A CLOSED MODEL OF PRODUCTION SYSTEM FOR

ENERGY SELF-SUFFICIENCY IN RICE MILL

MUHAMMAD NURDIANSYAH

DEPARTMENT OF AGROINDUSTRIAL TECHNOLOGY FACULTY OF AGRICULTURAL TECHNOLOGY

BOGOR AGRICULTURAL UNIVERSITY BOGOR

STATEMENT OF ORIGINALITY, INFORMATION SOURCE

AND COPYRIGHT TRANSFER

I declare that Skripsi entitled: “A Closed Model of Production System for Energy Self-sufficiency in Rice Mill” is my own work assisted by supervisor and I have never submitted it in any form to any collage. Source of information from published or unpublished works are cited in the text and listed in the references section. Hereby, I state that the copyright of this paper is transferred to Bogor Agricultural University.

Bogor, August 2015

Muhammad Nurdiansyah

ABSTRACT

MUHAMMAD NURDIANSYAH. A Closed Model of Production System for Energy Self-sufficiency in Rice Mill. Supervised by: TAJUDDIN BANTACUT.

Rice mills consumed a lot of energy. The fossil fuel has been the main source of energy which availability is declining, and in addition the use of it caused negative impact on the environment. A more sustainable energy resource, such as biomass should be considered to replace fossil energy. This research was aimed to develop a model of a self-sufficiency rice mill by converting by-products into energy. The model is based on principle of mass balance by assuming linear equation in each compartment. The simplest model assumed the rice mill as a single compartment, the level II model assumed main process as compartment, and the complex model used a more detailed step of processes as compartment. The complex model was chosen to be the most suitable model to represent actual process of rice mill. According to this model, head rice yield, rice husk ratio, and bran ratio obtained is 0.572; 0.231, and 0.074 of dried paddy respectively. Energy potential of by-product conversion is 18,827 MJ/day from processing 20 tons paddy. This energy potential exceeded the need with surplus of 28.25%. This research revealed that rice mills can be energy self-sufficient. Therefore, it is possible to limit fossil fuel energy used in rice mill.

Keywords: rice mill, closed production system, self-sufficient energy industry ABSTRAK

MUHAMMAD NURDIANSYAH. Model Sistem Tertutup untuk Pengembangan Industri Penggilingan Padi Mandiri Energi. Dibimbing oleh: TAJUDDIN BANTACUT.

industri penggilingan padi dapat mandiri energi dengan memanfaatkan hasil sampingnya sehingga dimungkinkan pembatasan penggunaan energi fosil pada penggilingan padi.

A CLOSED MODEL OF PRODUCTION SYSTEM FOR

ENERGY SELF-SUFFICIENCY IN RICE MILL

MUHAMMAD NURDIANSYAH

Skripsi

As partial fulfillment of the requirements for the degree of Bachelor (Honour) of Agricultural Technology

at

Department of Agroindustrial Technology

DEPARTMENT OF AGROINDUSTRIAL TECHNOLOGY FACULTY OF AGRICULTURAL TECHNOLOGY

BOGOR AGRICULTURAL UNIVERSITY BOGOR

Skripsi title : A Closed Model of Production System for Energy Self-sufficiency in Rice Mill

Name : Muhammad Nurdiansyah

NIM : F34110022

Approved by

Dr Ir Tajuddin Bantacut MSc Supervisor

Acknowledged by

Prof Dr Ir Nastiti Siswi Indrasti

Head of Department of Agroindustrial Technology

PREFACE

Praise and thanks to Allah SWT the Almighty for mercies and blessings so the author could finish this skripsi on time. There is no power of the author to complete this skripsi without His help and mercies. Sholawat and salam may still delivered to Prophet Muhammad SAW because of his guidance so that we can know the true way of life that is Islam Religion.

Author thank to:

1. Dr Tajuddin Bantacut as the author’s supervisor for his guidance, support and motivation until this Skripsi finished.

2. Parents and author’s big family for their pray and support.

3. All of lecturers and staffs of Agroindustrial Technology Department which provide excellent facilities and services.

4. Author’s partner: Mohammad Ryan Pratama, Andreas Zuriel and Aryosan Tetuko Haryono who have stood together to carry out this research.

5. Author also thanks to Yunita Siti Mardhiyyah, Anisa Nurul Rosnadia, Yudhistira Chandra Bayu and Indra Kurniawati as correctors of this skripsi. 6. Author’s classmates of Agroindustrial Technology 48 generation especially

for P1 class who have stayed together in happiness and sorrow.

7. Family of Al Khidmah Kampus IPB: Bagus Sukma Agung, Muhammad Iqbal, Dewi Anggraeni, Afif Bahruddin and close friends: Mirra Chan, Fajar Syahreza, Aldilah Fazy, M. Nizam Mustaqim, Diki Dwi Aji, Ahmad Muhaimin and comrade AKSEL 25 who always motivate.

8. Big Family of Himasurya Plus IPB, KMNU IPB, IMAJATIM IPB which always stay with the author when he was bored.

9. All of author’s friend include alma mater or not and all parties that support completion of this skripsi.

The Author hopes this skripsi can contribute significantly to the development of science and technology. Author expects critics and suggestion for further development of better agriculture.

Bogor, June 2015

TABLE OF CONTENTS

LIST OF FIGURES xii

LIST OF TABLES xii

LIST OF APPENDICES xii

INTRODUCTION 1

Background 1

Research Objective 2

Scopes of the Research 2

METHOD 2

Data Collection 2

System Boundary 3

Model Description 3

Mass Balance 3

Energy Content of Rice Production By-product 4

Process Flow of Self-sufficiency on Rice Mill 4

MASS BALANCE MODEL OF RICE MILL 5

Mass Balance Model Level 1 5

Mass Balance Model Level 2 5

Mass Balance Model Level 3 8

RESULT AND DISCUSSION 13

Mass Balance Model 13

Energy Self-sufficiency in Rice Mills 16

Closed System Production of Rice Mill 18

CONCLUSION AND RECOMMENDATION 19

Conclusion 19

Recommendation 19

REFERENCES 20

LIST OF FIGURES

1 Mass Balance Model Level 1 (I = P + W) 5

2 Mass Balance Model Level 2 6

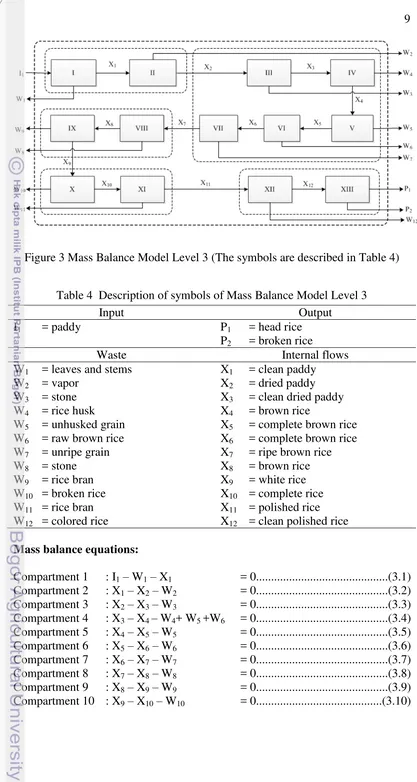

3 Mass Balance Model Level 3 9

4 Result of Mass Balance Model Level 3 operation 15

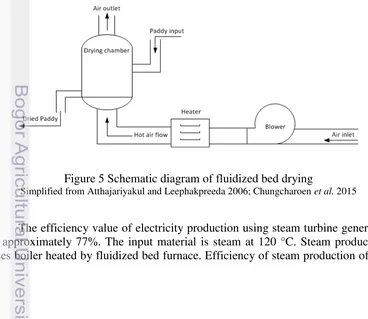

5 Schematic diagram of fluidized bed drying 16

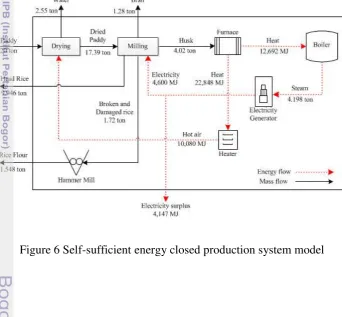

6 Self-sufficient energy closed production system model 18

LIST OF TABLES

1 Supporting data for energy potency calculation 4

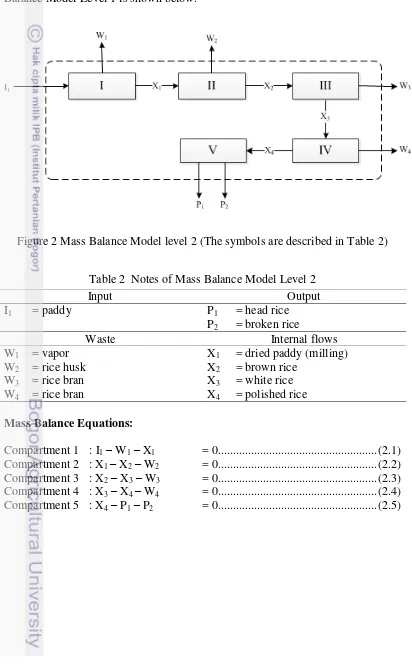

2 Notes of Mass Balance Model Level 2 6

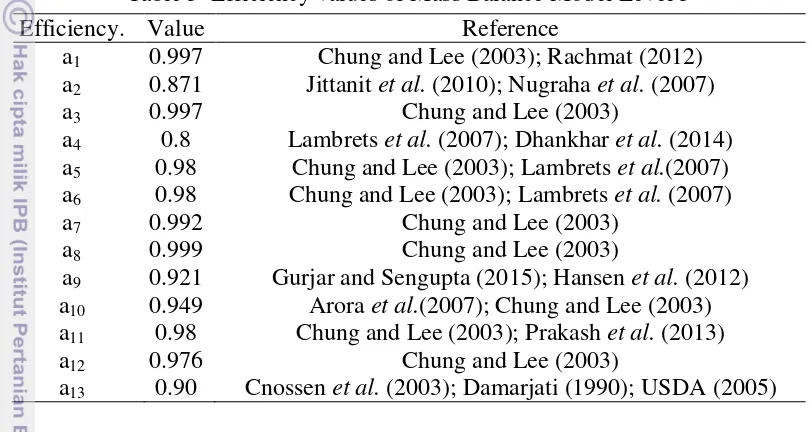

3 Efficiency values of Mass Balance Model Level 2 8 4 Description of symbols of Mass Balance Model Level 3 9 5 Efficiency values of Mass Balance Model Level 3 13 6 Comparison of models and IRRI standards by dried paddy 14 7 Comparison of Model level 3 with actual data by dried paddy 14

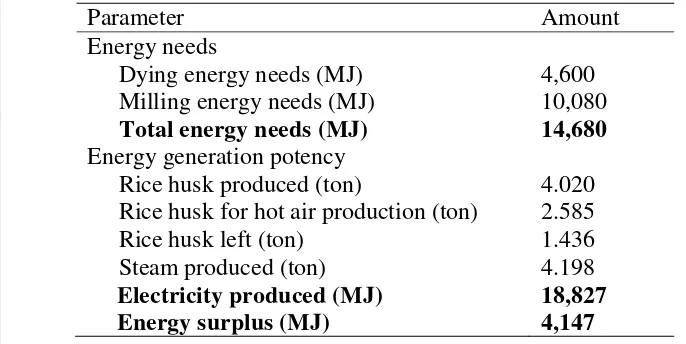

8 Rice husk potency for energy generation 17

LIST OF APPENDICES

1 Input value and inverse matrix operation of Model Level 2 24 2 Multiplier value and result of matrix operation of Model Level 2 25 3 Input value and inverse matrix operation of Model Level 3 26 4 Multiplier value and result of matrix operation of Model Level 3 27 5 Completed information of energy generation potency of rice mill 28

1 consumed by domestic people (Lim et al. 2014). This makes rice milling industry is vital for national food security.

Rice milling industry is one of the energy consuming industries. The amount of consumption varies from 734–1194.2 MJ/ton paddy input (Basappaji and Nagesha 2013; Goyal et al.2012; Kapur et al. 1995).The variation depends on its capacity and complexity of technology process.

The energy needs will continue to increase as much as the rice demands. The fulfillment of the energy needs is dominated by fossil energy resources. For the country, the consumed energy is fulfilled by fossil fuel (48%), coal (19%), natural gas (14%), LPG (5%), electricity (13%) and other resources (1%). The industrial sector has the largest share of energy consumption, as much as 33% of total national energy consumption with an average growth of 4.5% per year (KESDM 2014). Meanwhile, stocks of oil, coal and natural gas are declining and will be limited for near future. Rice mills will face serious substitute fossil fuel resources. Sustainable alternative energy resources are needed to replace fossil energy sources. Biomass is one of the potential alternative energy which can be the right solution for that energy problem.

The application of biomass-based energy sources is safer to the environment than the fossil energy since the content of sulfur and nitrogen is lower (Chungsangunsit et al. 2004; Sarasuk and Boonrod 2011). According to the study by Gadde et al. (2009), the application of biomass as an energy resource for rice production can prevent greenhouse gas emission (GHG) in three countries; India, Thailand and Philippines for 0.75%, 1.81% and 4.31% respectively based on the national specific GHG. The developed countries also fulfill their energy needs (up to 35%) using biomass energy resource (Basappaji and Nagesha 2013). Biomass utilization as an alternative energy resource is a promising choice for the sustainable rice mill.

Rice husk is a potential biomass energy resource produced from rice milling industries since it has high calorific value of 13–15.4 MJ/kg of rice husk in 14% moisture content (Ahiduzzaman and Islam 2009; Hiloidhari 2014). It is also conveniently converted into energy (UNEP 2007). Rice milling process produces rice husk as much as 20–22% of dried paddy weight (Buggenhout 2013; Lamberts

2

Okehet al. (2014) who analyzed the potency of rice husk for alternative energy resource in Nigeria, show that rice milling industry has a potency to fulfill its energy needs by rice husk utilization. However, those research are not adequate to estimate the independence of rice mill. Detailed modeling and estimation of how far rice mill can be self-sufficient in energy fulfilling will be the scope of this research.

Energy generation from rice husk may be utilized in a closed system, without any energy input from outside of the system. Based on the environmental engineering rules, closed system means a system which each input and output flows are known (Davis and Cornwell 2013). This research refers to that rule. Some useful methods used are mass balance modeling and rice husk potency analysis. Developed closed system is expected to integrate rice production and rice husk utilization as an energy resource to achieve self-sufficient energy rice mill.

Research Objective

This research aims at developing a model of self-sufficient energy rice production system. It can be achieved by the followings:

1. Developing rice production mass balance model. 2. Calculating energy needs of rice mill.

3. Calculating rice husk potency for energy generation. 4. Developing closed rice production system.

Scopes of the Research

Scopes of this research are rice production mass balance modeling and rice husk potency analysis as the energy resource. The input of the mass balance model is paddy and the outputs are head rice and broken rice. The value of input flow is 20 tons paddy/day. This value is following the observed rice mill capacity. The compared parameters of the models are head rice yield, rice husk ratio, and rice bran ratio.

The energy produced from rice husk utilization is compared to the rice mill energy consumption of rice mill based on the literature. This comparison determines the rice mill energy independence. If the energy generated is greater than energy need, the rice mill can potentially be independent for its energy. However, if the energy generated is smaller, the system is not independent for its energy.

METHOD

Data Collection

3 and by-product generation) from research reports, journals, books, thesis and other scientific articles. The field research was conducted in Cianjur Rice Mill (West Java) and the desk work in Department of Agroindustrial Technology, Faculty of Agricultural Technology, Bogor Agricultural University (February–April 2015).

System Boundary

Rice production is a complex system which involves many factors which are connected to each other. Those are material, energy requirement and by-product. A comprehensive approach is used to minimize energy usage, optimize production and utilize by-product. Therefore, a system approach is used to analyze the flow of mass, energy needs and energy potency from the by-product.

In general, rice production is divided into five compartments (process): drying, dehusking, whitening, polishing and grading. The material input is 20 tons paddy per day (based on the field observation). The main output is head rice and the secondary outputs (by-products) are broken rice, rice husk and rice bran. Broken rice is output of compartment 5 (grading), rice husk from compartment 2 (dehusking) and rice bran from compartment 3 and 4 (whitening and polishing).

Model Description

The model was developed based on mass balance of process flow and compartments to describe the real situation of rice production. The development of model notes to obtain the appropriate model which is able to represent real rice production. It was also to confirm the models consistency. The input is the independent variable while output and by-product are dependent variables. Modeling also used the ratio value (efficiency) of the variables based on the linear equation principal as the supporting data to develop the model. The calculation of the variables passed through matrix operation using Microsoft Excel.

The basis of mass balance modeling was white rice production at 20 tons of paddy per day capacity. The results of the model calculation were then compared with the international standard of rice production from International Rice Research Institute (IRRI) and the factual data of white rice production. It was used to confirm and validate the accuracy of the model.

The model was used to identify and calculate the amount of by-products that potential for energy source to meet the energy needs of rice mill. The model which had a high degree of consistency and appropriate with real rice production was used to the next analysis (energy potency analysis) to develop a self-sufficient energy rice mill.

Mass Balance

4

The first step is identifying the compartments of the rice production process. Then set mass balance to link the variables as input (paddy) and output (head rice and by-products) for all compartments. By-product is assumed to be recyclable. In identifying, the efficiency equation (the ratio of variables) used secondary data from literature study. Then, the mass balance can be determined.

Mass balance model is a series of mass balances illustrating rice production process. Matrix operation is used to calculate the value of variables. The input values for matrix operation are variables of mass balance and efficiency value of each compartment. It will be developed into three levels of mass balance model based on complexity of production process. This development aims at checking the consistency of the models. Then, the most suitable model to describe the real rice milling process will be chosen for the next analysis (energy analysis).

Energy Content of Rice Production By-product

The potential energy will be calculated by the equation: Potential energy (MJ) = Mass (ton) x calorific value (MJ/ton). Mass of by product will be obtained from model calculation whereas the calorific value will be obtained from the literature (13–15.4 MJ/kg of rice husk). This research used lowest calorific value, which was 13 MJ/kg of rice husk as a self-sufficient energy potency analysis.

Process Flow of Self-sufficiency on Rice Mill

The analysis of self-sufficient energy potency needs actual energy consumption of rice mill for the comparison. Actual energy consumption of rice mill is obtained from literature. The value is varied depends on applied technology and capacity. Several studies stated that it was about 734 MJ/ton paddies. (Basappaji and Nagesha 2013). Besides, it also needs some supporting data to calculate the generated energy from rice husk. Table 1 summarizes the properties of the calculation

Table 1 Supporting data for energy potency calculation

Supporting data Value Reference

5 mill needs energy from the outside then the system is not independent in its energy.

MASS BALANCE MODEL OF RICE MILL

Mass balance model of rice mill is developed into three levels based on complexity of production process. The simplest model assumed the rice mill as a single compartment, the level II model assumed the main process as a compartment, and the complex model used a more detailed step of process as a compartment.

Mass Balance Model Level 1

Mass Balance Model Level 1 is the simplest model by assuming all steps of the process as single compartments. It explains total amount of input and output of the system generally. Thus it only contains single efficiency value, which is head rice yield (HRY). In general, rice milling in Indonesia produce HRY as much as

45% based on rough paddy, stated in Indonesia as “Gabah Kering Panen” or “GKP” (Rachmat 2012).

Figure 1 Mass Balance Model Level 1 (I = P + W) Notes: I = input, P = product, W = waste

Mass Balance Model Level 2

Mass Balance Model Level 2 is the development of the previous model. It shows a more detailed explanation of rice production process than the previous model. This model contains several compartments as an extension of the previous model corresponding with general rice milling processes. Those are drying, dehusking, whitening, polishing and grading. Drying is to decrease moisture content of harvested paddy (De Datta 1981). Dehusking is rice husk removal with a minimum damage (Araullo et al. 1976). Whitening is rice bran removal (Araullo

6

There are 5 mass balance equations based on number of compartment. Thus, the number of efficiency value is as much as the number of mass balance equations (5 values). It consists of 1 independent variable (I1) and 10 dependent variables (X1, X2, X3, X4, W1, W2, W3, W4, P1 and P2). The independent variable is a consistent variable which has a given value (20 tons of paddy) while the dependent variables have various value depended on efficiency values. Mass Balance Model Level 1 is shown below.

Figure 2 Mass Balance Model level 2 (The symbols are described in Table 2)

Table 2 Notes of Mass Balance Model Level 2

Input Output

I1 = paddy P1 = head rice

P2 = broken rice

Waste Internal flows

W1 = vapor W2 = rice husk W3 = rice bran W4 = rice bran

X1 = dried paddy (milling) X2 = brown rice

X3 = white rice X4 = polished rice Mass Balance Equations:

7 Efficiency values:

Drying efficiency (a1)

a dried paddy

paddy I ( 6

Drying process is basically the transfer of heat by converting the water in grain to a vapor and transferring it to the atmosphere (De Datta 1981). In tropical countries, the moisture content of harvested paddy is about 25% (Jittanit et al. 2010). It needs to be decreased to 14% (Rahmat 2012; Steffe et al. 1980). Based on the mass balance equation (2.1), 12.8% of water from the paddy needs to be evaporated to obtain 14% moisture content. Thus the efficiency value of drying process (a1) is 87.2%.

Husking efficiency (a2)

a dried paddybrown rice ( 7

Husking is process of removing rice husk from harvested paddy with a minimum of damage to the bran layer (Araullo et al. 1976; Lambrets et al. 2007). Rice husk accounts for 20% of the weight of dried paddy (Chungsangunsit et al. 2004; Nugraha et al. 2007). Thus the efficiency value of rice husk removal (a2) is 80%. Whitening efficiency (a3)

a brown ricewhite rice ( 8

Whitening is a process to remove bran from brown rice (Araullo et al. 1976; De Datta 1981). Rice bran produced as much as 10% by weight of dried paddy (Naito

et al. 2015; Rachmat 2012). Based on the mass balance equation (2.3), it is as much as 12.5% of the weight of brown rice. Thus the efficiency value of brown rice milling (a3) is 87.5%.

Polishing efficiency (a4)

a polished rice

( 9

8

Head rice grading efficiency (a5)

a head rice

Table 3 Efficiency values of Mass Balance Model Level 2

Efficiency Value Reference

Mass Balance Model Level 3 is the development of the second model which shows more detailed explanation from the previous. This model contains several compartments as extension of the compartments of the second model related to the complex rice production process. Drying is extended into paddy cleaning (pre-cleaning) and drying. Pre-cleaning is removing the impurities from rice (De Datta 1981). Husking is extended into general destoning (stone removal), dehusking, screen sorting, brown rice separating and thickness grading (immature grain separation). Screen sorting and brown rice separating are to recycle the uncompleted brown rice (Chung and Lee 2003). Whitening is extended into brown rice destoning (secondary stone removal), whitening and rotary shifting (broken rice separation). Polishing is extended into polishing and color sorting. Grading is a single step so it is not extended (Chung and Lee 2013).

9

Figure 3 Mass Balance Model Level 3 (The symbols are described in Table 4)

Table 4 Description of symbols of Mass Balance Model Level 3

10

Compartment 11 : X10– X11– W11 = 0...(3.11) Compartment 12 : X11– X12– W12 = 0...(3.12) Compartment 13 : X12 – P1 – P2 = 0...(3.13) Efficiency values:

Precleaning efficiency (a1)

a rough paddyclean paddy I ( 4

Pre-cleaning process separates impurities such as weed, seed, leaves and stalks (De Datta 1981). It applies oscillating sieve mechanism. Impurities generated as much as 0.25% by weight of rough paddy (Chung and Lee 2003; Rachmat 2012). Thus efficiency value of precleaning (a1) is 99.75%.

Drying efficiency (a2)

a dried paddyclean paddy ( 5

Drying process is basically the transfer of heat by converting the water in grain to a vapor and transferring it to the atmosphere (De Datta 1981). In tropical countries, the moisture content of harvested paddy is about 25% (Jittanit et al. 2010). It needs to be decreased to 14% (Rahmat 2012; Steffe et al. 1980). Based on the mass balance equation (2.1), 12.8% of water from the paddy needs to be evaporated to obtain 14% moisture content. Thus the efficiency value of drying process (a1) is 87.2%.

Destoningefficiency (a3)

a clean dried paddydried paddy ( 6

Destoning process removes stone from paddy (Chung and Lee 2003). This process takes advantage of gravitation force to separates stone from paddy. It generates various value depends on harvesting process (IRRI 2015). In estimation, stone generated about 0.25% by weight of clean dried paddy (Chung and Lee 2003). Thus efficiency value of destoning (a3) is 99.75%.

Dehusking efficiency (a4)

a clean dried paddybrown rice ( 7

11 2007; Dhankhar et al. 2014). Thus the efficiency value of rice husk removal (a4) is 80%.

Screen sorting efficiency (a5)

a complete brown ricebrown rice ( 8

Screen sorting is a recycling process to bring back the uncompleted brown rice to dehusking process using compartment separator (Chung and Lee 2003; Lambrets

et al. 2007). It is assumed the value of screen sorting (a5) is 98%. Brown rice separating efficiency (a6)

a complete brown ricecomplete brown rice ( 9

Brown rice separating is a secondary recycle of uncompleted brown rice based on paddy size by using a tray separator. It also applies oscillating mechanism so that the complete brown rice can be separated (Chung and Lee 2003; Lambrets et al.

2007). It is assumed that the value of brown rice separating (a6) is 98%. Thickness gradingefficiency (a7)

a complete brown rice mature brown rice ( 0

Thickness grading is to separate unripe grain based on the thickness (De Datta 1981; Chung and Lee 2003). It has various value based on the harvesting time (IRRI 2015). This process separates unripe grain as much as 0.455% of the weight of dried paddy (Chung and Lee 2003). It is equivalent to 0.782% of the weight of complete brown rice 2. Thus, the efficiency value of thickness grading (a7) is 99.218%.

Brown rice destoning efficiency (a8)

a mature brown riceclean brown rice (

12

Whitening efficiency (a9)

a cleanwhite rice

(

Whitening is to remove rice bran from grain surface to obtain white rice (Araullo

et al. 1976; De Datta 1981). Rice bran generated is as much as 4.58% by weight of paddy (Gurjar and Sengupta 2015; Hansen et al. 2012). It is equivalent to 7.95% by weight of clean brown rice. Thus the efficiency value of whitening (a9) is 92.05%.

Rotary shifting efficiency (a10)

a complete white ricewhite rice (

Rotary shifting process is to separate complete white rice with broken rice (De Datta 1981). Broken rice is uncompleted grain which has less than 50% whole kernel length. (Rachmat 2012). The produced broken rice is as much as 2.68% of the weight of paddy (Arora et al. 2007; Chung and Lee 2003). It is equivalent to 5.054% of the weight of white rice. Thus, the efficiency value of rotary shifting (a10) is 94.946%.

Polishing efficiency (a11)

a complete white ricepolished rice

( 4

Polishing is removal of existing fine rice bran on the kernel to smooth its surface (De Datta 1981). This process apply abrasive polisher. Polished rice produced is about 98% by weight of white (Chung and Lee 2003; Prakash et al. 2013). Thus the efficiency value of polishing (a11) is 98%.

Color sorting(a12)

a clean polished ricepolished rice

( 5

Color sorting separates the colored rice from the polished rice by using color identifier (Chung and Lee 2003). The produced colored rice is about 1.2% of the weight of paddy (Chung and Lee 2003). It is equivalent to 2.438% of the weight of the polished rice. Thus, the efficiency value of color sorting (a12) is 97.562%. Length grading (a13)

a clean polished ricehead rice P

13 Length grading is a removal of broken rice from clean polished rice to produce head rice based on kernel length (Houston 1972). Head rice has 75%–80% of whole kernel length. Head rice produced about 90% by weight of clean polished rice (Cnossen et al. 2003; Damarjati 1990; USDA 2005). Thus the efficiency value of length grading (a13) is 90%. Table 5 summarizes the efficiency values used in Mass Balance Model Level 3.

Table 5 Efficiency values of Mass Balance Model Level 3

Efficiency. Value Reference Chung and Lee (2003); Lambrets et al.(2007) Chung and Lee (2003); Lambrets et al. (2007)

Chung and Lee (2003) Chung and Lee (2003)

Gurjar and Sengupta (2015); Hansen et al. (2012) Arora et al.(2007); Chung and Lee (2003) Chung and Lee (2003); Prakash et al. (2013)

Chung and Lee (2003)

Cnossen et al. (2003); Damarjati (1990); USDA (2005)

RESULT AND DISCUSSION

Mass Balance Model

Head rice yield of Model Level 1 is lower than other models (Table 6). This model is also not appropriate to illustrate the actual condition of rice mill. The produced waste is expressed in aggregate (not clearly identified). It will cause difficulties in energy potency analysis although the HRY is identified. Meanwhile, the consistency analysis needs a value from this model as a comparison.

Mass Balance Model Level 2 is larger than the level 1 because it is an extension of compartments of the previous model (Table 6). Meanwhile, this model is not capable to identify impurities of rice production. The development of this model is needed to identify all impurities and also to increase the HRY if possible. But the first and second models are still needed to determine the consistency of the models.

14

is clear enough to illustrate actual situation of the rice mill. Mass Balance Model 3 is shown in Figure 4.

Table 6 Comparison of models and IRRI standards by dried paddy Parameter Model level 1 Model level 2 Model level 3 IRRI (2013)

Recycle process also lead to increase of rice husk ratio (0.231 of the weight of dried paddy). This is not corresponding with IRRI standards (0.2–0.23). Recycle process brings back the unprocessed brown rice to the husking process then the input of husking process increased. This improvement causes higher number of the rice husk production. Thus, the recycle process is not only able to improve HRY but also cause increasing of rice husk produced.

Next, this model is compared to the actual data from factory to verify its accuracy (Table 7). The difference of HRY from this calculation is 10.287% according to the actual data. It is acceptable because it is not too different.

Table 7 Comparison of Model level 3 with actual data by dried paddy Variables Model Level 3 Actual data Difference

Head rice yield 0.572 0.517 0.053

Rice husk ratio 0.231 0.229 0.002

Rice bran ratio 0.074 0.125 0.051

Broken rice ratio 0.063 0.063 0

The difference of rice bran ratio from Table 7 is caused by the difference of applied technology between the model and the factory. The Model developed models and actual data and also meets the IRRI standards. Although it meets the IRRI standards in HRY parameter only, it has not significant difference with IRRI standards. So this model is accepted to be the best model of all. Thus, the next analysis (energy potency analysis) examines the result of Mass Balance Model Level 3.

15

16

Energy Self-sufficiency in Rice Mills

Rice husk utilization for energy generation is to fulfill thermal and electrical energy needs of rice mill. The thermal energy is used for the drying process while the electrical energy for the milling process. Variation of the amount of energy consumption is depending on the capacity and technology applied.

There are several methods to utilize rice husk for energy generation. Generally, they are divided into two paths, thermochemistry and biochemistry. Thermochemistry path consists of combustion, gasification and pyrolysis while biochemistry path consists of fermentation and esterification (Soltani 2015). Thermochemistry path tends to be chosen because it is easier to be applied. While biochemistry paths are more difficult to be installed.

Direct combustion for electricity generation using steam power has been applied using wood biomass. It is also applicable for straw and husk biomass (Matsumura 2005). Fluidized bed combustion is proper technology for low density biomass conversion into energy since it has good mass transfer and heat transfer characteristics (Loha et al. 2013). But the high content of silica also causes high ash residue (Bazargan et al. 2015). Rice husk is not properly applied for the fermentation process because of the high content of lignin and silica (Pode

et al. 2015). Thus, the direct combustion is chosen to be analyzed.

Rice husk combustion is used to produce hot air to supply the drying energy needs. Hot air production uses fluidized bed dryer (FBD) which has an efficiency of 30% (Basappaji and Nagesha 2013). FBD is an effective method for drying the high moisture grain. The main advantages are fast drying rate, moisture content similarity and high drying capacity due to a complete mixing between drying air and paddy (Aghbaslo et al. 2013; Atthajariyakul and Leephakpreeda 2006; Golmohammadi et al. 2015).The schematic diagram of drying process through FBD is shown below.

Figure 5 Schematic diagram of fluidized bed drying

Simplified from Atthajariyakul and Leephakpreeda 2006; Chungcharoen et al. 2015

17 boiler is 68% (Yadav and Singh 2011). The calculation of energy independency trough rice husk utilization is shown in Table 8.

Table 8 Rice husk potency for energy generation

Parameter Amount Rice husk for hot air production (ton) 2.585

Rice husk left (ton) 1.436

According to Table 8, rice husk is combusted to operate the heater for hot air production. Leftover rice husk is burned to produce steam. Steam production uses a boiler with equity of 4.3 kg of steam per kg of rice husk (Yadav and Singh 2011). Thus, the electricity can be produced with surplus of 4,147 MJ, equivalent to 28.25% based on the total production energy needs. The complete information is shown in Appendix 5.

Based on the calculation above, self-sufficient energy rice mill is achievable by applying closed production system by utilizing the rice husk as the energy resource. Energy fulfillment achieved is 128.25% of the total production energy needs. This energy surplus can be used for the energy reserve.

The using of rice husk as energy resource can reduce the use of fossil fuel in the rice mills. If the energy need of rice mill is assumed to be fulfilled by the grid, it can reduce the coal consumption. Energy produced by PLN comes from coal with ratio of 2,655 kWh per ton of coal (Sulistyono 2012). If the rice mill consumes 204 kWh per ton of paddy, it will consume 76.8 kg coal per ton of paddy. In comparison, rice mill needs 162 kg rice husk to process 1 ton of paddy. Thus, the rice husk utilization will reduce the use of coal as much as 474 kg of coal per ton of rice husk.

For the other approach, rice mill consumed about 6.44 liter of diesel (for electricity) generation and 1.56 liter of kerosene (for drying) to process a ton of harvested paddy (UCFCCC 2007). Based on this research, it is possible to reduce the usage of fuel as much as 128.8 liter of diesel and 31.2 liter of kerosene per day. It is equivalent to about 50 liter of fossil fuel per ton of rice husk (3.24 rice husk used per day).

18

kerosene). Thus, the use of rice husk will prevent the emission of CO2 as much as 105.339 kg CO2 per ton of rice husk.

Closed System Production of Rice Mill

By-product of rice production can be utilized as an energy resource and value added product. Broken rice can be converted into rice flour. These conversion passes through dry process using hammer mills followed by the drying process. The range of rice flour yield production is 90% to 95%. While the rice bran is proper to be sold for animal feed or converted into bran oil (Bagchi et al.

2015; Rachmat 2012). The closed production system model is shown in Figure 8 and the completed model is in Appendix 6.

19 CONCLUSION AND RECOMMENDATION

Conclusion

Mass Balance Model Level 3 is chosen to be the most suitable to illustrate real rice mill. This model is a consistent model and is able to illustrate actual condition of rice mill because there is no significant difference with IRRI standards and actual data. Head rice yield, rice husk ratio and rice bran ratio generated as much as 0.572; 0.231 and 0.074 of the weight of dried paddy, respectively.

Rice mill can be self-sufficient in energy fulfillment by applying closed production system based on the rice husk utilization. Rice mill consumes energy as much as 14,680 MJ for 20 tons of raw paddy. It was estimated that energy fulfillment achieved was 128.25% of the total production energy needs. In addition, rice bran can be utilized for animal feed or bran oil. Broken rice was converted into rice flour.

Based on this research, every ton of rice husk utilization as an energy resource will reduce 474 kg of coal or 50 liter of fuel (diesel and kerosene). The use of rice husk also has potency to reduce CO2 as much as 105.339 kg CO2 per ton of rice husk.

Recommendation

20 analysis of drying processes and systems. Renewable and Sustainable Energy Reviews. 22:1–22. doi: 10.1016/j.rser.2013.01.015.

Ahiduzzaman M, Islam AKSM. 2009. Energy utilization and environmental aspect of rice processing industries on Bangladesh. Journal of Energies. 2: 134–149. doi: 10.3390/en20100134.

Araullo EV, De Padua DB, Graham M. 1976. Rice Postharvest Technology. Ottawa (CA): International Development Research Centre.

Atthajariyakul S, Leephakpreeda T. 2006. Fluidized bed drying in optimal conditions via adaptive fuzzy logic control. Journal of Food Engineering. 75: 104–114. doi: 10.1016/j.jfoodeng.2005.03.055.

[BPS] Badan Pusat Statistik. 2015. Tabel Dinamis (ID). Available in http://www.bps.go.id/site/pilihdata.

Bagchi TB, Sharma S, Chattopadhyay K. 2015. Development of NIRS models to predict protein and amylose content of brown rice and proximate composition of rice bran. Journal of Food Chemistry. http://dx.doi.org/10.1016/j.foodchem.2015.05.038.

Basappaji KM, Nagesha N. 2013. Cleaner production in rice processing: an efficient energy utilization approach. IJAER. 8 (15):1783–1790.

Bazargan A, Bazargan M, McKay G. 2015. Optimization of rice husk pretreatment for energy production. Journal of Renewable Energy. 77: 512– 520.

Buggenhout J, Brijs K, Celcus I, Delcour JA. 2013. The breakage susceptibility of raw and parboiled rice: A review. Journal of Food Engineering. 117: 304–315. doi: 10.1016/j.jfoodeng.2013.03.009.

Capareda SC. 2014. Introduction to Biomass Energy Conversions. New York (US): CRC Pr.

Chung JH, Lee YB. 2003. Simulation of rice mill process. Journal of Biosystems Engineering. 86 (2): 145–150. doi:10.1016/S1537-5110(03)00119-3.

Chungcharoen T, Prachayawarakorn S, Tungtrakul P, Soponronnarit S. 2015. Effects of germination time and drying temperature on drying characteristics and quality of germinated paddy. Journal of Food and Bioproducts Processing. 94: 707–716.

Chungsangunsit T, Gheewala SH, Patumsawad S. 2004. Environmental assessment of electricity production from rice husk: a case study in Thailand. Electricity Supply Industry in Transition: Issues and Prospect for Asia. 20:51–62.

21 Dalen VG. 2004. Determination of the size distribution and percentage of broken kernels of rice using flat bed scanning and image analysis. Journal of Food Research International. 137:51–58. doi: 10.1016/j.foodres.2003.09.001. Damardjati DS. 1990. Prospek Peningkatan Mutu Beras di Indonesia. (in):

Nugraha S, Thahir R, Lubis S, Sutrisno. 2007. Analisis model pengolahan padi. Jurnal Enjiniring Pertanian. 5 (1):13–26.

Davis ML, Cornwell DA. 2013. Introduction to Environmental Engineering 5th edition. New York (US): McGraw Hill Companies. ISBN 9780073401140. De Datta SK. 1981. Principles and Practices of Rice Production. New Jersey

(US): John Wiley and Sons, Inc.

Dhankhar P, Tech M, Hissar T. 2014. Rice milling. IOSRJEN. 4:34–42.

Golmohammadi M, Assar M, Hamaneh MR, Hashemi SJ. 2015. Energy efficiency investigation ot intermittent paddy rice dryer: modeling and experimental study. Journal of Food and Bioproducts Processing. 94:275– 283. doi: 10.1016/j.fbp.2014.03.004.

Goyal SK, Jogdand SV, Agrawal AK. 2012. Energy use pattern in rice milling industries-a critical appraisal [Internet]. Journal of Food Science and Technology. doi: 10.1007/s13197-012-0747-3. [downloaded at June 26th 2015] Available in http://www.researchgate.net/publication/228083663. Gurjar J, Sengupta B. 2015. Production of surfactin from rice mill polishing

residue by submerged fermentation using Bacillus subtilis MTCC 2423.

Journal of Bioresource Technology. 189:243–249. doi:

10.1016/j.biortech.2015.04.013.

Hansen TH, Lombi E, Fitzgerald M, Laursen KH, Frydenvang J, Husted S, Boulaphanh C, Resurrecion A, Howard DL, Jonge MD et al. 2012. Losses of essential mineral nutrients by polishing of rice differ among genotypes due to contrasting grain hardness and mineral distribution. Journal of Cereal Science. 56:307–315. doi: 10.1016/j.jcs.2012.07.002.

Hiloidhari M, Baruah DC. 2014. GIS mapping of rice straw residue for bioenergy purpose in a rural area of Assam, India. Journal of Biomass and Bioenergy. 71:125–133. doi: 10.1016/j.biombioe.2014.10.018.

Houston DF. 1972. Rice Chemistry and Technology. New Orleans (US): American Association of Cereal Chemists, Inc.

[IRRI] International Rice Research Institute. 2013. Teaching Manual Rice Milling. Rice Knowledge Bank International Rice Research Institute (PH).

[IRRI] International Rice Research Institute. 2015. Physical Quality Of Milled Rice. Rice Knowledge Bank International Rice Research Institute (PH). Jittanit W, Saeteaw N, Charoenchaisri A. 2010. Industrial paddy drying and

energy saving option. Journal of Stored Products Research. 46:209–213. doi: 10.1016/j.jspr.2010.04.005.

Loha C, Chattopadhyay H, Chatterjee PK. 2013. Energy generation from fluidized bed gasification of rice husk. (in) Soltani N, Bahrami A, Pech-Canul MI, Gonzalez LA. 2015. Review on the physicochemical treatments of rice husk for production of advanced materials. Journal of Chemical Engineering. 264:899–935. doi: 10.1016/j.cej.2014.11.056.

22

[KESDM] Kementerian Energy dan Sumber Daya Mineral. 2014. Indonesia Energy Outlook. Pusat Data dan Informasi Energi Sumber Daya Mineral Kementrian Energi dan Sumber Daya Mineral (ID).

Lamberts L, Bie ED, Vandeputte GE, Veraverbeke WS, Derycke V, Man WD, Delcour JA. 2007. Effect of milling on colour and nutritional properties of rice. Journal of Food Chemistry. 100:1496–1503. doi: rice husk into organic fertilizer through vermicomposting. Ecological Engineering. 41: 60-64. doi: 10.1016/j.ecoleng.2012.01.011.

Majhi BK, Jash T. 2014. Studies on performance of the cogeneration programme in rice mills in West Bengal. Journal of Energy Procedia. 54:105–110. doi: 10.1016/j.egypro.2014.07.252.

Jurnal Enjiniring Pertanian. 5 (1):13–26.

Okeh OC, Onwosi CO, Odibo FJC. 2014. Biogas production from rice husks generated from various rice mills in Ebonyi State, Nigeria. Journal of Renewable Energy. 62:204–208. doi: 10.1016/j.renene.2013.07.006.

Pode R, Diouf D, Pode G. 2015. Sustainable rural electrification using rice husk biomass energy: a case study of Cambodia. Journal of Renewable and Sustainable Energy Reviews. 44:530–542. doi: 10.1016/j.rser.2015.01.018. Prakash KS, Someswararao Ch, Das SK. 2013. Pneumatic polishing of rice in a

horizontal abrasive pipe: a new approach in rice polishing. Journal of Innovative Food Science and Emerging Technologies. 22:175–179. doi: 10.1016/j.ifset.2013.12.006.

Rachmat R. 2012. Model penggilingan padi terpadu untuk meningkatkan nilai tambah. Buletin Teknologi Pascapanen Pertanian. 8 (2):99–111.

Sarasuk K, Boonrod S. 2011. Design of lab scale two-stage rice husk gasifier.

Energy Procedia. 9:178–185. doi: 10.1016/j.egypro.2011.09.019.

23 Soltani N, Bahrami A, Pech-Canul MI, Gonzalez LA. 2015. Review on the physicochemical treatments of rice husk for production of advanced materials. Journal of Chemical Engineering. 264: 899–935. doi: 10.1016/j.cej.2014.11.056.

Steffe J, Singh R, Miller G. Luh S, editor. 1980 Harvest, drying and storage of rough rice. (in) Lim JS, Manan ZA, Hashim H, Alwi SRW. 2013. Towards an integrated, resource-efficient rice mill complex. Journal of Resource,

Conservation and Recycling. 75: 41–51. doi:

10.1016/j.resconrec.2013.04.001.

Suh, Jungho. 2014. Theory and reality of integrated rice-duck farming in Asian developing countries: A systematic review and SWOT analysis. Journal of Agricultural System. 125: 74–81.

Sulistyono D. 2012. Analisis potensi pembangkit listrik tenaga GAS batubara di Kabupaten Sintang. J ELKHA. 4(2):38–42

[UNEP] United Nations Environmental Programme. 2007. Technical Study Report on Biomass Fired Fluidized Bed Combustion Boiler Technology for

Cogeneration. [Internet]. Available in:

http://www.unep.org/climatechange/mitigation/Portals/93/documents/Energ yEfficiency/FBC_30_sep_2007.pdf.

[UNFCCC] United Nations Framework Convention on Climate Change. 2007.. Clean Development Project Design Document Form (CDM-SSC-PDD) Ver 03.

[USDA] United States Department of Agriculture. 2005. United States Standards for Rice. Federal Grain Inspection service. Washington DC (US)

24

25 Appendix 2 Multiplier value and result of matrix operation of Model Level 2

26

27 Appendix 4 Multiplier value and result of matrix operation of Model Level 3

28

30

BIOGRAPHY

Author was born in Gresik at August 15th 1992. He is the first son of Mohammad Asykur and Husnul Ummah. He graduated from Senior High School 1 Gresik at 2011. He is accepted as Student of Agroindustrial Technology Study Program, Bogor Agricultural University in the same year through SNMPTN.

Author joined internal and external organizations during the lectures. Author got mandate as a chief of Student Association of Surabaya, Gresik, Mojokerto and Sidoarjo and also chairman of Al Khidmah Kampus IPB in 2014–2015. He served as a member of Kajian and Pelestarian Tradisi Division of KMNU IPB 2011–2015 also teach Rebana Al Banjari art. He contributed as Practical Assistant of Agroindustrial Equipment and Machinery course in 2014–2015. He conducted Field Practice in