Mairodi ST MT

Teknik Kontrol

Dosen : Mairodi, ST.,MT. Semester : Genap

SKS : 3 sks

Buku Referensi : Programmable Logic Controller, Penulis: James A. Rehg dan Glenn J. Sartori Jumlah Peserta Total : ………...

1. Pengantar Sistem Kontrol 2. Pengantar PLC

3. Field Devices 4. Hardware PLC

5. Driver Interface PLC 6. Mengkonfigurasi PLC

7. Software pemrograman PLC

8. Sistem Bilangan dan Sistem Memory dalam PLC 9. Logika Boolean dalam Pemrograman

10 Instruksi Bit 10. Instruksi Bit

11. timer dan Counter 12. Instruksi Matematika

13. Instruksi Perbandingan/comparison

2

g p

1 Pengantar Sistem Kontrol

1. Pengantar Sistem Kontrol

Loop Kontrol

Jenis Pengontrol:

¾Analog dan digital

¾On-off dan PID

Controller Process

+

Actuator

¾On off dan PID

¾Feedback, Feedforward dan Cascade Control

Sensor + Sensor + Transmitter

Tujuan Pengontrolan :

– Menjaga/mempertahankan nilai besaran pada referensi tertentu – Mengatasi gangguan/efek perubahan pada sistem

– Meningkatkan performansi sistem

Contoh-contoh pengontrol yang

Contoh contoh pengontrol yang

sering dipakai dalam industri :

•

Programmable logic controller (PLC)

Mi

t

ll

DIBAHAS DALAM KULIAH INI

•

Microcontroller

•

DCS (Distributed Control System)

•

SCADA (Supervisory Control and Data

SCADA (Supervisory Control and Data

Acquisition) System

Definition (1)

( )

•

Process

– A series of interrelated actions which transform material

It covers all resources that are involved in the process and It covers all resources that are involved in the process and talks about

process “inputs” (e.g. resources, raw material) and “outputs” (e.g.

fi i h d d t)

Raw Materials Products

Energies Out finished product)

Process

Energies Out Energies OutControl

– To maintain desired conditions in a physical system by adjusting

6

Definition (2)

( )

•

Process Control

– To maintain desired conditions in a physical system

To maintain desired conditions in a physical system

by adjusting selected variables in the system in spite

of disturbances affecting the system and observation

noise

noise

Corrective Action Process

Knowledge Data

Information

7

Daylife Example: Driving a Car

Brain:

Daylife Example: Driving a Car

• Control Objective (Setpoint):

Maintain car in proper lane Brain:

Control calculation

Eyes: Sensor

Maintain car in proper lane

• Controlled variable:

Location on the road

• Manipulated variable:

Orientation of the front wheels Orientation of the front wheels

• Actuator:

Steering wheel

• Sensor:

D i ’

Driver’s eyes • Controller: Driver • Disturbance: Steering wheel: Actuator

Curve in road

• Noise:

Rain, fog

Industrial Example #1: Heat

Exchanger

• Control Objective (Setpoint):

Maintain temperature

Product

Stream TC Steam

Maintain temperature

• Controlled variable:

Outlet temperature of product stream

• Manipulated variable:

TT

Steam flow

• Actuator:

Control valve on steam line

• Sensor:

Feed Condensate

Thermocouple on product stream

• Controller:

Temperature controller

• Disturbance:Disturbance:

Changes in the inlet feed temperature

• Noise:

Measurement noise

Industrial Example #2: Liquid

C

Level Control

• Control Objective (Setpoint):

Maintain level Maintain level

• Controlled variable:

Fluid level in the tank

• Manipulated variable:

Fluid

Fluid flow

• Actuator:

Control valve on fluid line

• Sensor:

LC

Level transmitter on the tank

• Controller:

Level controller

• Disturbance:

LC

Disturbance:

Changes in the inlet feed flow

• Noise:

Measurement noise

LT

Elements of Process Control Loop

• Sensor

Elements of Process Control Loop

Measure process variable

• Transmitter

Convert the measured process variable into standard signal Convert the measured process variable into standard signal

• Controller

Drive actuator by giving an appropriate controller output signal

A t

t

• Actuator

Adjust manipulated variable based on the value of the controller output signal

• Process

Physical system to be controlled

Istilah-istilah (I)

Istilah istilah (I)

• Control Objective (Setpoint,

SP

)

• Controlled Variable (CV) or Process Variable (

PV

)

• Measured Process Variable (

PV

m)

• Controller Output (

CO

)

• Controller Output (

CO

)

• Manipulated Variable (

MV

)

• Final Control Element (Actuator)

• Sensor/Transmitter

• Controller

• Disturbance Variable (

DV

)

• Disturbance Variable (

DV

)

• Measurement Noise

Goal of Process Operation

24 hours process operation? Hmm… I think, to achieve

Goal of Process Operation

Hmm… I think, to achieve those, we need to continuously

monitor & control the process 24 hours a day,

7 days a week!!!

• Safety & Reliability

• Product Specification

Product Specification

• Environmental Regulation

• Operating Constraint

• Operating Constraint

• Efficiency

• Maximum profit

• Maximum profit

Safety and Reliability

Safety and Reliability

• The control system must provide safe operation

Alarms, safety constraint control, start-up and shutdown

• A control system must be able to “absorb” a variety of disturbances and keep the process in a good

of disturbances and keep the process in a good operating region

Feed composition upsets, temporary loss of utilities (e g steam supply) day to night variation in the (e.g., steam supply), day to night variation in the process

Product Specification

• Quality

– Products with reduced variability

Product Specification

N C ll

– Products with reduced variability

For many cases, reduced variability products are in high demand and have high value added (e.g. feedstocks for polymers)

p u rity n tr at io n Limit p ur it y en tr atio n Limit

Old Controller New Controller

Time Im p Co n ce n Time Im p C onc e

Product certification procedures (e g ISO 9000) are

• Product certification procedures (e.g., ISO 9000) are

used to guarantee product quality and place a large

emphasis on process control

Environmental Regulation

Environmental Regulation

• Various government laws may specify that the

Various government laws may specify that the

temperatures, concentrations of chemicals,

and flow rates of the effluents from a process

p

be within certain limit

Examples:

– Regulations on the amounts of SO

2that a

process can eject to the atmosphere, and on the

lit

f

t

t

d t

i

l k

quality of water returned to a river or a lake

Operational Constraint

Operational Constraint

• All real process have constrained inherent to

All real process have constrained inherent to

their operation which should be satisfied

throughout the operation

g

p

Examples:

– Tank should not overflow or go dry

g

y

– Distillation column should not be flooded

– Catalytic reactor temperature should not exceed

y

p

an upper limit since the catalyst will be destroyed

Efficiency

Efficiency

• The operation of a

• The operation of a

process should be as

i

l

ibl

economical as possible

in utilization of raw

material, energy and

capital

p

Maximizing the Profit of a Plant (1)

Maximizing the Profit of a Plant (1)

• The operation of a process may many

p

p

y

y

times involves controlling against

constraints

Th

l

th t

bl t

• The closer that you are able to

operate to these constraints, the more

profit you can make

Example:

– Maximizing the product production rate usually involving controlling the process y g g p against one or more process constraints

Maximizing the Profit of a Plant (2)

Constraint control example: A reactor temperature control

Maximizing the Profit of a Plant (2)

• At excessively high temperatures the reactor will experience a temperature runaway and explode

• But the higher the temperature the greater the product yield

• Therefore better reactor temperature control allows safe operation at a

New Controller Improved Performance

• Therefore, better reactor temperature control allows safe operation at a higher reactor temperature and thus more profit

The History of Process Control

• 1960s Pneumatic analog instrumentation, controllers, and computing modules • 1970s Electronic analog instrumentation controllers and computing modules

The History of Process Control

• 1970s Electronic analog instrumentation, controllers, and computing modules

– Direct digital control with special algorithms programmed in main frame computer

• 1980s Electronic analog instrumentation and digital distributed control systems (DCS)

– Supervisory and model predictive control configured in special purpose computers

• 1990s Smart analog instrumentation, valves, and digital distributed control systemsg g y

– Supervisory and model predictive control configured in special purpose computers – Neural networks, online diagnostics, and expert systems in special purpose computers – Real time optimization using model libraries in special purpose computers

• 2000s Field bus based digital smart instrumentation, valves, and control systems

Digital bus takes full advantage of smartness and accuracy of instrumentation and valves – Digital bus takes full advantage of smartness and accuracy of instrumentation and valves – Some fast PID controllers such as flow and pressure go to the field transmitter or valve – Model predictive control, neural networks, online diagnostics, and expert systems are

integrated into the graphically configurable field bus based control systems and move to PCs

Common Types of Control Strategy

Common Types of Control Strategy

• Manual vs. Automatic

• Servo vs. Regulator

• Open-loop vs. Closed-loop

• Control strategies

– Feedback Control Feedforward Control – Feedforward Control – Cascade Control

• Single-Input Single-Output (SISO) vs. Input

Multi-Output (MIMO, also known as multivariable)

Manual vs Automatic

Temperature indicator

Should I adjust h l

Manual vs. Automatic

• Manual

the valve or should I run?

– Human has to adjust the MV to obtain the desired value of the PV based on observation and

i i

Emergency cooling

prior experiences

• Automatic

– The computer (or other device) – The computer (or other device)

autonomously controls the

process and may report status back to a operator

23

Regulator vs Servo

Regulator vs. Servo

• Regulatory control

Regulatory control

Servo control

– Follow constant

setpoint, overcoming

Servo control

• Follow the changing

setpoint

7.00 AM: 80 C… 8.00 AM: 70 C… 9 00 AM: 60 C

o o o

the disturbance

75.5 C… 75.3 C… 75.4 C…

o o o

9.00 AM: 60 C…

Open-loop vs Closed-loop

DV

Open loop vs. Closed loop

• Open-loop

PV CO

Process

Decisions

C t ll

p

p

– Process is controlled based on predetermined scenario

Ex.: When food is done in an

Controller

SP

oven, timers on outdoor lights

DV

PV CO

P

• Closed-loop

– The information from sensor

Decisions

Controller

Process

– The information from sensor is used to adjust the MV to obtain the desired value of the PV

Control Strategies (1)

• Feedback Control

C ti ti b d i bl (PV)

Control Strategies (1)

– Corrective action based on process variable (PV)

DV SP SP PV Feedback Controller CO Process Advantage

Requires no knowledge of the source or nature of disturbances, and minimal detailed information about how the process itself works

Disadvantage

Controller takes some corrective actions after some changes occurs in process variable PV

Control Strategies (2)

• Feedforward Control

B d th t f di t b (DV) Æ f df d t ll

Control Strategies (2)

– Based on the measurement of disturbance (DV) Æ feedforward controller can respond even before any changes occurs in PV

DV

Advantage

SP Feedforward CO PV

Controller Process

Advantage

Controller takes some corrective actions before the process output is different from the setpoint Æ theoretically, perfect disturbance rejection is possible!

Disadvantage

• Requires process model which can predict the effect of disturbance on PV • Requires process model which can predict the effect of disturbance on PV

• If there are some modeling error, feedforward control action will be erroneous (no corrective action)

• Feedforward controller can be quite complex

Control Strategies (3)

Control Strategies (3)

• Feedback/Feedforward Control

– Feedforward controller will adjust CO as soon as the DV is detected – If the feedforward action is not enough due to model error,

measurement error and etc., feedback controller will compensate the

DV

PV CO

difference

SP Feedforward/ CO PV

Feedback Controller

Process

Control Strategies (4)

Control Strategies (4)

• Cascade Control

– The disturbance DV1 arising within the inner loop are corrected by the

inner controller before it can affects the PV of the outer one Example: Control valve + positioner

DV SP DV1 Inner loop Outer loop SP PV CO Outer Feedback Controller Inner Feedback

Controller ProcessInner ProcessOuter

CO

Control Strategies (5)

Control Strategies (5)

• Feedback/Feedforward + Cascade Control

DV

Outer loop

Feedback/Feedforward + Cascade Control

SP

PV CO

Outer Feedback

C ll Inner Feedback Inner O ter

DV1

CO

Inner loop

PV CO

Controller Inner Feedback

Controller ProcessInner ProcessOuter

CO

SISO vs MIMO

SISO vs. MIMO

• Based on how many

PV

and

MV

we have in a process

DVs

SISO

MIMO

y

p

DV PV COProcess

…

…

CO Process PV…

…

Decisions

Controller

Process COs PVs

Performances of Process Control System

• Closeness to setpoint

• Short transient to one setpoint to other setpoint

1

2

y

• Short transient to one setpoint to other setpoint

• Smaller overshoot and less oscillation

• Smooth and minimum changes of variable

2

Smooth and minimum changes of variable

manipulation

• Minimum usage of raw materials and energy

Istilah-istilah (II)

• Manual control

Servo controlIstilah istilah (II)

• Automatic control

• Open-loop control

Servo control

Regulatory control

SISO control

MIMO control

• Closed-loop control

• Feedback control

f

MIMO control

Transient response

Overshoot

O ill ti

• Feedforward control

• Cascade control

Oscillation

Ringkasan

Ringkasan

• Control has to do with adjusting manipulated

Control has to do with adjusting manipulated

variables of the process to maintain controlled

variables at desired values

• All control loops have a controller, an actuator, a

process and a sensor/transmitter

process, and a sensor/transmitter

• Various controller strategies can be realized to

hi

d

i d

bj

ti

&

d

t

achieve desired process objectives & product

specifications

Pertemuan ke-2

Pe nga nt a r PLC

Pertemuan ke 2

Sasaran Pelatihan

• Mengetahui sejarah perkembangan PLC • Mengetahui pengontrolan dengan Relay • Prinsip dasar operasi PLC

Sejarah Singkat Sistem Kontrol Industri

j

g

• Proses kontinyu• Sederhana

• Sinyal elektrik analog 4-20 mA • Sistem kontrol digital

• Proses kontinyu • Lebih kompleks

• Sinyal elektrik analog 4-20 mA, FF, HART

g

• Input output terbatas • Sistem kontrol digital • Input output banyak • Algoritma pengontrol PID

Era Pneumatic Era PLC

Era DDC Era DCS

Smart Instrument FCS Electric Instrument

Tradisional Instrument

Era Pneumatic Era PLC

- Proses Diskrit S d h

• Menggantikan relay

• Sinyal digital

- Sederhana

- Sinyal pneumatic 3-15 psi - Sistem kontrol

penumatik-mekanik

- Input/output terbatas

• Sinyal elektrik 4-20mA • Sistem kontrol digital • Input/output banyak

• Sistem kontrol yang lebih

• Sinyal digital • FF network

• Direct download

p p

Direct Digital Control (DDC)

g

(

)

IBM Control Station Controller

IBM Control Station

Apple Control Station

Traditional Signal :

4 – 20 mA

1 – 5 V Instrument Card TT CV CV

Process A

TT TT TTFT LT LT LT PUMP

Process A

TT

Distributed Control System (DCS)

Contoh :

DCS

PLC

NI – FP

Hub – Switch

Contr

oller

Traditional Signal Semi-digital Signal Digital Signal

Industrial Comm : High Speed Data Exchange : HSE, DH+, FF, CAN

TT CV CV Spur Controller Digital Signal 0 mA Digitized :FF/DH+/CAN m A Spur TT TT TT

FT LT LT LT PUMP

Process A

4 – 2 4 – 20 m TTField Control System (FCS)

Computer Function :

Data logging

Supervisory Monitoring

Contoh :

NI – CAN

NI – FF

Setting Input

Programming

PLC/DCS

NI – FP

Industrial Communication Card

Contr

oller

Fully

Digital Signal Industrial Comm : High Speed Data Exchange : HSE, DH+, FF, CAN Spur TT CV CV Spur Controller Digitized :FF/DH+/CAN Spur Spur TT TT TT

FT LT LT LT PUMP

Process A

Controller

TT

Mengapa menggunakan PLC

g p

gg

• Bisa mengontrol komplet proses manufaktur

• Mencapai konsistensi dalam manufaktur

• Meningkatkan kualitas dan akurasi

B k j d l

li

k

lit/b h

• Bekerja dalam lingkungan yang sulit/bahaya

• Meningkatkan produktivitas

• Memperpendek waktu pemasaran

Memperpendek waktu pemasaran

• Menyediakan variasi produk yang lebih besar

Kemudahan dengan PLC

g

• PLC merupakan hardened industrial computer

• Sekuens kontrol PLC dengan mudah diubah dengan

pemrograman. Beberapa fungsi advance

:

• Aritmatika

• Manipulasi data

• Shift registers

• Penyimpanan dataPenyimpanan data

• Pemrograman LD menggunakan PC

• Link komunikasi dan jaringan antara PLC dan PC

Bagian-bagian PLC

g

g

• Bagian sensing • Bagian input • Controller • Programmer • Bagian outputBagian output

Pengontrolan di Masa Lalu

g

• Kelistrikan telah digunakan untuk mengontrol

g

g

• Berbasis pada relay

• Relay ini memungkinkan daya listrik men-switch on atau

off tanpa men-switch secara mekanik

Perkembangan PLC

g

• Pengembangan komputer dengan biaya rendah telah membawa kepada revolusi teknologi yaitu teknologi PLC

• Penggunaan PLC dimulai sejak tahun 1970 an dan menjadi pilihan utama dalam pengontrolan di industri manufaktur

• Keuntungan dari PLC :g

– Efektifitas biaya dalam mengontrol sistem kompleks – Fleksibel

Kemampuan komputasi untuk kontrol canggih – Kemampuan komputasi untuk kontrol canggih

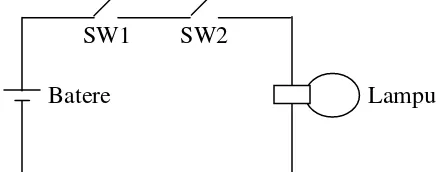

Relay

y

• Relay digunakan untuk logika kontrol

• Relay adalah alat sederhana yang menggunakan medan magnetik y y g gg g untuk mengontrol switch

• Kontak yang menutup pada saat energized coil disebut normally open. Kontak yang menutup pada saat tidak ada energized coil p y g p p g disebut normally closed

Coil

Bagaimana Mengontrol Relay ?

g

g

y

Input tunggal push button

Meng-energized coil

Mendrive output relay 220V AC

Cara Kerja Program PLC

j

g

• PLC diprogram dengan teknik berdasarkan logika skema pengkabelan

relay

• Daya listrik ada di sebelah kiri, garis vertikal, hot rail.

• Di sebelah kanan disebut neutral rail.

N t l

I t

Hot Rail

Neutral

Input

Rung Rung

PLC Connections

I O

PUMP

nput utput

Tanki

Ketika proses dikontrol, PLC

menggunakan input dari

k

b

sensor untuk membuat

keputusan dan meng-update

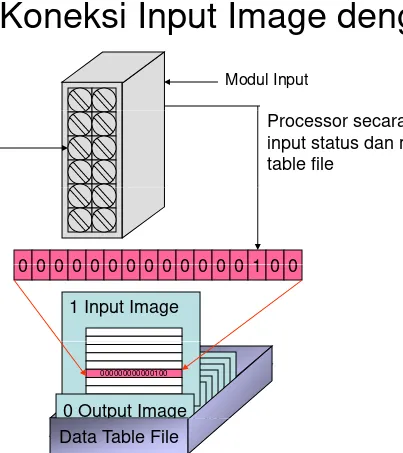

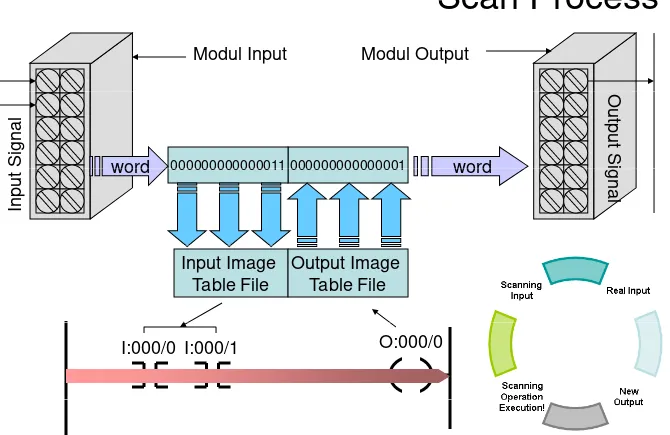

Cara Kerja CPU

j

Scanning POWER ON

Loop kontrol adalah siklus

kontinyu dari pembacaan

ScanningInput Real Input

kontinyu dari pembacaan

input PLC, memecahkan

logika LLD, kemudian

mengubah output

Scanning

Operation New

Output p

Cara Kerja PLC

Sanity Check

POWER ON

POWER ON

j

Error

STOP Yes

• Power On

• Men-check apakah hardware

bekerja dengan benar

Error

Indikator On

Scanning

Save to

bekerja dengan benar

• Jika ada masalah PLC akan

berhenti dan menyalakan indikator error No Scanning All Inputs Save to Memori

L dd

L

i S l

d

• Mulai membaca (scan) semua

input

• Ladder logic akan discan

(dipecahkan) menggunakan

Ladder Logic Solved

Scanning

( p ) gg

nilai input yang tersimpan tersebut.

• Output akan discan

• Nilai ouput berubah

Scanning All Outputs

O

C

• Nilai ouput berubah

• Waktu yang diperlukan untuk

masing-masing tahapan dalam milliseconds.

Konfigurasi Fisik PLC

g

• Fixed

– Terdiri dari prosesor, modul input-output, catu daya

dalam satu unit

Chassis adalah suatu tempat

• Modular

– Terdiri dari prosesor, semua

modul input-output sebagai Chassis adalah suatu tempat yang terdiri dari slot-slot…

… tempat modul I/O…

p p g

perangkat keras yang dapat dipasang dan dilepas secara terpisah

A Picture of PLC System

y

Man-Machine Interface Programming Device C

PLC Network

PLC PLC PLC PLC

Tipikal Panel Pengontrol (PLC)

p

g

(

)

PLC vs. PC

• PC

– Menerima masukan dari keyboard dan menampilkan hasil operasi program pada monitor

• PLC

– Menerima masukan dari suatu alat, seperti switch atau , p termokopel, dan menetapkan suatu keluaran, seperti

PLC vs. PC

• PLC didesain untuk beroperasi di lingkungan industri:

Temperatur dan kelembaban lingkungan yang fluktuatif dalam p g g y g rentang yang besar.

PLC yang didesain dengan baik tidak dipengaruhi oleh noise elektrik

elektrik.

• Hardware dan software PLC didesain sedemikian

sehingga mempermudah penggunaan oleh electrician

d

k i i

dan teknisi.

PLC diprogram dengan relay ladder logic.

PLC tampil dengan bahasa pemrograman yang dibangun dalam p g p g y g g memory permanennya,

PLC vs. PC (2)

• PC merupakan mesin komputasi yang kompleks

Mampu mengeksekusi beberapa program atau tugas secara

( )

p g p p g g

simultan dan dengan beberapa urutan

• Sedangkan PLC mengeksekusi program tunggal secara

ber r tan dan sek ensial dari instr ksi a al sampai akhir

berurutan dan sekuensial dari instruksi awal sampai akhir

• Troubleshooting dipermudah karena pada PLC sudah

didesain fault indicator/information

PLC vs. PC (3)

• Software PLC yang dijalankan pada PC

dikategorikan dalam 2 hal berikut

:

( )

dikategorikan dalam 2 hal berikut

:

Software PLC yang digunakan user untuk memprogram dan mendokumentasikan

S ft PLC di k t k it d

Typical Configurations for PLC

yp

g

Medium

Large

Small

Typical Configurations for PLC

• Small size

:yp

g

sampai 128 I/O

memory sampai 2 KB

M di

i

• Medium size

: sampai 2048 I/O

memory sampai 32 KB

• Large size

: sampai 16000 I/O

memory sampai 2 MB

Tiga tipe aplikasi PLC

Tiga tipe aplikasi PLC

• Single Ended

• Multitask

C

t l

t

• Control management

A lik i SLC 500 t ll Aplikasi SLC 500 controllers: • Packaging Machinery

• Conveyors and other Material Handling Machinery

M hi T l

• Machine Tools • Textile Machinery

• Food Products Machinery

Pertemuan ke-3

M easurem ent Variables

M easurem ent Variables

Sensors • level/volume Actuators • motors • mass • pressure • flow

AC motor DC motor

• valves

• temperature

• status

• voltage, current

block valve control valve

• relay g ,

• pH

• gas detector

• moisture

• buzzer

• etc

• valve positioner

• proximity

Field Device Im portant A spects

Field Device Im portant A spects

Range of measurement

Operating conditions

Calibration method

Dimensions p g Accuracy Precision Linearity Age Availability

Product support

Linearity

Hysteresis

Physical characteristics

Product support (maintenance)

Spare parts • temperature effects

• overpressure effects

• vibration effects

• humidity effects

• power supply effects

• load effects

Range and A ccuracy

Range and A ccuracy

y

y

Range

• Minimum and maximum value of physics quantity that canMinimum and maximum value of physics quantity that can be measured under reference operating conditions

Accuracy

• A number or quantity that defines the limit that errors will not exceed when the device is used under reference operating conditions

• example :

± 1 oF

± 1% of actual output reading

Reference Operating Conditions

Linearity

Linearity

y

y

The closeness to which a curve approximates a

straight line

(a) independent linearity (b) zero-based linearity

(a) independent linearity

(c) terminal-based linearity

linearity

(b) b d (b) zero-based

Hysteresis

Hysteresis

y

y

Hysteresis

The maximum difference for the same input between the upscale and downscale

output values during a full

t i h

range traverse in each direction

• hysteresis

Repeatability & Reproducibility

Repeatability & Reproducibility

y

y

y

y

Repeatability

The closeness of agreement b f ti among a number of consecutive measurements of the output for

• the same value of the input

• under the same operatingunder the same operating conditions

• approaching from the same direction

Reproducibility

The closeness of agreement among repeated measurements of the output for :

of the output for :

• the same value of input mode

• under the same operating

conditions over a period of time

Environm ent Conditions

Environm ent Conditions

Humidity

• Field device should be capable of operating in environments with 0-p p g 100% humidity

• Working fluid and the ambient environment should be considererd for corrosiveness

Temperature effect

• High ambient temperature on solid state electronics adversely affect component life

• Causing some electronic failures

Vibration effect

Hazardous Locations

• flammable gases or vapors

• combustible dust

A nother Im portant Factor

A nother Im portant Factor

Range adjustability

→ reduce the number of

Modular plug-in circuit

boards and easily accessible spare parts that have to be

kept on hand

Adjustable damping

test points → minimize field down-time

Interchangeable parts

Protective features

• Reverse polarity protection

• Current limiting

minimize spare parts inventory

Good local service and

g

• Lightning suppression

• Corrosive and ambient temperature control

spare parts availability

→ minimizes potential down-time

Installation consideration • Mounting flexibility

• Easy installation

Reliability based on field experience

y

Field Devices Classification

Field Devices Classification

Fieldbus

Digital Signaling

Fieldbus

HART

HART

(Highway Addressable

Remote Transducer)

Analog Signaling

Conventional Devices

Conventional Devices

Analog data (0 - 100%) is represented by analog

signal

signal

• electrical : 4-20 mA or 1-5 V

• pneumatic :

Example :

Differential pressure transmitter (0-150 psi operating

range and 4-20 mA output)

g

p )

• 4 mA → 0 psi

• 20 mA → 150 psi

psi

mA

(

150

0

)

56

.

25

4

20

4

10

10

×

−

=

Conventional Device Configuration

Conventional Device Configuration

Point-to-point

fi

ti

configuration

Requires dedicated

wiring for each

HA RT Device

HA RT Device

Interconnects smart transmitters in a two-wire

network

Simultaneous analog and digital signaling

1200 bps data rate

Shi ld d T i t d P i (2

i

l

)

Shielded Twisted Pair (2 wire loop)

Support multivariable transmitter with the use of

HART splitter

p

Can be used as either conventional transmitter or

smart transmitter

Normally not used for control caused by low data rate

HA RT Frequency Shift Keying

HA RT Frequency Shift Keying

y

y

y

y

Uses Bell202 modem

frequencies and handshakes

• ±0.5 mA variation of

conventional 4-20 mA signal

• 1200 Hz for logic 1

• 2200 Hz for logic 0

Because the average value of the FSK signal is always zero, the 4–20 mA analog signal is not affected.

The digital signal has a response time of

Simultaneous transmission of analog and digital signal

approximately 2–3 data updates per second

HA RT Point

HA RT Point-

-to

to-

-point

point

4–20 mA signal is used to communicate one process

i bl variable

Additional process variables, configuration parameters, and other device data are

other device data are transferred digitally for

• operations

• commissioning

• maintenance

• diagnostic

HA RT M ulti

HA RT M ulti-

-drop

drop

Requires only a single pair of wires and, if applicable,

safety barriers and an

auxiliary power supply for up to 15 field devices

All process values are transmitted digitally.

All field device polling

Used for supervisory control

addresses are >0

The current through each device is fixed to a minimum installations that are widely

spaced, such as pipelines, custody transfer stations, and tank farms

value (typically 4 mA).

M ulti

M ulti-

-m aster System

m aster System

y

y

Allows two masters (primary and secondary) to :

• communicate with slave devices

• provide additional operational flexibility.

Ensures interoperablility among devices through

i l d

The use of common tools for

universal commands

Enable hosts to easily access and communicate th t

products of different vendors minimizes the amount of

equipment and training

needed to maintain a plant the most common

parameters used in field devices.

HA RT A dvantages

HA RT A dvantages

Improved plant operation • Cost saving in comissioningg g

• Improved quality of measurement

• Cost saving in maintenance

Operational flexibility

Instrumentation investment protection

p

• compatibility of HART revision

• backward compatibility

• open system connection

Fieldbus Device

Fieldbus Device

Devices are configured in a 2 wire network

31 25 Kbps 1 Mbps and 2 5 Mbps data rate

31.25 Kbps, 1 Mbps, and 2.5 Mbps data rate

Analog/digital data is sent as digital signal

Data communication within devices is conformed to a

Data communication within devices is conformed to a

standard protocol (Foundation Fieldbus or Profibus)

Based on microprocessor and embedded system

t

h

l

technology

Allows point-to-point or multi-drop configuration

Simplified wiring drawings and easier control

Simplified wiring, drawings, and easier control

engineering

Inside a Fieldbus Transm itter

Inside a Fieldbus Transm itter

HARDWARE

Medium Attachment Unit (MAU) comprises the circuit needed to connect the

device to the actual bus wires

wires.

Microprocessor

A/D converter

Sensor converts the

SOFTWARE

Si l diti i

Sensor converts the physical phenomenon change into electric signal

• Conventional

Signal conditioning

Transducer block

• diagnostics

• calibration

• Silicon-based

• calibration Function block

• high/low/rate of change limits

Inside a Fieldbus Control Valve

Inside a Fieldbus Control Valve

HARDWARE

Medium Attachment Unit (MAU)

Microprocessor

D/A and A/D converter

Electric to pneumatic converter (E/P) provide

pressure signal to modulate actuator

SOFTWARE

P iti d f ti

actuator

Mechanical to electric

transducer (M/E) to monitor actuator position

Positioner and servo function

Transducer block : diagnostics and calibration

Function block

p

• high/low/rate of change limits

• control action

• fault-state mechanism

Fieldbus Devices A dvantage

Fieldbus Devices A dvantage

Reduced installation cost

• wiringwiring

• terminators

• I/O cards t l l

• control panel space

Improved quality of measurement

Distributed control design

Distributed control design

Interoperability

Online diagnostics, troubleshooting and calibration

g

,

g

P t

k 4

PLC

PLC’s

’s H a rdw a re

H a rdw a re

Pertemuan ke-4

PLC

Sa sa ra n Pe la t iha n

Sa sa ra n Pe la t iha n

Menyusun dan menggambarkan fungsi dari PLC dari

komponen-komponen hardware yang digunakan

p

p

y

g

g

Mendeskripsikan rangkaian elektrik dasar dan aplikasinya

untuk diskrit dan analog modul

Menginterprestasikan tipikal I/O dan spesifikasi CPU

Menjelaskan addresing I/O

Menggambarkan secara umum kelas dan tipe komponen

Menggambarkan secara umum kelas dan tipe komponen

memori PLC

Ba gia n I /O(1 )

Ba gia n I /O(1 )

g

g

( )

( )

Antarmuka Input dan output dianalogikan sebagai indra bagi otak PLC yaitu CPU

Bagian I/O terdiri dari I/O Chassis dan individual modul

CPU

I/O Modul di Chassis I/O Modul di Chassis

1 2 3 4 5 6 7

Power Supply

Chassis/Rack

I /O Cha ssis(1 )

I /O Cha ssis(1 )

( )

( )

AB SLC5/05 sistem 1746 merupakan sistem modular.

• Memerlukan sebuah 1746 I/O chassis untuk memuat beberapa modul.

• Chassis tersedia dalam beberapa ukuran slot modul 4, 7, 10 dan 13.

I /O Cha ssis(2 )

I /O Cha ssis(3 )

I /O Cha ssis(3 )

( )

( )

Pow e r Supply

I /O M odule a nd Cha nne l Addre ssing

I /O M odule a nd Cha nne l Addre ssing

g

g

Digunakan untuk memetakan input/output channel pada

i i d l

masing-masing module

Setiap jenis PLC dari vendor yang berbeda mempunyai k kh d l

kekhususan dalam

mengindetifikasi alamat-alamat channel di masing-masing

I nput da n Out put Addre ssing unt uk PLC SLC5 /0 5

I nput da n Out put Addre ssing unt uk PLC SLC5 /0 5

Alle n Bra dle y (1 )

Alle n Bra dle y (1 )

y ( )

y ( )

Output Input

Modul : 1 Modul : 2

O:000 O:001

I:000 I:001 Modul : 3

Modul : 4

O:002 O:003

I:002 I:003 Modul : 5

Modul : 6

O:004 O:005

I:004 I:005 Modul : 7 O:006

8 Words

I:006

I nput da n Out put Addre ssing unt uk PLC SLC5 /0 5

I nput da n Out put Addre ssing unt uk PLC SLC5 /0 5

Alle n Bra dle y (2 )

Alle n Bra dle y (2 )

y ( )

y ( )

Octal numbering system Æ PLC 5 AB

Alamat modul I:00

0 1 2 3 4 5 6 7 10 11 12 13 14 15 16 17

Alamat Channel

O:00

I nput da n Out put Addre ssing unt uk

I nput da n Out put Addre ssing unt uk

PLC SLC5 /0 5 All

B

dl

(3 )

PLC SLC5 /0 5 All

B

dl

(3 )

PLC SLC5 /0 5 Alle n Bra dle y (3 )

PLC SLC5 /0 5 Alle n Bra dle y (3 )

Decimal numbering system

Æ

PLC SLC 500 AB

Alamat modulI:00

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Alamat Channel

O:00

P

L

C

S

L

C

5

0

0

A

B

A

d

d

re

s

s

in

g

F

o

rm

a

t

P

L

C

S

L

C

5

0

0

A

B

A

d

d

re

s

s

in

g

F

o

rm

a

t

gg

Address : I1: 0.1/6 I1 0 1 6 etc) etc) I=Input,e I=Input,e r /word r /word ot ot O=output, O=output, er er nt number nt number r/terminal r/terminal umber /slo umber /slo le Type (Ole Type (O

T ipik a l I nput m odul

T ipik a l I nput m odul

p

p

p

p

Status Indicator

T ipik a l Wiring I nput M odul (1 )

T ipik a l Wiring I nput M odul (1 )

p

p

g

g

p

p

( )

( )

T ipik a l Wiring I nput M odul (2 )

T ipik a l Wiring I nput M odul (2 )

p

p

g

g

p

p

( )

( )

T ipik a l Wiring I nput M odul (3 )

T ipik a l Wiring I nput M odul (3 )

p

p

g

g

p

p

( )

( )

T ipik a l Out put M odul

T ipik a l Out put M odul

p

p

p

p

Status Indicator

T ipik a l Wiring Out put M odul (1 )

T ipik a l Wiring Out put M odul (1 )

p

p

g

g

p

p

( )

( )

T Wi D i

T Wi D i

T ipik a l Wiring Out put M odul (2 )

T ipik a l Wiring Out put M odul (2 )

p

p

g

g

p

p

( )

( )

T ipik a l Wiring Out put M odul (4 )

T ipik a l Wiring Out put M odul (4 )

p

p

g

g

p

p

( )

( )

Com m on Ra t ings for Disc re t e I /O M odule

g

Input Interface :

• 24 VAC/DC 48 VAC/DC

Output Interface :

• 24 VAC/DC

• 48 VAC/DC

• 120 VAC/DC

• 230 VAC/DC

• 5 V DC(TTL Level)

• 48 VAC/DC

• 120 VAC/DC

• 230 VAC/DC

5 V DC(TTL Level)

• 5 V DC(TTL Level)

• 24 VDC

AC disc re t e I nput M odule

AC disc re t e I nput M odule

p

p

Power

T ipik a l K one k si Pe ngk a be la n M odul

T ipik a l K one k si Pe ngk a be la n M odul

I

t AC

I

t AC

I nput AC

I nput AC

Input Field Devices Input Field Devices

Switch

T ipik a l K one k si Pe ngk a be la n M odul Out put AC

T ipik a l K one k si Pe ngk a be la n M odul Out put AC

p

p

g

g

p

p

Ana log I /O M odule

Ana log I /O M odule

g

g

PLC berbasis I/O discrete hanya dapat mengendalikan

peralatan ON/OFF, keterbatasan ini berarti PLC hanya

mempunyai kontrol parsial terhadap beberapa aplikasi

kontrol proses

Analog Input modul terdiri dari rangkaian elektronik yang

g

p

g

y

g

dapat menerima sinyal analog dari peralatan lapangan.

Sinyal input ini dikonversikan dari besaran analog ke

besaran digital dengan menggunakan Analog to Digital

besaran digital dengan menggunakan Analog to Digital

Converter (ADC)

Analog Output Modulu terdiri dari rangkaian elektronik

yang dapat mengirim sinyal analog ke peralatan lapangan

yang dapat mengirim sinyal analog ke peralatan lapangan

Sinyal output ini dikonversikan dari besaran digital ke

besaran analog dengan menggunakan Digital to Analog

C

(

C)

M odul I nput Ana log

M odul I nput Ana log

p

p

g

g

Single-ended Differential Differential

Arus (0-20 mA) Tegangan (1-5 V) Tegangan (1 5 V)

I mpedansi tinggi untuk menghindari

beban sinyal

M odul Out put Ana log

M odul Out put Ana log

p

p

g

g

Isolasi antara rangkaian keluaran dan rangkaian logic dilakukan oleh

optical couplers

M odule I /O K husus

M odule I /O K husus

High Speed Counter Module

• Digunakan untuk mnyediakan interface untuk aplikasi yang g y p y g

memerlukan kecepatan counter yang tidak bisa disediakan oleh program ladder PLC. Module ini digunakan untuk menghitung pulsa dari sensor, encoder, dan switch dengan kecepatan tinggi. Dapat menghitung pulsa sampai 75 KHz

Thumb-Wheel Module

• Module ini memungkinkan penggunaan thumb-wheel switch untukModule ini memungkinkan penggunaan thumb wheel switch untuk memberikan informasi kepada PLC untuk digunakan dalam

M odule I /O K husus

M odule I /O K husus

TTL Module

• Module ini meungkinkan menstransmisikan dan menerima sinyal g y TTL untuk komunikasi dengan Processor PLC. Level sinyal TTL adalah sinyal yang dapat diterima oleh processor dan hanya butuh buffering saja

Encoder-Counter Module

• Encoder-counter module memungkinkan monitoring kontinyu pada sebuah encoder pejumlah atau encoder absolut Encoder pada sebuah encoder pejumlah atau encoder absolut. Encoder menjaga jalur posisi dari batang atau axis.

BASIC atau ASCII Module

ASCII d l ki k t k i k t i fil

• ASCII modul memunkinkan untuk mengirmkan atau menerima file ASCII. File ini biasanya program atau data yang tersusun

(manufacturing data). Modul ini biasanya diprogram dengan menggunakan bahasa BASIC

M odule I /O K husus

M odule I /O K husus

Stepper Motor Module

• Module ini menyediakan pulsa berurut ke translator Steper motor, y p p , yang memungkinkan untuk mengontrol stepper motor. Perintah untuk module dihitung oleh program pengendali di CPU

BCD Output module

BCD Output module

• Module output BCD memungkinkan sebuah PLC untuk

mengoperasikan alat yang menggunakan sinyal kode BCD seperti seven-segment display

I nt e llige nt M odule (1 )

I nt e llige nt M odule (1 )

g

g

( )

( )

Intelligent Module adalah module yang mempunyai

processor sendiri yang dapat berfungsi pararel dengan

p

y

g

p

g

p

g

PLC

PID Module

M d l P ti l I t l d D i ti di k t k

• Modul Proportional Integral and Derivative yang digunakan untuk aplikasi process control. Modul ini memungkinkan untuk

mengontrol proses diluar CPU, sehingga proses perhitungan yang rumit di CPU tidak berpengaruh terhadap perhitungan PID di

rumit di CPU tidak berpengaruh terhadap perhitungan PID di modul PID.

Servo Module

I nt e llige nt M odule (2 )

I nt e llige nt M odule (2 )

g

g

( )

( )

Communication Module

• Sebagai sistem yang terintegrasi, data harus dapat dibagi melalui g y g g , p g sistem, PLC harus dapat berkomunikasi dengan komputer,

komputer kontrol numerik (Computer Numerical Control, CNC), robot atau PLC lainnya. Modul ini memigkinkan pengguna untuk mengkoneksikan PLC ke jaringan lokal (Local Area Network, LAN), yang mungkin berbeda dengan komunikasi yang

disediakan PLC

Language Module

• Modul ini memungkinkan pengguna menuliskan program di perintah bahasa tingkat tinggi (high-level language). Dengan

p g gg ( g g g ) g

menggunakan pengubah bahasa tingkat tinggi menjadi bahasa mesin yang dipahami oleh Processor PLC. Tersedia dalam

I nt e llige nt M odule (3 )

I nt e llige nt M odule (3 )

g

g

( )

( )

Modul ini digunakan untuk mendigitasi pengejaan kata,

frase atau kalimat oleh manusia. Suara yang

y

g

terdigitalisasi disimpan dalam memori modul. Setiap kata,

frase atau kalimat diberi nomor. Ladder logic

Spe sifik a si I /O (1 )

Spe sifik a si I /O (1 )

p

p

( )

( )

Nominal Input Voltage

• Spesifikasi AC atau DC dan besarnya tegangan yang digunakan

On-State Input Voltage Range

• Nilai ini menspesifikasikan tegangan di mana input signal diidentifkasi nyala absolut (On)

Nominal Current per Input

• Nilai ini menspesifikasikan arus listrik minimum di mana peralatan mampu untuk beroperasip p

Ambient temperature rating

• Nilai ini menspesifikasikan temperatur maksimum dari udara yang menyelimuti modul I/O untuk kondisi operasi terbaik

menyelimuti modul I/O untuk kondisi operasi terbaik

Input Delay

• Juga diketahui sebagai waktu respon (respones time), nilai ini menspesifikasikan durasi waktu sinyal input yang menyala

Spe sifik a si I /O (2 )

Spe sifik a si I /O (2 )

p

p

( )

( )

Nominal Output Voltage

• Spesifikasi nilai DC atau AC yang besar dan tipe sumber p y g p tegangannya dapat dikontrol oleh output

Output Voltage Range

• Nilai ini menspesifikasikan tegangan operasi output minimum dan

• Nilai ini menspesifikasikan tegangan operasi output minimum dan maximum. Sebuah rangkain output beroperasi pada 120 V AC, mempunyai selang kerja antara 92 V AC (min) sampai 138 V AC (max)

(max)

Maximum Output Current Rating per Output and Module

CPU : PLC SLC AB

CPU : PLC SLC AB

SLC 5/01 The SLC 5/01 processors let you configure modular controllers of up to 960 I/O and a 1K- or 4K-instruction memory capacity.

SLC 5/02 The SLC 5/02 processors let you configure modular controllers of up to 4096 inputs plus 4096 outputs nominally and a 4K-instruction memory. By installing an optional scanner module into one of the 30 I/O module slots, you can add Remote I/O or DeviceNet I/O to the system. They offer 19 additional instructions, including a message instruction for initiating peer-to peer communication.

SLC 5/03 The SLC 5/03 processors let you configure modular controllers of up to 4096 inputs plus 4096 outputs and a memory of 8K or

SLC 5/03 The SLC 5/03 processors let you configure modular controllers of up to 4096 inputs plus 4096 outputs and a memory of 8K or 16K words. In addition to the features of the SLC 5/02, they have a second built-in communication port — an RS-232-C port that can be configured for ASCII or DF1 protocol, and can be configured for connection to a 1761-NET-AIC converter to provide access to a DH-485 network. SLC 5/03 processors provide bit-instruction execution times of 0.44ms and an overall system throughput of up to 10 times faster than competitive processors. Additional capabilities include: floating-point math, online programming and run-time editing, flash memory upgrades, built-in key-switch, and a built-in real-time clock and calendar.

SLC 5/04 The SLC 5/04 processors let you configure modular controllers of up to 4096 inputs plus 4096 outputs and a memory of either 16K, 32K, or 64K words. They have all the features of the SLC 5/03 processors, plus a faster communication port and shorter execution times (bit-instruction execution times of 0.37ms). Instead of a DH-485 port, the SLC 5/04 has a built-in DH+ port for communication with other SLC 5/04 and PLC processors, operator interfaces, and programming terminals. Communication via the DH+ network is three times faster than DH-485 communication.

K e y Sw it c h

K e y Sw it c h

y

y

RUN

• Mengeksekusi program ladder dan mengenergisasi output dan mengenergisasi output

• Mencegah pengguna untuk mengedit program

REM

REM

• Memungkinkan untuk mengubah mode

programmer/operator interface

RUN p g p

• Memungkinkan untuk mengedit secara online

PROG

R E M

• Program ladder tidak bisa discann/run

• Memungkinkan untuk mengedit

PROG

T ipe

T ipe --t ipe M e m ori

p

p

t ipe M e m ori

p

p

Read Only Memory (ROM)

• Memori ini didesain informasi di dalamnya hanya dapat dibaca saja dan tidak dapat diubah

tidak dapat diubah

Random Acces Memori (RAM)

• RAM sering juga disebut R/W Memori, didesain informasi di dalamnya dapat ditulis atau dibacap

• Informasi mengenai timer/counter, Input/Output Status disimpan di RAM

• Jika daya dimatikan, maka informasi dalam RAM akan ikut hilang

Programmable Read Only Memory (PROM)

• PROM informasi program di dalamnya hanya dapat dibaca, jika ada perubahan program, maka PROM dapat diganti

Erasable Programmable Read Only Memory (EPROM)

S ti PROM t t i i f i d t dih d di l

• Seperti PROM tetapi informasinya dapat dihapus dan diprogram ulang, sehingga EPROM dapat dipakai berulang-ulang

Electrically Erasable Programmable Read Only Memory (EEPROM)

• EEPROM menawarkan fleksibelitas seperti EPROM tetapi EEPROM

Progra m m ing De vic e s

Progra m m ing De vic e s

g

g

g

g

Programming Devices

Programming Devices

adalah peralatan yang

adalah peralatan yang

p

p

y

y

g

g

dapat memprogram ladder

dapat memprogram ladder

yang akan di

yang akan di--download ke

download ke

dalam CPU PLC

dalam CPU PLC

dalam CPU PLC

dalam CPU PLC

Programming devices

Programming devices

g

g

g

g

terdiri dari :

terdiri dari :

•• PCPC

•• LaptopLaptop

•• LaptopLaptop

•• Handheld UnitHandheld Unit

PLC’s Interface Driver

Pertemuan ke-5

Sasaran

Peserta mampu untuk mengkonfigurasi

protokol komunikasi PLC dengan

protokol komunikasi PLC dengan

Komunikasi Antara PLC

Komunikasi antara PLC, PLC lainnya dan remote I/O.

Komunikasi PLC dengan Komputer

g

p

Komunikasi antara Komputer dan PLC menggunakan RS Komunikasi antara Komputer dan PLC menggunakan RS

232.

Digunakan pada saat pertama kali mengakses PLC dan download parameter pada EEPROM kosong dalam

Konfigurasi PLC dengan

Programming Software

Programming Driver :

Programming Software Programming & Communication Software Driver : - RS232 - RS 485 - ENET

Modb s

Communication Driver : RS232

- Modbus

Download

Download file dari Komputer ke PLC :

ke PLC :

- Ladder Logic

- Data File Structure

- Data Table Values

DH Plus

Menghubungkan maksimum 64 perangkat per link (dianjurkan Menghubungkan maksimum 64 perangkat per link (dianjurkan

15 atau lebih sedikit node per link) PLC-5 dan SLC 5/04

KomputerKomputer

Ethernet

Menggunakan kabel UTP untuk transfer data dari dan ke PLC.

Konfigurasi PLC

g

Konfigurasi PLC merupakan penghubung antara program

PLC dan perangkat kerasnya

p

g

y

Meliputi:

– Pemilihan tipe prosesor – Pemilihan modul-modul I/O – Pemilihan media komunikasi

+ Lokasi slot

RSLinx

RSLinx merupakan aplikasi 32-bit yang memungkinkan komunikasi p p y g g pada aplikasi yang luas dan mendukung Rockwell Software serta Allen-Bradley programming, MMI, dan produk software komponen

RS Linx

RsLinx menyediakan komunikasi secara luas pada aplikasi yang meliputi:

•Produk Rockwell Software

•Produk Hardware PLC Allen-Bradley P d k MMI / HMI d h d

RSLinx

Aktifkan RSLinx :

Start>>Programs>>Rockwell Software>>RSLinx>>RSLinx

RSWho

RSWho merupakan jendela/window untuk melihat driver mana saja ktif

Konfigurasi Driver RS-232

g

Pasang kabel Serial to Parallel Converter (1774-CP10)

Konfigurasi protokol komunikasi dengan menggunakan

g

p

g

gg

driver RS-232

Dialog Box : Configure RS-232 DF1 Devices

g

g

Browsing Processor

g

Checklist

Mengkonfigurasi PLC SLC5/05

Mengkonfigurasi PLC SLC5/05

dengan RSLogix

Aktifkan RSLogix500

Membuat File Baru

1. KLIK

2. Nama processor

Setting IP Address PLC

g

2 2

1

Men-do