Copyright © 2009 by ASME 1

INTRODUCTION

Bioactive ceramic materials like tricalcium phosphates (TCP) have been emerging as alternative and valid approaches to the current therapies of bone scaffolding to target major diseases such as fracture healing, osteoporosis, and osteoarthritis [1]. These scaffolds can induce bone formation by acting as carriers or guides for enhanced bone regeneration by cell migration, proliferation, and differentiation. Previous studies have shown that both material and architectural characteristics influence the mechanical strength of bone scaffolds and their biological functionality [2]. In this study, the physical and mechanical properties of three sets of TCP scaffolds were analyzed. The physical properties that were evaluated included volume, mass, density and porosity. The scaffold compressive mechanical properties were evaluated in air at room temperature and in saline at 37°C.

METHODS

Physical Properties

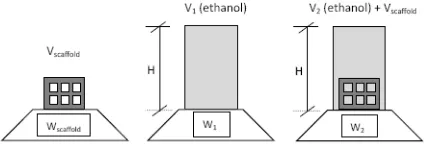

The volume and mass of TCP bone scaffolds fabricated with three different sintering temperatures (defined as A, B, and C in order of increasing temperatures) were evaluated (n=50 per set). The dry bulk dimensions of the scaffolds were measured using a digital vernier caliper. Dry and wet weights were measured with a digital balance (Series PB-S, Mettler Toledo, Columbos, OH). To evaluate water absorption, specimens were submerged in distilled water for 24 hrs and centrifuged (Model TJ-6, Beckman, Fullerton, CA) at 3000 rpm for 3 minutes to eliminate excess water on their surface. The wet scaffolds were then weighed, Wscaffold.

Material volume was measured using a technique based on displacement of a known-density fluid (ethanol solution, ρethanol).

Previous validations studies found a mean error of 0.975% when measuring known volumes. A container of volume V1 was completely

filled to level H with the ethanol solution and weighed (W1) (Figure

1). After the scaffolds were water-saturated, they were immersed in the container with ethanol, and the volume of alcohol was adjusted so that the container with the scaffold was completely filled again level H. For each specimen the ethanol was agitated until no air bubbles emerged from the scaffold and all pores were filled. This new volume is composed of the scaffold (Vscaffold) and the remaining ethanol (V2).

The the scaffold’s volume is given by Equation 1. Using the displaced fluid volume method, material volume, density and porosity measurements for the three sets (n = 8 per set) were determined (Table 1).

Vscaffold = V1 – V2 = (W1 – W2 + Wscaffold) / ρethanol (1)

Figure 1. Measurement of scaffold material volume

Mechanical Testing

Mechanical testing was performed using the ZETOS Bone Loading System, a custom-made device that uses a piezoelectric actuator (PZA) to apply compressive displacement to a specimen [3]. Applied force and specimen deformation were recorded during the test and were processed to find specimen stiffness or apparent elastic Proceedings of the ASME 2009 Summer Bioengineering Conference (SBC2009)

June 17-21, Resort at Squaw Creek, Lake Tahoe, CA, USA

MATERIAL AND MECHANICAL PROPERTIES OF TRICALCIUM PHOSPHATE-BASED

(TCP) SCAFFOLDS

Juan Vivanco (1), Sylvana García-Rodríguez (1), Everett L. Smith (2), Heidi-Lynn Ploeg (1)

(1) Department of Mechanical Engineering and Material Science Program, University of

Wisconsin-Madison

(2) Department of Population Health Sciences, University of Wisconsin-Madison

Copyright © 2009 by ASME 2

modulus. All the scaffolds underwent two preconditioning trials (preload of 10 N followed by compressive displacement of 5 µm). Due to the maximum displacement range of the PZA (70 µm), a series of tests were performed on each scaffold until the specimen failed. Displacement was applied gradually at approximately 0.50 µm/s until either the maximum force (1500 N) or maximum displacement (70 µm) was reached. The linear region of the force-displacement curve (Figure 2b) was chosen to calculate stiffness, K, defined as the slope of the linear fit of the region. Stiffness was converted to apparent elastic modulus Eapp using Hooke’s law, Eapp = KL/A (where F is the

applied force, d is the compressive displacement, A is the bulk area of the top surface and L is the bulk length of the specimen in the dimension parallel to the loading direction) (Figure 2a). Failure, or partial cracking, was identified in the force-displacement curve as a sudden decrease in force.

Figure 2. (a) Definition of loading direction. (b) Typical force-displacement scaffold curve

Strain energy was calculated by finding the area under the stress-strain curve until failure. Most scaffolds failed during the first load cycles. To obtain a quantitative measure and take the number of load cycles into account, the parameter cumulative strain energy (CSE) was defined as the sum of strain energy to failure. Thus, if failure was found in the second load cycle, the cumulative strain energy was the sum of the strain energy from the first two load cycles. This must not be considered as the strain energy to failure; it is only a measure for comparison purposes, and it does not have the same meaning as total strain energy to failure. The compressive mechanical properties of the three sets of scaffolds (A, B and C) were determined in air at room temperature (n=4 per set) and wet with saline at 37°C (n=6 per set).

RESULTS

A paired t-test (α = 0.05) was performed to determine if there was a difference in weight as a consequence of a dry or wet state. Only the weight of set C was not significantly different due to water absorption.

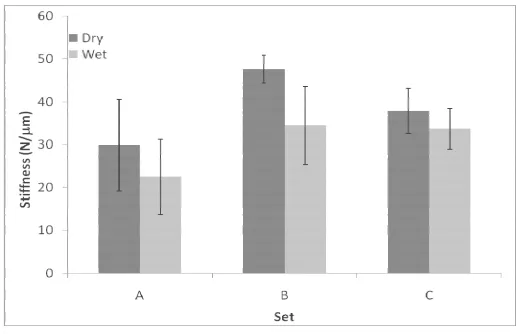

Statistical analyses (ANOVA and Tukey Test, α = 0.05) found a difference between the scaffold sets regarding material volume and material density (p-value < 0.05 for both). On the other hand, porosity was not different due to sintering temperature (Table 1). Set A was the least stiff (22.5 N/µm in saline at 37°C) and sets B and C were the stiffest (34.4 and 33.7 N/µm, respectively) (Figure 3 and Table 2). A two-way ANOVA and Tukey Test (α = 0.05) found that both sintering temperature and testing environment, affected the scaffold compressive stiffness (p-value < 0.05 for both factors).

Table 1. TCP scaffold physical properties, mean (std dev) Set Wet weight (g) Volume (mm3) Density (g/cm3) Porosity, %

A 0.2147 (0.006) 85.9 (6.45) 2.5 (0.14) 50.7 (3.63) B 0.1982 (0.002) 68.6 (4.97) 2.9 (0.19) 49.1 (3.70) C 0.1913 (0.004) 59.6 (4.51) 3.2 (0.29) 52.1 (3.77)

Figure 3. Mean scaffold stiffness (N/µµµµm)

Table 2. Stiffness and apparent elastic modulus for each set and test environment, mean (std dev)

Set K (N/µm) Dry, room Temperature E Saline, body Temperature Mean K (N/µm)

Table 3. Cumulative strain energy for each set and test environment, mean (std dev)

Set Dry, room Temperature Saline, body Temperature Mean CSE (GPa) CSE (GPa) CSE (GPa) affected by the sintering temperature of the fabrication process as well as the test environment. TCP scaffolds sintered at the lowest temperature had the highest bulk volume, lowest material density, lowest apparent modulus and absorbed the most water. The structural stiffness for all the TCP scaffolds was reduced when tested at 37°C in saline. Dry, room temperature conditions are practical for characterization of the structure, but future applications will be at 37°C and in a saline environment. It is therefore important to investigate the scaffolds mechanical properties under these conditions.

Factors such as surface quality, ductility of the structure, cellular response, characteristics of the culture medium and general conditions of the test environment are only a few factors that need be to be considered in future investigations of the scaffold-cell system.

REFERENCES

1. Schenberger D. and Bafan M., 2008. , "Bioceramics: The Future of Joint Healing" Med-Tech Precision Magazine, Spring. 2. Hutmacher DW., 2000, "Scaffolds in tissue engineering bone and

cartilage," Biomaterials, 21(24):2529-2543.