The Effect of Glycerol and Oil Palm Empty Fruit Bunches

Microcrystalline Cellulose Loading on Tensile Properties and Water

Absorption of Cassava Starch Composite

Novie Hairani

1,a*, Hamidah Harahap

1,b, Tjahjono Herawan

2,c, Taslim

1,d1Department of Chemical Engineering, University of Sumatera Utara, Jalan Almamater, Kampus

USU Medan 20155, North Sumatra, Indonesia

2Indonesian Oil Palm Research Institute, Jalan Brigjen Katamso No. 51, Medan 20158,

North Sumatra, Indonesia

a[email protected],b[email protected] c[email protected], d[email protected]

Keywords: Microcrystalline Cellulose, Oil Palm Empty Fruit Bunches, Cassava Starch, Glycerol, Composites

Abstract. The development and the utilization of starch as a packaging material which is eco-friendly, renewable and biodegradable have increased in recent years. In this study, cassava starch was modified into composites by adding glycerol as plasticizer and oil palm empty fruit bunches (OPEFB) microcrystalline cellulose (MCC) as fillers. The MCC was prepared via the pulping process of OPEFB and acid hydrolysis. The composites were cast into films by varying glycerol and MCC compositions. The effect of glycerol and OPEFBMCC loading on tensile properties and water absorption of composite was investigated. The results showed that MCC content at 10% created denser composite surface and enhanced the interfacial adhesion which led the tensile strength to increase but the elongation at break decreased. The filler loading also reduced the diffusion of water molecules and water absorption. However, the addition of glycerol in cassava starch composite to any MCC composition lowered the tensile strength but increased the water absorption. SEM images revealed that the addition of MCC in composite constructed the linkages among starch, glycerol, and MCC.

Introduction

Green composite materials which could be made by combining biodegradable matrix and fillers have revived the interest of some scholars to conduct studies and development in this topic in recent years. The exciting facts of this material are being eco-friendly, fully biodegradable, and renewable and thus these materials could be defined "green" in every aspect. In the end of its usage, this composite could be reused to produce compost without endangering environment [1].

Starch is well known as fully biodegraded material in soil and water and has the potential as an effective packaging material because of its cheapness and quickly biodegraded characteristics. Some starches have been used as a matrix such as corn starch, pea starch, cassava starch, potato starch, and rice starch [2-6]. However, the starches have high viscosity and harsh melting point that make them difficult to process. In addition, the starch-based products are very fragile and sensitive to water [7]. To encounter these problems, starch could be modified by several methods such as mixing with synthetic polymer and natural polymer, casting into composites and crosslinking [7].

In this study, modification of starch was performed by forming composites of cassava starch as a matrix, oil palm empty fruit bunches microcrystalline cellulose (OPEFBMCC) as filler, and glycerol as plasticizer. The particle size and degree of crystallinity of OPEFBMCC were expected to affect the mechanical strength and water absorption of produced material composites.

Experimental Procedure

Commercial cassava starch (“Sanghee” trade mark produced in Bogor, Indonesia) was used as a matrix. Glycerol solution (85%) as plasticizer was laboratory grade (Sigma-Aldrich). OPEFB was

Advanced Materials Research Vol. 1123 (2015) pp 151-154 Submitted: 2014-08-11

© (2015) Trans Tech Publications, Switzerland Revised: 2015-03-27

doi:10.4028/www.scientific.net/AMR.1123.151 Accepted: 2015-03-27

obtained from Indonesian Oil Palm Research Institute. The supporting chemicals used such as KOH, NaClO, NaOH, HCl, and Mg(NO3)2 were laboratory grade (Merck).

Oil palm empty fruit bunches (OPEFB) with the size of ± 1 mm and the solution of KOH 5% were mixed and refluxed in a reactor for 2 h. and the result was then flushed until being neutral. Next, the fibers were immersed in a solution of NaClO 1% for 24 h. followed by flushing and drying. The obtained cellulose fibers were hydrolyzed by the solution of HCl 2.16 N (20 mL/gram fiber) for 3 h. at 110±1oC. After being hydrolyzed, the product was washed and dried in an oven at 60oC. Later, the dried product was granulated and being stored at a dry container at least 7 days before usage. The degree of crystallinity of OPEFB microcrystalline cellulose (OPEFBMCC) was measured by using an x-ray diffractometer (Philip Analytical X-Ray B.V).

Note that starch must be converted into thermoplastic starch by the addition of plasticizer combined with the application of heat and shear forces [8]. Glycerol was chosen as plasticizer because it is the best substance that could lower the friction between starch molecules [9]. Cassava

starch of 12 grams was mixed with 120 mL of aquadest, glycerol and OPEFBMCC at 90°C for 15

min. The glycerols were 20, 25, 30, and 35% (wt.% of starch) while OPEFBMCCs were 0, 5, 10, and 15% (wt.% of mixture of starch and glycerol). The mixture was then poured over a transparent glass with the size of 16×16 cm and dried at 50oC in the oven. The dried samples were stored in desiccator

with relative humidity of 50% (by applying saturated solution of Mg(NO3)2) at room temperature for

40 h. before being tested. The tensile test was performed in accordance with ASTM D-882 using Universal Testing Machine (GOTECH Al-7000M). The water absorption of sample was evaluated in accordance with ASTM D-570. The morphology of OPEFBMCC and composites were observed using Scanning Electron Microscope (SEM) (JSM-6510 LV).

Results and Discussion

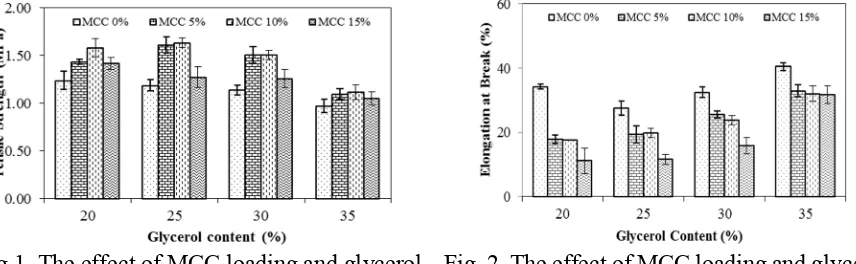

The effect of OPEFBMCC loading and glycerol content on tensile strength is given in Fig. 1. It can be observed that the tensile strength increases by MCC loading in the matrix. However, the tensile strength drops for MCC loading of 15% as well as the addition of glycerol in each composition of MCC. The improvement of tensile strength might be due to high degree of crystallinity and small particle size, thus, the MCC particles could be homogenously distributed in the composite. Note that the degree of crystallinity of OPEFBMCC that was derived from XRD analysis was 80.95% with the size range of 15-75 µm. The appropriate particle distribution and interfacial bonding between matrix and fillers could generate effective stress transfer from the matrix to the fillers. Hence, the composites could accommodate the efficient loading and improve its properties [10-12]. Meanwhile, the agglomeration of MCC might occur as its content was above 10%. This might cause the interfacial adhesion in matrix and fillers which are incapable in resisting the given stress and the tensile strength therefore drops. The addition of glycerol might also lower the tensile strength as the interaction of molecules diminishes and the humidity content increases in the composites due to hygroscopic properties inherited by glycerol [13-14].

Fig.1. The effect of MCC loading and glycerol

The effect of OPEFBMCC loading and glycerol content on elongation at break is given in Fig. 2. It shows that addition of MCC might decrease the elongation at break yet the value increased after treated with glycerol for any of MCC content. When the MCC was loaded in the matrix, the film surface became denser thus created a difficulty in molecules movement and lowered the flexibility of films and elongation at break. This is related to the crystallinity and MCC size that were well distributed and the polar interaction between molecules in composites which generated the solidity of film surface. On the other hand, glycerol treatment might improve the elongation at break due to its hydrophilicity with low molecular mass and thus it could enter the starch chain without any hindrance. Next, the glycerol might remove the intermolecular interaction in starch and increase the gap between the starch chain [6,15]. This might allow the starch molecules to move freely when stress was applied and thus lowered the tensile strength and increased its elongation at break.

The plastic materials could absorb several amount of water and its presence could provoke the characteristic of plastics. The effect of OPEFBMCC loading and glycerol content on water absorption (WA) is given in Fig. 3. It could be seen that the WA decreases as the MCC content increases but the WA increases as the glycerol content increases for each composition of MCC. The addition of MCC would decline the WA ability due to high degree of crystallinity of MCC. Besides, this could also be affected by the formation of hydrogen bonding from cassava starch with hydroxyl group from cellulose molecule that might reduce the diffusion of water molecules in the composites. The addition of glycerol increased the WA as the hydrophilicity of composite films was enhanced, thus there were more hydroxyl groups that could interact with water through hydrogen bonding [16].

Fig.3 Effect of MCC loading and glycerol content on water absorption.

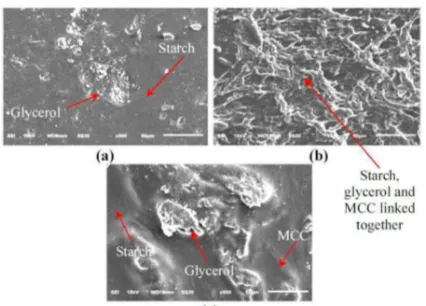

Fig.4. SEM micrographs of: (a) Glycerol 20% and MCC 0%, (b) Glycerol 20% and MCC 10%, and (c) Glycerol 35% and MCC 10%.

The SEM micrographs of composites fracture are shown in Fig. 4. There is a difference in morphology of the composites between Fig. 4.(a) and Fig. 4.(b) indicating that the addition of MCC in composites influences the starch, glycerol and MCC to be attached together. This explains that the enhancement in tensile strength is due to the addition of MCC in cassava starch composites. When the glycerol content was increased (Fig. 4.(c)), it might cover up the surface of starch matrix hence the interaction between starch molecules and between starch-MCC lessened and resulted in deteriorating properties of mechanical strength.

Conclusion

The addition of OPEFBMCC as filler has improved characteristics of cassava starch composites, mainly in tensile strength properties and water absorption. In this study, maximum concentration of OPEFBMCC that could load in cassava starch composites for giving the best characteristic was 10%. However, for each OPEFBMCC composition, the addition of glycerol (20-35%) gave opposing characteristics of cassava starch composites.

Acknowledgement

The first author (Novie Hairani) would like to thank Indonesian Oil Palm Research Institute, Medan, Indonesia for the financial support.

References

[1] M. J. John and S. Thomas, Biofibres and biocomposites, Carbohydrate Polymers 71 (2008) 343-364.

[2] A. Wattanakornsiri, K. Pachana, S. Kaewpirom, P. Sawangwong, C.Migliaresi, Green

composites of thermoplastic corn starch and recycled paper cellulose fibers, Songklanakarin J. Sci. Technol. 33 (2011) 461-467.

[3] L. Dagang, Z. Tuhua, P. R. Chang, L. Kaifu, W. Qinglin, Starch composites reinforced by bamboo crystals, Bioresour. Technol. 101 (2010) 2529-2536.

[4] A. R. Jeefferie, O. N. Fariha, A.R. Mohd. Warikh, M.Y. Yuhazri, H.Sihombing, J. Ramli, Preliminary study on the physical and mechanical properties of tapioca starch/sugarcane fiber cellulose composite, J. Eng. Appl. Sci. 6 (2011) 7-15.

[5] A. Dufresne, Processing of polymer nanocomposites reinforced with polysaccharide

nanocrystals, Molecules 15 (2010) 4111-4128.

[6] J. Prachayawarakorn, P. Sangnitidej, P. Boonpasith, Properties of thermoplastic rice starch composites reinforced by cotton fiber or low-density polyethylene, Carbohyd. Polym. 81 (2010) 425-433.

[7] P. Kampeerapappun, K. Srikulkit, D. Pentrakoon, Preparation of cassava starch/montmorillonite nanocomposite film, J. Sci. Res. Chula. Univ. 29 (2004) 183-197.

[8] H. Angellier, S. Boisseau, M. P. Dole, A. Dufresne, Thermoplastic–waxy maize starch nanocrystal nanocomposites, Biomacromolecules 7 (2006) 531-539.

[9] L.P.B.M. Jansen, L. Moscicki, Thermoplastic starch as packaging material, Acta Sci. Pol. Technica Agraria 5 (2006) 19-25.

[10]G.M. Brown, F. Ellyin, Assessing the predictive capability of two phase models for the mechanical behavior of alumina/epoxy nanocomposites, J. Appl. Polym. Sci. 98 (2005) 869-879. [11]M. Abdelmouleh, S. Boufi, M. N. Belgacem, A. Dufresne, A. Gandini, Modification of cellulose fibers with functionalized silanes: Effect of the fiber treatment on the mechanical performances of cellulose-thermoset composites, J. Appl. Polym. Sci. 98 (2005) 974-984.

[12]K. Piyada, S. Waranyou, W. Thawien, Mechanical, thermal and structural properties of rice starch films reinforced with rice starch nanocrystals, Int. Food Res. J. 20 (2013) 439-449. [13]P.J.A. Sobral, F.C. Menegalli, M.D. Hubinger, M.A. Roques, Mechanical, water vapour barrier

and thermal properties of gelatin based edible film, Food Hydrocolloid 15 (2001) 423-432. [14]T. Bourtoom, Plasticizer effect on the properties of biodegradable blend film from rice starch

chitosan, Songklanakarin J. Sci. Technol. 30 (2008) 149-165.

[15]T. Wittaya, Influence of type and concentration of plasticizers on the properties of edible film from mung bean proteins, KMTL Sci. Technol. J. 13 (2013) 51-58.

[16]S. Mali, L.S. Sakanaka, F. Yamashita, M.V.E. Grossmann, Water sorption and mechanical properties of cassava starch films and their relation to plasticizing effect, Carbohyd. Polym. 60 (2005) 283-289.