PURIFICATION AND CHARACTERIZATION

OF

THEMOSTABLE CHITINASES FROM

BaciUus

licheni/ornris

MB-2

ARlS

TOHARISMAN

SCHOOL OF

GRADUATE PROGRAM

BOGOR AGRICULTURAL

UNIVERSITY

ABSTRACT

ARIS TOHARISMAN

.

Purification and Characterization of Themstable C h i t k s h m Bacillus Eicheniformis MB-2. Under the supervision of MAGGY T. SUHARTONO, ANTONIUS SUWANTO, and TRESNAWATI PURWADARSAChitinases are of great biotechnological interest and have received remarkable attention. A themophilic bacterium, Bacillus lichenifomis

MB-2,

from Tompaso hot spring, North Sulawesi Indonesia, secreted thermostable chitinases into culture media. Preliminary study showed that the enzymes occur in multiple formsand

were stable at a high temperature and a broad range of pH. The objectives of this research were to purify and characterize thermostable chitinasesfrom B. lichenrformis MB-2.

The extracellular chitinases were isolated by successive column

chromatographies on Phenyl Sepharose CL4B, DEAE Sephacel, and Superdex G-75. The purified enzymes had molecular weight of 67 (Chi-67) and 102 kDa

(Chi-102), estimated by SDS-PAGE (sodium dodecyl sulfate-polyacrylamide gel electrophoresis). Chi-67 and Chi-102

had

an endo- and exo- chitinolytic activities, respectively. The optimal temperature of Chi-67 was 70°C, whereas Chi-102 was 60"C.

The optimal pH for both enzymes was 6.0. Chi-67 wets stable below 60°C and over a broad pH range of 4-1 1 for 1 h. In contrast, Chi- 102 was not stable at temperature above 50 "C and only stable at its optimum pH for 1 h.Chi-47 was resistant to denaturation by urea, Tween-20 and Triton-X, but unstable toward organic solvents such as propanol, ethanol, DMSO (dimethyl sdfoxide), and PEG (polyethylene glycol), indicating that hydrophobic interaction of proteins plays an important role

in

maintaining enzyme activity. Ionic interactions are also important for Chi-67 fold as the activity was reduced by guanidine hydrochloride and NaCl (1 M). Chi- 1 02 was relatively more stable toward various organic solvents than Chi-67.Both enzymes hydrolyzed colloidal chitin, glycol chitin, or glycol chitosan, but were less active to regenerated chitin, fine powder of chitin, or methyl cellulose. The Michaelis constants &) for colloidal chitin, glycol chitin, 4- methylumbelliferyl N', W-diacetylchitobioside [MUF(GICNAC)~], 4- methyiumbelliferyl

N',

N', M-triacetylchitotrioside [MCTF(G~CNAC)~] for Chi-67were 3.08 mg ml-', 0.3 15 mg ml-', 0.02 pmol d-' and 0.02 pmol dl,

respectively. Meanwhile, the K, for colloidal chitin, glycol chitin and MUF(GlcNAc) for Chi-102 were 2.00 mg ml-', 1.32 rng ml-', and 0.03

m M

ml-',respectively. The first 13 N-tertninal amino

acids

of Chi-67 were determined to be SGKNYKIIGYYPS, which is identical to chitinase from B. licImenIfomrisPR-

DECLARATION

I hereby declare that this thesis is my own work and has not been accepted for the

award of any other degree or diplorna in any university or other institute of higher

leadng.

To the best of my knowledge and belief, this thesis contains no material previously published by any other person except where due acknowledgment has

been made.

Bogor, May 20U4

PURIFICATION AND CHARACTERIZATION

OF THERMOSTABLE CHITINASES FROM

BaciNus lichenifomis

MB-2

BY

ARIS TOHARISMAN

A DISSERTATION

Submitted

to Bogor Agricultural University

in partial fulfillment

of

the requirements for

the Doctorate Degree

in

Food Sciences

GRADUATE PROGRAM

BOGOR AGRICULTURAL UNIVERSITY

BOGOR

Title

:Purification

and Characterization of

Thermostable

C

hitinases

from

BaciNus

lichen(ftorrnis

MB-2

Name

:Aris

Toharisman

Student

Number

:PO9600004

Study Program

:Food Sciences

Approved by:

1

.

Advisor BoardProf.

Dr.

Ir. Antonius Suwanto MemberDr.

Tresnawati Purwadaria MemtKr2. Head of Food Sciences Study Program of Graduate Program

BIOGRAPHY

Aris Toharisman was

born

on January 19, 1966 in Kuningan, West Java, thefourth of five children of M. Suwarman and Hj.

C,

Suwarman. The author finished his study at Senior High School (SMAN I Surnedang) in 1984 andstarted his undergraduate work at Bogor Agricultural University (IPB). The author received a Bachelor of Science degree

in

Agriculture from IPB and aMaster of Applied Science degree in Biotechnology from the University of New

South Wales Australia

in

1989 and 1997, respectively. Since 1989, the authorhas been working at the Indonesian Sugar Research Institute, involved in sugar-

industry waste treatment and its co-product utilization research. September 2000,

the author started his

PhD

program at Food Sciences Department ofPB,

with the scholarship from Indonesian Department of Agriculture.The

author had also got a scholarship for 5 months, March-July 2003, from Deutscher AkademischerAustausch Dienst (DAAD) to do Sandwich in Bioscience Programme at

Department of General Zoology and Endocrinology, the University of Ulm,

Germany. The author had done the project entitled Purification and

Foremost, I would like to express my sincere gratitude to my major supervisor:

Prof. Dr. Maggy T. Suhartono, for her thoughtful and invaluable guidance during

my study. It was a great pleasure to me to conduct research under her supervision. I am deeply indebted to my other supervisors, Prof. Dr. Antonius

Suwmto and Dr. Tresnawati Purwadaria, for their encouragement and

stimulaiing suggestions. Special thank is due to Prof. Margarethe Spindler-

Barth for having accepted me to do research at Department of General Zoology

and Endocrinology, UniversiGt Ulm, Germany. She gave me great help and

constant support during my work in her laboratow along the way.

I am grateful to all the staff and students of the Microbiology and

Biochemistry Laboratory, Research Center for Biotechnology, Bogor

Agricultural University: especially to ibu Ika Malikha, ibu Eni Sutnartini, ibu

Endang Yuli, ibu Rosita Lintang, pak Sumardi, ibu Yuyun, ibu Tati, mbak Nur Azizah, mbak Emma, Yanti Lim, Winda, Ace, Dim, teh Ida, Pudin, and Yanti

for their assistance and supports. I

thank

ibu Ekowati Chasanah for the cooperative spirit and fruitful discussion during my research.I am thankful to Prof. Dr. Margarethe Spindler-Bartb p u p especially to

Michael Wagemann, Natalja Mobius and Karin Dengler for dl their assistance on

laboratory works. Special

thank

goes to Dr. Yaya Rukayadi for sending mevaluable journals and other information and Dra Tami Indiyanti, MSc (Indonesian

I am grateful to both the Agricultural Department for the scholarship given to

me

and

tothe

Director of the Indonesian Sugar Research Institute for giving methe chance to study at the IPB. Also, I greatly appreciate hancial support fiom Bioproduct s Research Center, Y onsei University (Korea) and the scholarship

fiom Deutscher Akadernischer Austausch Dienst (DAAD).

Many thanks to my familes for their emotional and spiritual supports. I

must thank my wife. She has put a lot of enthusiasm and energy into eliminating

many short comings in various ways.

Many more persons participated in various ways to ensure my research succeeded and I am thankful to them all.

F W , I want to express my gratitude to

Allah

SWT whose blessings made this effort fruitful.LIST OF TABLES

...

Variation in chitin contents at d e r e n t organismsWorldwide market for chitin derived products in year 2002

...

...

Applications of chitin and its derivativesNomenclature of chitholytic and cellulolytic enzymes

...

...

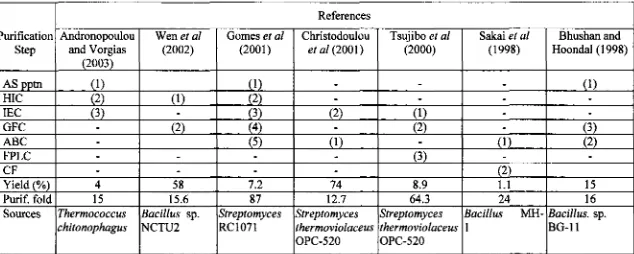

Purification steps of some thermostable chithases

...

Properties of Some Bacterial C h i t h s

...

The pH stability of some chitinases

Activators

and

inhibitors of some kcterial chitinases...

...

Kinetic parameters of some chitinases...

Classification of extremophiles and example of applications of some their enzyme

Proposed structural thennostabiiizing mechanisms of protein

...

Chitinolyt ic index of the isolates fiom Tompaso grown at 5 S°C. .

Ammonium sulhte precipitation of chitinases produced...

by Bacillus licheniformis MB-2

Relative activity of crude-extract chitinases to wards

...

Various chit in substratesChit inase precipitation using 80% ammonium sulfate at

...

various pHYield

and

purity of chitimes treated with...

several methodsEffect of salts removal of precipitated chitinases

...

on enzyme yield and purityYield and purity ocf chitinases after binding

...

with 3 different substrates

....

Effect of heat treatment on pudlcation results of c h i t k s Protein recovery from HIC columns eluted with...

various conditions

...

Purification steps of endochitinase produced byB. lichenifomis MB-2

Purification steps of exochitinase produced by

...

B. lichenifomis MB-26-2 Relative activity of Chi-67 and Chi-102 towards

. . .

.

. .

.

. . ..

1 18 various chitin substrates6-3 Kinetic parameters of Chi-67 for natural and artificial chitins

. .

.

. .

123 6-4 Kinetic parameters of Chi- 102 for natural and arti6cimtl chitins. . .

123 7- 1 Chracterist ics of crude-extract, Chi-67 and Chi- 1 02 chitinases. . .

129 7-2 Characteristics of MB-2 pure chit inases and two other chitinases. 130 7-3 Comparison of N-terminal amino acid residues of chitinase. . .

.

.

.

136...

Time course of chitinases production by B, licheniformis MB-2 in medium containing 0.5% colloidal chitin (pH 7.0) at 5 5 O C

...

Chitinase yield of pellet

and

supematant precipitated at different ammonium sulfate concentrationActivities of endochitinase and exochitinase after

...

exchange buffer using ultrafiltration at 1 kDa(1, fdtrate; 2, effluent)

and

10 kDa (3, filtrate; 4, effluent)Percentage of chitbases bound by various chitin substrates

Elution profile of chitinase &om Phenyl Sepharose CL4B

...

c o b chromatography with gradients of ammonium sulfateat pH 7.0

Elution profle of chitinase from Phenyl Sepharose C L 4 B

...

column chromatography with gradients of ammonium sulfate at pH 8.0Elution profile of chit inase h m PhenyI Sepharose CL-4B

...

column chromatography with gradients of ammonium sulhte at pH 8.0 and decreasing pH gradient...

Elution profile of chit& from Phenyl Sepharose CL-4Bcolumn chromatography with gradients of ammonium sulfate at pH 8.0 and increasing pH gradient

Elution profile of chitinas. from Phenyl Sepharose

CL-4B

...

column chromatography with gradients of ammonium sulfate

at pH 8.0 and increasing urea gradient

...

Elution profle of chitinase fiom Phenyl Sepharose CL-4Bcolumn chromatography with gradients of ammonium sulfate at pH 8.0 and increasing propanol gradient

...

Elution profile of chit& from Phenyl Sepharose CL-4Bcolumn chromatography with gradients of ammonium sulfate at pH 8.0

and

increasing Tween-20 gradient...

Elution proiile of chitinase &om DEAE Sephacef column

chromatography with gradients NaCl at pH 8.0 (-) and increasing Tween-20 gradient

...

Elution profle of chitinase fiom Sephadex G-75 columnchromatography

The scheme of chitinase pu&cation steps

...

...

SDS-PAGE of peak fractions fiom different purification stepsSDS-PAGE and native PAGE of exochitinase fractions

...

fiom different p d c a t i o n stepsHeat stability of Chi-67

...

...

Heat stability of Chi- 1 02

pH stability ofchi-67

and

Chi-102 aRer 1 h and 4 h...

Effect of metal ions on Chi-67 andChi-

1 02 activities...

Synergism effect of Chi-67 and Chi- 1 02 for various...

chitin substratesChitinax activities on flourogenic substrates as a function of

...

incubation time...

Chitinase activities on flourogenic substrates as a functionof enzyme-

LIST OF APPENDICES

...

Sequences of 16s rRNA of MB-2 (1478 bases)

...

Phylogenetic Tree of Bacteria-Producing Chitinases...

Sequence Producing Alignments of Chi-67 N-terminal

...

Conserved Domain Search of Chi-67

...

Amino Acid Composition of Chi-67...

Predicted of Chi-67 Catalytic Domain Structure h mGenBank Database

...

Predicted of Chi-67 Substrate Binding Domain Structurefiom GenBank Database

1.

INTRODUCTION

Chitin, an insoluble polysaccharide consisting of P-(14) linked N-ace@-D-

glucosamine (GicNAc) units, is the second most abundant polysacc&de

in

nature, after cellulose. It is widely distributed as structural component of

crustaceans, insects, and other arthropods, as we1 as component of the cell walls

of most fungi and some algae. About 10" tons of chitin is produced annually in the aquatic biosphere alone, however, only 0.1% of this material is cmently being

converted to valuable products.

Chitin and its derivatives exhibit interesting properties

and

constitute avaluable materials for biomedical, cosmetic, food and agricultural applications.

Currently they are used as immunoadjuvants, drug delivery systems, dietary

fibers, agrochemicals,

and

flocculants of wastewater sludge. In the f a d areaschitin and its derivatives are used for clarification of beverages, food wraps,

recovery of solid materials from f a d processing wastes

and

water, and irnmobiiization of enzymes. Chitin oligomers may promote the growth of Bifidus bacteria and suppress spoilage organisms, reduce toxinsand

detrimentalenzymes, prevent diarrhea and constipation, lower serum cholesterol, protect liver

function, and protect against cancer (Shahidi el al, 1 999).

Enzymatic degradation of chitin is performed by chitinases and appears to

occur in two steps. An endochitinase (EC 3.2.1.14) reduces the polymer to oligomers, which are subsequently degraded to monomers by exwhitinax-

chitobiase (P-N-acetylhexosaminidase, EC 3.2.1.52). Chitinases are found

in

aThe enzymes are also known to be synthesized by some of the protozoans,

coelenterates, nematodes, mollusks and +pods (Muzzarelli, 2002).

Chitinases are of great biotechnological interest and have received remarkable

attention. First, these enzymes may be used to convert chitin-containing biomass into biologically reusable forms such as oligosaccharides, chitobiox

and

N-

acetylglucosamine. Secondly, chitinases may be exploited for the control offungal

and

insect pathogens of plants. Thirdly, chitinase inhibitors potentiallyinhibit growth of chitin-containing pathogens and plague insects that

need

chitinases for normal development. Chitinase inhibitors have generated a lot of

interest given their potential as insecticides, fungicides, and antimalarials. Efforts are going on throughout the world to enhance the production and purity of

chitinases. Some characteristics of chitinases have been reported but only a few

thermostable chitinolytic enzymes are known.

Exploration of extremozymes with their unusual stability towards heat, organic

solvents, extreme pHs, detergents, and resistance to common protein denaturing

agents has attracted quite a number of researchers as such features confer a

number of advantages with r e s p t to industrial applications. Usage of

themostable enzymes in biotechnological processes will allow faster reaction

times and reduction of contaminations, reduce energy costs

in

large scalefermentations, less viscosity and kter solubility of chemicals intended to be

~ r d u d at high temperatures, and reduce pathogen contamination and efficient

product recovery p m s s e s such as distillation. Investigation of thermostable

enzymes is fundamental for the elucidation of the structural basis for their

it may be possible to engineer proteins designed for the conditions required in various industrial processes. Additionally, such enzymes are also suited for

studying structure-function relationships and mechanisms for promoting and

maintaining tertiary structures at extreme conditions.

Thermophilic microorganisms that grow optimally at temperature of a b u t 50

to over 90 "C are potential sources of thermostable chitinases. The natural

environment for thermophilic microorganisms are multifaceted throughout

Indonesia, including crater, terrestrial hot spring, and deep-sea thermal vents.

Many microorganisms producing various thermostable enzymes such as

protease (Mubarik er al, 2000; Wahyuntari et al, 2000), keratinase

(Lintang

et al, 2002), chitin deacetylase (Toharisman et al, 2001, 2002a), chitinase (Natsir et al, 2002; Suhartono et al, 20031, and chitosanase (Azizah et al, 2002; Haliza et al, 2002) have been isolated in our laboratory. Furthermore, we screened more than50 therrnophiles from Tompaso hot spring (North Sulawesi), able to hydrolyse

chitin. Among them, isolate MB-2 identified as Bacillus licheniformis MB-2,

secreted a variety of thermostable enzymes including chitinases into culture

media. Preliminary study with zymograrn analysis showed that partial purified

chitinases occur in multiple forms and were stable at a high temperature and a

broad range of pH. However, these chitinases have not yet been purified and fkrther characterized.

The objectives of the research are to purify and characterize thermostable

chitinases from B. licheniformis MB-2. Pure enzymes are required for research and analysis in biochemical and clinical chemistry, whereas information of

as understanding of structural-function of protein (enzyme). Thus, there is a

rapidly increasing demand for enzymes of high purity with comprehensive

characteristics. Characterization of the purified enzymes includes analysis of

substrates specificity, optimum pH and temperature, heat stability, the effect of

cations, stability of enzymes towards specific inhibitors and denaturant

substances, analysis of molecular weight, enzyme kinetics, and N-terminal

amino acid sequencing.

This research should greatly contribute for developing marine industry in

Indonesia, as the country presently has 170 shrimp processing units with capacity

of

500 000 tons per year. It is predicted that Indonesia produces chitin of about1 00 000 tons annually. Enzymatic conversion of chitinous materials into valuable

and marketable products may drive the development of marine industries in

2.

LITERATURE

REVIEW

2.1. Chitin

2.1.1. Structure and Distribution

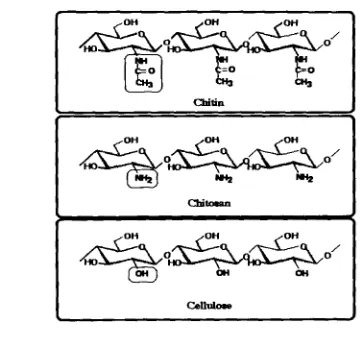

Chitin is a polymer formed primarily of repeating units of P-1-4-linked 2

wtamido-2deoxy -b-D-glucopyranose residues (GlcNAL). Its structure is similar

to the structure of cellulose, except that acety1arnino groups have replaced the

hydroxyl groups in position C-2 (Fig 2-1). Chitin polymer tends to form

microfibrils of about 3 nrn in diameter that are stabilized by hydrogen b n d s formed between the amine and carbonyl groups (Gooday, 1994).

Chitin

[image:22.630.122.482.376.716.2]I

X-ray diffraction analysis suggested that micrwrystalline structure chitin

occurs in a-,

p-

and y- arrangements. in the a form, all chains exhibit an anti-parallel orientation; in the

0 form, the chains are

arranged in a parallel manner; and in the y form sets of two parallel strands dtemate with single anti-parallelstrands. The anti-parallel arrangement allows tight packaging into chitin

microfibrib, consisting of 20 single chitin chains that are stabilized by

a

highnumber of hydrogen bonds formed within and between the molecules. In contrast,

in the

p-

and y-chains, packing tightness and numbers of inter-chain hydrogen bonds are reduced, resulting in an increased number of hydrogen bonds withwater. The high degree of hydration and reduced packaging tightness result in

more flexible and soft chitinous structures (Goosen, 1997).

The most abundant form of chitin is a-chitin. It is found in the hydrozoa,

nematodes, rotifers, mollusks and arthropods. 0-chitin, a less stable and more

degradable form of chitin, is occurred in mollusks, squid pen, diatoms, cuttlefish

bone, insect exoskeletons and cocoons, and is major component of cell walls. The

y form is found in stomach lining of squid (Gooday, 1990).

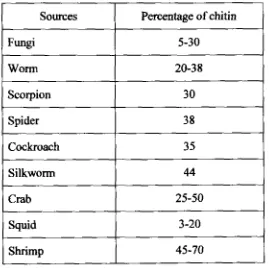

Chitin has a very wide distribution among organisms (Table 2-1) and slightly

different structure and associated proteins and minerals. Variations in the

amounts of chitin may depend on physiological parameters

in

naturalenvironments. Chitin is always found cross linked to other structural

components such as protein and glucan. In insects and other invertebrates, chitin

is always aswiated with specific proteins, whereas in fungal walls it is found to

covalently bonded to glucans, either directly or via peptide bridges (Gooday,

Table 2.1. Variation in chitin contents at different organisms (Skj ak-Braek and Sandford, 1 989)

Chitin varies in crystallinity, degree of covalent bonding to other components

such as glucms, and degree of deaeetylation. Degree of chitin acetylation is between 0 to 1 OOO/o, but the natural chitin is approximately 16% deacetylated.

Deacetylation of above 80% chitin units is generally termed as chitosan

(Goosen, 1 997).

Chitosan is composed primarily of GlcNAc and GlcN (2-amino-2-deoxy-P-~-

glucopyranose) residues, Unlike most polysaccharides, chitosan has three types

of reactiond functional groups, an amino group as well as both primary and

secondary hydroxy l groups at the C-2, C-3, and C-6 positions, respectively. Chemical modifications of these groups provide numerous useful materials in

Sources

Fungi

Worm

Scorpion

Spider

Cockroach

Silkworm

Crab

Squid

Shrimp

Pacentage of chitin

5-30

20-38

30

38

3 5

44

25-50

3-20

[image:24.624.193.462.137.405.2]different field of applications. The molecular weight of chitosan is about 0.1-0.5 x

10' Dalton, whereas native chitin is about 1 - 2 x1

o6

Dalton (Goosen, 1997).In 2002 about

id

tons of chitin were recovered industriallyh m

marineindustry, approximately 65% of which was converted into glucosamine, 25% into

chitosan and 10% into chitooligosacchrtrides. The world market of chitin and its

derivatives was estimated to reach $ 1 3 7 million (Table 2-2).

Table 2-2. Worldwide market for chitin derived products in year 2002 (Sandford, 2003)

2.1.2. Application

During the past 20 years, a substantial amount of work has been published on

chitin and its derivates and their potential use in various applications such as in food, agriculture, medicine, biotechnology, pharmacology, and waste treatment

(Table 2-3).

In

food processing, chitin and its derivates may beused

for clarification ofwine, beer and juices, deacidification of fruit juices, formation of biodegradable

films, production of flavor compounds, preservation of foods from microbial Derivative Chitom Glucosamine Oligosaccharides Quantity (Tom)

6

700

4 000

500

Price ($/ton)

10 000 10 000

60 000

I

Value ($ million)

67 40 30

deterioration, recovery of waste material from

focd

processing discards, andreducing

warmed over flavor in precooked meats (Shahidi et al, 1999). They areused as food supplement

and

may reduce plasma cholesterol and triglycerides dueto their ability to bind dietary lipids (Koide, 1998).

Chitin

has

been reported to regulate some interactions between plantpathogenic fungi and their plant host. The fungi-resistant properties of chitin

derivates have resulted in their application as fertilizer, soil stabilizer, and seed protector (Kohle et al, 1984; Kauss et al, 1989; Shirnosaka et el, 1993 and 1995;

Leger et a/, 1996).

h the biomedical area, chitin and its derivates have been observed to accelerate

wound healing properties and the attainment of an attractive skin surface. It has

been suggested that the mechanism by chitin and its derivates act at wound site

involves activation of neutrophiles and macrophages. These compounds stimulate

the migration of plymorphonuclear and mononuclear cells and accelerate the reformation of connective tissue and angiogenesis (Bianco et al, 2000). Because of its high oxygen permeability, the chitin derivate was used as a material for contact and intramular lenses.

It

has also been found to expedite blocd clotting and can form complexes with other natural polymers, such as collagenand

keratin,

to form materials with unique biomedical properties (Sand ford, 1 989). The fact that chitin and its derivates are biodegradable and biocompatiblemakes them particularly appropriate for

use

in drug delivery systems (Thacharodiand

Rao, 1995; Genta et al, 1997; Zecchi et al, 1997). This property is extremely valuable in cancer chemotherapy since the agents are often highly toxic andBecause of their binding and ionic properties, chitin derivates can be used as a

flocculating agent to remove heavy metals and other contaminants h m

wastewater. Current applications

in

this area include treatment of sewage [image:27.620.86.519.291.750.2]effluents, paper mill wastes, metal-finishing residues,

and

radioactive wastes (Guibal er al, 1997).Table 2-3. Applications of chitin and its derivatives

1

Areas1

Applications1

Nutritional uses Dietary supplement

Fiber source

Texture-enhancing agent Emulsifying

Beverage clarifier

Food Neutriceutical

Flavor preservative Flavor enhancer Biomedicine

1

Wound healing Burn healing Contact lensesB l d dialysis membranes Antitumor

Skin and hair care

Others

Moisturizing creams and lotions Hair care products

Environment and agriculture

Paper finishing Sorption of dyes Solid state batteries Feed additive Contact lens

Chromatographic supports Water treatment

Seed treatment

Chitin oligomers or chitin oligosaccharides [chitooligosaccharides),

customarily used for saccharides having the degree of polymerization of 2-10,

are biologically active compounds. The products have activities as elicitors,

anti bacterial agents, immuno-enhancers

and

1 y sozyme inducers ( Ai ba, 1 994; Shahidi et a], 1999; Wang el al, 2002a md 2002b). Aiba (1994) reported that (GlcNAc), (n=2-5) are useful in agriculture and medicine, meanwhile (GlcNAc),activate macrophages and the immune system. Another chitooligosaccharide,

(GICNAC)~, is claimed to be a potent anti-metastatic agent against

mouse

bearing Lewis lung carcinoma (Roseman etat,

1999). Monomer of chitin, GlcNAc, is avaluable pharmacological agent in the treatment of a wide variety of ailments

including gastritis, fwd allergies, inflammatory bowel disease (IBD) and

diverticulitis. It does not have m y established negative side effects (Haynes et

al, 1999).

2.13. Biodegradation of Chitin

Chitin degradation towards chitosoligosaccharides, GlcNAc, GlcN and other

derivatives can be obtained by various treatments. The most used method is

chemical treatment using strong acid at high temperatures for extended of time.

Unfortunately, it is not easily controlled and environmentally unsafe. The product

has a broad range of molecular weight and a heterogeneous extent of deacetylation, so it is not suitable in food, cosmetics and pharmaceuticals

industries, which need high purity grade

and

uniform prducts.In

addition, themethod i s disadvantageous due to the occurrence of side reactions, energy-

1997; Yoon et al, 1998; Kolodziejska et al, 2000). Enzymatically process, on the other hand, could be employed under mild conditions, would not yield side

product, and results

in

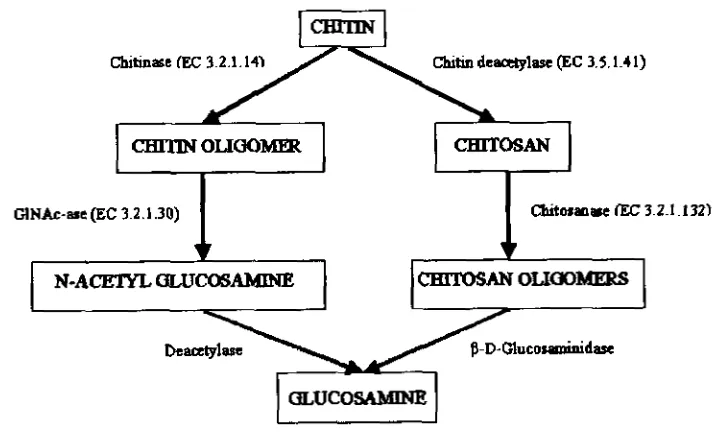

specific products with good quality.There are two possible pathways of chitin biodegradation (Fig 2-2, Gooday,

1990). First, it involves the initial hydrolysis of 1,4 P-glycosidic bond of chitin,

[image:29.622.151.509.356.575.2]Second, it is the deacetylation of chitin to chitosan. The fonner is accomplished by chitholytic enzymes and the latter by chitin deacetylase

and

chitosanase.Figure 2-2. Enzymatic pathways of chitin degradation (Gooday, 1 990)

Cbitinase [eC 3.2.1.141 Chitin d e q l a w (EC 3.5.1.41)

~ O ~ C # ) M W CHlTOS AN

Chitinolytic enzymes catalyze the hydrolysis of chitin by cleaving the bond

between the C1 and C4 of two consecutive N-acetylglucosamines, chitin deacetylase (EC 3 -5.1.4 1 ) modify chitin into chitosan molecule through

GIN&-MC @C 3.2.1.30) Cbitolana~ (EC 3.2.1 -132)

f 7

N - A m mWAMmE cmTOSAN 0LICK)MERS

deacetylation mechanism, while chitosanase

(EC

3 -2.1.1 3 2 or 3 -2.1 -99) hydrolyzechitosan to chitosan oligomers (Somashekar and Joseph, 19%; Cohen-Kupiec and

Chet, 1998).

23.

Chitinase2.2.1. Biologica1 Role

Different organisms p d u c e a wide variety of chitinases that exhibit different

substrate specificities and other properties useful for various functions. In

bacteria, chitinases play roles in nutrition (Bati ZU et al, 2000; Tsujibo et al, 2000; Folders et al, 2001) and parasitism (Grenier et al, 1993; Wenuganen, 1996;

Khaeruni, 1998; Kobayashi et al, 2002; Lutz et al, 2003; Malik et

al,

2003a and2003b), whereas in fungi, protozoa and invertebrates, they role in rnorphogenesis

(Bakkers ef al, 1997). Plant chitinases function in a self-defense mechanism against pathogenic fungi (Hou et al, 1998; Minic et 01, 1998; Vander er 01, 1998; Velazhahan et a!, 2000). Baculovirus, which are used for biological control of

insect pests, also produce chitinase for pathogenesis (You et al, 2003). Chitinase

activity

in

human serumhas

recently been described. The possible role suggested is a defense against fungal pathogens (Escottand

Adams, 1995; Langer el 01,2002).

Chitinase from marine organisms play a crucial role in the recycling of

chitinous materials for maintenance of the ecosystem in the marine environment.

Many bacteria and fungi containing chitinolytic enzymes convert chitin

into

Chitinase plays an important role in insect growth

and

development. It involves in molting and cuticle turnover by hydrolyzing the structural polymerchitin, a principal component of the insect exoskeleton and gut lining. Chitinase

activity has been identified in the molting fluids

and

midguts of several insectsincluding Bornbyx mori, Manducu sexta, Ae&s aegypti,

and

the wasp Chelonus (Royer et al, 2002). Chitinase is also important in the life cycle of arthropods (Spindler et al, 1 997).Plants do not have an immune system and instead use various defense mechanisms to protect their vegetative and reproductive organs against pathogen

infection. One response to pathogenic attack involves expression of pathogenesis-

related proteins such as chitinases (Andersen et al, 1997). The enzymes are capable of releasing chitin oligomers that elicit a series of defense reaction from

the fungus invading the plant (Nishizawa et a/, 1999; Staehelin et a), 2000). Purified barley and bean chitinases inhibited the growth of fungal hyphae (Leah at

al, 1991). It has also been demonstrated that transgenic plants that over express chitinases have increased resistance to fungal attack (Wiendi, 2002). In root

nodules, chitinases may protect the symbiotically infected zone from external

pathogens (Minic et al, 1998).

2.2.2. Application

Chitinases have

many

industrial and agricultural applications such aspreparation of chitooligosacc~des, biocontrol of plant pathogenic fungi,

production of single-cell protein, fungal protoplast technology and chitochemical

2002). Chitinases can be exploited to produce chitmligosaccharides

from

chitin.A chitinase from Vibrio alginolyticus

was used

to prepare chitopentaose and chitotriose fiom colloidal chitin ( M m el al, 1992). Strepdomyces chitinase wasutilized for the enzymatic hydrolysis of colloidal chitin. The chitobiose produced

was subjected to chemical modifications to produce novel disaccharides

derivatives of 2-acetamido-2-deoxy-~al1oppose moieties that are potential

intermediates for the synthesis of an enzyme inhibitor (Ohtakara et al, 1 W). Fungal formulations containing chitinases are perceived as safe alternatives to

chemical pesticides for insect treatment. Entomophatogenic fungi e.g. Beauveria bassima, Metharizizrm anisoplue and Verticillium Iecanii (Leger ef a/, 1996; Freimoser et al, 2003) are parasites of various pests including potato beetle, sugarcane frog hopper and aphids. A numlxr of soil bacteria produce chitinolytic enzymes that can also be used to inhibit fungal infection (Lodto et a/, 1996).

The enzymatic conversion of waste chitin to yeast single-cell protein (SCP) has

been investigated. Revah-Moiseev and Carroad (1981) used the S. marcescens

chitinase system to hydrolase the chitin and Pichia kuclriavezevii to yield the SCP. Vyas and Deshpande (1 99 1) showed that the M. verrucaria chitinase complex and

S. cerevisiae can also be used for SCP production h m chitinous waste. The total protein and nucleic acid contents of produced SCP were 61% and 3.1%,

respectively.

Since chitin is the major structural component in the cell walls of most fungi,

chitinolflc enzymes play a significant role in protoplast isolation. H d y n et a1

isolation and found that high chitinase levels permit effective mycelia

degradation.

The lectins, due to their specific monosaccharide-binding properties, can

be

used to locate sugar residues in thin section of plant and fungi. Similarly,

hydrolytic enzymes like chitinase can be also employed to Iucate fungal pathogens

that possessd chitinous cell wall. The chitinase-gold complex can be

used

forthis purpose (Peters and Latka, 1997).

2.23. Classification

Based

on amino acid sequences homology of glycosyl hydrolases, chitinaseswere grouped into two evolutionarily unrelated groups, designed as families 18

and 19 (Henrissat and Davies, 1997). Family 1 8 chitinases include most of the

chitinases from bacteria, fmg, insects, plants (class I11 and

V

chitinases), and animals. Family 19 chitinases include classes I,ll

andIV

of the plant chitinases(Meins et ai, 1992; Gijzen et al, 2001) and a chitinase from Streptomyces griseus (Ohno et a/, 1996). Class I

and

IV of plant chitimes consist of the sequence with a highly conserved main structure and an N-terminal Cys-rich domain. ClassIV

chitinases are smaller

than

class I chitinases due to deletionsin

both the cysteine-rich domain and the catalytic domain. Class I1 chitinases are structurally homologous to class I and

JV

but lack the Cys-rich domain. Class III chitinasesshow little sequence similarity to the enzymes

in

classes I,II,

orlV

and

are morethey possess a different substrate specificity (Roberts and Selitrenikoff, 1 988; Collinge et al, 1993).

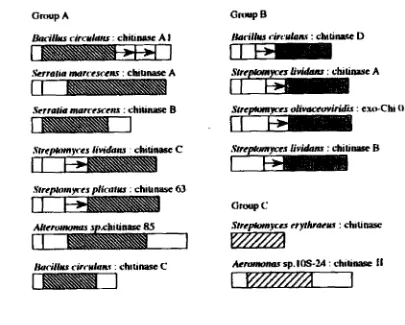

Family 18 chitinase is further classified into 3 groups: A, B,

and

C, based onthe amino acid sequence of individual catalytic domains (Fig 2-3). Chitinases

in

group A have an insertion domain between the seventh and eight P-strands of the

(P/(~)~-barrel basic structure, whereas chitinases in group B and C do not have

such an insertion domain (Uchiyama et a], 2001 ; Suzuki et al, 2002).

~ t r e a # r r r w e ~ dimmiridis : ex* Chi 0 1

SrrcIUmn w s dintru : chi u nasc 63

Aemmmm sp. IOS-2.4 : chili- f 1

[image:34.626.123.528.339.664.2]Based on the mode of action, chitinases were classified into endochitinases

and exochitinases. Endochitham (EC 3.2.1.14) cleave chitin randomly at

internal site generating soluble low molecular mass muftimers of GlcNAc such as

chitotetraose, chitotriose, and the dirner of di-acetylchito biose. Exochitinase can

be divided into two subcategories: chitobiosidases (EC 3.2.1.29) which catalyze the progressive release of di-acetylchito biose starting at the non-reducing end of

the chitin microfibril; and 1 -4-~~N-acetylglucosamidase (EC 3.2.1 -30) which

cleave the oligomeric product of endochitinase and chitobiosidases generating

[image:35.624.89.517.441.732.2]monomers of GlcNAc (Cohen-Kupiec and Chet, 1998). This class5cation is almost parallel to the cellulolytic complex (Table 2-4).

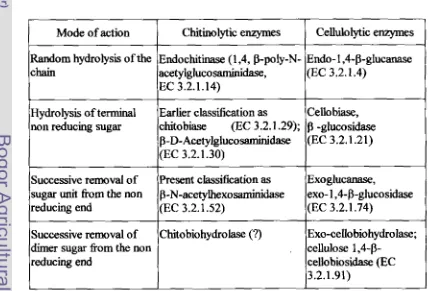

Table 2-4. Nomenclature of chitinokytic and celluloZytic enzymes (Patil et al, 2000)

Cellulolytic enzymes

Endo- 1 ,CP-glucanase (EC 3.2.1.4)

Cello biase, -gluwsidase (EC 3.2.1.21)

Exoglucanase,

exo- l,4-b-glucosidase

(EC 3.2.1.74)

Exo-cello biohydrolase; cellulose 1,4-P-

cellobiosidase (EC 3.2.1.91)

Mode of action

Random hydrolysis of the chain

Hydrolysis of terminal non reducing sugar

Successive removal of sugar unit from the non reducing end

Successive removal of dimer sugar fiom the non reducing end

Chitinolytic enzymes

Endochitinase (1,4, P-ply-N- a&y1gluco saminidase,

EC 3.2.1.14)

Earlier classification as

chitobiase (EC 3.2.1 -29); P-D-Acetylgluco~dase (EC 3.2.1.30)

Present classikation as p-N-acetylhexoddase (EC 3.2.1.52)

The classification of endo and exochitinase depends mainly on the substrate.

For example, the Streptomyces chitinase complex degrades pure cry stdine

P-

chitin of diatom spines only from the non-reducing ends to yield diacetylchitobiose, whereas colloidal chitin is degraded to a mixture of oligomers

and diacetylchitobiose. Some 1 -4-P-N-acetylgluwsamidases can also act weakly

as exochitinases cleaving monomer units

f k m

the non-reducing ends of chitinchain (Gooday, 1 994).

23.4. Structure and Catalytic Mechanism

Crystal structure of chitinases has been successively reported. The crystal

structure of 26 kDa chitinase from barley seeds (Hordem vulgare L.), which is classifid into family 19, was first solved. After

that,

the structures of a 60 kDac h i w e A from S. murcescens and a 29 kDa chitinase from rubber tree (Hevea

brasiliensis) were reported. Both are family 18 enzymes.

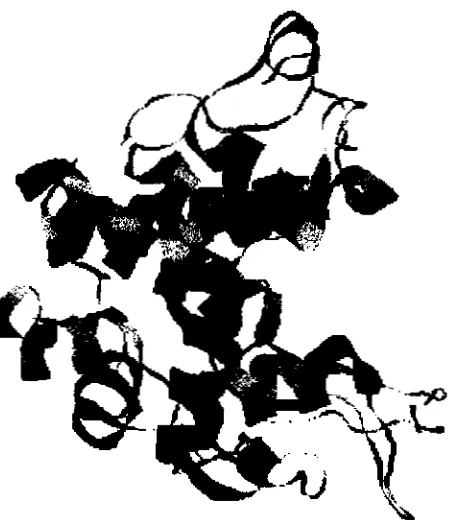

Comparison between the structures of family 18 and 19

chitinases

revealed aclear different in their structures. The family 18 chitinase has a typical (dB)s

barrel structure composed of eight a-helices and an eight stranded &sheet (Fig 2-

4). In addition to the main barrel domain, it has an N-termid p-strand-rich

domain

and

a small (a+P) domain. The crystal structures of other family 18chitinases exhibit similar barrel structure. Apparently, in family 18 chitinases, the sequence homology results in the similarity in three-dimensional structure

(Fukamizo, 2000; van Aalten et al, 2001; Watanabe el al, 2003). On the other

hand, barley chitiaase (family 1 9) is composed of two loks, each of which is rich

(GICNAC)~, the substrate binding cleft is estimated to lie between the two lobes. The hypothetical binding cleft is composed of two a-helices and three-stranded

p-

sheet (Fukamizo, 2000).

Fig 2-5. A ribbon drawing of barley chitinase (family 19 chitinase) revealing a mixture of secondary structure, including 10 a-helical segments and one three-stranded

P

sheet. The structure shows a globular protein with high a-helical content and an elongated cleft nmning the length of the protein, presumably for substrate binding and catalysis (Robertus and Monzingo, 1 999)Family 18 bacterial chitinases contain the consensus sequences SXGG and

DXXDXDXE. The sequences SXGG and DXXDXDXE are substrate-binding

and active sites, respectively. Several runs of conserved amino acids for family

18 h m Coccidioides immitis (Yang et al, 1997), Trichderma harzianurn (Garcia et al, 1 994), Aphanocladium album (Blaiseau and Lafay, 1 992), and Serratia murcescens (Brurberg et al, 1994) are shown in Fig 2-6. A section of signature sequence for the family 19 is shown

in

Fig 2-7, This represents the [image:38.616.211.436.91.351.2]tuberosum (Gaynor, 1 988), Arabidopsis thulium (Sarnac ef 02, 1 9901, and pea,

Pisum sativum (Chang et al, 1995).

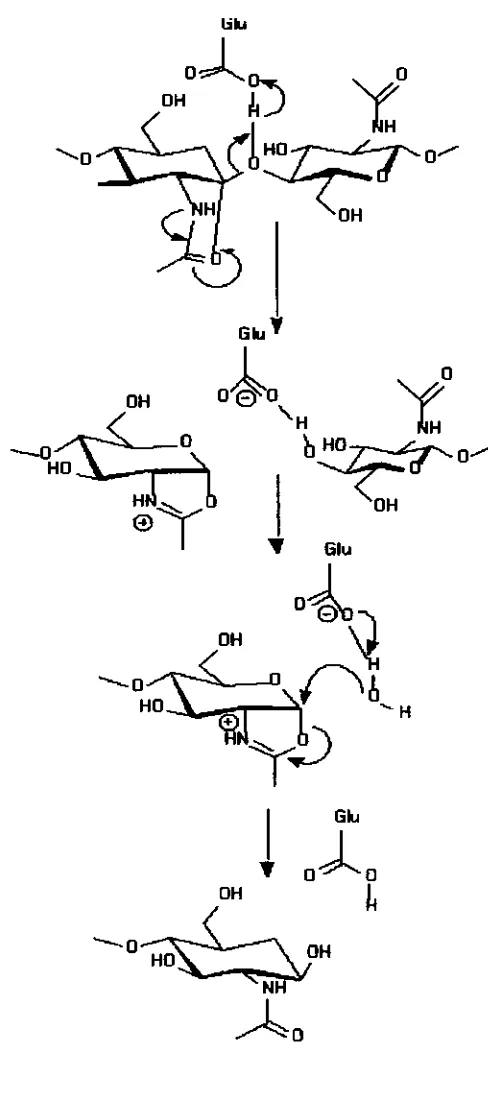

In addition to the difference in

3D

structure, chitinases of the two familiesshow the difference in catalytic mechanism (Fig 2-8 and Fig 2-91, Family 118

chitinase hydrolyze the glycosidic

bond

with retention of the anornericconfiguration (Sasaki et al, 2002), whereas family 19 chitinases with inversion (Ohno et al, 1996). Substrate assisted catalysis is the most widely accepted model for the catalytic mechanism of family 18 (Brameld et al, 1998), whereas a general acid and base mechanism has been suggested to be the catalytic mechanism of family 19 (Ohno er al, 1996). Family 1 8 c h i t h s hydrolyse GlcNAc-GlcNAc and GlcNAc-GlcN, meanwhile family 19 chitinases hydrolyse GlcNAc-GlcNAc

and GlcN-GlcNAc linkage (Ohno et al, 1996; Mitsutorni eb

ai,

1997). Family 18 chitinases are sensitive to allosarnidin, but a family 19 chitinase from higherplants has been shown to

k

insensitive (Koga et aI, 1999).130 170

Chi-ci LSIGGWTYSPNF FDGIDIDWEYPED

Chi-th LSIGGWTWSTNF FDGIDlDWEYPAD Chi-aa LSlGGWTWSTNF FDGDIDWEYPAD Chi-sm PSIGGWTLSDPF FDGVDIDWEFPGG

60

70

80 90 100Chi-hv KREVAAFLAQTSHE'ZTGGWATAPDGAFAW GYCFKQERGASSDYCTPSAQWPCAPGK

Chi-st KREIAAFLA QTSHEmCCWASAPDGPYAWGYCFLR ERGNPGDYCPPSQQWPCAPGK

Chi-at KReVMFGQTSHETLY;GWATAPDCPYSWGYCFKQEQNPD YCEPSATWPCASGE

Chi-ps KREIAAFLG QTSHEITGGWPTAPDGPYAWGYCFLR EQNP

-

SWCQASSEFPCASGKFig 2-7. Conserved amino acid on the active site of family 19 chitinases. The sequence numbers correspand to barley chitinase, Hordeum vulgare

(Chi-hv);

Chi-st,

Solanurn iuberosum;Chi-at,

Arabidopsis thuliana; Chi-ps, Pasum safivumThe catalytic mechanism of W y - 1 8 chitinase was first reported by Watanabe

et al (1990) for chitinase A1 h m B. circulam. The Glu204 residue was considered to be a proton donor

in

its catalysis since site-directed mutagenesis of the residue completely e h t e d its activity. The glutamic residue was alsofound to & conserved in family 18. In S, marcescem chitinase A and B, the catalytic carboxylate corresponding to Glu204 of B. circulans chitinase AT is Glu3 1 5 and

Gh

144, respectively (Vaaje-Kolstad et al, 2004).In the consensus region of the catalytic domain of family- 1 8 chitinases, there

are several consewed carboxylic amino acid residues. For example, Asp200 and

Asp202 in chitinase A1 from 3. circulam, Asp3 1 1 and Asp313

in

S. marcescens (Watanabe et al, 1992 and 1993). The location of these residues does not correspond to that of the second carboxyhtein

lysozyrne (Asp52) or in family 19 barley chitinase (Glu89). Thus, the second carbxylate cannot be identikd in anyh d y 18 chitiwise. Therefore, the family 18 c h i t b s should have a different mechanism of catalysis. Recent studies on the family 18 chitimes indicate that

the catalytic reaction of the enzymes takes place through a substrate-assisted

As shown in Fig 2-8, a putative oxocarboniurn ion intermediate is stabilized by

an anchimeric assistance of the sugar N-acetyl group after donation of a proton

from the catalytic carboxylate to the leaving group. Such a stabilization might

occur either through a charge interaction between the C 1 carbon and the carbonyl

oxygen. The mechanism does not require the second carboxylate and can rationalize the anomer retaining reaction of the enzyme without the second

carboxylate (Fukarnizo, 2000).

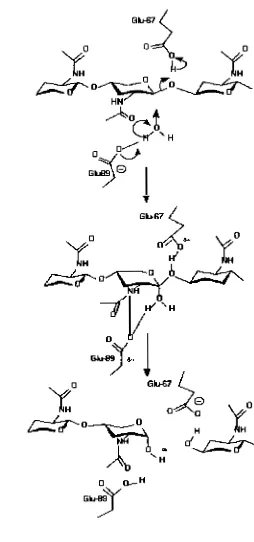

The catalytic mechanism of family 19 chitinase is shown in Fig 2-9. At first,

the general acid, Glu67, protonates the

P-

1,4-glycosidic oxygen atom forming anoxacarbonium ion intermediate. The water molecule, activated by the general

base (Glu89), attacks the C1 atom of the intermediate state for the a-side to

complete the reaction.

The

separated location of the two catalytic residues mightbe permit the water molecule to be located in between the anomeric C1 atom and

the carboxyl oxygen of the general base (Glu89). This location of the water

molecule would result in the anomeric inversion of the reaction products. From

the molecular dynamic simulations, however, Glu89 was found not only to

activate the nucleophilicity of the water molecule but also to act as a stabilizer of

the carbonium ion intermediate (Brameld and Goddard, 1 998). In addition, the

simulation study indicated that the (G~CNAC)~ substrate binds to barley chitinase

with all sugar residues in a chair conformation, no sugar residue distortion was

2.2.5. Chitin Binding Domain

Chitinases generally consist of multiple functional domains, such as C-terminal

domains which binds especially to insoluble chitin (chitin binding domains, ChBD), fibronectin type III-like donins (FnIIIDs), and a N-terminal catalytic

domain. The fimtion of each dolllain except for the ChBD has not been yet elucidated (Morimoto at al, 1997; Gao et al, 2003). The ChDB has been

demonstrated to be important in the degradation of insoluble chitin (Wu et al,

2001 ; Jee el d, 2002; Royer et al, 2002; Orikoshi

er

al, 2003).B, circulans

WL-

1 2 produces ChiAl , Chic 1and

ChiD 1 as the initial products of the three chitinase genes (Alam et a!, 1996). ChiAlhas

the highest hydrolyzmg activity against insoluble chitin. This chitinase comprises the catalytic domain (CatD), two FnlIIDs, and the C-terminal ChBD ( Watanabe et 01, 1 992; 2003), The deletion of FnIIIDs did not affect chitin binding but decreased hydrolysis ofinsoluble substrate like colloidal chitin. However, hydrolysis of soluble substrate

either carboxymethy 1 or chitin-oligomer was not significantly affected. In

addition to its involvement in binding to insoluble substrate, the type I11 dornain

could possibly

IE

involved in the exo-hydrolytic mechanism (Watanabe et al, 1992; Tsujib at al, 1998b).Suzuki

et a1 (1999) identified the chitinase C1 and C2 fiom S. marcescens 21 70. Chitinase C 1 lacks a signal sequence and consists of a catalytic domain belonging to glycoside hydrolase family 18, FnlIID and a C-terminal. ChitinaseC2 corresponds to the catalytic domain of C1 and is probably generated by proteolytic removal of the FnIIID and ChBD. The loss of the C-terminal portion

but not towards colloidal chitin and glycol chitin, illustrating the importance of

the ChBD for the efficient hydrolysis of crystalline chitin.

Unlike cellulose binding domain (CBD), the tertiary structure of ChsD remains unclear. Chitin differs chemically from cellulose only in that each C2 hydroxyl (-OH) group in cellulose is replaced by an acetamide (-NHCOCH3) group in chitin, hence the mechanism by which ChBD binds to chitin was expected to be similar to the mechanism by which CBD

bind

to ceILulose(Ikegami el al, 2000).

The most accepted model for the binding of

CBD

to cellulose is that aromaticrings arranged in the flat face of a CBD

are

stacked on every other pyranose ringof plysaccharides through hydrophobic interactions. The involvement of

arormdic residues

in

the interactions has been observed using NMR, site-directedmutagenesis, and chemical modscation. In CBD, the st WWst motif is widely

c o r n e d . This motif is also found in Aeromonas caviae extracellular chitinase A, Alteromonas sp. strain

0-7

chitinax 85, Janthinobacterium lividurn chitinase 85 (Ikegami et al, 2000).2.2.6. Dual Active Sites

Microorganisms posses two catalytic domains on a single polypeptide have

been rare reported. Tanaka er a1 (2001 j found that the chitinase fiom the hyperthermophilic archaeon T bdahraensis KOD1 has an interesting multidomain structure containing dual catalytic domains and triple chit in-binding

domains. From the analysis of hydrolysates of N-acetyl-chitooligosaccharides

(ChiA

A

5 and ChiAA4). ChiAA5 showed exochitinolytic activity that mainlyhydrolyzed the second glycosidic bond and slightly hydrolyzed the third one

h m

the nonreducing end of chitin chains. On the other hand, ChiAA4 showed

endochitinolytic activity that randomly hydrolyzed glycosidic bonds other than the terminal

b n d

at the non reducing end.Howard ef a1 (2004) recently reported that chititme B of Microbulbifer

degradam 2-40 is a modular protein that

is

predicted to contain two catalyticdomains. Each of domains was shown to be catalytically active against chitin.

The presence of both domains

in

a single reaction increased the amount of reducing sugars released from native chitin to 140% above the theoretical combined rate, indicating that the domains function cooperatively to degradechitin.

227. Purification

Chithases have been purified using the conventional protein purification

techniques like ammonium sulfate hctionation, gel filtration, ion-exchange

chromatography, af5nity chromatography, isoelectric focusing, and hydrophobic

chromatography. Purification process of c h i t b e s is usually conducted in series

of steps. However, Ilyina et a1 (1995) proposed one step purdication system

using an affinity chromatography sorbent based on cross-linked chitin. The sorbent retained selectivity one of the four extracellular chitinases in the culture

supernatant produced by Streptomyces kurssanovii.

M c a t i o n of thennostable c h i t i s were performed with similar procedures

themostable chitinases

h m

various bacterial sources are shown in Table 2-5.The first issue in handling

an

extracellular enzyme is to recover the enzyme ofinterest from the fermentation medium. In classical process, the culture filtrate of

fermentation is fmt treated

with

ammonium sulfate to obtain crude proteinprecipitate. However, Wen et a1 (2002) reported that the step was not applicable

in their works. They proposed two steps purification system using Phenyl

sepharose and Sephadex G-75 purifying an extracellular chitinase from the culture

supernatant of Bacillus sp. NCTU2. Similarly, Sakai ef a1 (1998) purified three

thermostable chitinases from Buci~~ecs. MH-1 using two steps of purifications. Chitinases were first adsorbed on colloidal chitin

and

then separated onchromatofocusing. Three isoforms of endochitinases ((L, M, and S) were

purified to homogeneity with the yield and purification fold of 0.67-2.2% and 18-

24, respectively.

The two-steps chromatographic p r d u r e s for large-scale purScation of the

recombinant thermostable chitinase cloned from S. thermoviolaceus were performed using metal-&nity chromatography, followed by ion-exchange

chromatography. The pure protein

was

highly active and hermostable, with a 12.7 purification fold (Christdoulou et al, 2001). A thermostable actinomycete chitinase was purified by concentration, precipitation, hydrophobic interaction, gelfiltration and adsorption p r d u r e s (Gomes et al, 2001). Thermostable chitinase from Bacillus sp. BG 11 was purified by chitin-binding affinity and gel

chromatography. This scheme resulted in a homogeneous enzyme preparation

Table 2-5. Purification steps of some thermostable chi tinasec'

"The number in the bracket indicates the order steps of purification; AS pptn, ammonium sulfate precipitation; HIC, hydrophobic interaction chromatography; IEC, ion exchange chromatography;

GFC,

gel filtration chromatography; ABC, affinity binding chromatography; FPLC, fast performance liquid chromatography; CF, chromatofocusingPurification step AS pptn HIC IEC

GFC

ABC FPLC CF Yield (%) Purif. fold SourcesReferences Andronopoulou

and Vorgias (2003)

(1

1

(2) (3)

-

-

-

4 15 Therrnococcus chitonophagusWen et a1

(2002) (1)

-

(2)-

-

58 15.6 Bacillus sp. NCTU2B

hus han and Hoondal ( 1 998)(1)

-

(3) (2) 15 16 Bacillus. sp. BG-11 Gomes et al(2001)

(I)

(2)

(3)

(4)

( 5 )

-

7.2 87

SfPeptomyces

RC1071

Sakai st a1

(1 998)

-

-

-

-

(1) - (2) 1.1 24Bacillus MH- 1

Christodoulou et a1 (2001)

-

-

(2)-

(1)-

-

74 12.7 Streptomyces ~hermoviolaceus OPC-520Tsujibo el

d

[image:48.829.92.726.169.423.2]2.2.8. Characteristics

There is considerable heterogeneity in the reported biochemical properties of

bacterial chitinases. The enzymes display a wide range of molecular mass,

temperature

and

pH optima, pI and thermostability (Table 2-6). Several chitinasesfrom higher plants such as carrot and from insects such as the tobacco hornworm

and silkworm

are

glycoproteins. The enzymes h m microorganisms likeThermococcus kodakaraensis, Aeromonas and Rhizopus were reported to be glycoproteins (Koga, 1996; Hollis et al, 1997; T& er al, 2001; Merzendorfer and Zimoch, 2003).

Some chitinases can do the trmsglycosylation reaction, which is the reverse of

hydrolysis. Such chitinases are found in microorgani