) (±0.50) (±0.04)

PVDF 22 30.20 71.45 82.45 95.20 185

(±1.01) (±0.28) (±0.09) (±0.31)

a

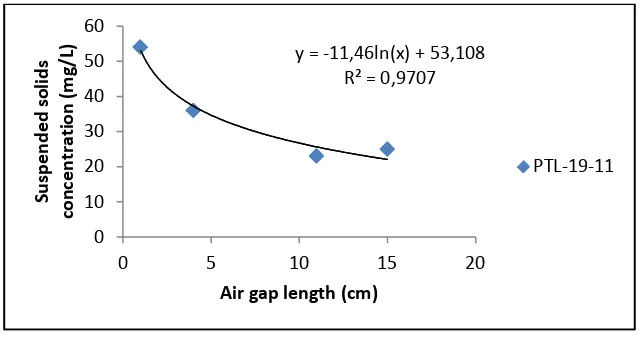

A224-13 Figure 4 shows the retention of suspended solids with different percentages of PVDF

content based on suspended solids of 3.0 g/L and 4.5 g/L.

Figure 4: Suspended solids retention of hollow fibers prepared from 16 to 22 wt. %of PVDF

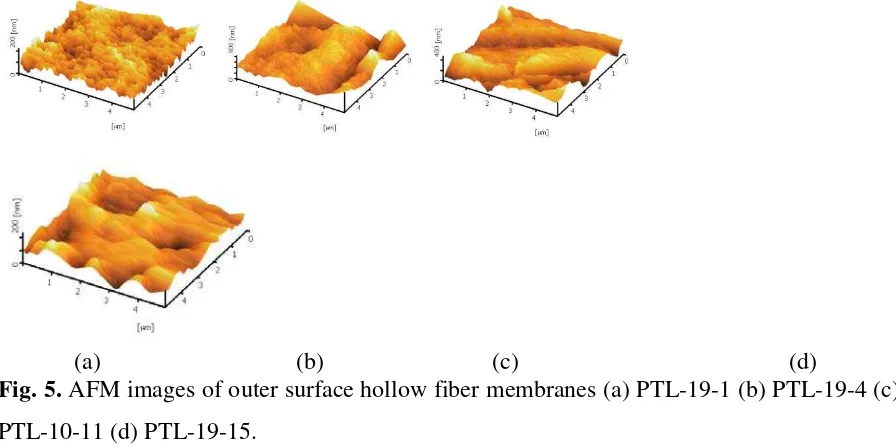

3.2 Effect of air gap length on the membrane structural and separation performance

It is well known that in hollow fiber spinning, the pressurized viscous solution is

subjected to various stresses when it extrudes thorugh the complicated channel within a

spinneret. These stresses may influence molecular orientation and relaxation, and

subsequently fiber formation and separation performance, as well as productivity [23].

Macromolecules may experience swell and relax when exiting from spinneret, if there is an

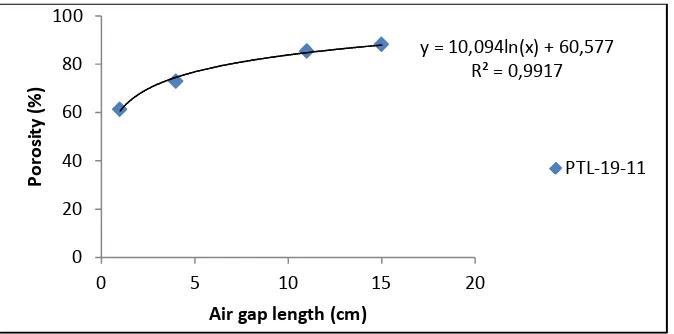

air gap before coagulation and will change their orientation.Figure 5 represents the AFM

images of the surface properties of PVDF hollow fibers. These images revealed that the

membrane surfaces were not smooth and that the nodule aggregates were formed at the

surfaces of the PVDF hollow fibers. The mean roughness parameter Ra obtained from the

AFM images showed 23.45, 15.02, 12.28, and 9.85 for the PTL-19-1, PTL-19-4, PTL-19-11,

and PTL-19-15, respectively. The high peaks seen as bright regions in the AFM images

characterize the nodules while the pores are seen as dark depression. The figures further

indicate that the surface nodule appears to be randomly arranged when the air gap is small but

forms small rows of nodule aggregates aligned in the spinning direction for high air gap

lengths. Generally, the average nodule size at the outer surface seems to increase with an

increase of the air gap length. Molecular chains that experinced higher air gap tend to align

themselves much better than those experienced lower air gap length; and this enhanced

orientation will cause the polymer molecules to be packed closer to each other resulting in a

tigher structure. The nodule size from the AFM images are listed in Table 4. Therefore, the

0 20 40 60 80 100

SS 6

S

u

sp

e

n

d

e

d

s

o

li

d

re

mo

v

a

l (

%)

Membranes

PVDF 16 PVDF 19 PVDF 22

A224-14 average nodule size (nm) and standard deviation (S.D.) for air gap length of 1 cm larger than

those of the other hollow fibers. This may be partly attributed to the fact that polymer

macromolecules may experience die swell when existing from the spinneret as stated by Qin

et al., (2001) [24]. For the dry-jet wet spun fibers, 1 cm air gap length is not enough for

molecular orientation induced by shear stress within the spinneret to relax in the air gap

region. The average nodule size of hollow fibers increases clearly with increasing the air gap

length (>4 cm). This may be due to the increase of interchain entanglement and the annealing

of polymer chain with the air gap length. The radius of gyration and the collision frequency

of polymer chains have also affected the nodule size on membrane surface.

(a) (b) (c) (d)

Fig. 5. AFM images of outer surface hollow fiber membranes (a) PTL-19-1 (b) PTL-19-4 (c)

PTL-10-11 (d) PTL-19-15.

Table 4. Results of the AFM analysis of the outer surfaces of PVDF hollow fiber membranes

Membrane Nodule size Roughness parameters

(nm) S.D. Ra (nm) Rq (nm) Rz (nm)

PTL-19-1 52.30 1.03 23.45 29.55 178.51

PTL-19-4 65.23 1.72 15.02 20.34 133.90

PTL-19-11 86.93 1.19 12.28 15.03 111.50

PTL-19-15 90.08 0.93 9.85 13.75 90.40

As can be seen from the table, it is noticed that the increase of air gap length impacted

the higher values of pure water flux. Because the permeation flux is significantly influenced

by the membrane thickness as given by the Hagen-Poisseuille equation, it is difficult to